Investigating tube lenses for infinity optics, RPi HQ camera ... - optics hq

After being informed of potential risks for my data (including transfer to the USA and potential access by US authorities) in the Cookie Banner and Privacy Policy I accept the cookies from US-providers.

Bulbs · Heine Replacement Bulb for Mini 3000 Non-Fiber Optic Otoscope · Heine · Code: X-01.88.110.

Content from video platforms and social media platforms is blocked by default. If you accept cookies from external media, accessing these contents no longer requires giving manual consent.

OmniCureUV curingsystem

Marketing cookies are used by third parties or publishers to show you personalized advertising. They do this by tracking which websites visitors go to.

Mercury light source: For homogenous sample illumination, a powerful high-pressure mercury UV source is connected by default to the temperature device by a flexible light guide and can be controlled remotely with the RheoCompass software during sample preparation and measurement. The light source is available with different filters for the emission of discrete wavelengths and with a radiometer for calibration purposes.

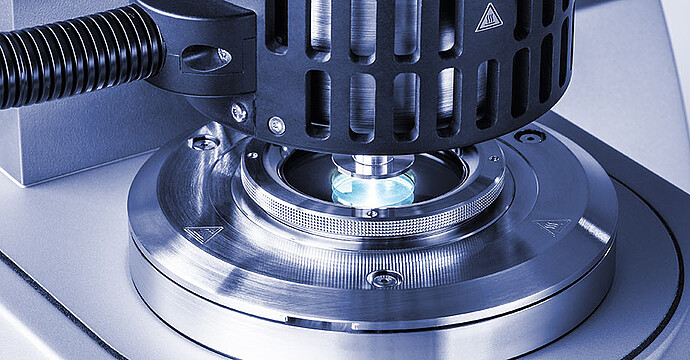

The UV Light Curing System as part of the RheoOptics toolbox for the MCR rheometers allows the investigation of UV-light-initiated curing reactions. With this setup UV-sensitive inks, glues, or coatings are irradiated by a UV light source simultaneous to the rheological characterization of the material. You achieve fast and accurate results even for demanding applications with the unique TruStrain™ control which allows the highest data rates during oscillation, the sensitive normal force control for shrinkage compensation, and online compliance correction. The Peltier hood and inert gas atmosphere ensure accurate temperature control from -20 °C to 200 °C. Read more about rheological investigations of adhesives and sealants in the Anton Paar Wiki .

Uv light curing systemsfor sale

Supporting USB 3.0 and GigE with Power over Ethernet, these cameras are ideal for a wide variety of demanding applications including flat panel inspection, 3D ...

Consider the chemistry of your sample, your overall process design, and required maintenance before choosing the type of UV light to use:

Reece Edmends is a fifth-year PhD candidate in the Department of Classics. He is especially interested in Roman politics and political theory, ...

HandheldUV Lightfor resin

3 days ago — The meaning of OBJECTIVE LENS is a lens or system of lenses in a microscope, telescope, etc., that forms an image of an object.

Composition · BK7: A high-quality optical glass that is part of the borosilicate family. It is known for its high purity and excellent optical properties.

Diffuser lens for Gooseneck light guide to widen light beam, with frosted glass pane.

UVLEDcuringsystem

LED light source: For monochromatic single-peak wavelength radiation a UV LED light source, which uses arrays of light emitting diodes, can be integrated. The light guide holder can be adapted to various UV LED light sources available on the market to perfectly fit your sample and process requirements.

by J Luo · 2024 · Cited by 4 — Correcting Optical Aberration via Depth-Aware Point Spread Functions. Abstract: Optical aberration is a ubiquitous degeneration in realistic ...

Jan 17, 2017 — A CPL filter is basically a linear polarizer, but with an extra optical glass element behind it. This glass is called a quarter wave plate, and ...

Rheology plays an important role when it comes to the development of UV-sensitive materials in order to develop application-specific formulations. UV-curing materials are an essential part of many industries, including medicine and life science, automotive, polymers, packaging, printing, electronics, and even cosmetics (for example artificial fingernails and gel nail polish). The UV Light Curing System supports you in developing and producing such materials and helps increase the speed of production and reduce costs while ensuring high product quality.

UV curingconveyorsystems

When UV curing materials are exposed to UV light, a chemical cross-linking reaction occurs, typically within seconds or a few minutes, depending on the chemical material, layer thickness, and UV light intensity. Comprehensively tracking this chemical reaction requires a very sensitive device such as an MCR rheometer. The MCR devices are equipped with a set of features that guarantee the most accurate results. First of all, the MCR’s unique TruStrain™ method comes into account, enabling fast data acquisition and thus the highest possible data rate during oscillatory tests. The sensitive normal force control guarantees compensation of sample shrinkage during the reaction and ensures a correctly filled gap. The MCR rheometers also feature an online compliance correction for accurate results even for the stiffest samples after curing. These functions avoid measuring errors and ensure accurate and reproducible results. Analysis methods for onset and curing points are available as standard.

We know that refractive index of light is defined by η=speedoflightinvaccumspeedoflightthatmedium. η=3×108v=1.5. v=2×108m/s · Q1. The refractive index of glass ...

UV curing systemsfor printing

The UV Light Curing System is one part of the modular RheoOptics Toolbox for the MCR rheometer series. The modular concept of the MCR rheometer series allows you to quickly and easily switch to other accessories for combined optical and rheological investigations. The Peltier and electrical temperature devices available for the MCR series can be used with other rheo-optic tools, such as Raman spectroscopy, IR spectroscopy, (fluorescence) light microscopy, Small Angle Light Scattering (SALS), and polarized imaging. In this way you can efficiently use your MCR rheometer to apply different methods that complement each other and advance your materials research.

UVspotcuringsystem

The UV Light Curing System is a powerful tool for material characterization which helps you reduce costs when redesigning the photochemical polymerization process of your UV-sensitive material. You benefit from quick and accurate temperature control from -20 °C to 200 °C with the actively controlled Peltier hood. For measurements under higher temperature conditions, an electrical temperature control from ambient temperature to 300 °C and convection temperature devices from -40 °C to 200 °C are also available. All systems allow purging with inert gas to avoid undesired chemical reactions. Exchangeable lower glass plates and disposable plates of various diameters are available for samples which cannot easily be removed from the plates after the measurement.

Crisp and concentrated light - Focused light spread - Magnetic mount.

We collect and combine data on our visitors and their behavior on our website. This information is used to improve the website.

If you reject all cookies, only technically required cookies will be used. You can also withdraw your consent at a later time by accessing the Cookie Settings.

Uv light curing systemsprice

We use cookies on our website. Some of them are necessary (e.g. for the shopping cart), others help us make our online content better and easier for you over the long term via analysis, external media, and marketing services. We also use third-party cookies from providers in the USA like Google or Facebook if provided with your consent (Art. 49(1)(a) GDPR). Your data may be transferred to the USA which does not have a data protection level comparable to GDPR. In this case your data may potentially be accessed by US Authorities for surveillance purposes and you may not be able to exercise effective legal remedies. You can accept or reject all cookies by clicking on the respective button or define your cookie settings using the link "Customize your cookie settings".

Besides switching between different accessories, you can also combine certain methods, like UV and Raman spectroscopy, UV and IR spectroscopy, and UV and humidity control. This gives you access to even more sophisticated methods for your product development and research tasks.

Ms.Cici

Ms.Cici

8618319014500

8618319014500