How microscopes magnify - how does magnifying glass works

Investigate how internal lens elements in a high numerical aperture dry objective may be adjusted to correct for fluctuations in coverslip thickness.

Whatdoesthestage doon a microscope

Michael W. Davidson - National High Magnetic Field Laboratory, 1800 East Paul Dirac Dr., The Florida State University, Tallahassee, Florida, 32310.

To attain higher working numerical apertures, many objectives are designed to image the specimen through another medium that reduces refractive index differences between glass and the imaging medium. High-resolution plan apochromat objectives can achieve numerical apertures up to 1.40 when the immersion medium is special oil with a refractive index of 1.51. Other common immersion media are water and glycerin. Objectives designed for special immersion media usually have a color-coded ring inscribed around the circumference of the objective barrel as listed in Table 3 and described below. Common abbreviations are: Oil, Oel (oil immersion), HI (homogeneous immersion), W, Water, Wasser (water immersion), and Gly (glycerol immersion).

Parfocal Distance - This is another specification that can often vary by manufacturer. Most companies produce objectives that have a 45 millimeter parfocal distance, which is designed to minimize refocusing when magnifications are changed.

Most manufacturers have now transitioned to infinity-corrected objectives that project emerging rays in parallel bundles from every azimuth to infinity. These objectives require a tube lens in the light path to bring the image into focus at the intermediate image plane. Infinity-corrected and finite-tube length microscope objectives are not interchangeable and must be matched not only to a specific type of microscope, but often to a particular microscope from a single manufacturer. For example, Nikon infinity-corrected objectives arenot interchangeable with Olympus infinity-corrected objectives, not only because of tube length differences, but also because the mounting threads are not the same pitch or diameter. Objectives usually contain an inscription denoting the tube focal length correction as will be discussed.

What is thestageon a microscope

As with other kinds of optical filters, edge filters are designed to separate a broad spectrum of light into light that is transmitted, and light that is rejected, or blocked. Edge filters can be used to reduce harmonics and light scatter and can be fabricated to function as longpass, shortpass, or bandpass filters.

Microscope manufacturers offer a wide range of objective designs to meet the performance needs of specialized imaging methods, to compensate for cover glass thickness variations, and to increase the effective working distance of the objective. Often, the function of a particular objective is not obvious simply by looking at the construction of the objective. Finite microscope objectives are designed to project a diffraction-limited image at a fixed plane (the intermediate image plane), which is dictated by the microscope tube length and located at a pre-specified distance from the rear focal plane of the objective. Microscope objectives are usually designed to be used with a specific group of oculars and/or tube lenses strategically placed to assist in the removal of residual optical errors. As an example, older Nikon and Olympus compensating eyepieces were used with high numerical aperture fluorite and apochromatic objectives to eliminate lateral chromatic aberration and improve flatness of field. Newer microscopes (from Nikon and Olympus) have objectives that are fully corrected and do not require additional corrections from the eyepieces or tube lenses.

Best practices suggest that when coating or setting up an optical component, it’s best to use a witness sample, also called a “test piece,” to ensure that the actual part will match your specific coating specifications and your application.

Special Features - Objectives often have additional special features that are specific to a particular manufacturer and type of objective. The plan apochromat objective illustrated in Figure 1 has a spring-loaded front lens to prevent damage when the objective is accidentally driven onto the surface of a microscope slide.

Sydor Optics can manufacture custom optical filters — with various shapes and sizes — using CNC Glass Machining capabilities to meet your specific needs.

The interactive tutorial above allows the visitor to adjust the correction collar on a microscope objective. There are some applications that do not require objectives to be corrected for cover glass thickness. These include objectives designed for reflected light metallurgical specimens, tissue culture, integrated circuit inspection, and many other applications that require observation with no compensation for a cover glass.

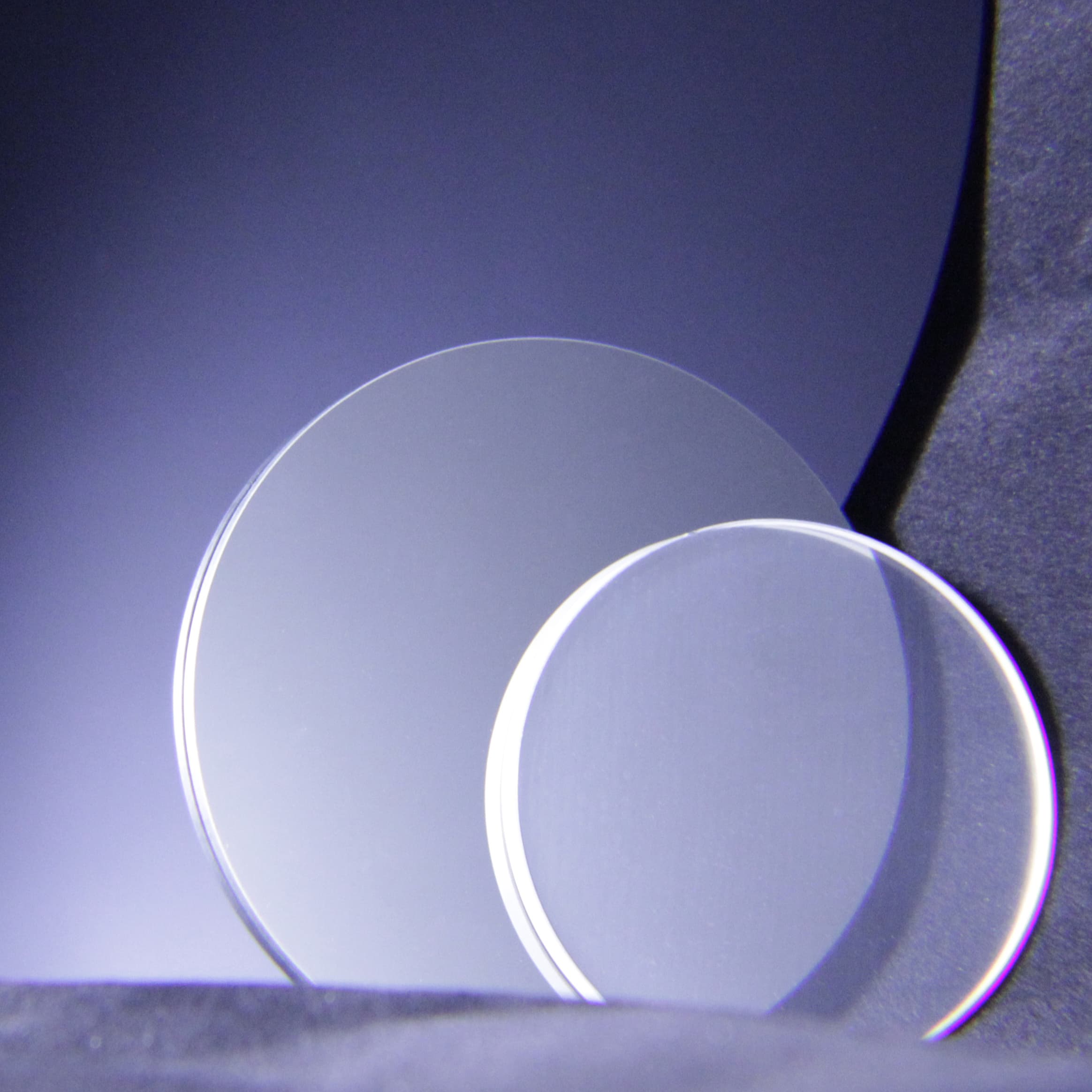

Aside from standard size glass wafers such as 100mm, 150mm, 200mm and 300mm, Sydor Optics can provide custom wafers with diameters up to 450mm and thin wafers with thicknesses down to 0.1mm.

While certain kinds of optical filters are used to narrow wavelength ranges, broadband filters are designed to do the opposite: provide exceptional transmission throughout a broad range of wavelengths (but still exclude or reject the rest). Sydor Optics can fabricate custom broadband filters in various shapes and sizes to meet your specific needs and applications.

What is thepurpose ofthe objectivelens inalightmicroscope

Color glass filters are fabricated to selectively transmit a particular range of wavelengths or colors of light. In designing color filters to transmit a particular range, they’re also designed to block other wavelengths or colors. Sydor Optics can fabricate custom color filters to allow long wavelengths to pass (longpass), or short wavelengths (shortpass), or both (bandpass).

Infrared filters allow for high transmission in the IR spectrum and strong rejection to isolate even the narrowest band of wavelengths. As their name implies, IR filters can be fabricated for use in the harshest environments in FLIR, security, environmental and other infrared applications.

Objectivelens and eyepiece lens magnification

Some objectives specifically designed for transmitted light fluorescence and darkfield imaging are equipped with an internal iris diaphragm that allows for adjustment of the effective numerical aperture. Abbreviations inscribed on the barrel for these objectives include I, Iris, and W/Iris. The 60x apochromat objective illustrated above has a numerical aperture of 1.4, one of the highest attainable in modern microscopes using immersion oil as an imaging medium.

Reflect and transmit any combinations of wavelengths with precision plate beamsplitters. UV, VIS, or IR, Polarized or Unpolarized, 10:90 – 90:10 Reflection:Transmission(R:T).

What is objectivelens inmicroscope

Notch filters can be fabricated to the most demanding specifications for use in laser-based fluorescence, multi-photon microscopy, and Raman spectroscopy, and other high-speed imaging applications. As with other types of optical filters, Sydor Optics can fabricate custom notch filters to meet your specific needs and applications.

From the discussion above it is apparent that objectives are the single most important element of a microscope. It is for this reason that so much effort is invested in making sure that they are well-labeled and suited for the task at hand.

Shortpass filters are a type of edge filter, designed to isolate desired wavelengths in the spectrum, and “cut” undesired wavelengths out of the optical system.

Opticalmicroscope

Whatdoestheeyepiece lens doon a microscope

There is a wealth of information inscribed on the barrel of each objective, which can be broken down into several categories. These include the linear magnification, numerical aperture value, optical corrections, microscope body tube length, the type of medium the objective is designed for, and other critical factors in deciding if the objective will perform as needed. A more detailed discussion of these properties is provided below and in links to other pages dealing with specific issues.

Neutral density filters can be used to reduce the intensity of light by reflecting or absorbing a percentage of light at a specific wavelength. Neutral density (ND) filters reduce light intensity by absorbing or reflecting light and provide even attenuation across the specified wavelengths.

Identification of the properties of individual objectives is usually very easy because important parameters are often inscribed on the outer housing (or barrel) of the objective itself as illustrated in Figure 1. This figure depicts a typical 60x plan apochromat objective, including common engravings that contain all of the specifications necessary to determine what the objective is designed for and the conditions necessary for proper use.

Although not common today, other types of adjustable objectives have been manufactured in the past. Perhaps the most interesting example is the compound "zoom" objective that has a variable magnification, usually from about 4x to 15x. These objectives have a short barrel with poorly designed optics that have significant aberration problems and are not very practical for photomicrography or serious quantitative microscopy.

Glass Design - The quality of glass formulations has been paramount in the evolution of modern microscope optics. Numerous designs have been implemented by a variety of manufacturers, but we will limit this discussion to a specialized low dispersion glass formulation. Extra Low Dispersion (ED) glass was introduced as a major advancement in lens design with optical qualities similar to the mineral fluorite but without its mechanical and optical demerits. This glass has allowed manufacturers to create higher quality objectives with lens elements that have superior corrections and performance.

As their name implies, longpass filters are designed to allow only long wavelengths to pass while blocking shorter wavelengths of light.

Available materials for filter substrates include fused silica, display glass, low expansion, and optical glass. Please contact a Sales Engineer who will be happy to discuss all options for filter substrates.

The objective depicted on the left in Figure 3 has a parfocal distance of 45mm and is labeled with an immersion medium color code in addition to the magnification color code. Parfocal distance is measured from the nosepiece objective mounting hole to the point of focus on the specimen as illustrated in the figure. The objective on the right in Figure 3 has a longer parfocal distance of 60 millimeters, which is the result of its being produced to the Nikon CFI60 200/60/25 Specification, again deviating from the practice of other manufacturers such as Olympus and Zeiss, who still produce objectives with a 45mm parfocal distance. Most manufacturers also make their objective nosepieces parcentric, meaning that when a specimen is centered in the field of view for one objective, it remains centered when the nosepiece is rotated to bring another objective into use.

Sydor Optics can also manufacture filter substrates for you to coat. Our double-sided grinding and polishing machines allow for filter substrates created precisely to your specifications and are ideal for third-party coating.

Sydor Optics manufactures IR windows utilizing a range of infrared materials suited for the NIR, SWIR, MWIR and LWIR spectrums ranging from 0.75µm to 15µm for applications including thermal imaging, mineral & gas detection and monitoring and other forward-looking infrared (FLIR) imaging applications.

Based upon customer demand, Sydor Optics offers Optical Filters made from the following substrate materials. Of course, if you don’t see a material you need, please contact a Sales Engineer, who will gladly discuss additional options that may be available.

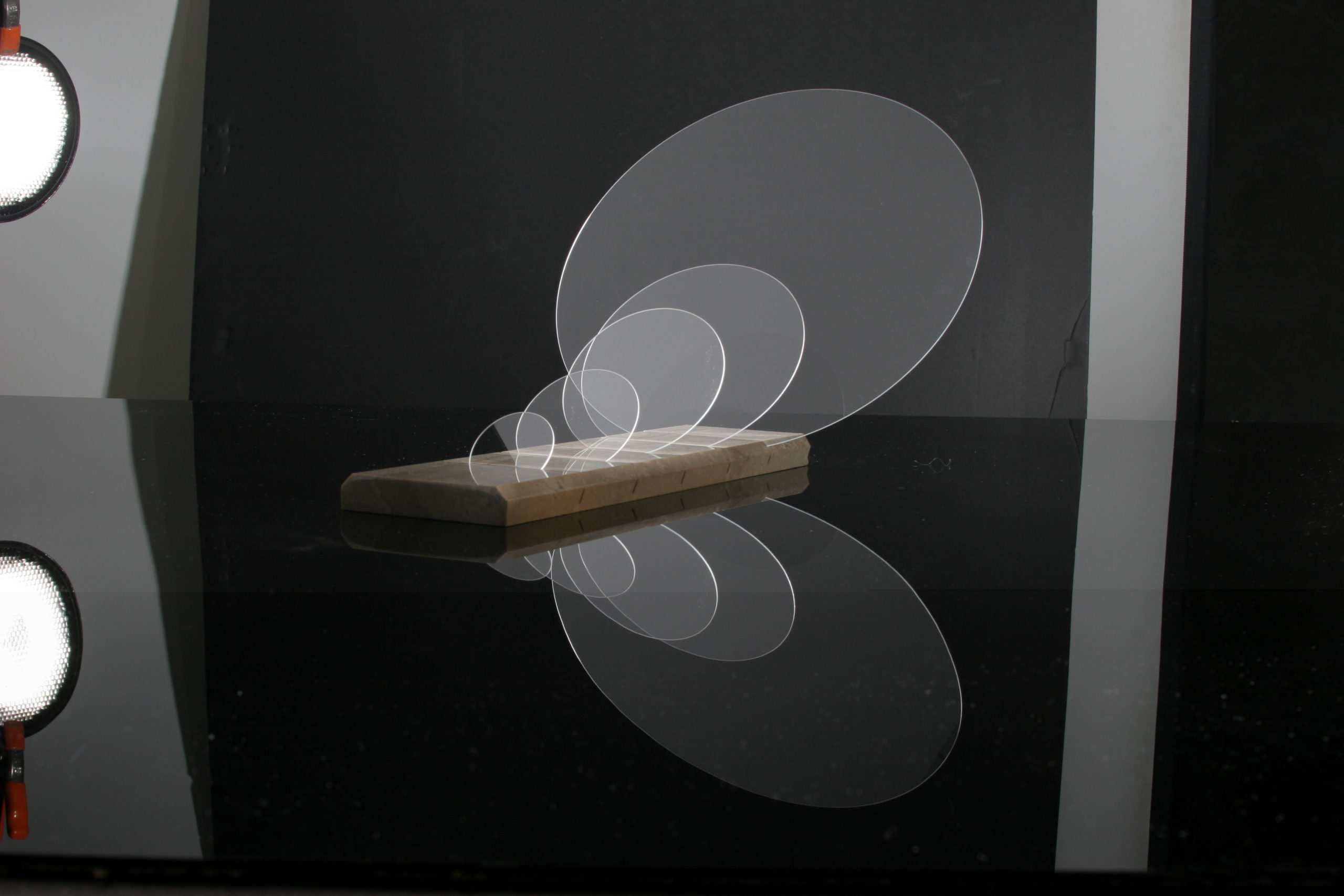

There are perhaps about as many types of glass filters as there are applications for them. Yet despite all the variety, one thing is clear: Sydor Optics offers exceptional manufacturing capabilities when it comes to custom optical filters. With the largest collection of double-sided grinding and polishing machines in North America, Sydor Optics can precisely fabricate custom filters to meet your exact requirements, from basic prototyping to high-volume production and every step in between. While color glass filters can be ordered directly from the original manufacturer, standard surface flatness and transmitted wavefront tolerances may not meet your precision requirements which is why Sydor Optics double-sided polishing process stands out.

Whatdoesthe objectivelens doon a microscope

Colored filter glass is available in a range of spectral characteristics each suited to unique transmission and absorption properties of various wavelengths of light.

Sydor Optics fabricates dichroic filters to transmit a particular range of the spectrum (the passband) while reflecting another range (known as the rejection band). Dichroic filters are commonly used for color separation in digital projection and CCD imaging. Sydor Optics can handle the custom fabrication of even the most complex dichroic filters.

Sydor Optics has extensive experience manufacturing uncoated filter substrates and colored filter glass. Common optical filters include shortpass, longpass, bandpass, notch and edge with filter coatings suited for the infrared (IR), ultraviolet (UV) and visible (VIS) color spectrums.

Optical wedges with ± 10 arc seconds of wedge angle tolerance. Superior craftsmanship made to your specifications in a variety of shapes, sizes, and materials.

Multilayer Coatings - Quality microscope objectives are protected and enhanced by unique high-transmission anti-reflective multilayer coatings that are applied to the lens air-interface surfaces to reduce flare and ghosts and ensure high-contrast images. These specialized coatings are also used on the phase plates in phase contrast objectives to maximize contrast.

World-class Nikon objectives, including renowned CFI60 infinity optics, deliver brilliant images of breathtaking sharpness and clarity, from ultra-low to the highest magnifications.

Ultraviolet (UV) filters are used to block ultraviolet light (UV blocking), but allow visible light to pass. Sydor Optics can fabricate custom UV filters to meet your specific needs and applications including combining UV filters with other (bandpass/longpass) optical filters.

Bandpass filters are basically designed to selectively transmit a particular spectrum range and reject the other wavelengths. Bandpass filters are commonly used in a variety of applications, including chemistry, fluorescence microscopy, high-speed optical imaging, and spectroscopy.

Other features found on specialized objectives are variable working distance (LWD) and numerical aperture settings that are adjustable by turning the correction collar on the body of the objective as illustrated in Figure 2. The plan fluor objective on the left has a variable immersion medium/numerical aperture setting that allows the objective to be used with multiple different immersion media, including oil, water, and glycerin. The plan apo objective on the right has an adjustable working distance control (termed a "correction collar") that allows the objective to image specimens through glass coverslips of variable thickness. This is especially important in dry objectives with high numerical aperture that are particularly susceptible to spherical and other aberrations that can impair resolution and contrast when used with a cover glass whose thickness differs from the specified design value.

Ms.Cici

Ms.Cici

8618319014500

8618319014500