Golden Design Rules for Plastics Packaging - plastic guide

HANTENCNC’s 300W pulse laser stripper is a device designed for efficient surface cleaning and is suitable for various industries and applications.

Laser cleaners can help restore ancient artefacts with paint, stains, or other contaminants, such as stone carvings, steles, pottery, and metalware. Traditional cleaning methods may cause secondary damage to cultural relics. The laser cleaning machine can accurately control the energy and position of cleaning to avoid damage to cultural relics. In addition, the laser cleaning machine can also clean some difficult-to-clean parts, such as small sculptures or complex three-dimensional structures.

Valley Design laps, polishes and CNC machines a wide variety of metals and alloys including Stainless Steel, Aluminum, Copper, Hastalloy, Brass, Inconnel, Titanium, Steel Alloys, Low Carbon Steel, Tool Steel, Tungsten Carbide, Invar, Bronze, Kovar and Cast Iron Zinc. Mirror surface finishes as good as < 10 Angstroms are achievable on some metal materials.

Valley Design is a high precision CNC machining company, focusing on rapid, high quality on-demand 3, 4 and 5 axis CNC machining services. Our CNC department provides full CNC machining services from custom prototyping to full production manufacturing on a wide variety of hard and soft materials. Materials CNC machined include Alumina ceramics, Aluminum Nitride, Fused Silica, Glass, Sapphire, Silicon Carbide SiC, and Silicon Silicon-Carbide SiSiC. Our custom CNC machining capabilities combined with 50 years of diamond tool and fixturing expertise make us the industry standard for excellence, quality and precision for complex CNC machined components.

Laser cleaning machines can clean building materials such as marble, granite, and concrete. Laser cleaning machines can clean large areas of stone more quickly. It can also avoid using chemical cleaning agents to pollute the environment. In addition, the laser cleaning machine can accurately control the depth and intensity of cleaning. It can prevent damage to the stone surface.

CNC machine safetyglassreplacement

Add: 402B, Building 16, Xingfu Liancheng Photoelectric Innovation Park, No. 1287, Kejia Road, Gaoxin Zone, Jinan City, Shandong Province, China

We use button housings to protect the wiring. The material of these button housings is PVC+POM buttons, which are flame retardant and have passed SGS certification.

201751 — They are a bit hard to find but are cheap and have the best performance in term of ultraviolet transmission. This kind of lenses will also ...

Valley Design provides lapping and polishing services of flat mechanical seals, pump parts, valve seats and discs. Valve components made from a large variety of materials include Hastelloy, Inconel, Monel, Stainless Steel, Carbon Steel, Copper, Nickel, Ceramics, Glass, Sapphire, Macor and many exotic materials. We have even polished large wind tunnels for NASA.

Valley Design understands the importance of precision in microelectronic devices substrates. In our nearly 50 years of experience, we’ve delivered a multitude of important semiconductor materials for electronics, and we’re pleased to include 450-mm silicon wafers. We offer 300mm and 450mm diameter wafer back grinding, lapping and polishing services on a wide variety of materials such as ceramics, glass, Fused Silica and Sapphire.

Shop for Solderless Breadboards at Walmart.com. Save money. Live better.

Since 1975, Valley Design has been recognized as an industry leader in advanced materials processing as providers of precision lapping and polishing services, 4 & 5 axis CNC machining, dicing, backgrinding, hole drilling, and other precision machining services on a wide variety of both hard and soft materials.

The 300w pulse laser cleaning machine is a newly designed product. This product uses non-contact cleaning, which can effectively degrease, rust, stain and paint the base material. It can be applied to metal, stainless steel and other materials.

CVD Silicon Carbide theoretically dense and intrinsically pure, is available as lapped or polished substrates and wafers from 2″ diameter up to 300mm diameter with surface finishes to better than 10 angstroms, while maintaining a 1/4 wave flatness depending on thickness and size.

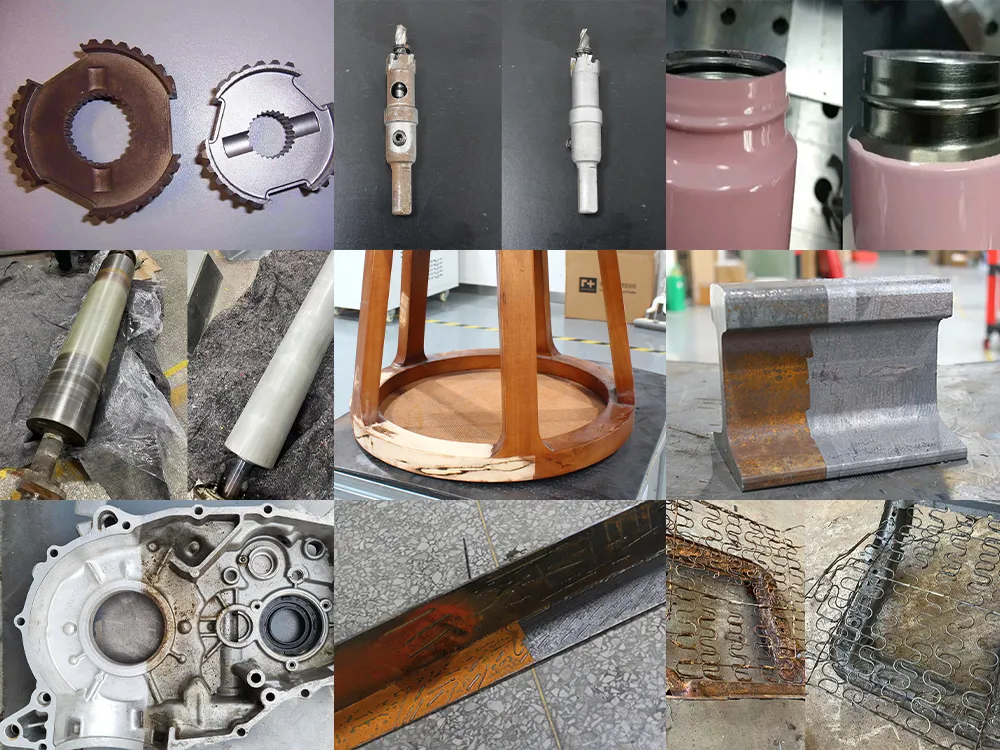

Cleaning laser machines are mainly used for equipment, tools, parts, etc. For example, mechanical equipment, aviation equipment, electronic equipment, etc. During equipment maintenance, corrosion, rust, and other contaminants often appear on the surface. Using conventional cleaning may wear down the surface of the equipment. The substrate is not damaged during laser cleaning. It is safety, environmental protection, and high efficiency.

Due to our pulse laser stripper’s efficiency, lack of chemical pollution, and environmental friendliness, it is increasingly favoured across different sectors.

Glass wafers and glass substrates as well as Fused Silica, Fused Quartz, Soda Lime Glass, AF45, BK7, B270, Borofloat 33, D263, Gorilla Glass, Eagle XG Glass, Borosilicate glass, and other materials such as 99.6% and 96% Alumina, Sapphire and Aluminum Nitride, are available to SEMI specifications in sizes ranging from 50mm (2″) up to 450mm (17.7″). These SEMI standard wafers can also be fabricated with a SEMI notch or one or two SEMI flats.

HANTENCNC’s 300W laser derusting machine currently supports Chinese, Traditional Chinese, English, Russian, Japanese, Spanish, German, Korean, French, Polish and 16 other languages.

Machining glassnear me

CNC machining offers unmatched precision and repeatability over conventional grinding, hole drilling and milling techniques, especially when complex features and shapes are required.

Polished colored filter glass can be used in place of thin-film coated filters as an economical alternative. Color glass filters in standard and custom sizes are now available optically polished from high quality optical glass from Valley Design. Color Filter Glass components are available from as small as .127mm square up to 300mm, and thickness from as thin as 75um up to 10.0mm thick. Please click here for equivalent color filter glass types cross-referenced to Schott and Hoya.

Cncmachining glass

In 1975, Valley Design began polishing 2” diameter Silicon wafers, then continually expanded our polishing capabilities in keeping with the Semiconductor Industry to 3” diameter, then 100mm, 125mm, 150mm, 200mm eventually landing at 300mm diameter. Looking forward, the Semiconductor industry contemplated transitioning lithography fabs to 450mm, but it was not generally accepted by the equipment manufacturers. Valley Design has performed back grinding and lapping of 450mm diameter Silicon wafers, and also routinely laps, polishes, dices and CNC machines Silicon in all sizes. Ultra-thin is also available as thin as 20um thick.

Valley Design is a worldwide leader in providing high quality, custom CNC machining on glass as well as many other materials. Come to Valley Design for all your glass CNC machining requirements.

Our custom glass CNC machining capabilities are combined with the highest level of CAD/CTM software and programming tools with nearly 50 years of machining experience and diamond tooling knowledge. This combination along with our other extensive Glass Fabrication expertise enables us to meet the most demanding challenges in the Precision Glass Machining Industry. Our dedication to complying with ISO9001: 2015 and AS9100D (Aerospace) standards invokes confidence in our many hundreds of customers worldwide.

The constant temperature of the water cooling system controls the heat generated by the laser cleaning system. It can better protect laser equipment to function correctly.

HANTENCNC’s laser derusting machine is portable, powerful, high-efficiency, and competitively priced. This pulse industries laser stripper is for sale;

Precision lapping and polishing services on all types of materials both hard and soft has been a specialty of Valley Design for nearly 50 years. We operate over 100 single and double sided lapping and polishing machines ranging in size from 12”,18”,24” 28”, 32” 36”48”and 64” diameters producing parts from as small as .127mm (.005”) sq. to 450mm diameter and larger. Depending on the material, lapped finishes can range from 10-25u” Ra. Polished surfaces on ceramics can range from 0.3 -3u” Ra, and optical finishes on fused silica and glass can be as good as 3A Ra.

The upfront price of purchasing glass and CNC machines is the primary disadvantage. Making long-term commitments to the Glass Machining Industry offsets this disadvantage.

Our laser cleaning gun has fast scanning speed and high accuracy, meeting various cleaning needs. Equipped with front-end control screen and focal length display screen, capable of measuring focal length and achieving high-precision cleaning.

Jinan Hanteng Laser Technology Co., Ltd. is located in Jinan City, Shandong Province. We are a laser machine manufacturer. Our products have laser cleaning machines, laser cutting machines, laser welding machines and UV printers. As a laser machine manufacturer, we are professional enough and we can give you the best service.

Valley Design produces and stocks wafers and substrates of Fused Silica and Fused Quartz as large as 300mm diameter to 1cm square to as thin as 10-15um thick. Advantages of Fused Silica and Fused Quartz include low thermal expansion, resistance to thermal shock, superior electrical insulation, high transparency from the Ultraviolet light spectrum to the Infrared range, high softening temperature and thermal resistance. Valley Design has thousands of finished Fused Silica wafers available from stock. Single Crystal Quartz is also available lapped, polished, diced and CNC machined.

Fused Silica and Fused Quartz polished wafers, windows, substrates, plates and discs are available from Valley Design. We offer polished optical surface finishes to 10/5 scratch/dig < 7 Angstroms. Custom sizes can be shipped in just a few days. Many standard sized wafers and windows are in stock and available for immediate shipment. Along with SEMI standard wafer sizes, we specialize in ultra-thin, as thin as 10-15um.

Our pulse laser stripper tool can remove paint, coatings, oxides, dirt, and other contaminants. HANTENCNC’s laser derusting machine has extensive applications in automotive manufacturing, aerospace, ship maintenance, metal processing, construction, and cultural heritage preservation, among others.

You can easily switch between these language options directly on the laser stripper’s interface. If you require any other languages, we also provide customized language services.

Email: info@valleydesign.com Phone: 978.425.3030 Fax: 978.425.3031

Fused Silica& Fused Quartz Optical Glass Ceramics Sapphire Colored Filter Glass 96% Alumina &99.6% Alumina Aluminum Nitride Ferrites Macor Molybdenum Metals Germanium Silicon Silicon Carbide (SiC) Silicon-Silicon Carbide (SiSic)

Aluminum Nitride Ceramic is the perfect material choice when high thermal conductivity and electrical insulation properties are needed. Aluminum Nitride has a combination of high dielectric strengthening, high electrical insulation properties, and low thermal expansion. Valley Design supplies Aluminum Nitride with thermal conductivity of 170 W/mK, 180 W/mK, 200 W/mK and 230 W/mK. AlN Aluminum Nitride is optimal for hybrid, power and microwave electronics applications where an electrically insulating nontoxic substrate material is required. It is the ideal material for a wide variety of uses in the growing Semiconductor, Aerospace, Defense and Medical Industries.

Machiningquartzglass

Valley Design produces standard and custom lapped or polished Sapphire wafers in all common orientations including A, C and R-plane Sapphire. Valley also provides ultra-thin polished Sapphire substrates and wafers. The size of Sapphire that can be polished is limited only by the material availability. Sapphire blanks up to 12″ diameter can be lapped, optically polished, diced and CNC machined. Holding precise tolerances as well as flatness, and parallelism is critical for many applications.

The laser derusting machine is a high-tech product. It has the advantages of high efficiency, environmental protection, no pollution, and low energy consumption. It is widely used in manufacturing, maintenance, moulding, the restoration of cultural relics, the stone industry, and other fields.

Small optical blanks from Filter Glass, Fused Silica, Zerodur, Pyrex and all other optical glasses are precision fabricated by 4 & 5 Axis CNC precision glass machining, diamond core drilling, ultrasonic drilling, impact grinding, diamond sawing, dicing, grinding, lapping and polishing. Silicon wafers with features may also be produced by silicon machining and polishing.

As a leader in precision materials processing for nearly 50 years, Valley has extensive experience with a wide variety of materials. We process various semiconductor materials, optical materials and materials used in electro optics.

Valley Design provides precision glass machining and manufacturing of flat plano/plano optical and technical glass windows and discs as small as 1mm in diameter which can be thinned and polished to as thin as 1. These may be optically machined and polished to 10-15 microns thick with no edge drop off. Other geometries such as squares and rectangles with similar dimensions are also available. Valley provides CNC glass machining and glass machining services on all types of glass.

Precision shims spacer and submount components from Valley Design with accurate pitch tolerances and sequentially spaced to less than 1/4 micron, flat to less than 1/10 wave, with lapped or polished mirror finishes available.

At Valley Design, we are the experts in precision dicing. Our dicing services can cover all your needs from prototypes to production dicing services. With 15 K&S and DISCO dicing saws, we have one of the highest diamond dicing volume capacity in the industry. Silicon die from as small as .127mm square to Silicon stacks as high as 6.25mm can be diced, as well as a wide variety of hard materials including Fused Silica, Glass, Aluminum Nitride, Alumina ceramics, Sapphire, Silicon Carbide SiC, Silicon Silicon-Carbide (SiSiC) and many others.

Light is transmitted through a light guide by means of total internal reflection. Light guides are usually made of optical grade materials such as acrylic resin ...

Contaminants such as oil stains and welding slag are often attached to the surface of the mould. These pollutants will affect the life of the mould and the use effect. Laser derusting machines can effectively avoid mould surface wear and reduce mould accuracy and other problems.

The chemical composition of Optical Glass is designed to selectively transmit or block different wavelengths of light in the optical light spectrum, from UV Ultraviolet, to Visible light, to IR Infrared light. Valley Design laps, polishes , dices and CNC machines optical glass of all types, and works with the premier optical glass manufacturers such as Corning, Schott, and Hoya. Optical glass is used every day by consumers, for vision, magnification, telephotography, science research and more which is why precision and quality is key for optical glass suppliers such as Valley Design.

Anti interference design: Ensure stable operation of the laser cleaning gun in various complex environments and improve equipment reliability.

Jul 26, 2024 — For both setups, the angular measurement from the lens axis to the frame edge is called 'Angle', measured in degrees. The FOV of the lens is ...

Laser cleaner machine is mainly used for cleaning metal surfaces. Parts of cars, planes and railways are cleaned during manufacturing. Laser cleaning can effectively remove the rust, oxide layer, oil stains, and other elements that form on the metal surface. Traditional cleaning methods can cause damage to the substrate surface. Laser cleaning machines can quickly, efficiently and non-destructively clean metal surfaces.

With this variety of glass CNC machining centers, Valley Design offers incredible fabrication flexibility when complex shapes, geometries and accuracy are required.

Sep 30, 2023 — Protected Silver mirrors have a thin layer of dielectric material added to the Silver (Ag) layer. The dielectric layer shields the Silver from ...

Building on our nearly 50 years of expertise in processing a variety of materials to ultra thin thicknesses, Valley Design has leveraged this knowledge to push new limits in ultra thin processing, polishing some materials to as thin as 10 microns.

Email: info@valleydesign.com Phone: 831.420.0595 Fax: 831.420.0592

An Optical Transmission Curve is a graph that shows an optical medium plotted against the wavelength. The graph describes the transmission fraction of an optical filter as a function of wavelength. These transmission curves can be used by optical designers and engineers to determine the most suitable material to use for their applications.

This Laser Derusting Machine is a self-developed pulse laser cleaning machine. The chassis is green and white, making it look more high-end. This product has the three primary characteristics of being lightweight, pushable, and safe, making it more convenient for laser cleaning operations.

Our capabilities in providing precision machining services make us a world-leading company in precision materials engineering and manufacturing. For nearly 50 years, our services have grown and evolved with the changing trends in precision material engineering and manufacturing. Our in-depth experience with components needed in the manufacturing of electro-static chucks (ESD) for the semiconductor industry, combined with our 3, 4 and 5 axis CNC machining services put Valley Design at the cutting edge of technology. We also offer CNC hole drilling, optical edge polishing services and small diameter core drilling. Basic optical coating services are also offered by Valley Design.

What is collimated meaning in Tamil? The word or phrase collimated refers to adjust the line of sight of (an optical instrument), or make or place parallel to ...

Oct 5, 2020 — Radial distortion: This type of distortion usually occur due unequal bending of light. · Tangential distortion: This usually occurs when image ...

The machine is capable of multifunctional display. It is equipped with a one-button start switch for easy use. The machine’s cleaning system is stable and efficient.

96% Alumina and 99.6% Alumina substrates and wafers are stocked and processed by Valley Design. 99.6% Alumina Al203 substrates are typically referred to as thin film substrates and are manufactured using tape cast or pressed methods. This material comes As-Fired .005” – .080” thick, and then is lapped and/or polished by Valley Design into any custom thickness specified. 96% Alumina substrates are typically referred to as thick film substrates, and are used for high power electronic and RF Microwave applications. A previous project involved lapping 1000’s of 96% Alumina substrates 4” square to 75um thick.

The distance from the center of the lens to the image focal point (=image sensor surface) is known as the focal length. It is expressed in millimeter (mm) ...

Valley’s over 50 years of experience enables us to produce precision diamond machined parts by CNC machining, grinding, dicing, drilling, lapping, ultrasonic shaping, polishing and optical machining. Our expertise in hard and brittle materials is unique in the industry. Other hard materials processed include Silicon Carbide machining, and Sapphire machining.

Valley Design offers a wide variety of optically polished metal mirrors including Stainless Steel, Molybdenum, Brass, Copper and many other alloys. Surface roughness of < 10 Angstroms are possible on some materials. Metal chucks and vacuum chucks are lapped, polished and CNC machined to micron level tolerances.

For nearly 50 years, Valley Design has served as a valuable technical resource to its customers on Research & Development projects and provided technical support to the leading research institutions and labs worldwide. These include such distinguished technology centers as Lawrence Livermore National Lab, Los Almos National Lab, Lawrence Berkeley National Lab, Sandia National Lab, Army Research Lab, Massachusetts Institute of Technology (MIT), Rutherford Appleton Lab (UK) and Max Planck Institute (Germany).

Jul 9, 2021 — A higher depth of field would see the whole image from foreground to background sharp and in focus, a lower depth would result in blurry ...

Valley Design serves numerous high-tech industries including Semiconductor, Medical and Biomedical, Aerospace, Defense and Sensing, Photonics and Optics, Telecommunications, Lithography, along with Research and Development industries. Applications include Substrates, Wafers and Electro-optical and Micro-electronic components for sensors, integrated circuits, capacitors, semiconductors, optoelectronics, microfluidics, MEMS devices, Machine vision, Optical Switches, Electro static chucks (ESD) for ion implanters, and optical instrumentation.

The laser derusting machine is compact, light, and effortlessly portable, making it easy to move around, which is suitable for diverse cleaning scenarios in different conditions.

These hard and brittle materials can be machined into small heat sinks, washers, precision shims and spacers, cubes, wafers, seals, diode mounts and other intricate shapes. Valley Design is your resource for all your CNC glass fabrication and hard material machining requirements.

Building on our nearly 50 years of expertise in processing a variety of materials to ultra-thin thicknesses, Valley Design has leveraged this knowledge to push new limits in ultra-thin processing, polishing materials to as thin as 10 -15 microns. Materials that can be polished to these ultra-thin thicknesses include Fused Silica and Fused Quartz. Glass, BK7, Alumina ceramics and Silicon can be thinned and polished to 15-20um thick.

Known for thermal stability, chemical resistance and good mechanical properties, polyimide plastic is an extremely flexible material best used in insulation. Valley Design expertly fabricates high-quality polyimide plastic products for a variety of industries include the automobile and air filter manufacturing industries.

Valley Design manufactures standard and custom sized substrates, wafers, discs, windows and flat optics of all types of materials, many from stock. We manufacture precision shims, spacers, washers, submounts and rings, which can be sequentially spaced to < ¼ micron, flat to 1/10 wave, lapped or polished. SEMI standard dummy wafers up to 450mm diameter, prisms, wedges, beamsplitters, flat lenses, etalons and color glass filters are all produced by Valley Design. We also offer large geometry ceramics, wafer and vacuum chucks and polished Aluminum mirrors.

Organized internal wiring makes the positions of cables and connectors clear and easy for maintenance personnel to quickly locate and solve problems, reducing repair time and costs.

Valley Design manufactures wafers, substrates and discs from all materials including Fused Silica, Glass of all types, Colored Filter Glass 96% Alumina, 99.6% Alumina and Aluminum Nitride ceramics, Sapphire, CVD Silicon Carbide SiC and metals including Stainless Steel. We provide wafers in SEMI standard sizes, as well as custom sizes, and have 1,000’s of finished wafers and substrates available from stock.

Valley Design proudly offers special capabilities to our CNC machining services such as ultra thinning to as thin as 10-15um, polishing to Angstrom level finishes, micron level tolerances and TTV (Total Thickness Variation) specifications. We process a wide variety of materials from our extensive inventory, as well as customer supplied materials. Commonly processed materials include ceramics of all types, 96% Alumina, 99.6% Alumina, Aluminum Nitride, Fused Silica, Glass, Sapphire, Macor, Silicon Carbide SiC, Silicon Silicon-Carbide SiSiC and many others.

The goal of this application example is to teach you how to use Luceda IPKISS to design, layout and simulate a Mach-Zehnder Modulator (MZM). This device is very ...

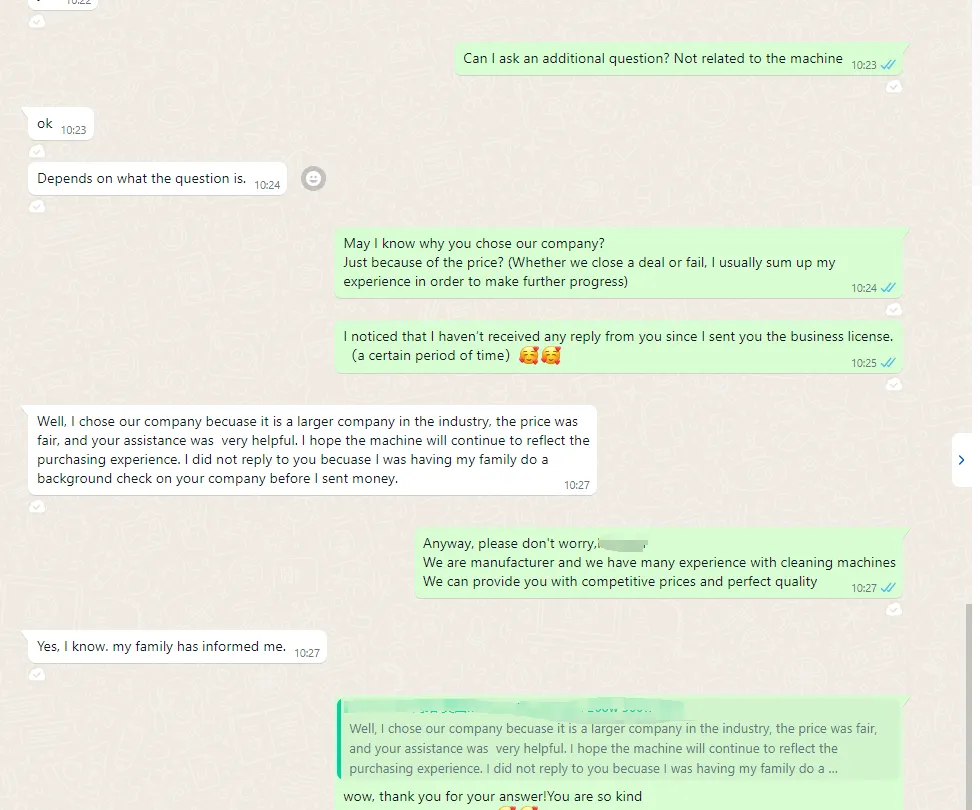

Ms.Cici

Ms.Cici

8618319014500

8618319014500