Intro to Optical Filters - optical notch filter

One of the main advantages of electron microscopes is their ability to provide detailed images of structures that are too small to be resolved by optical microscopes. This has revolutionized various scientific fields, including materials science, biology, and nanotechnology. Electron microscopes have been instrumental in advancing our understanding of the atomic and molecular structures of materials, the intricate details of cellular components, and the behavior of nanoparticles.

Due to the machine kinematics with 5+3 axes, special demands are placed on the CAM-NC data chain. Fraunhofer ILT develops solutions that enable the user to use a well-known CAM system for milling, but also for path planning in laser polishing. A downstream technology processor, which combines the functions of a post-processor with specific adjustments, converts the milling paths into laser polishing paths. The 3D laser scanner is controlled by a flexible software system that can be seamlessly integrated into the NC control of the machine. The machine and the CAM-NC data chain are available for component- and application-specific test series at Fraunhofer ILT.

It is important to note that the magnification power of an electron microscope is not the only factor that determines the quality of the image. The resolution, which refers to the ability to distinguish between two closely spaced objects, is also crucial. Electron microscopes can achieve much higher resolution than optical microscopes, allowing for the visualization of fine details and structures.

Burrs and edges can be removed by laser machining and remelted as a function of the requirements. In this case, when a defined shape is melted, for example, uniform rounding can be achieved.

Lasercleaning Machine 1000W price

In recent years, advancements in microscopy technology have led to the development of high-powered microscopes with even greater magnification capabilities. For example, electron microscopes can achieve magnifications of up to several million times. These advanced microscopes have revolutionized scientific research and have allowed scientists to observe and study objects at the nanoscale.

Electron microscopes utilize a beam of electrons instead of light to magnify the specimen. This allows for much higher magnification and resolution, enabling scientists to observe objects at the nanoscale level. The magnification power of an electron microscope can range from a few hundred times to several million times, depending on the specific type of electron microscope and the techniques used.

In conclusion, the magnification power of an electron microscope is significantly higher than that of an optical microscope. Electron microscopes have revolutionized scientific research by providing detailed images of structures at the nanoscale level. Ongoing advancements in electron microscopy techniques continue to push the boundaries of magnification power and resolution, opening up new possibilities for scientific discovery and technological advancements.

Rust removallaserprice

For the processes used in tool and mold making, the state of the art is manual polishing, which has processing times of often more than 10 min/cm². Therefore, there is a great need, particularly in this industry, for automated polishing processes for complex 3D surfaces. The roughness it requires is often in the range of Ra = 0.05 to 0.3 μm.

Together with partners from the industry, Fraunhofer ILT has developed a machine tool for laser polishing of complex 3D components. The laboratory results and experience have been transferred to a robust machine technology suitable for industrial production. The basis is a five-axis portal machine, which positions the workpieces and performs slow feed movements. In combination with a highly dynamic three-axis laser scanner, the machine can reach the required process speeds of up to 1 m/s.

Laserpaint stripping machine for sale

When laser radiation is used to polish metals, a thin surface layer of the workpiece is remelted and the surface smoothed due to interfacial tension. The innovation of laser polishing lies in its fundamentally different mode of action (remelting) compared to conventional grinding and polishing processes (ablation). For metallic materials, diode-pumped solid-state lasers are generally used. If the surfaces already have a low roughness, e. g. after grinding, pulsed lasers with pulse durations of several 100 ns can be used. If the surfaces are rougher, e. g. after milling or additive manufacturing, continuous lasers are used. The remelting depth is between a few 100 nm when pulsed lasers are used and up to 100 μm with continuous lasers.

Titanium materials are often used in medical technology. While these can be polished with conventional, cutting processes, there is a great expenditure of time and personnel. When this process is automated using laser polishing, machining time and cost can be significantly reduced. Laser-polished surfaces have a high degree of geometrical accuracy owing the principle involved and, therefore, allow tight tolerances. The absence of grinding and polishing agents also means that the surfaces have a high chemical purity after laser polishing, which is particularly important for implants.

It is important to note that the total magnification is not the only factor that determines the quality of the image. Other factors, such as the numerical aperture of the lenses, the resolution of the microscope, and the quality of the optics, also play a significant role in achieving a clear and detailed image.

In recent years, there have been advancements in microscope technology that have improved the numerical aperture and, consequently, the resolving power and light-gathering ability of microscopes. For example, the development of high numerical aperture objectives and the use of techniques such as confocal microscopy and super-resolution microscopy have allowed scientists to observe structures and processes at a much finer scale.

Laserpolishing machine

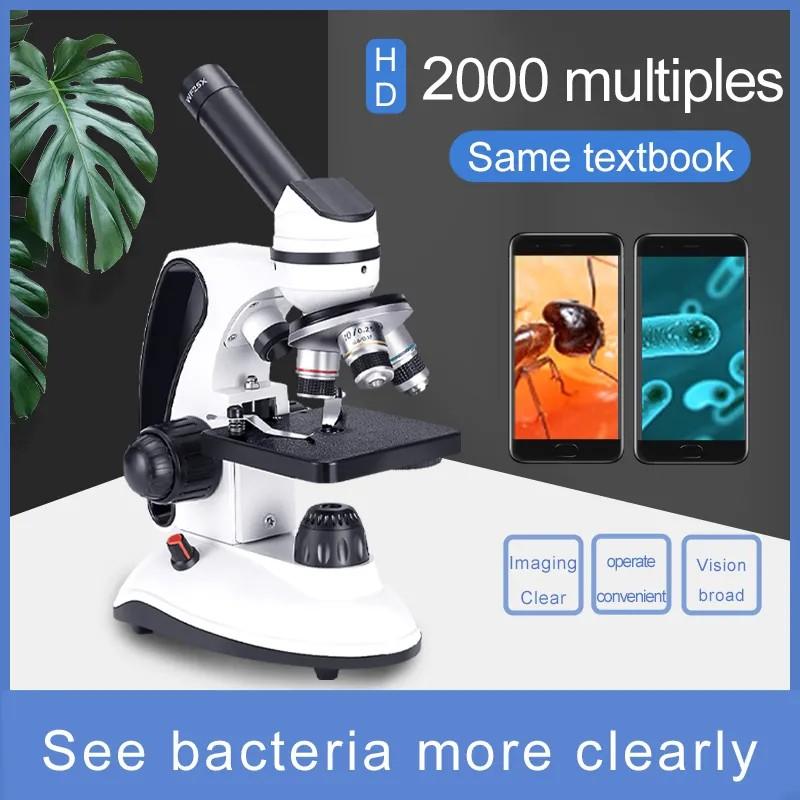

The magnification power of a microscope refers to the degree to which the image of an object is enlarged when viewed through the microscope. It is a measure of how much larger the object appears compared to its actual size. Magnification power is determined by the combination of the objective lens and the eyepiece lens of the microscope. The objective lens is responsible for gathering light and forming the initial magnified image, while the eyepiece lens further magnifies this image for the viewer. The total magnification power is calculated by multiplying the magnification of the objective lens by the magnification of the eyepiece lens. For example, if the objective lens has a magnification of 10x and the eyepiece lens has a magnification of 20x, the total magnification power would be 200x. Different microscopes have different magnification powers, and higher magnification allows for more detailed observation of small structures.

Laser polisherprice

In addition, when the process parameters are modulated, the gloss level on tool surfaces can be adjusted with high local resolution (150 μm), which also makes it possible to produce two-color and multi-gloss effects. In leather grain, for example, only the recesses of the grain are polished in the tool, the webs remain unprocessed.

Laser polishing is particularly well suited for nickel, titanium and cobalt/chromium alloys. Even with an initial roughness in the range Ra = 1 to 15 μm, a roughness of Ra < 0.2 μm can be achieved with an area rate of 1 to 5 cm²/min. Other steels and cast alloys can also be polished. The polishing result depends on the material and its homogeneity.

In recent years, advancements in digital imaging technology have led to the development of high-resolution cameras and sophisticated image processing algorithms. This has significantly improved the digital magnification capabilities of microscopes. Researchers and scientists can now achieve higher levels of magnification and resolution, allowing for more accurate and detailed analysis of specimens.

The magnification power of a microscope refers to the degree to which an object can be enlarged and observed under the microscope. In the case of an electron microscope, the magnification power is significantly higher than that of an optical microscope.

LaserPolishing Machine price

The magnification power of a microscope refers to the ability of the microscope to enlarge the size of an object being observed. It is typically expressed as a ratio, such as 10x or 100x, indicating that the object appears 10 or 100 times larger than its actual size.

Resolving power refers to the ability of a microscope to distinguish between two closely spaced objects as separate entities. The higher the numerical aperture, the better the resolving power of the microscope. This is because a larger numerical aperture allows more light to enter the lens, resulting in a sharper and more detailed image.

However, it is important to note that the magnification power alone does not determine the quality of the image produced by a microscope. Another crucial factor is the numerical aperture (NA) of the lens. The numerical aperture determines the resolving power and light-gathering ability of the lens.

Digital magnification is achieved by capturing an image of the specimen using a digital camera attached to the microscope. The image is then processed and enlarged using software algorithms. This allows for further magnification beyond the limitations of the physical lenses. The level of digital magnification depends on the resolution of the camera and the software used for image processing.

On the tool steels 1.2343, 1.2311, 1.2379 and 1.3207, laser polishing can be used to smooth milled and eroded surfaces with a roughness of Ra = 1 to 4 μm down to a roughness of Ra = 0.05 to 0.2 μm. The surface rate here is about 1 cm²/min, but can be increased to up to 10 cm²/min by material-adapted intensity distributions. Injection molding and embossing tools with laser-polished surfaces have comparable service lives to those of manually polished tools.

The Fraunhofer Institute for Laser Technology ILT uses laser radiation to automatically polish components with complex 3D surfaces. With this new process, users from various industries, such as those from tool and mold industry or medical technology, can avoid tedious manual p rocessing and save both money and time.

The magnification power of a microscope refers to the ability of the microscope to enlarge the image of the specimen being observed. It is a crucial factor in microscopy as it determines the level of detail and clarity that can be achieved during observation.

Laser polisherfor metal

The advantage of digital magnification is that it provides a higher level of detail and clarity compared to traditional optical magnification. It allows for precise examination of fine structures and enables researchers to capture and analyze images in real-time. Digital magnification also offers the ability to store and share images electronically, facilitating collaboration and documentation.

The magnification power of a microscope refers to its ability to enlarge an object or specimen for detailed observation. Traditionally, magnification power was determined by the combination of the objective lens and the eyepiece lens. However, with the advent of digital technology, microscopes now offer additional magnification capabilities through image processing and zooming capabilities.

The magnification power of the objective lens is typically higher than that of the eyepiece. Objective lenses are available in various magnification powers, such as 4x, 10x, 40x, and 100x. The eyepiece usually has a fixed magnification power of 10x. Therefore, the total magnification of a microscope can range from 40x (4x objective lens multiplied by 10x eyepiece) to 1000x (100x objective lens multiplied by 10x eyepiece).

In conclusion, the magnification power of a microscope has been enhanced through digital technology. Digital magnification, achieved through image processing and zooming capabilities, provides researchers with the ability to observe and analyze specimens at a higher level of detail. With ongoing advancements in digital imaging, the magnification power of microscopes continues to improve, enabling scientists to push the boundaries of scientific discovery.

Lasercleaning machine price

It is important to note that digital magnification does have its limitations. While it can enhance the level of detail, it cannot overcome the physical limitations of the microscope's resolution. Additionally, excessive digital magnification can result in pixelation and loss of image quality.

In conclusion, while the magnification power of a microscope is important, the numerical aperture of the lens plays a crucial role in determining the quality of the image produced. A higher numerical aperture leads to better resolving power and light-gathering ability, resulting in sharper, more detailed, and brighter images. Ongoing advancements in microscope technology continue to push the boundaries of what can be observed and studied at the microscopic level.

On diamond-milled surfaces with an initial roughness of Ra ≈ 0.3 μm, a roughness of Ra ≤ 0.1 μm can be achieved when polished with pulsed laser radiation. The processing time is only 3 s/cm² and, thus, significantly shorter than that of manual polishing.

In recent years, there have been significant advancements in electron microscopy techniques, leading to even higher magnification powers and improved resolution. For example, the development of aberration-corrected electron microscopy has allowed for the visualization of individual atoms and atomic-scale defects in materials. Additionally, the introduction of cryo-electron microscopy has revolutionized the field of structural biology, enabling the determination of high-resolution structures of biological macromolecules.

The light-gathering ability of the lens is also determined by the numerical aperture. A higher numerical aperture means that the lens can gather more light, resulting in a brighter image. This is particularly important when observing specimens that are not very transparent or have low contrast.

In conclusion, the magnification power of a microscope is determined by the product of the objective lens and eyepiece magnifications. The total magnification determines the level of enlargement and detail that can be achieved during observation. However, it is important to consider other factors such as resolution and numerical aperture to obtain a clear and detailed image. With advancements in technology, microscopes with higher magnification powers have been developed, enabling scientists to explore the microscopic world in greater detail.

The total magnification of a microscope is the product of the magnification of the objective lens and the eyepiece. The objective lens is located near the specimen and is responsible for gathering light and forming the initial magnified image. The eyepiece, on the other hand, is located at the top of the microscope and further magnifies the image formed by the objective lens.

Ms.Cici

Ms.Cici

8618319014500

8618319014500