Low IR reflective material - ir reflective material

UVlaserpointer

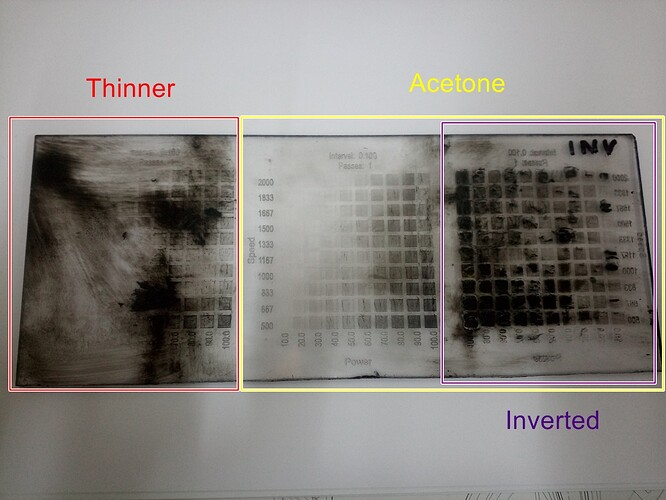

Third test, as i do not have any solvent at my disposal I try to invert the acrylic sample and and run a material test. Until here all tests were made with painted surface face up, this test was made with painted surface face down. I run a test like this because I intend to evaluate the reflection effect on acrylic. The result was interesting,… cracks everywhere, down side (painted side) melted on the most power and lower speeds hits, and curios is at 100% power between 2000 and 1500mm/min it burns face up side. Testing acrilyc011040×780 182 KB Testing acrilyc021920×1440 150 KB

Meanwhile,… Some material test i have made with acrylic. Power from 10 to 100%, speed from 500 to 2000mm/min, 40W diode laser 450nm and air assist. Spayed with black acrylic paint on one side.

What are UV lasers used for

Tanks Jack. For now I am clear about the doubt that originated this topic. Of course now I’m more curious about UV lasers but that will be a subject for debate later.

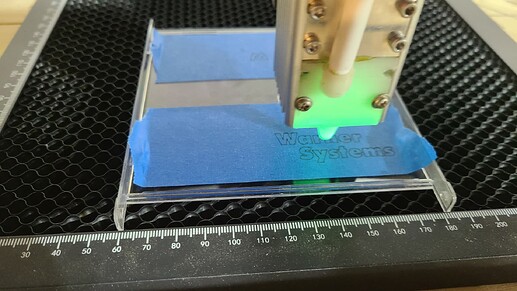

What you can do is mask the clear acrylic with something like tape or paint. My guess is that when the laser burns the mask, it will melt the acrylic underneath and make it seem engraved. I have a 450nm 7watt diode laser and have done this with glass achiving pretty good results.

I was wondering: my laser has 455 nm wavelength too. It is beyond UV, of course, in the blue range: that’s the visible color when it works. Isn’t blue tape (or anything blue) inefficient? My understanding of physics (which might be wrong) is that blue material is blue because it strongly reflects this color. Isn’t something red or orange, or just plain black, more efficient for such masking?

Ultravioletlaserwavelength

EDIT: Just tried with blue painters tape on an old CD case. I know I have some real acrylic around, but I just moved and cannot find it.

Excimerlaser

If I understood correctly, then from what you mention and the image below, only diodes that work at a frequency below 400nm are considered UV, right? Wavelength723×377 25 KB

20230508_2225311920×1080 177 KB 20230508_2228251920×1080 219 KB 20230508_2232501920×1080 257 KB 20230508_2234511920×1080 217 KB

I’m working with Lightburn and a diode laser GRBL generic machine. I’ve been experimenting a lot with different materials (as ideas come up). Right now I’m trying to engrave clear acrylic and from what I’ve read UV technology would be the most suitable for what I want. Knowing some of the risks of diode laser machines due to the emission of UV rays, I had a doubt whether a diode laser is the same thing as a UV laser.

All content on this website, including dictionary, thesaurus, literature, geography, and other reference data is for informational purposes only. This information should not be considered complete, up to date, and is not intended to be used in place of a visit, consultation, or advice of a legal, medical, or any other professional.

First test i try to remove the paint with thinner. (I am convinced that I already clean acrylic with thinner but,… maybe not. )

Hi Tim, I think that is “stick remover” and yes it possible to buy here in Portugal. Which by the way is a good country to born if you want to talk Portuguese.

UVlaserWikipedia

Are UV lasers dangerous

Hi Jack, thanks for the quick response. If I understand correctly, summarizing the technology (if that’s what it can be called) a generic laser diode (in my case 40W) is not considered UV because, quite simply speaking, you can see the beam of light and from what I saw in a video of a UV laser the ash is invisible, only the engraving is visible.

Anything that damages material will produce some type of debris… the laser doesn’t destroy things out of existence. Could be gas if it vaporizes the material or any size of debris depending on how the laser damages the material…

If the laser is in the visible spectrum of frequencies then anything that is clear will not be able to damage (cut or engrave) that material…

It does leave some residue on the plastic, but was easily removed with a product called “Goo Gone”. I’m sure it is sold under different names, also called citrus cleaner, or something like that. The cleaner does not harm the plastic at all.

Ultravioletlaserweapon

Hello Tim, thank you for your reply. That’s an option I’ve been thinking about. My concern is if it left any residues of tape on acrylic. That´s not suitable for what I intend to do.

Here’s some more glass lasering. I mirrored the cut and put the tape on the bottom of the glass. I figured that way it’s burning the tape closest to the glass first, instead of burning thorough the tape. 200mm/min, 100% power, “Fill” in Lightburn...

I understand they work for acrylic but I don’t have one of those, mine are led, co2 and fiber… they have a different to no effect, depending on the material.

Ultravioletlaserdiode

If it’s not in the visible range you can’t see it… that’s a lot of bandwidth of frequencies that can be used… There are a few…

I found a recent thread mentioning that you can order it from Amazon in Portugal. https://www.reddit.com/r/MonsterHigh/comments/12zrvcu/anyone_know_of_an_alternate_to_goo_gone_available/

Hello everyone! By the topic you can guess how noob I am. I am portuguese and my english is far from perfect, so sorry in advance. (Any misunderstood is google translator fault ) So, i’ve tried to clarify my doubt on the internet but I haven’t found anything that clarifies me properly. I resort to your help hoping this is not already a debated subject (at least I didn’t find anything enlightening on the forum)

You are correct. If we were sipping amps in some mission-critical application, or using a much lower power laser, efficiency might be a concern. At this level, unless its white tape, I don’t think it’s factor worth worrying about.

Ms.Cici

Ms.Cici

8618319014500

8618319014500