ND Filters – In Depth Guide For Beginners - neutral density meaning

You can’t truly say you’ve used everything available in your industry when you haven’t tried DLC coatings. Whether you’re in automotive or firearms, you need a trusty finisher that applies better strength and durability to metal. Take a look at our guide if you desire to learn everything you need to know about DLC coatings.

That’s a good question! So many manufacturers not only rely on the product, but they also enjoy the fact that it’s a multipurpose solution that’s usable in other areas of their production.

The mold industry requires a coating that helps the produced parts last a long time while maintaining durability and corrosion resistance. With the help of DLC, workers see production time cut in half, as they don’t need to worry about reapplying in the process.

Wear and tear is a big deal in industries dealing with metal. The automotive industry knows that parts of motors wear out over time, so applying a coat of DLC helps improve longevity and increase strength.

DLC coating near me

When used in outdoor products, builders apply the finisher for a beautiful appearance and resistance from the elements. Other industries like sports and aerospace workers could benefit greatly from the coating.

Thorlabs offers both Absorptive and Reflective Neutral Density Filters in unmounted and mounted designs, with optical densities from 0.1 to 8.0.

Thicker structures show more success over how well a product holds up. When applying multiple layers, the problem with thickness and stress gets eliminated. When adding more coats, you’re stacking everything. Stacking helps build better resistance and a better combination of benefits like lower friction and wear rates and plenty of hardness.

The Field of View (FoV) is the diameter of the circle of light that you see when looking into a microscope. The higher your magnification, the smaller the ...

There are benefits to using diamond look coating on metal products and non-metal items. For instance, you have the amount of hardness contributed by the DLC’s chemical compound. Here’s an overview of the three benefits of DLC coating.

Diamond like carbonreview

The hardness contributes to enhancing an object’s performance while extending its lifespan. However, for an object to appear strong and enhance its life, you need the right measurement in your finisher. For a harder appearance and feel, you want a ta-C that’s at least 5000HV. The higher the volume, the harder the surface is for a product.

All rights reserved. The original images, graphics, and text herein contain the proprietary information of Practicon, Inc. and cannot be used without written permisson.

When doping these coatings, the process creates resistance to electricity. Sometimes the DLC only allows minimal fixes, so that it still acts as a semiconductor between layers of insulated parts. However, the higher the ranges, the wider the insulation expands to resist electrical currents.

The strongest of handfiles, Kerr K-Files bypass obstructions with greater ease and less separation potential. They provide a smooth, tactile sense inside canal during instrumentation.

Diamond-likecarbondriver

Use only lens paper or gauze and cleaning solution. Never use your finger, handkerchief, paper towels or spit to clean the lenses. Do not remove any parts for ...

Kerr K-Files 25mm Size 10 Purple 6/Pack Strong Kerr™ K-Files deliver smooth instrumentation The strongest of handfiles, Kerr K-Files bypass obstructions with greater ease and less separation potential. They provide a smooth, tactile sense inside canal during instrumentation.

Corning ALTOS® cables provide stable performance over a wide temperature range and are compatible with any telecommunications-grade optical fiber.

Diamond like carbonvsdiamond

Premium 10 degree Focusing Lens Premium 45, Universal, Universal Mini, Double Flange, and Mini Double Flange Extrusions.

The automotive industry deals with metal all the time. However, the metal still corrodes and breaks easily. For it to finally hold shape, it needs coats of DLC. DLC coating grants longevity to motor parts that slide. This material hardens the material, so it doesn’t wear down while operating.

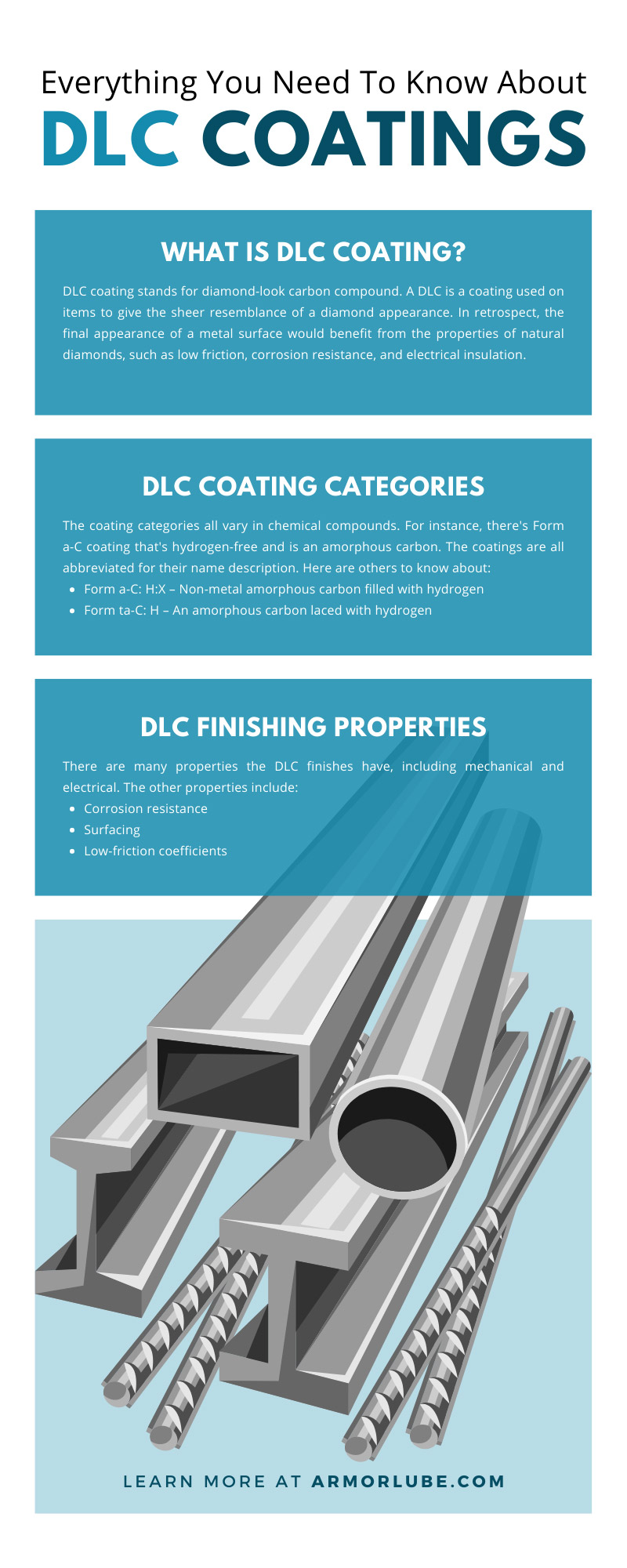

The coating categories all vary in chemical compounds. For instance, there’s Form a-C coating that’s hydrogen-free and is an amorphous carbon. The coatings are all abbreviated for their name description. Here are others to know about:

Overall, the ratings of each DLC coating determine the total toughness a product has by the end of its manufacturing process. The manufacturing industries desire tough products, so they’d benefit most from a nitride coating service.

DLC coating price

Some manufacturers specializing in metal or non-metal products can take a gander at using DLC finishes. Many firearms, building materials, and luxury goods benefit plenty from DLC, as the material strengthens the products.

DLC coating stands for diamond-look carbon compound. A DLC is a coating used on items to give the sheer resemblance of a diamond appearance. In retrospect, the final appearance of a metal surface would benefit from the properties of natural diamonds, such as low friction, corrosion resistance, and electrical insulation.

Focal length magnification. Focal length magnification describes the phenomenon, where the use of different sized film- or CCD-formats (or the use of lenses ...

To overcome the restrictions, new concepts and materials have to be invented and utilized. In this laboratory, we investigate the high-speed response of new ...

No matter the coating you use, you benefit from both greatly, as DLC finishes generally have great properties that allow them to be placed onto metals, alloys, and glass. There are different categories of DLC coatings you should know about.

diamond-like coating for firearms

While the above properties are essential for DLC, the mechanical and electrical properties of DLC finishes add plenty more benefits for users in various trades.

![]()

DLC coating thickness

diamond-likecarbonelectrical conductivity

Diamond-like carbon coating is a product that you’ll find just as useful for your projects, from stacking layers to achieving a certain combination of benefits to help put together different molds for products.

Every DLC coating has its own set of mechanical properties. Some contain properties that don’t create enough strength for metal or non-metal pieces, while others have components that increase a metal or other object’s strength and appearance.

Over the years, DLC has developed to improve operations for various industries. The biggest issue manufacturers have had is adhesion. Adhesion is a bond, which means that if not enough of the DLC is layered on, it won’t thicken.

Shop various price points with kits from Thames & Kosmos, Smithsonian, Science Wiz, and more. Find a lab kit for kids as young as 3 with the Primary Learning ...

Established in 1982, Practicon, Inc. began with a vision of improving dental health and dentists' professional success through patient education. Building on this mission to Make Dentistry Better, the family business has grown to become a leading developer and marketer of "Practical Innovations" that provide innovative solutions to common problems. Learn more >>

The DLC coating method falls into two categories: diamond and graphite structure. Both methods produce different effects. For instance, diamond possesses stronger properties, whereas graphite is softer and easily absorbs lubricants.

There’s a ton more information on DLC coating, but so far, this is pretty much everything you need to know about DLC coating. As you learn more about diamond-like coating, look at the projects you plan to complete, and see which ones could use the coating the most.

Dec 1, 2020 — Optics – Optics is a branch of physics that focuses on the study of light and its behavior. It encompasses a wide range of phenomena ...

To reduce θ we must expand the waist of the beam. This can be achieved by expanding a laser beam with a beam expander. A beam expander consists of two ...

The DLC coating is one of the best to use in every industry. Contact ArmorLube today to find out more about our DLC coating services. Today’s a good day to outperform yourself in your production process and create stronger items with DLC coating!

Ms.Cici

Ms.Cici

8618319014500

8618319014500