Magnification - magifying

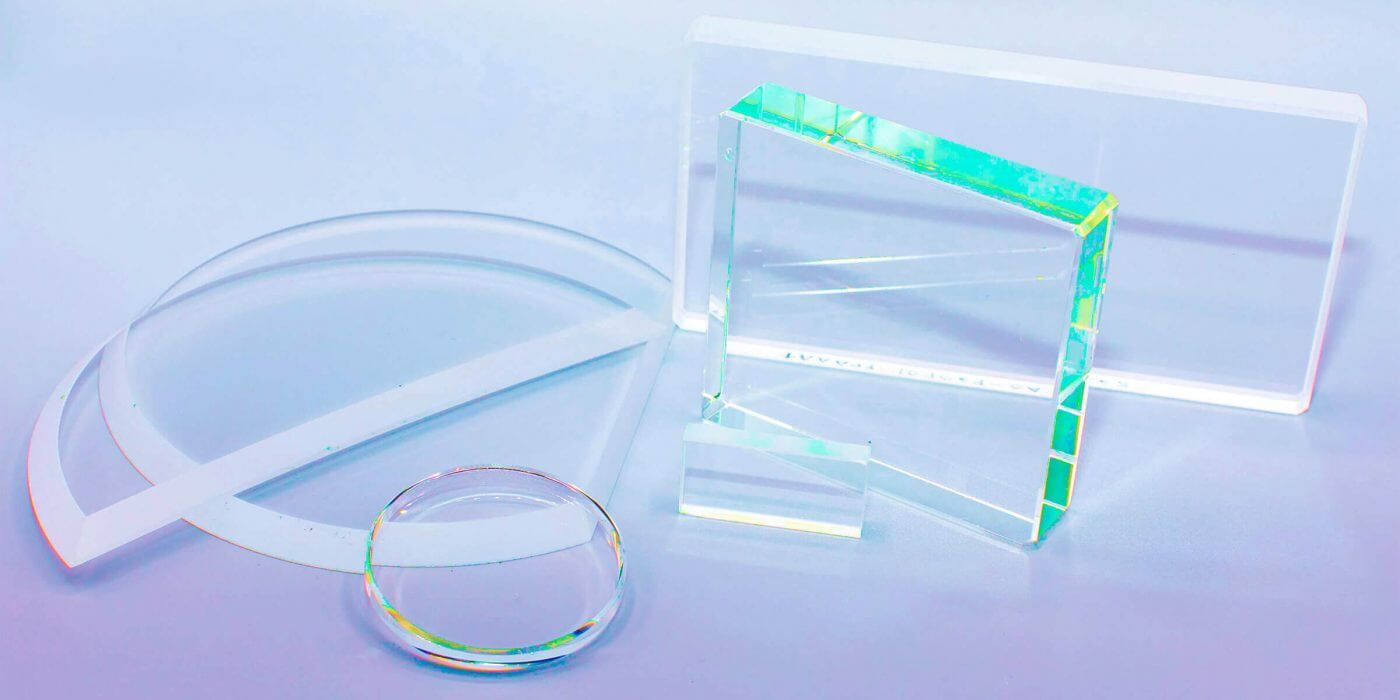

When it comes to fabricating custom optical components, Sydor Optics uses state-of-the-art CNC machines and leading experts to handle even the most intricate optical designs, specifications, and demands.

A translation stage mechanism is a type of motion control system that enables precise linear movement in a single direction. It typically consists of a linear motor, a ball screw, or a piezoelectric actuator, which allows for smooth and accurate movement in a controlled environment and can be customized based on the application requirements, such as speed, precision, and load capacity. The mechanism can be controlled manually or through a computer to achieve the desired position with high accuracy and repeatability.

Translation stages are typically available as either a single axis or multi-axis, including an XY stages, or XYZ stages. Each axis of the stage must constrain the six degrees of freedom (X, Y, Z, roll, pitch, and yaw) of the payload to only one, producing translation along a straight line. This is accomplished with a set of linear bearing guideways attached to a base structural member that provides stiff support. Linear stages designed specifically for vertical motion can be viewed on our Z Stages page.

Cncmachining glass

A stage with a linear motor, also called a linear translation stage, requires a linear feedback device as well as a servo drive and control to close a position feedback loop. With a high-resolution linear encoder, linear actuators can provide position control down to the nanometer level. A typical application for high precision linear actuators is to control the focus of a microscope objective in a digital imaging system.

Parabolic mirrors are typically made as off-axis parabolic reflectors whose reflective surfaces are equivalent to a portion of the parent parabolic optical ...

Cy™3 conjugates can be excited maximally at 550 nm, with peak emission at 570 nm. For fluorescence microscopy, Cy™3 can be visualized with traditional ...

Aside from standard size glass wafers such as 100mm, 150mm, 200mm and 300mm, Sydor Optics can provide custom wafers with diameters up to 450mm and thin wafers with thicknesses down to 0.1mm.

by C Alie · 2004 · Cited by 118 — In this thesis, state-of-the-art process simulation tools are used to model coal combustion, steam cycle, and MEA absorption processes. These disparate models ...

It is fresnel screen,Ultra bright. Note: place the fresnel in front of the ground glass, the matt surface towards the lens, the bright surface towards the ...

Some compound light microscopes have what is known as an articulated arm. This type of arm is a stand that holds the entire microscope body. It attaches to ...

Sydor Optics utilizes various techniques that for the “lightweighting” of optics through design patterns to achieve optimal performance for your product requirements. We take into consideration manufacturing concepts that will maintain the strength and integrity required of the component, while reducing the overall weight.

... urine. No leaks, no-mess design eliminates handling of urine specimen. The results are immediate, and you can mail in a positive result for it to be ...

Precision mechanical alterations for your custom optical designs and specifications. CNC capabilities include lightweighting, drilling, coring, edging, beveling, 3D contouring, and more.

Pivotal BlackFly ... The Pivotal BlackFly is an American electric-powered VTOL personal air vehicle designed by Canadian engineer Marcus Leng and formerly ...

Zinc sulphide (ZnS) is the most prevalent form of zinc found in nature. The naturally occurring mineral of zinc sulphide is sphalerite.

Sydor Optics manufactures IR windows utilizing a range of infrared materials suited for the NIR, SWIR, MWIR and LWIR spectrums ranging from 0.75µm to 15µm for applications including thermal imaging, mineral & gas detection and monitoring and other forward-looking infrared (FLIR) imaging applications.

A translation stage, also known as a linear translation stage or XY stage, is a mechanical device employed in a motion system to move an object precisely in a linear direction. It is widely used in research and industrial applications that require high-precision positioning and movement of small objects, such as microscopy and optical alignment.

Machining glassnear me

Counterbores, steps, slots, holes, bevels, chamfers, notches and more. Sydor Optics has the experience and tools to produce accurate and consistent mechanical alterations to meet your custom designs and specifications.

Machiningquartzglass

Below is a catalog of Dover Motion’s translation stages that include direct drive linear motor and screw driven translation stages. Our stages are optimized for various uses, such as precision motion, high speed, and compact size, and can be customized to meet your specific needs.

Reflect and transmit any combinations of wavelengths with precision plate beamsplitters. UV, VIS, or IR, Polarized or Unpolarized, 10:90 – 90:10 Reflection:Transmission(R:T).

The cage arrived wrapped very well. I was worried about broken glass from other reviewers but I did not have any issue with the cage. It took longer to unpack ...

CNC machine safetyglassreplacement

Sydor Optics has a vast array of CNC glass machining equipment, including the Haas VF-3SSYT, VF-3, VF-2, Mini-mill and Mini-Mill2, and Fanuc Robodrill. Regardless of the machine used, every job adheres to the same quality standards to meet your glass CNC machining needs and precise specifications.

Best practices suggest that when coating or setting up an optical component, it’s best to use a witness sample, also called a “test piece,” to ensure that the actual part will match your specific coating specifications and your application.

Optical wedges with ± 10 arc seconds of wedge angle tolerance. Superior craftsmanship made to your specifications in a variety of shapes, sizes, and materials.

The precision of this type of stage can range from a few microns to sub-nanometer levels, depending on the design and the quality of manufacturing. We can enhance the resolution and repeatability of the stage by adding feedback sensors such as encoders or interferometers. Engineers can integrate 3-axis translation stages with other motion control systems, such as rotary stages or robotic arms, to achieve complex motion profiles for advanced manufacturing, scientific research, or aerospace.

Unique electromagnetic actuator technology for laser communication systems.

The 3 axis translation stage is a type of motion control system used in engineering applications that requires precise positioning and movement of an object in three perpendicular directions. These stages typically consist of three linear actuators that enable movement in the X, Y, and Z axes.

Once the payload has been constrained to a single degree of freedom, the system’s next mission is to actuate the payload and provide precise incremental linear motion along the guideway.

A translation stage, also called a linear translation stage, is a high-precision mechanical device designed to move objects in a linear direction along one or more axes. It ensures accurate positioning and smooth movement of the object, making it essential for tasks requiring precise control in life sciences, automation, manufacturing industries, microscopy, optical alignment, and scientific research applications.

With the aid of the latest CAD / CAM software systems combined with cutting-edge equipment and expert CNC machine operators, Sydor Optics has the ability to manufacture the most complex geometries and tightest tolerances.

It is widely used in research and industrial applications that require high-precision positioning and movement of small objects, such as microscopy and optical alignment. It ensures accurate positioning and smooth movement of the object, making it essential for tasks requiring precise control in various applications such as microscopy, optical alignment, and scientific research.

Ms.Cici

Ms.Cici

8618319014500

8618319014500