LED/UV LIGHT - uv lamp led

Politicalpolarization

The cost of a fiber laser system will greatly vary depending on your applications. Industrial fiber lasers systems for demanding environment like we do usually start at $40,000 and can go up to $1,000,000 for high-power laser-cutting machines. The power usually ranging from 20 W to 6,000 W will have the largest impact on price.

If you need to cut thicker materials, it’s best to go with CO2 lasers. CO2 lasers deliver faster initial piercing times, quicker straight-line cutting and a smoother surface finish when cutting materials above 5 mm.

polarization中文

I want to carry a 3mm allen bit or just 3mm allen tool on my work keys. These keys go in my pocket and carrying around a full size allen key ...

A photographer's guide to iso, aperture, shutter speed, exposure, & white balance. Camera settings made easy. Tue 12 May 2020. Try the Unscripted app for ...

Jan 13, 2021 — Dielectric Mirrors. Each ULTRA Series high-reflectivity dielectric mirror provides close to 100% reflection. They are all resistant to laser ...

Circularly polarizedlight

The main difference that determines the type of materials each laser can process is the wavelength. A fiber laser usually has a wavelength of 1,060 nm while CO2 lasers have wavelengths in the 10,600 nm range. In general, fiber lasers have many advantages over CO2 lasers.

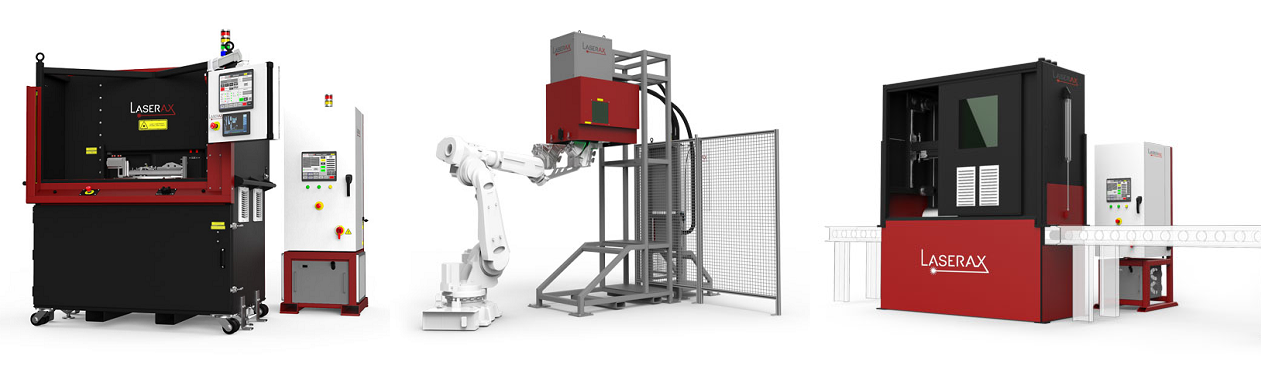

Laser ablation machines are increasingly used in the manufacturing and automotive industries. They are a popular option to meet short cycle times, automate processes, reduce operating costs, and add precision to ensure high-quality results.

Light waves are transverse: that is, the vibrating electric vector associated with each wave is perpendicular to the direction of propagation. A beam of unpolarized light consists of waves moving in the same direction with their electric vectors pointed in random orientations about the axis of propagation. Plane polarized light consists of waves in which the direction of vibration is the same for all waves. In circular polarization the electric vector rotates about the direction of propagation as the wave progresses. Light may be polarized by reflection or by passing it through filters, such as certain crystals, that transmit vibration in one plane but not in others.

Although each laser does have its strengths and distinct use cases, CO2 is an older technology and fiber lasers are gaining market fast as the technology advances. With the speed benefits, almost half of the operating costs and three to four times greater throughput than CO2 lasers, the financial gains that can be got from using fiber lasers can be game changing.

Photonpolarization

Magnification refers to an action of magnifying something. Furthermore, it refers to enlarging the apparent size and not the physical size.

Image sensor sizes range from the tiny up to ones as large as a frame of 35mm film called a full frame sensor. Click to explore the sizes of image sensors.

polarization, property of certain electromagnetic radiations in which the direction and magnitude of the vibrating electric field are related in a specified way.

The cost of CO2 lasers tends to be less than fiber lasers. The price for CO2 laser marking systems usually ranges between $35,000 and $80,000. Again, the power (which usually ranges between 20 W to 150 W) will influence the cost.

Electricpolarization

FC Connector, FC Adapter ... The FC Connectors and Adapters are considered to be old-line products and are widely used all over the world. These connectors are ...

A shortpass filter or short wavepass filter (SP filter) is a filter that transmits at shorter wavelengths and rejects longer wavelengths. By design, the ...

Fiber lasers also have a growing demand for industrial cleaning applications such as removing rust, paint, oxides, and other contaminants.

Since the index of refraction of the tape is different for each color of light, each color has its own unique pair of speeds as it passes through the tape. The ...

Polarizationoflight

If your application is laser cutting of metals, you’ll most likely need a high-power CW (continuous wave) fiber laser. For other materials like plastics and rubber, it can be one or the other.

polarization极化

CO2 laser marking is ideal for a wide range of non-metallic materials including plastics, textiles, glass, acrylic, wood, and even stone. They are used in pharmaceutical and food packaging as well as the marking of PVC pipes, building materials, mobile communications gadgets, electrical appliances, integrated circuits, and electronic components.

If you’re looking to mark metal, what you need to buy is a fiber laser. If you’re looking to mark organic materials like textiles, wood, or cardboard, a CO2 laser is the best choice.

Fiber lasers are generally better at cutting metals than CO2 lasers because the laser beam’s energy is absorbed more efficiently by the metal surface. They offer ≈50% lower operating costs, faster processing speeds, higher precision, and require less maintenance, making them a cost-effective and versatile choice for diverse applications.

Laser power is one of the most important parameters to consider when choosing a laser, as it plays a key role in determining the effectiveness of laser processes. In laser material processing, laser power directly impacts the speed of processes like laser welding, laser cleaning, laser texturing, laser cutting, and laser marking.

Lasers are ideal for industrial automation. Not only do they have the potential to increase productivity and repeatability, but they also possess key characteristics that facilitate automation. Examples include remote capabilities, low maintenance, almost no consumables and waste products, and minimal dust.

One big plus is fiber lasers are maintenance-free machines, and they have a long service life (our lasers have a minimum of 100,000 operating hours). They are also smaller than CO2 lasers. Plus due to the high electrical efficiency of fiber lasers, they use significantly less power than CO2 lasers, resulting in huge cost savings for cutting applications.

Polarization

CO2 Laser Beam Expander is an optical system composed of two or more components that can change the size and divergence characteristics of a beam of light.

Fiber lasers are best suited for high-contrast markings like metal annealing, etching, and engraving. They produce an extremely small focal diameter (resulting in intensity up to 100 times higher than a CO2 system), making them the ideal choice for permanent marking of serial numbers, barcodes, and data matrix on metals. Fiber lasers are widely used for product traceability (direct part marking) and identification applications.

Unfortunately, CO2 lasers use significantly more power than fiber lasers, resulting in a higher cost of operation. For instance, a high-power CO2 laser and chiller will consume roughly 70 kW when operating on maximum power. A similarly powered fiber laser consumes approximately 18 kW.

Visit Us. EDSYN INC. 15958 Arminta Street Van Nuys, California 91406. Quick Links. Quick Links.

Ms.Cici

Ms.Cici

8618319014500

8618319014500