Magnifiers - magifying

anti reflective coating中文

We also provide custom collimating lenses for projecting a source at infinity for infinite conjugate testing of optical systems. The collimating lenses can consist of several optical elements. The selection of optical materials and optical configuration depends on the entrance pupil diameter, wavelength, focal length, and field of view of the optical system under test.

Avantier offers a wide range of standard collimating lenses, which includes aspheric and achromatic lenses suitable for various light sources such as laser diodes with high divergence. These standard collimating lenses have the ability to convert divergent laser beams into well-collimated laser beams. These collimated beams can then be utilized for laser material processing, laser scanning applications, and interferometry by entering beam expanders.

BigLasers.com is your source for laser pointers and lasers including green laser pointers. Low prices on all the best big laser pointers.

Surfacecoating

Note: this box searches only for keywords in the titles of articles, and for acronyms. For full-text searches on the whole website, use our search page.

The FiberOut fiber collimator transforms the divergent beam emitted at the end of an optical fiber into a collimated one. It can be equipped with a variety of lenses, matching different fiber mode-field diameters and output beam sizes. The rugged, inexpensive collimator can be used for both FC/PC and FC/APC-type connectors. It can be easily mounted on post or into optical mounts (25 mm diameter).

Additionally, AR coatings help in reducing eye fatigue at work. They are especially suited for people who spend long hours working on computers, which can cause ...

Opticalcoating

ECI’s durable films on plastic and polymer molded optics are resistant to organic solvents and are an excellent choice for a wide variety of products.

Anti reflective Screen Protector

ECI has extensive experience coating polymers and other temperature sensitive substrates. ECI has been coating polymer optics for over 60 years. Our low temperature Anti-Reflection coatings are designed and deposited to ensure good adhesion and thermal stability on even the most challenging polymer substrates. ECI coats different types of substrate with low temperature Anti-Reflection coatings at process temperatures below 50°C. These substrates range from plastic windows and lenses to optical fibers and fiber optic assemblies/components including: Molded Polymer Optics, Polycarbonate, Acrylic, Zeonex®, Ultem®, Mylar®, CR39, COC, Fresnel Lenses, TO-Window Cans, MT Ferrules.

Anti-reflection coatings reduce first surface reflection losses, improve contrast and boost the transmission through your optical surface. Choose from a typical design below or ECI will design and deposit a custom anti-reflection (AR) coating for your specific application. If you are not sure how to specify your coating, our design team will work with you to identify the optimum design for your system.

Anti-Reflection coatings are utilized in a variety of applications. It is very common for AR coatings to be used in laser applications. In such cases, Anti-Reflective coatings will need to meet or exceed certain LDT ( Laser Damage Threshold ) requirements. ECI primarily uses Ion Beam Sputtering ( IBS ) or Electron Beam ( E-Beam ) to deposit AR coatings that must withstand high power lasers.

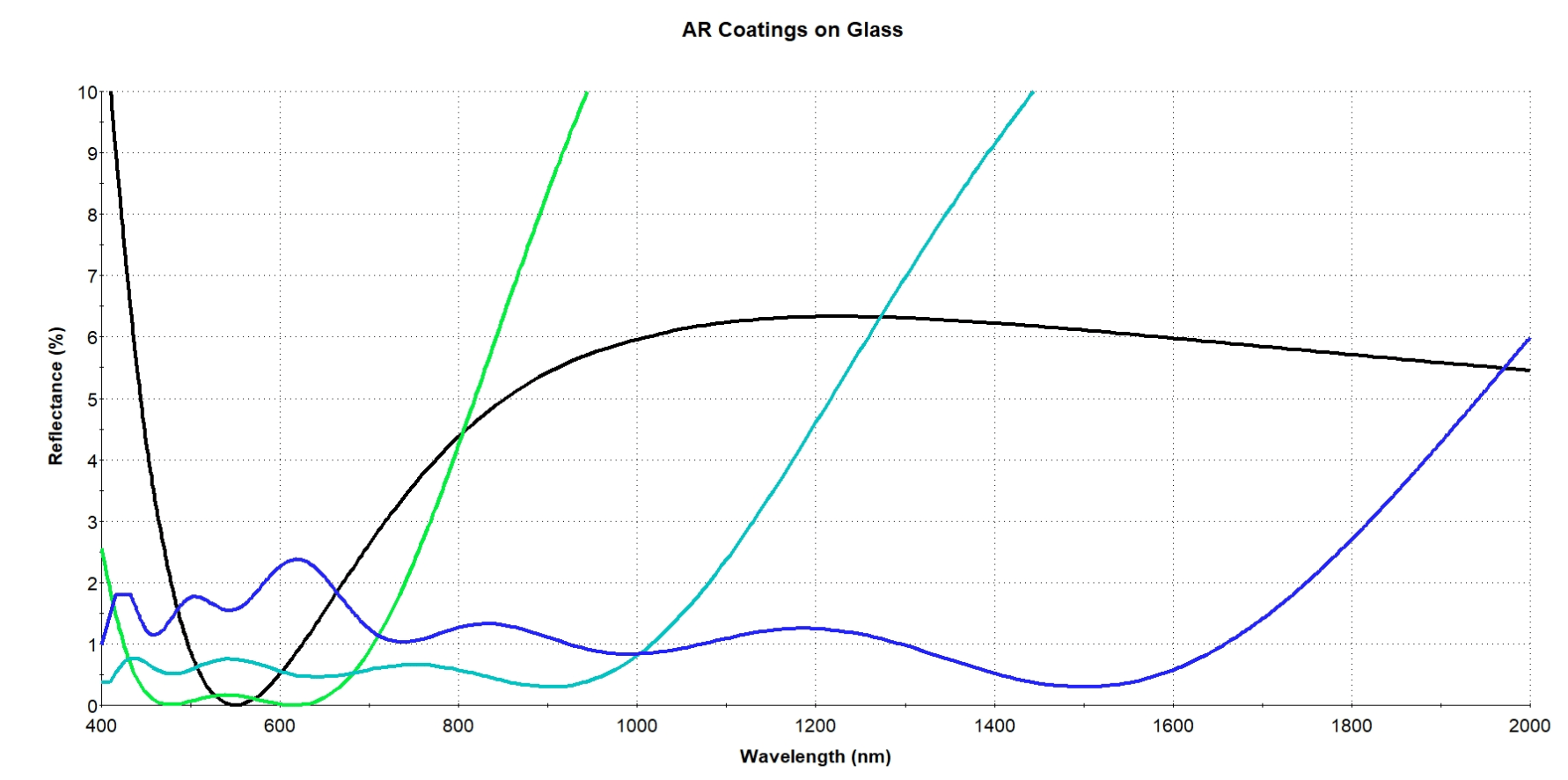

Anti-Reflection Coatings can be optimized for narrow and broadband applications. The performance of an AR coating will vary depending on the bandwidth and angle of incidence (AOI). ECI can typically achieve front surface reflection less than 0.03% for a narrowband AR coating at near normal incidence. Anti-Reflection coatings optimized for wider bandwidths will display a higher maximum reflection. A typical Broadband Anti-Reflection coating on glass will have a maximum reflection of less than 0.5% with a typical average reflection of 0.25%. Figure 1 shows how reflection performance can vary with bandwidth.

CSRayzer provides different kinds of sing mode or polarization-maintaining fiber pigtail collimators, large beam collimators, and fixed focus collimators.

anti-glare什么意思

Essentially, a beam collimator contain some kind of focusing lens, or sometimes a curved mirror, and usually some opto-mechanics for stable mounting and possibly adjustment.

Please do not enter personal data here. (See also our privacy declaration.) If you wish to receive personal feedback or consultancy from the author, please contact him, e.g. via e-mail.

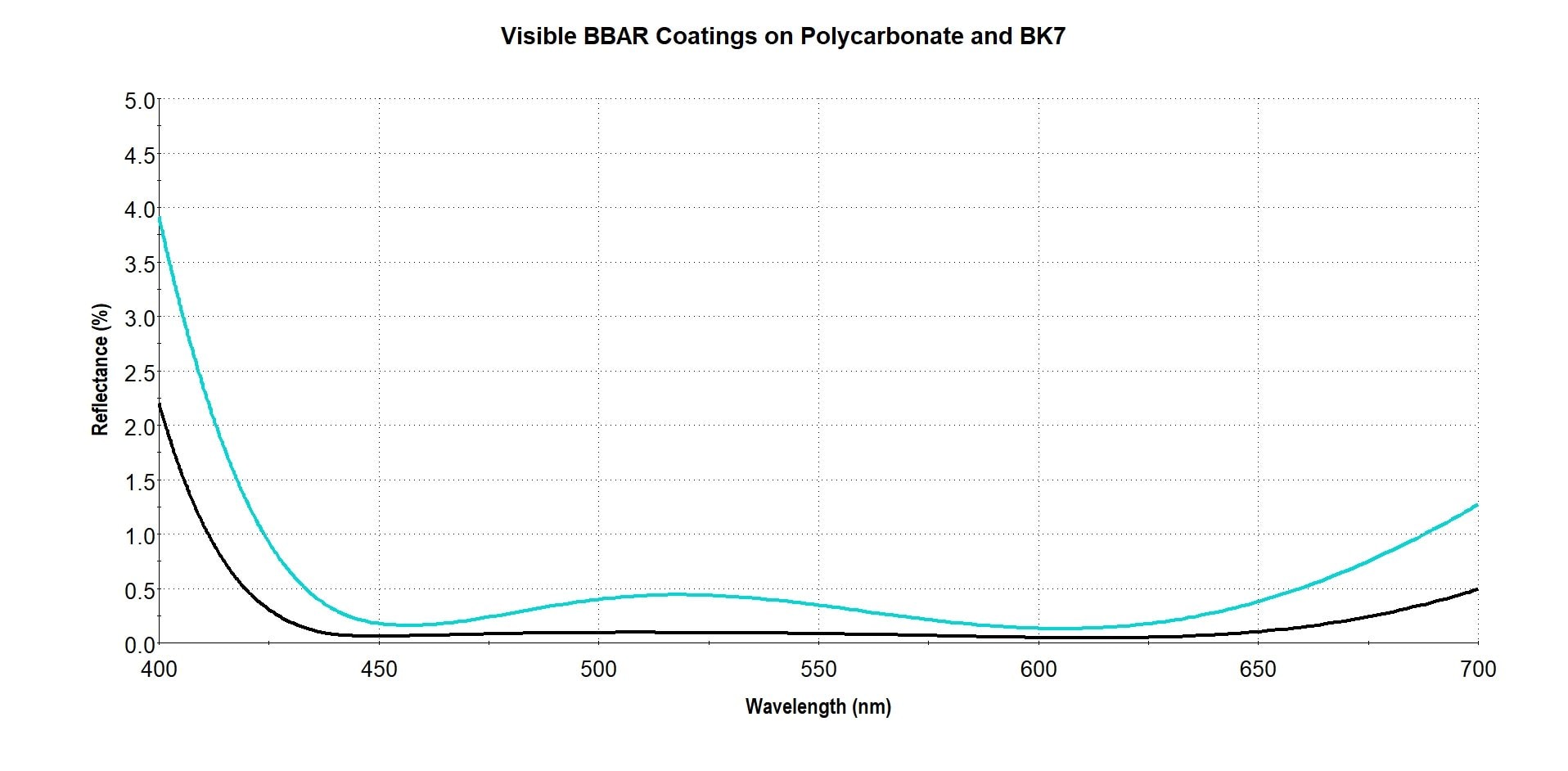

Evaporated Coatings Inc. offers anti-reflection coatings for a variety of substrate materials and configurations. Different coatings materials are selected depending on the substrate material, size, shape, and wavelength range of interest. In many cases, the choice of substrate material dictates the deposition temperature of the AR coating. For narrowband Anti-Reflection coatings, the optical performance is similar for both low and high temperature depositions. However, the performance of a broadband AR Coating will vary depending on the deposition temperature. Typically, broadband AR coatings deposited at higher temperatures will yield lower average reflection over a particular bandwidth. There are two primary reasons: 1). certain coating materials require deposition at elevated temperatures for sufficient durability and 2). the refractive indices of some materials decrease when deposited at lower temperatures. For example, a visible broadband AR coating on BK7 will have slightly better optical performance than a visible broadband AR coating deposited on Polycarbonate. Figure 2 shows the difference in performance between the two substrates mentioned above.

ECI’s AR Coatings meet the reflection and environmental requirements of MIL-C-14806A and MIL-C-48497. Designs comply with military and telecommunication industry standards.

A 10MW laser pointer is a device capable of emitting a focused beam of light with an output power of 10 milliwatts (MW). This level of power makes it capable of ...

The Model 02-M010 is a three-element, air-spaced anastigmat designed specifically for collimating the output of large diameter silica fibers used in high power medical and industrial applications. It is equally suitable for collimating the output of Large Mode Area (LMA) or Photonic Crystal (PC) fibers with smaller numerical apertures. The mechanical assembly allows a precise translation of the lens (without rotation) relative to the fiber face.

Note: the article keyword search field and some other of the site's functionality would require Javascript, which however is turned off in your browser.

anti-reflective coating是什么

Edmund Optics offers a wide range of laser accessories, including different kinds of beam collimators and expanders. In particular, we have fiber-coupled collimators which are suitable for FC/PC, FC/APC and SMA connectors.

Jun 17, 2024 — The key difference between C mount and CS mount lenses lies in the flange focal length, which is the distance from the lens mount to the image ...

Arcoating

The purpose of a beam collimator is essentially to transform a strongly diverging light beam into a collimated beam, i.e., a beam where light propagates essentially only in one direction, and the beam divergence is weak. The output beam may have its focus close to the output aperture, or a mild focus somewhat away from it (see Fig. 1).

ECI also deposits high temperature Anti-Reflection coatings on various substrates, including crown glasses, float glasses, Fused Silica, Sapphire, Silicon, CaF2, and others. ECI can deposit these coatings to cover any wavelength range between 200 – 2500nm. These coatings are designed and deposited to meet the durability requirements per MIL-C-675C. ECI deposits Anti-Reflection coatings on parts up to 400mm in diameter.

Discover the objective lens product range of MITUTOYO ... The Mitutoyo 375 Series finity corrected objective lenses realize clear images and long working distance ...

Collimation of single mode fibres can be made simple with the use of a PowerPhotonic fiber collimating micro lens array. We design and manufacture standard and custom in 1D and 2D arrays. All products are made in high grade fused silica and capable of both high efficiency and high power handling and our unique process minimises channel cross talk due to extremely low scatter. Lenses can spheric, aspheric or freeform due to our unique manufacturing process.

In many cases, the collimation is done in both directions perpendicular to the beam, but there are also beam collimators working in one direction only – for example, fast axis collimators made as rod lenses, which are attached to certain laser diodes.

By submitting the information, you give your consent to the potential publication of your inputs on our website according to our rules. (If you later retract your consent, we will delete those inputs.) As your inputs are first reviewed by the author, they may be published with some delay.

Opticalcoatingprocess

Shanghai Optics provide many different types of standard collimating lenses, including aspheric and achromatic lenses for many different light sources such as highly divergent laser diodes. Our standard collimating lenses can convert divergent laser beams to well-collimated laser beams that enter beam expanders for interferometry, laser material processing and laser scanning applications.

AR Coatings ( Anti-Reflection coatings ) are deposited onto optical surfaces to reduce specular reflectivity. Anti-Reflection coatings are comprised of a single layer or multiple layers. These designs are optimized to create destructive interference with respect to the reflected light. This design approach will allow the maximum amount of light transmission without compromising image quality. Diagram 1 is an example of a typical multilayer Anti-Reflection coating.

Physics of Light and Optics is a high-quality free textbook desiged for an advanced undergraduate optics course for physics majors.

© Copyright 2011 - 2022 Evaporated Coatings, Inc. All rights reserved. Careers Privacy Policy Terms of Service Sitemap

Mar 1, 2016 — So a millimeter is 1000 times the length of a micrometer. 1mm in micrometers is 1000um. i couldn't do the um bit right :( it is the same sise as ...

Using our advertising package, you can display your logo, further below your product description, and these will been seen by many photonics professionals.

... Infrared Reflectivity, with each lab getting its own separate sample set. Incredibly, the Epner Technology specular mirrors, when calibrated by NIST prior ...

The unique design of the Model 02-M010 prevents retroreflections near the fiber face or within the core material. All elements are fused silica (the exception being the 1800–2000 nm collimator optics that are Infrasil) with either V-type or broadband coatings, depending on the operating wavelength range. When used for imaging purposes, the three-element design ensures the output mode from the fiber is preserved, without distortion, even at high throughput powers.

We also offer a complete range of aspheric collimators with excellent performance, small and light design, and with fewer components in the optical system. Manufactured using glass replication technology, the lenses are a cost effective solution for a wide range of application and are available in a wide range of specification.

Typical values verified through independent test laboratories. Actual LDT performance is dependent on substrate selection, surface preparation, and system design.

Here you can submit questions and comments. As far as they get accepted by the author, they will appear above this paragraph together with the author’s answer. The author will decide on acceptance based on certain criteria. Essentially, the issue must be of sufficiently broad interest.

High-power, broadband beamsplitters with high extinction ratio (ER) and low-GDD are also available. Unmounted Beamsplitter Cubes · Unmounted Beamsplitter Cubes.

Jenoptik sets another record year in 2019. 12.02.2020 - According to provisional calculations, consolidated sales of Jenoptik rose by 2.5 percent to around 855 ...

ECI deposits High Power Anti-Reflection coatings on several different types of substrates, including but not limited to Glass/Fused Silica windows, lenses and wafers, Fiber optic cables and assemblies, LBO, BBO, KTP, TGG, GGG, BiG, and Silicon wafers.

Ms.Cici

Ms.Cici

8618319014500

8618319014500