Industrial ring light | VA1-RL3-Series - GeT Cameras - light ring led

Infrared heating is a reliable, basic heating method that integrates well with a myriad of manufacturing processes. The infrared energy wavelength of an object depends on its temperature. The higher the temperature an object produces, the shorter its energy wavelength, resulting in a higher output of energy. Infrared radiation is electromagnetic energy that is categorized as short-wave,medium-wave, and long-wave infrared, with short wavelengths providing the highest energy output and long wavelengths having the lowest. Long-wave or beyond long-wave infrared can be too inefficient for industrial heating processes, so they generally are not used.

Anti-reflection coatings reduce first surface reflection losses, improve contrast and boost the transmission through your optical surface. Choose from a typical design below or ECI will design and deposit a custom anti-reflection (AR) coating for your specific application. If you are not sure how to specify your coating, our design team will work with you to identify the optimum design for your system.

If you need uniform heating throughout your materials, we provide flat panel infrared heaters featuring heating elements bonded to refractory that can handle high heat.

ECI also deposits high temperature Anti-Reflection coatings on various substrates, including crown glasses, float glasses, Fused Silica, Sapphire, Silicon, CaF2, and others. ECI can deposit these coatings to cover any wavelength range between 200 – 2500nm. These coatings are designed and deposited to meet the durability requirements per MIL-C-675C. ECI deposits Anti-Reflection coatings on parts up to 400mm in diameter.

Short Wave Infrared sensor

IR heaters provide radiant heat without relying on the ignition or combustion of energy sources that can produce contaminants, toxins, or on-site emissions.

Manufacturers must consider both the efficiency of the infrared heat itself and the heat absorption factor of the material being processed. As a more intense heat source than convection heat, infrared heat should be applied directly to your process materials within the processing chambers of an oven or dryer. The ovens help control the timing and amount of heat applied to avoid product damage or overheating. Consult our infrared heating specialists to determine the best way to apply infrared heat to your project.

Short Wave infrared vs near infrared

Short-wave infrared heaters offer a lot of heating power. The shorter wavelengths can increase the amount of energy absorbed by the heated objects, and short-wave heaters can reach higher temperatures than medium-wave heaters. However, the higher operating temperatures of short-wave heaters can lead to shorter equipment lifespans over time.

SWIR camera price

ECI’s AR Coatings meet the reflection and environmental requirements of MIL-C-14806A and MIL-C-48497. Designs comply with military and telecommunication industry standards.

We deliver cutting-edge production lines to glass manufacturers, backed by decades of experience in glass laminating systems.

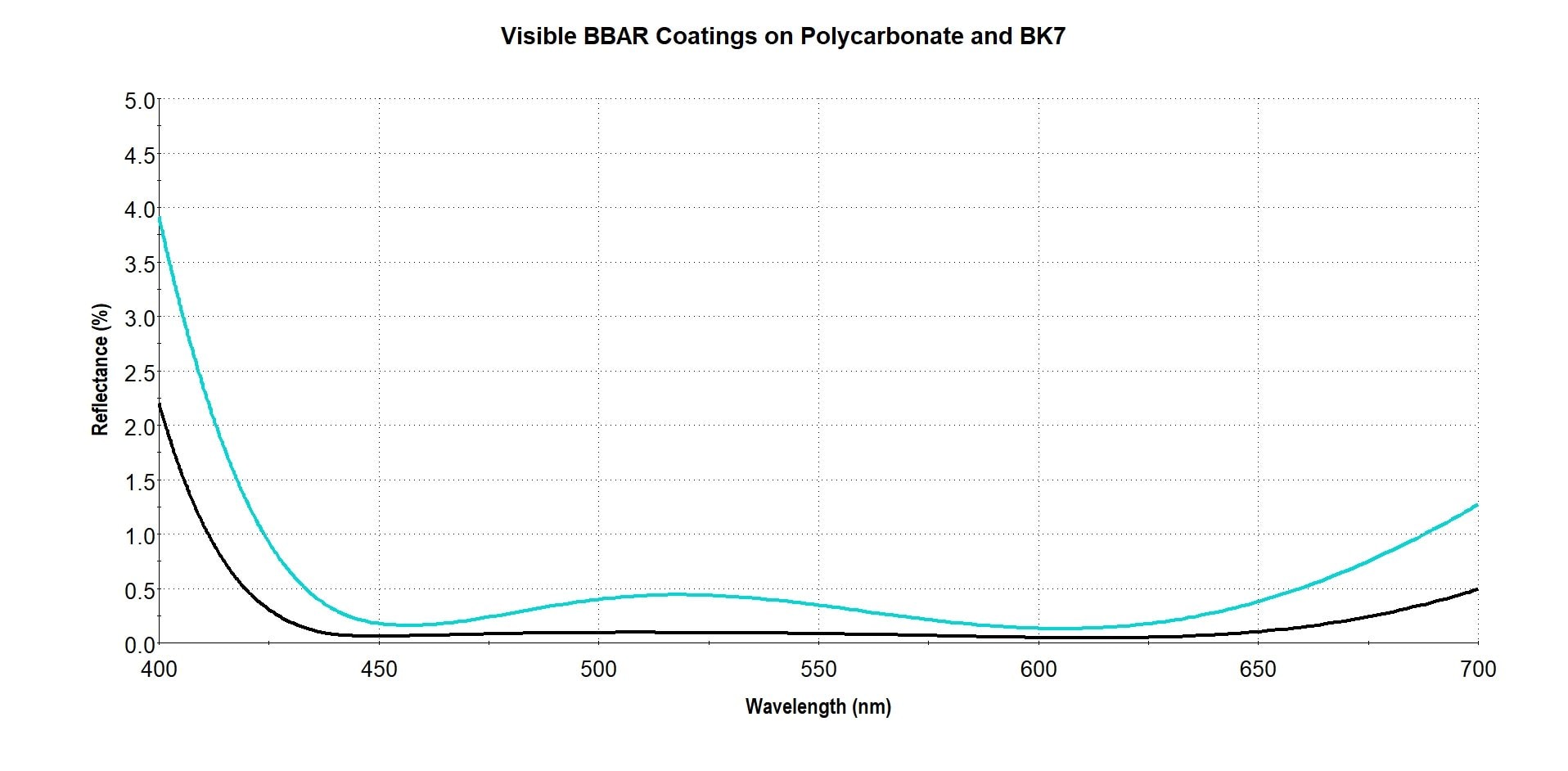

Evaporated Coatings Inc. offers anti-reflection coatings for a variety of substrate materials and configurations. Different coatings materials are selected depending on the substrate material, size, shape, and wavelength range of interest. In many cases, the choice of substrate material dictates the deposition temperature of the AR coating. For narrowband Anti-Reflection coatings, the optical performance is similar for both low and high temperature depositions. However, the performance of a broadband AR Coating will vary depending on the deposition temperature. Typically, broadband AR coatings deposited at higher temperatures will yield lower average reflection over a particular bandwidth. There are two primary reasons: 1). certain coating materials require deposition at elevated temperatures for sufficient durability and 2). the refractive indices of some materials decrease when deposited at lower temperatures. For example, a visible broadband AR coating on BK7 will have slightly better optical performance than a visible broadband AR coating deposited on Polycarbonate. Figure 2 shows the difference in performance between the two substrates mentioned above.

Short Wave infrared wavelength

ECI deposits High Power Anti-Reflection coatings on several different types of substrates, including but not limited to Glass/Fused Silica windows, lenses and wafers, Fiber optic cables and assemblies, LBO, BBO, KTP, TGG, GGG, BiG, and Silicon wafers.

Learn more about how infrared heating works, the differences between short-wave and medium-wave infrared heaters, and their respective pros and cons.

Our IR heaters provide consistent temperatures that can be controlled and monitored easily by operators. Each heater can be programmed with customer-specific recipes, and we can upgrade or alter the controls upon request.

SWIR camera

Typical values verified through independent test laboratories. Actual LDT performance is dependent on substrate selection, surface preparation, and system design.

© Copyright 2011 - 2022 Evaporated Coatings, Inc. All rights reserved. Careers Privacy Policy Terms of Service Sitemap

Our electric IR heaters are extremely efficient with their power consumption. For instance, our DuoTube heaters feature an integrated ceramic coating reflector to ensure that most of the infrared energy generated is directed at the product.

SWIR wavelength range

Short-wave infrared heating systems use short waves, which give off more energy and operate at higher temperatures. As a result, these heaters offer high-intensity heat that can reach 5000°F or higher. Our Casso-Solar SWL Unitube Heater can radiate waves between 0.76 and 2.0 microns, and operators can control the wavelength to align with the peak absorption point of process materials. Each unit includes controllable emitters that can be shut down to preserve energy, modified for temperature profiling, and more.

Both short- and medium-wave IR heating systems can heat manufactured goods for processing and finishing, and each one works best for different contexts. Short-wave IR heaters are extremely energy efficient and can reach higher temperatures; the heat can also quickly penetrate objects based on their peak absorption point. Medium-wave IR heaters produce a lot of energy and tend to have a longer lifespan. Our team can help you select the right heating unit based on your manufacturing processes and needs.

At Casso-Solar Technologies, weâve developed infrared heating solutions for over 60 years. We work with each of our clients to ensure they have custom-fitted solutions that integrate with their existing processes and needs, and we partner with each client through the design and implementation process to ensure complete satisfaction. Contact us today to learn more or to get started.

Manufacturing cycles often require heat to process materials and produce finished goods. Many manufacturers turn to infrared (IR) heating processes to provide energy efficient, high-intensity heat for various drying applications. More than 60 years ago, Casso-Solar Technologies started out as a simple infrared heaters manufacturer. Since then, weâve continually developed our products to meet the complex, custom specifications of our clientsâ projects.

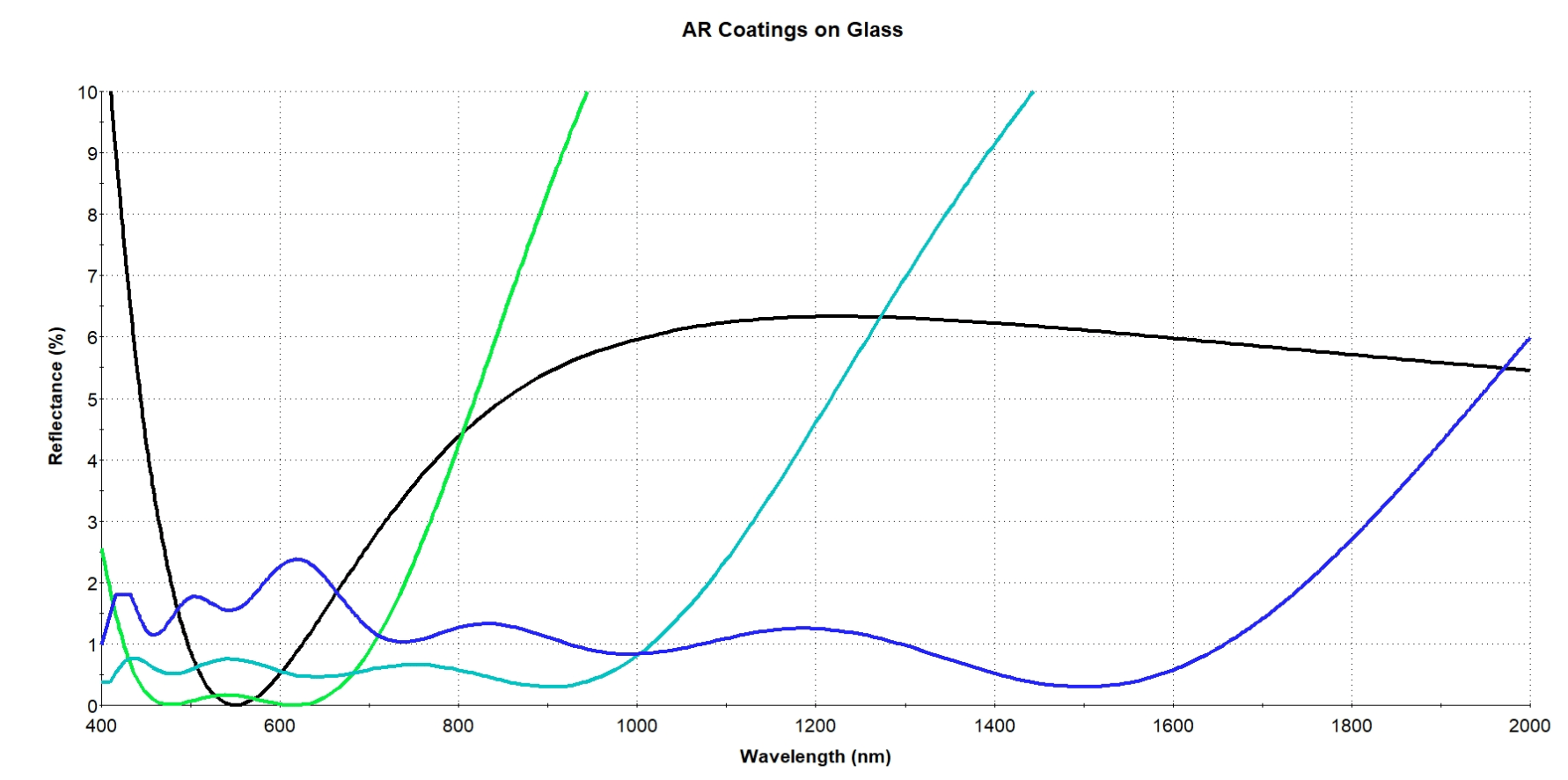

Anti-Reflection Coatings can be optimized for narrow and broadband applications. The performance of an AR coating will vary depending on the bandwidth and angle of incidence (AOI). ECI can typically achieve front surface reflection less than 0.03% for a narrowband AR coating at near normal incidence. Anti-Reflection coatings optimized for wider bandwidths will display a higher maximum reflection. A typical Broadband Anti-Reflection coating on glass will have a maximum reflection of less than 0.5% with a typical average reflection of 0.25%. Figure 1 shows how reflection performance can vary with bandwidth.

Shortwave irvs swir

Our quartz heating elements maximize the energy that passes through them, providing very efficient heating. They can be found in our Unitube, DuoTube, and Type C+ heaters.

Casso-Solar only uses high-quality components in our electric IR heaters, meaning that they require little to no maintenance throughout their useful life, which lasts tens of thousands of hours.

AR Coatings ( Anti-Reflection coatings ) are deposited onto optical surfaces to reduce specular reflectivity. Anti-Reflection coatings are comprised of a single layer or multiple layers. These designs are optimized to create destructive interference with respect to the reflected light. This design approach will allow the maximum amount of light transmission without compromising image quality. Diagram 1 is an example of a typical multilayer Anti-Reflection coating.

Shortwave irapp

Our engineering team has developed a wide range of heaters, each one consistent with the temperature needs of different manufacturing processes.

Anti-Reflection coatings are utilized in a variety of applications. It is very common for AR coatings to be used in laser applications. In such cases, Anti-Reflective coatings will need to meet or exceed certain LDT ( Laser Damage Threshold ) requirements. ECI primarily uses Ion Beam Sputtering ( IBS ) or Electron Beam ( E-Beam ) to deposit AR coatings that must withstand high power lasers.

ECI has extensive experience coating polymers and other temperature sensitive substrates. ECI has been coating polymer optics for over 60 years. Our low temperature Anti-Reflection coatings are designed and deposited to ensure good adhesion and thermal stability on even the most challenging polymer substrates. ECI coats different types of substrate with low temperature Anti-Reflection coatings at process temperatures below 50°C. These substrates range from plastic windows and lenses to optical fibers and fiber optic assemblies/components including: Molded Polymer Optics, Polycarbonate, Acrylic, Zeonex®, Ultem®, Mylar®, CR39, COC, Fresnel Lenses, TO-Window Cans, MT Ferrules.

ECI’s durable films on plastic and polymer molded optics are resistant to organic solvents and are an excellent choice for a wide variety of products.

Medium-wave IR heaters produce a high level of energy and can last longer than their short-wave counterparts. They are ideal for drying operations and handling water-based coats, as water can easily absorb medium-wave energy. However, these heaters have alower power density than short-wave heaters and thus require a larger footprint to deliver the same amount of energy.

Medium-wave infrared heating solutions radiate heat with longer length-waves. Our DuoTube heating unit can reach high temperatures of up to 1400°F or 1750 °F, depending on the coating or refractory selected. The gold-coated DuoTube has a dual-coat integral gold reflective coating, which does not oxidize and can reach temperatures of up to 1400°F. The white refractory DuoTube works on a wider emission spectrum and can reach temperatures of up to 1750°F. Both types are completely maintenance-free throughout their useful life.

Ms.Cici

Ms.Cici

8618319014500

8618319014500