Microscope Terms - eyepiece of microscope definition

Binocular headband magnifiers are perfect for tasks that require both hands. These headband magnifiers provide a clear field of view while leaving your hands free to manipulate components and tools. If you’re looking for a binocular headband with high optics that is comfortable to use, then the RS PRO 2.5X Headband Magnifier Optivisor would be a great choice. This padded headband magnifier provides comfort for wearers and comes with an impact-resistant plastic frame to ensure the durability of your magnifiers.

Today, with more technologies becoming compact, many electronic manufacturers go for more compact solutions to accommodate space limitations and improve convenience for customers always on the go. As a result, the electric components of these devices are designed to be smaller. When this happens, the naked eye is often insufficient for proper inspection and manipulation. Magnifying glasses bridge this gap by providing the necessary clarity and precision to effectively work with these tiny components.

resolving power中文

Our ability to image fine details in microscopy is limited by the resolving power of the microscope and of the camera. The microscope resolution is determined by the numerical aperture of the objective, which depends on the refractive index of immersion medium used, and the size of the back aperture of the objective, combined with the wavelength of light from the sample.

Diffractionresolution

So, whether you're exploring electronics assembly for the first time or looking to upgrade your equipment, RS Components offers a wide selection of magnifying glasses and tools to meet your specific needs. Take the first step towards precision and quality by choosing the right magnification tools for your projects. Get your magnifiers online at RS Components today.

RS Pro is the in-house brand of RS Components and a well-established name in the world of electronics and engineering. Known for its commitment to quality and innovation, RS Pro offers a wide range of products, including magnifying glasses, designed to meet the needs of professionals and hobbyists alike. From handheld magnifying glasses to magnifier lamps with adjustable arms, you can find what you need when you browse through our list of RS Pro products.

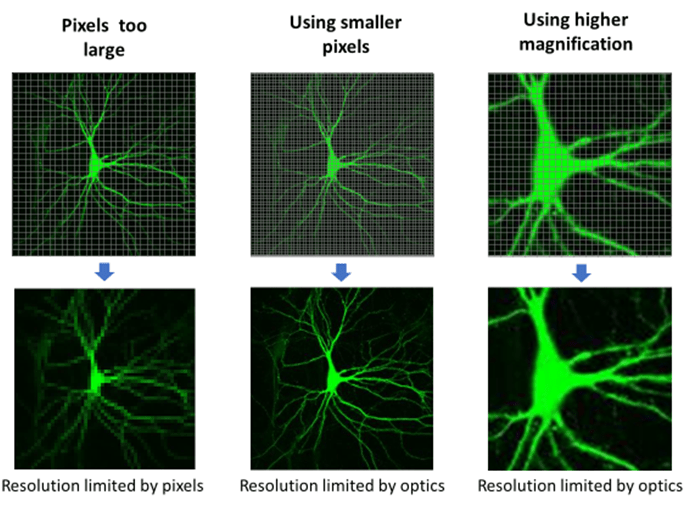

Fig.4 illustrates a case where the sensor's large pixels undersample the spatial information in the neuron. Using smaller pixels or increasing the magnification solves the problem.

An often-asked question in imaging is whether two objects are in the same or separate places. Resolution, the ability to tell two nearby features apart, is a key parameter of microscope optics that becomes more challenging at smaller length scales. Yet, this has surprisingly little to do with the microscope's ability to magnify. In this technical note, the underlying principles that define resolving power, and the conditions necessary to achieve that resolution in a microscope image, are considered.

There is a wide range of magnifying glasses in the market, all of which are made to cater to a specific application. These are the different types of magnifying tools used for electronic assembly:

As a single point of light is diffraction-limited and spreads out before meeting the sample, the image of a point on the sample is blurred. This blur is known as the point spread function (PSF) and has a characteristic shape known as an Airy disk, as illustrated in the map of intensity vs position shown in Fig.5.

Difference betweenresolutionand resolvingpowerin microscope

Handheld magnifying glasses are a convenient choice for beginners. They are portable, easy to use, and provide a quick and clear magnification of components. When you browse through our catalog, you will find different types of quality handheld magnifiers, which you can purchase online. One of the brands that you can consider is RS PRO, a trusted manufacturer of electronic and mechanical tools and components. The handheld magnifying glass that we recommend is their RS PRO Magnifier, 5X x Magnification, 70mm Diameter, which is an excellent hand tool for close-up precision work.

Magnifying glasses are beneficial for the assembly of electronics, especially when using small components. Learn more about magnifying glasses today.

Resolvingpower

The more open the aperture, the more angles of light that can pass through the lens to the sample, and the higher the NA. At its largest, the angle would be defined by the radius and focal length of the lens itself, but many objectives are made with smaller back apertures to control for aberrations at the periphery of lenses and other issues.

Diffraction-limited imaging defines the size of the smallest objects in the image. Anything smaller will be blurred by the microscope to the diffraction-limited size. Since the diffraction limit is set by the NA of the objective and the wavelength of light used, it may be mistakenly assumed that we are always performing diffraction-limited imaging. However, this is not necessarily true depending on the size of the camera's pixel and the magnification of the system.

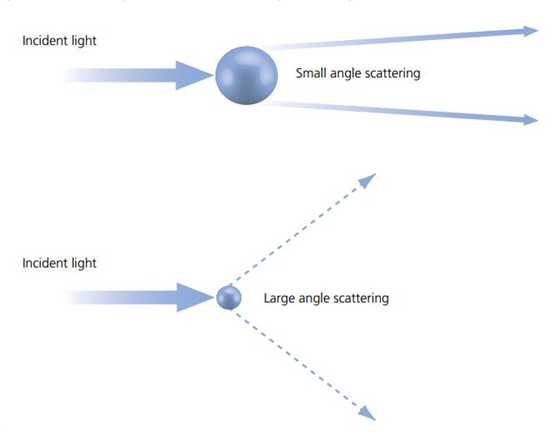

Figures 1 is taken from the Particle Size Analysis blog on Laser Light Scattering (https://technologypharmaceutical.wordpress.com/2014/12/10/laser-light-scattering-method/)

Fluorescent molecules emit in many directions. When examined in bulk, fluorescent molecules typically radiate light in all directions. Although individual fluorescent molecules can emit photons in a small range of angles, with the influence of molecular movement even single fluorescent molecules can be considered to be emitting in all directions.

Figure 5 was derived from Numerical Aperture and Resolution on the Nikon MicroscopyU website (https://www.microscopyu.com/tutorials/imageformation-airyna)

More often than not, professionals who can provide electronics assembly services will have magnifying glasses in their toolkits. Here’s why:

Massresolution

For longer assembly tasks, stand-mounted magnifiers are an excellent choice. They offer hands-free operation, allowing you to work comfortably and efficiently. RS PRO also has a stand-mounted magnifier available for you if you want a more hands-free magnifying tool. The RS PRO Magnifier, 2X x Magnification, is built with a stand and comes with mobile arms that can be turned in any direction for the view and angle you want. They’re great for inspecting the quality and assembly of the components you are working on.

A single photon could fall anywhere within the PSF, but if 100 photons are collected from a single point source, the localization precision could increase by a factor of 10. In the example used previously, where the resolution was 250 nm for a perfect air lens, collecting 100 photons from a unique point source, allows the center to be localized within 25 nm. This means with many photons, we could determine the location of point sources within the sample with great precision and resolve finer details.

In general, the larger the back aperture the wider the angles we can collect, the larger the NA, and the higher the resolution. The theoretical maximum angle that light can be collected by a lens is 180 (it would have to be a huge lens), making the maximum half-angle 90. Realistically, half-angles above 72 cannot currently be achieved. For an air lens with half-angle 72, the NA would then be 0.95 and the maximum resolution (the smallest object that could be observed) of the image would be 320 nm. Two objects closer than 320 nm would not be resolved and would appear as one object, and anything smaller than 320 nm would appear as a blurry blob 320 nm in size. This is the diffraction limit to imaging.

This Airy disk has most of the light power distributed in the central lobe, with lower amounts distributed to secondary lobes. If the area of the center of the peak can be located with greater precision, this can indicate the location of the point source. The precision with which one can localize the center of the PSF generated by a single point source depends on the number of photons detected from that source.

There's an inverse relationship between object size and the maximum angle at which light is scattered. As illustrated in Fig.1, objects that are small relative to the wavelength of incoming light scatter the light across wider angles than larger objects. For clarity, the light that didn't interact with the sample is excluded from the drawing in Fig.1. At extremely small particle sizes, scattered light leaves the object in all directions. This means the smaller the detail in a structure we're trying to resolve, the greater the spread of light coming from it.

Opticalresolution

The total magnification (M) of the optical system makes objects in the sample appear M times larger at the camera. For example, a microscope camera might have 2000×2000 pixels with each pixel measuring 6.5 µm by 6.5 µm. Depending on the magnification, the pixel will sample different regions in the sample. Using a 10x lens, one 6.5 µm by 6.5 µm pixel would sample 650 nm by 650 nm of the sample. In contrast, using a 100x lens that same pixel would sample 65 nm by 65 nm.

The maximum resolving power of an optical system is defined by the following: how close together can two small features be such that the blurring of their images doesn't lead to them appearing as one feature? This is a loose definition that depends on the wavelength of light used.

If microscopes are imaging through dense mediums such as oil, the refractive index (n) is greater, and the higher the NA. This is why higher magnification lenses often use oil and other immersion objectives.

Camera pixel size should be matched to the diffraction-limited blur. In order to differentiate between two objects, one must make a measurement in between them. By convention, the pixel size needs to be 1÷2.3 (~0.44) as large as the smallest object to be imaged. If the smallest object in a sample is 1 µm, the pixel size should be at least 0.44 µm in order to best image the sample. Pixel sizes larger than this will lose information, known as undersampling, while pixel sizes smaller than this provide no extra information, known as oversampling.

The NA is calculated from the refractive index in front of the objective and the half-angle (θ) of light that the lens transmits from the sample towards the detector.

Microscope imaging can typically be split into transmitted light techniques where light passes through a sample from a source opposite the objective lens, and fluorescence-based techniques where light is re-emitted from the sample due to an interaction with light. In both cases, the microscope's ability to differentiate fine details is limited by the diffraction behavior of light waves. Diffraction causes the light from the sample to spread out, and this spreading limits our ability to resolve.

As you start collecting your tools for your electronics assembly tool kit, finding the right one for your specific application is essential to get the job done right and efficiently. It’s especially important when dealing with electronics where precision is required in soldering and component placement. One of the tools you will need in your toolkit is a magnifying glass, which helps you see even the smallest components. With this, we give you insight into why magnifying glasses are essential in your electronics assembly toolkit and the different types of magnifying glasses for specific applications.

Even the smallest mistake in electronics assembly can have significant consequences. Short circuits and malfunctioning devices can result from overlooked defects. Magnifying glasses help identify and rectify these issues, ensuring the final product functions flawlessly.

Molex is a renowned brand in the electronics industry, specialising in innovative solutions for a wide range of applications. While they are best known for their electrical connectors, Molex also has magnifiers available for inspecting the condition of components used for electronic assembly.

For more product guides, check out our guide on digital multimeters and the top 13 tools for the best electrician tool kit.

Resolutionand resolvingpower ofmicroscope

For the example given earlier of a diffraction-limited resolution of 320 nm, one would need pixels sampling every 140 nm in the image to truly achieve this resolution. With a 6.5 µm pixel, 45-50x magnification would provide pixels of an appropriate size. Magnification has no influence on the optical blur of the microscope but does allow appropriate sampling to recover all the information transmitted by the microscope.

Magnifying lamps combine magnifiers with light, making them ideal for intricate tasks. Most magnifying lamps have adjustable arms, making it easier for you to adjust the magnifier to inspect components. Moreover, the lamp ensures you have the right lighting conditions to effectively work with small components. You can find many magnifying lamps in our catalog from different trusted manufacturers. However, one magnifying lamp that we recommend is the RS PRO Magnifying Lamp with Integral Base, 3 dpt, 12 dpt, 100mm Lens Dia., 100mm Lens. This magnifying lamp has a strong arm joint for quick positioning, allowing you to push or pull the magnifier away or closer to the workstation.

The success of electronics assembly lies in the details. Soldering connections and placing components require meticulous accuracy. Magnification helps engineers and repairmen ensure that every solder joint is flawless and each component is placed correctly, preventing costly errors in the process.

Figures 2 & 4 were derived from the lecture notes of Dr. Jerome Mertz' BE517 class at Boston University and modified for clarity.

The range of angles that a microscope objective can collect is represented by its numerical aperture (NA). There are two key determining factors for NA - the refractive index (n) of the medium between the objective and the sample, and the size of the objective lens aperture. The size of the aperture controls the range of angles that can be transmitted to the detector. Fig.2 illustrates the optical path of a modern infinity-corrected microscope for different size apertures.

So why does the emission of light in all directions influence resolution? The limiting factor of microscope resolution is how broad a range of angles of light from the sample the microscope objective can collect. For example, if a small object scattering light at a wide range of angles was imaged using a microscope objective, only a subset of that light would be collected - this would be indistinguishable from a larger object emitting a narrower range of angles. This 'coarsening' of length scale displays as blurring of the microscope image.

When light travels between mediums with different refractive indexes at an angle, the light slows and is bent, this is refraction. Typically this occurs when light emitted from the sample hits a glass-air interface. As illustrated in Fig.3, when air fills the interface gap between sample and objective, the higher angles are bent at the interface and fail to be collected by the objective. In contrast, when oil (much higher refractive index) fills the gap, light is bent less and is all collected by the objective.

A perfect air lens, meaning the gap between the front element of the objective and the sample is filled with air, can have a maximum NA of around 1.0 due to the refractive index of air. To achieve higher NA, it is necessary to fill the space between the objective and the sample with immersion media with n greater than 1.0, such as water (n=1.33), glycerol (n=1.46) or immersion oil (n=1.51).

Figure 3 was derived from the Immersion tutorial on Nikon's MicroscopyU website (https://www.microscopyu.com/tutorials/immersion)

Schermelleh L., Ferrand A., Huser T., Eggeling C., Sauer M., Biehlmaier O. and Drummen GPC. 2019 Super-Resolution microscopy demystified. Nature Cell BIolog v21:72 72-84

For transmitted light techniques, the diffraction behavior is determined by the scattering of light from features in the sample. Scattering occurs when light encounters a change in refractive index, such as at the interface of an object. The refractive index, n, is a measure of how much light slows as it passes through the material of that object. The speed of light is a constant in a vacuum, but slower in materials denser than a vacuum. Common refractive indexes are 1.0 for vacuum, 1.33 for water, 1.37-1.39 for biological materials, 1.57 for glass and a number just slightly greater than 1.0 for air.

Spectralresolution

However, this localization works only when we know that the photons within the PSF come from only one point source - which is not the case in conventional microscopy where fluorescent molecules are far more densely packed than the PSF size. Controlling the conditions so that single point sources can be imaged in a sample consisting of many point sources underpins PALM/STORM super-resolution microscopy techniques (Schermelleh et al. 2019 for review).

For thin samples mounted with index-matching medium, the glass and sample can be considered to have the same refractive index. When sample thickness increases, or where no index-matching medium can be used (live cell imaging), choosing immersion objectives that use water or glycerol as index matching fluids, being similar to the sample, can be more effective.

Magnifiers are essential tools for enhancing the visibility of minute electric components and improving the quality of your electronic assembly or even repair. If you want to consider providing electronic assembly services in the future, it's crucial to invest in quality magnifying tools to ensure your success in the field.

Ms.Cici

Ms.Cici

8618319014500

8618319014500