Laser safety - how to block laser light

For industrial radiography using gamma radiation sources such as iridium-192 or cobalt-60, a collimator (beam limiting device) allows the radiographer to control the exposure of radiation to expose a film and create a radiograph, to inspect materials for defects. A collimator in this instance is most commonly made of tungsten, and is rated according to how many half value layers it contains, i.e., how many times it reduces undesirable radiation by half. For instance, the thinnest walls on the sides of a 4 HVL tungsten collimator 13 mm (0.52 in) thick will reduce the intensity of radiation passing through them by 88.5%. The shape of these collimators allows emitted radiation to travel freely toward the specimen and the x-ray film, while blocking most of the radiation that is emitted in undesirable directions such as toward workers.

Mar 25, 2024 — ... Chicago Voice - About Us : The voice of West Chicago, Illinois - digital ... American Science and Surplus Hosts Windchime Kids Class. Business ...

Jan 13, 2022 — In photography, ND filters can help you slow down motion in bright conditions for shooting long exposure photography. Think a smooth flowing ...

As you evaluate different light guide manufacturers, there are important component characteristics to consider. A hallmark of high-quality light guide design is an optical pattern that is replicated via a repeatable process like embossing or injection molding. This ensures your final assembly can be manufactured at scale and create cost savings for you.

The positive impact of a high-quality and high-performance light guide can be transformative for your product or application. When you’re ready to begin your next illumination project, our team will be there to provide guidance and a wealth of experience every step of the way.

by P Ma · 2021 · Cited by 80 — Highlights. •. Coherent combination of 7-channel kW-level all-fiber amplifiers has been achieved. •. The total output power of the beam combining system is ~7.1 ...

Diamond-like carbon coating is a product that you'll find just as useful for your projects, from stacking layers to achieving a certain combination of ...

This can be very useful for geological mapping, anomalies.. Etc. The main issue with HSI is the cost and the availability which are very region ...

New systems involving multileaf collimators (MLCs) are used to further shape a beam to localise treatment fields in radiotherapy. MLCs consist of approximately 50–120 leaves of heavy, metal collimator plates which slide into place to form the desired field shape.

Without a collimator, rays from all directions will be recorded; for example, a ray that has passed through the top of the specimen (to the right of the diagram) but happens to be travelling in a downwards direction may be recorded at the bottom of the plate. The resultant image will be so blurred and indistinct as to be useless.

A collimator is a device which narrows a beam of particles or waves. To narrow can mean either to cause the directions of motion to become more aligned in a specific direction (i.e., make collimated light or parallel rays), or to cause the spatial cross section of the beam to become smaller (beam limiting device).

Allen wrench ... Size: ... These 3/32″ and 1/8" Allen wrenches are used for adjusting the arbors on our Hi-Tech Diamond machines. You can also find these at your ...

After components are identified and initial designs are approved, light guide manufacturers like Global Lighting Technologies will work with you to prototype and test. Learn more about prototyping here.

Light guides have hundreds of applications across many industries and are crucial to modern devices. Think of a laptop keyboard, exit sign in a commercial building, smart home hub device or illuminated medallion on the front of a car; each uses the power of light guides to enhance end-user experience.

The English physicist Henry Kater was the inventor of the floating collimator, which rendered a great service to practical astronomy. He reported about his invention in January 1825.[1] In his report, Kater mentioned previous work in this area by Carl Friedrich Gauss and Friedrich Bessel.

Our patented technology and engineering experience also enable us to create smaller, more efficient light guides. From consumer electronics to the automotive industry, common applications for our custom light guide solutions include:

Optical collimators are also used as gun sights in the collimator sight, which is a simple optical collimator with a cross hair or some other reticle at its focus. The viewer only sees an image of the reticle. They have to use it either with both eyes open and one eye looking into the collimator sight, with one eye open and moving the head to alternately see the sight and the target, or with one eye to partially see the sight and target at the same time.[5][clarification needed] Adding a beam splitter allows the viewer to see the reticle and the field of view, making a reflector sight.

We deliver excellence in illumination solutions to our customers and their end consumers. An investment in quality light guides often results in long-term cost savings, increased product longevity, more brightness while using less power and enhanced end-user experiences. Our proprietary high-performance technology, backed by an impressive portfolio of 350+ issued patents and an additional 10+ pending, contributes to these benefits.

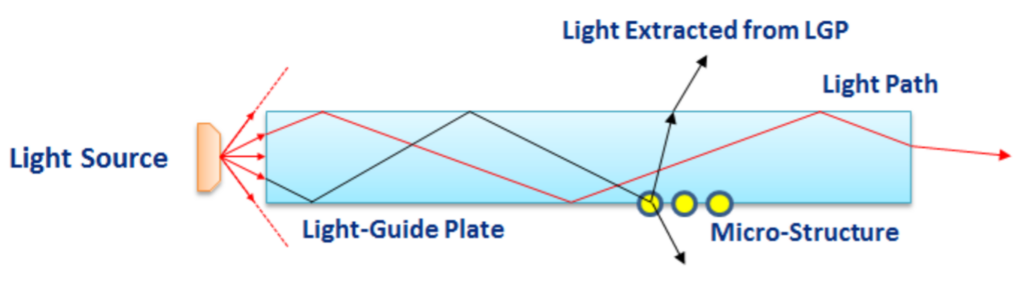

Light guides are typically made from a polymer material, and precision in crafting these components is crucial for optimal light transmission. Core components of light guides like those we create at Global Lighting Technologies are:

Our proprietary optical pattern used in the micro-structures is meticulously designed to achieve a uniform light output.

Although collimators improve resolution, they also reduce intensity by blocking incoming radiation, which is undesirable for remote sensing instruments that require high sensitivity. For this reason, the gamma ray spectrometer on the Mars Odyssey is a non-collimated instrument. Most lead collimators let less than 1% of incident photons through. Attempts have been made to replace collimators with electronic analysis. [citation needed]

Sep 24, 2019 — What does line pairs/mm of the CCD mean? Is this something like the number of pixels that will be resolved per CCD element? It just isn't ...

The figure to the right illustrates how a Söller collimator is used in neutron and X-ray machines. The upper panel shows a situation where a collimator is not used, while the lower panel introduces a collimator. In both panels the source of radiation is to the right, and the image is recorded on the gray plate at the left of the panels.

Collimators (beam limiting devices) are used in linear accelerators used for radiotherapy treatments. They help to shape the beam of radiation emerging from the machine and can limit the maximum field size of a beam.

In the lower panel of the figure, a collimator has been added (blue bars). This may be a sheet of lead or other material opaque to the incoming radiation with many tiny holes bored through it or in the case of neutrons it can be a sandwich arrangement (which can be up to several feet long; see ENGIN-X) with many layers alternating between neutron absorbing material (e.g., gadolinium) with neutron transmitting material. This can be something simple, such as air; alternatively, if mechanical strength is needed, a material such as aluminium may be used. If this forms part of a rotating assembly, the sandwich may be curved. This allows energy selection in addition to collimation; the curvature of the collimator and its rotation will present a straight path only to one energy of neutrons. Only rays that are travelling nearly parallel to the holes will pass through them—any others will be absorbed by hitting the plate surface or the side of a hole. This ensures that rays are recorded in their proper place on the plate, producing a clear image.

Optical collimators can be used to calibrate other optical devices,[3] to check if all elements are aligned on the optical axis, to set elements at proper focus, or to align two or more devices such as binoculars or gun barrels and gunsights.[4] A surveying camera may be collimated by setting its fiduciary markers so that they define the principal point, as in photogrammetry.

Across every industry and application, the significance of light guides in illumination can’t be overstated, but you may be asking, “What is a light guide?” Light guides enhance illumination, and illumination enhances the functionality and aesthetics of many applications. Light guides accomplish this by achieving optimal brightness and ensuring uniformity and visibility in desired areas. Explore the rest of this helpful primer on light guides and their components with insights from our engineers

Its primary function is to efficiently transmit and distribute light from a source to a desired location or surface. Light guides are designed to guide and control the propagation of light, ensuring it reaches its intended destination with minimal loss or dispersion.

At its core, a light guide is a transparent material that allows the light from a light source to enter and travel through the material.

In optics, a collimator may consist of a curved mirror or lens with some type of light source and/or an image at its focus. This can be used to replicate a target focused at infinity with little or no parallax.

Focal length is the distance from the center of the lens to the imaging point (focal plane) where the light for the image is collected. When a lens is described ...

To find the spatial resolution of a parallel hole collimator with a hole length, l {\displaystyle l} , a hole diameter D {\displaystyle D} and a distance to the imaged object s {\displaystyle s} , the following formula can be used R collimator = D + D s l effective {\displaystyle R_{\text{collimator}}=D+{\frac {Ds}{l_{\text{effective}}}}} where the effective length is defined as l effective = l − 2 μ {\displaystyle l_{\text{effective}}=l-{\frac {2}{\mu }}} Where μ {\displaystyle \mu } is the linear attenuation coefficient of the material from which the collimator is made.

Light guides contribute to both aesthetic and functional enhancements. Read on to explore the components that help light guides function.

Another component found in quality light guides is high-performance LEDs. They should be designed to couple and work with edge-lit light guide technology seamlessly.

Not all light guide manufacturers are the same. While some offer a one-size-fits-all solution, we customize each design to meet the needs of your unique application.

In X-ray optics, gamma ray optics, and neutron optics, a collimator is a device that filters a stream of rays so that only those traveling parallel to a specified direction are allowed through. Collimators are used for X-ray, gamma-ray, and neutron imaging because it is difficult to focus these types of radiation into an image using lenses, as is routine with electromagnetic radiation at optical or near-optical wavelengths. Collimators are also used in radiation detectors in nuclear power stations to make them directionally sensitive.

Collimators may be used with laser diodes and CO2 cutting lasers. Proper collimation of a laser source with long enough coherence length can be verified with a shearing interferometer.

Designed specifically for wide-angle photography, the Olympus Wide was an Olympus 35V camera fitted with a wide-angle lens. To facilitate framing, the ...

Additionally, our company-owned Asian manufacturing facilities help maintain a competitive cost base and manufacturing efficiencies that allow us to provide cost-effective solutions without compromising on quality. Beyond our cutting-edge technology and manufacturing capabilities, we are a company of engineers who understand the unique complexities of illumination and have an in-depth understanding of both optical and mechanical design.

The treatment head of a linear accelerator consists of both a primary and secondary collimator. The primary collimator is positioned after the electron beam has reached a vertical orientation. When using photons, it is placed after the beam has passed through the X-ray target. The secondary collimator is positioned after either a flattening filter (for photon therapy) or a scattering foil (for electron therapy). The secondary collimator consists of two jaws which can be moved to either enlarge or minimize the size of the treatment field.

Knight Optical's Fresnel lenses are one of our most popular products. Our stock catalogue consists of standard Fresnel lenses with focal lengths from 3 mm to ...

Ms.Cici

Ms.Cici

8618319014500

8618319014500