Heat Transfer Vinyl Flock Lumina 9200 15 - paper flock

UV laserwavelength

One common example of optics degradation by UVs is a phenomenon called solarization, which greatly impacts the transmittance of many glasses, alters their color and physical properties, and eventually renders them useless.

Thankfully, frequency conversion crystals can be used to convert the DPSS laser lines into shorter wavelengths. One common conversion is a frequency tripled 1064 nm YAG, which results in a 355 nm UV laser beam of high beam quality.

Diode-pumped solid-state (DPSS) lasers, such as YAG lasers, are industry workhorses that can produce beams of high quality. However, the crystals available for DPSS emit wavelengths in a limited range (that does not include UV).

Controller: The controller is responsible for controlling the motor's speed, acceleration, and position. It receives input signals from sensors and actuators and generates appropriate control signals to achieve the desired motion.

Excimer lasers can provide the highest powers and the shortest wavelength of all UV lasers. However, the setup is large and complicated, requires a lot of maintenance, is not particularly efficient, and produces a laser of low beam quality.

UV laserdiode

Excimers emit photons of UV wavelength to release excess energy and return to their ground state. Because this photon emission happens very quickly, high pump powers must be used to achieve population inversions (a precondition to lasing).

The SmartStage™ XY motorized stage features a built-in motion controller, ONE external cable and has a 5 nm resolution with 0.8 um bi-directional repeatability.

Motorized stages play a critical role in achieving high accuracy and efficiency in various applications, from scientific research to industrial automation. Yet, information on choosing the right motorized stage is not widely accessible. Our guide aims to provide a comprehensive overview, addressing common questions and highlighting key features to help you select the stage that best fits your application.

Motor: The motor is the driving force behind the stage's movement. It converts electrical energy into mechanical energy to move the stage platform.

UV laserweapon

Our XY tables include high performance, open frame, monolithic high load, and custom designed XY tables that move in two degrees of freedom and offer high precision and efficiency for digital imaging applications.

The short wavelength translates to a small spot size, which in turn means great spatial resolution. UV lasers can also cut and mark with almost no thermal distortion. What’s more, they are compatible with a plethora of materials. All this combines to make them the go-to laser for sensitive high-precision applications.

At Dover Motion, we specialize in designing and manufacturing motorized optical stages that meet the highest standards of accuracy and reliability. Our stages are designed to deliver smooth, stable motion with sub-micron positioning accuracy, even in harsh environments or challenging applications. They range from single-axis stages for simple applications to multi-axis systems for complex processes and are available in a variety of sizes and configurations, with options for linear or rotary motion. Our experienced team of engineers works closely with our customers to understand their specific requirements and design custom motorized optical stages that are tailored to their unique needs.

You may think it’s as “simple” as finding a material that lases at the right wavelength and then pairing it with UV-resistant optics. And you wouldn’t be wrong. That is a solution. It’s the one behind excimer lasers.

Drive Mechanism: The drive mechanism transmits the motion from the motor to the stage platform. It can be a screw drive, belt drive, or direct drive system.

The motorized stage provides precise automated positioning and is available in single or multi-axis architectures. It is also commonly referred to as a motorized table or motorized actuator. Each axis of a motorized stage must constrain the six degrees of freedom (X, Y, Z, roll, pitch, and yaw) of the payload to only one, producing automation along a single axis of motion. This is accomplished with a set of linear bearings, which are mounted to a metal base to provide a stiff structure. Our stages designed specifically for vertical motion can be viewed on our Z Stages page.

Because of its short wavelength, ultraviolet laser light is easily scattered and distorted by even weak surface roughness or bubbles. Therefore, only high-quality optics can be used for UV lasers.

A motorized stage with a linear motor requires a linear feedback device as well as a servo drive and control to close a position feedback loop. With a high-resolution linear encoder, linear actuators can provide position control down to the nanometer level. A typical application for high precision linear actuators is to control the focus of a microscope objective in a digital imaging system.

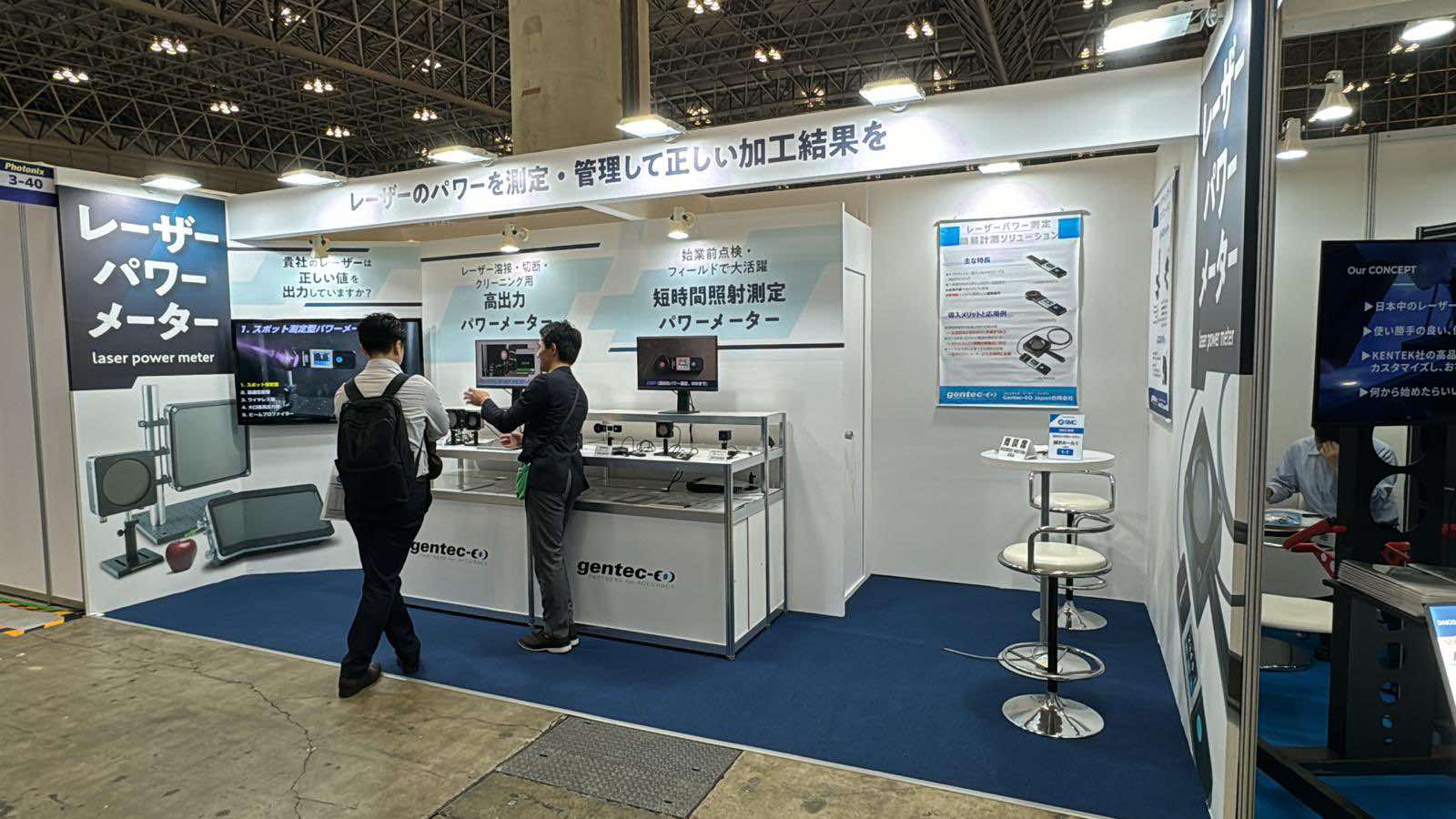

Laser specifications change over time for many reasons and it causes problems accross all industries. Learn about how laser output measurement solves numerous problems in YOUR industry. Download the guide below.

Our direct drive linear motor stages include linear servo motors and offer higher speed, acceleration, and accuracy than belt-drive, lead screw, or rack and pinion actuators.

Noble gases typically don’t interact with other elements. However, if they are excited (by an electrical discharge for instance), they can bind to other atoms to form a very short-lived molecule called an excimer.

On the flip side, getting a UV laser up and running has required some hard work from the scientific and engineering community.

UV laserAmazon

A motorized optical stage is a stage that is designed for use with optical instruments such as microscopes or cameras and is moved by a motor. It provides precise control over the position and movement of samples and optical components. The motorized optical stage has higher precision and accuracy requirements than the general motorized stage, as the movement of the sample or component needs to be very precise for accurate imaging or analysis. Some motorized optical stages have additional features such as encoder feedback for closed-loop control, joystick or computer control, and programmable motion profiles, which are specific to optical applications.

UV laserWikipedia

Our microscope stages are made with embedded high-performance precision electronics required to control motion within the stage without increasing its size.

Dover Motion's motorized stages include motorized translation stages with up to 635 mm of travel, XY tables, vertical Z stages, and microscope stages. Each motorized stage features stepper and servo single and multi-axis motors, built-in motion controllers, and optimal travel time for precision motion. As a leader in creating motion solutions for the life sciences industry, we also specialize in manufacturing standard and custom motorized optical stages that meet higher precision and accuracy requirements for use with optical instruments, including microscopes and cameras.

A motorized stage is a device used in various life science applications to move objects in a controlled and precise manner. The motorized stage consists of a platform that can be moved along one or more axes using motors and mechanical components.

A motorized stage is a high-performance positioning system that utilizes integrated motors to drive a platform with exceptional accuracy along one or more linear axes. These stages are instrumental in various automated applications across science and industry, particularly those requiring meticulous object manipulation.

Laser power detector for measurement up to 50 000 W that traps > 97 % of the incident light and handles high intensities of small beams.

Laser specifications change over time for many reasons and it causes problems accross all industries. Learn about how laser output measurement solves numerous problems in YOUR industry. Download the guide below. Gentec-EO's high-accuracy laser beam measurement instruments help engineers, scientists and technicians in all sorts of laser applications from the factory to the hospital, laboratory and research center. Learn about our solutions for these measurement types: Laser power meters Laser energy meters Laser beam profilers Terahertz power meters

Using a linear motor is generally considered to be optimal for high speed motion systems and is the most precise and repeatable linear motion actuation technology.

UV Laserprice

There is another approach, which doesn’t involve directly generating UV light. Instead, a more commonly available laser beam is passed through frequency-conversion crystals, converting it into UV. This solution is often referred to as DPSS UV lasers (diode-pumped solid-state).

Sensors: Sensors are used to measure the stage's position, velocity, and acceleration. They provide feedback to the controller, allowing it to maintain precise control over the stage's movement.

Gentec-EO's high-accuracy laser beam measurement instruments help engineers, scientists and technicians in all sorts of laser applications from the factory to the hospital, laboratory and research center. Learn about our solutions for these measurement types:

Once the payload has been constrained to a single degree of freedom, the system’s next mission is to actuate the payload and provide precise incremental linear motion along the guideway.

The Beamage profiling camera’s UV converter actually uses frequency conversion in reverse to accurately image UVs and even X-Rays without risking any damage to the optics.

Portable laser power meter for up to 250 W with flexible calibration options so the customers only pay for what they use. Includes 3 measurement modes : SSP, CWP and SSE.

UV laserengraver

Our screw driven motorized stages range from stages with monolithic integrated XY centers to low-cost, single axis stages with crossed roller ways and stepper motors.

UV laserlight

Our Z stages offering includes traditional Z stages for objective focusing and Z stages for sample positioning or Z-Lift stages .

The fact that UV light quickly degrades traditional optical components further limits the options available to laser designers. In fact, UV degradation isn’t something only laser designers have to take into account. Laser detectors also need to withstand the continued onslaught of UV rays and this is what makes pyroelectrics detectors a good fit for measuring UV.

First of all, the optics required are very special, because UV light quickly degrades traditional optics and is very sensitive to defects. Not to mention that generating a laser beam of UV wavelength is a challenge in and of itself. A problem to which the world has found 2 distinct solutions.

Linear motor stages offer higher speed and precision, while screw-driven stages are more cost-effective and suitable for less demanding applications.

A translation stage with a motor is a precision mechanical device used in motion control applications that allows for precise linear movement along single or multiple axes. The motor is used to drive the translation stage, providing smooth and precise motion control. Translation stages with a motor are commonly used in scientific research, bio-medical, life sciences, metrology, semiconductor, precise manufacturing, and other industries where precise positioning is required.

Ms.Cici

Ms.Cici

8618319014500

8618319014500