Functions and Parts of a Microscope - what is the function of the base in a microscope

Do I need a "lighted" magnifier? Good, clean lighting is an essential element to consider when choosing a magnifier. Many workplace locations have indirect and shadow-filled lighting conditions at best, resulting in marginal viewing performance. Lighted magnifiers compensate for this with a quality fluorescent, halogen or LED lighting element embedded around the viewing glass frame. Fluorescent lighting brings out clarity of view by shining a broad, cool and shadowless light. Halogen lamps will yield a warmer glow and heat up more quickly. LED lamps put out less lighting, yet tend to last much longer than either fluorescent or halogen bulbs.

2. Make sure the lens is positioned to keep your object in focus, with your eyes are 8” to 10” away from the glass. This will give you the best magnification with the least amount of distortion.

On the technical side, a vision system consists of a sensor that takes in information, an illuminator, a lens, as well as a data acquisition device and the software that enables data processing.

What does it mean to be ESD-Safe? Electrostatic Discharge (ESD), is defined as the transfer of electric charge, just like the spark of static electricity you get when walking across a carpet and touching someone's hand or a piece of metal. This discharge, while harmless to humans, can be damaging to delicate electrical circuit boards and sensitive components, which in turn, could cause severe injury to people working with the equipment. ESD-Safe magnifiers have special polymers applied to the lens, dissipative paints applied to the metal and the electrical layout is designed to minimize electrical discharge potential. They must also pass rigid ESD certification testing standards.

A magnifying lamp is an essential tool for anyone working with precision assembly, inspection or design. Because users can effortlessly view smaller details, lighted magnifying lamps are tremendously helpful in reducing eye strain and preventing vision fatigue. As a result, they are popular with jewelers, watch and electronics repair, dental clinics, industrial inspection, scientific research laboratories and the home office.

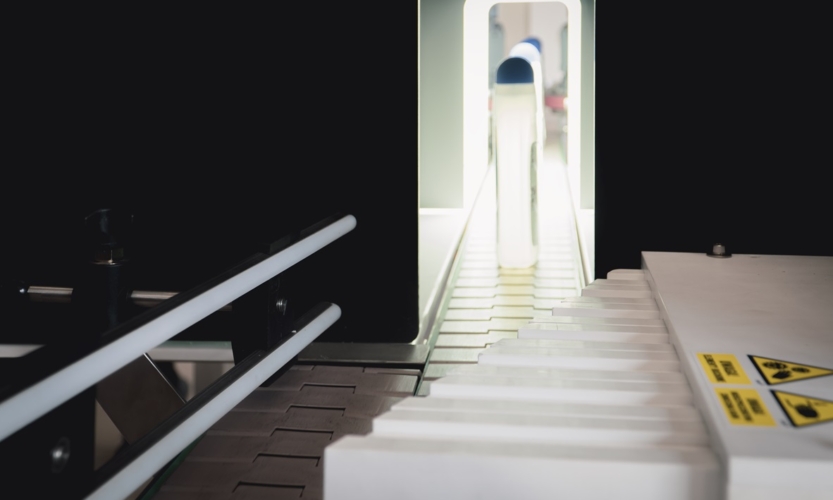

Lighting used in vision systems has been completely dominated by LED lighting. This is economical and, of course, environmentally friendly, as they provide great savings. They are available in a variety of light colors – so they can be appropriately matched to the production line. The types of lighting using LEDs by vision systems are: front illuminators, back illuminators, ring illuminators, shadowless illuminators, coaxial illuminators, linear illuminators, spot illuminators, and hyperspectral illuminators also called multispectral illuminators.

Despite the many similarities between the vision system and the human body, there is one major difference between the two. The vision system, unlike the human brain, will not lose concentration or get tired. This is especially important when the production line is high speed and running for long periods of time. The human eye is sometimes unreliable and cannot cope with such accurate and careful observation. Vision systems, despite the use of advanced technology, are universal. No new system is developed for each industry, but existing ones are adapted to the specific line and product specifications.

3. For best results, keep your chair height and working surface positioned to maintain good posture. You shouldn't be leaning away from the lens when viewing the object.

What does 'Diopter' mean? When looking at various magnifiers, you'll come across the term 'diopter'. This refers to the amount of curvature a lens will have. More curvature means a thicker lens, more magnification and a higher diopter number. To find the magnification level of a lens, simply divide its diopter by 4, and add 1. For example, if you're looking at a 3-diopter lens, it's magnification = ¾ + 1... or .75 + 1 = 1.75x. Objects viewed under a 3 diopter lens will appear 175% bigger than normal. A 5-diopter lens = 5/4 + 1... or 1.25 + 1 = 2.25x. Objects viewed under a 5 diopter lens will appear 225% bigger than normal.

A vision system is the most powerful image processing system based on machine vision. The machine vision system is a kind of “human sense of sight,” converting, like the human eye, images into information. The eyeballs are, in machine vision, specialized cameras that capture images, and the brain is the computer and software that interprets those images accordingly. Vision-based quality control is based on examining products against an ideal standard. The cameras scan the products and pick up deviations from the standard. A machine, like a human, has to learn certain things. By scanning products and collecting information about them in databases, it uses its “experience” and knowledge stored in computer memory to identify non-ideal products. Vision systems use the capabilities of cameras to capture physical characteristics of objects for measurement and inspection. Based on a learned pattern, they automatically pick up product with irregularities and eliminate it from the production line.

First, the main component of a vision system is the camera system including the lens. There are different types of them: image cameras – are used in scanning the image of the whole object or features, line cameras – used on moving production lines, and 3D cameras – showing a three-dimensional image of the product.

Vision-based quality control systems have many advantages. They streamline the work of production lines, are a safe and effective solution ensuring high precision and efficiency. Thanks to them, the company has a chance to optimize costs and eliminate to a minimum the number of defective products, which allows to avoid possible complaints of goods or even entire batches.

Lenses also can be divided into several basic types: fixed-focus lenses (the most popular), zoom lenses – used in robotics, telecentric lenses – used for precise dimensional analysis, and pericentric lenses – which allow simultaneous observation of the front and side surfaces of the lens.

Registered at: KSM Vision sp. z o.o. Sokołowska 9/117 01-142 Warszawa / Warsaw, Poland NIP/ TAX ID PL5272682660 KRS 0000429241 REGON 146277926

What does focal length mean? Focal length is defined as the distance from the lens to the point where an object is in focus (focal point) and it becomes important if you need space above the object in which to work. It's kind of like shining a flashlight on a dark wall. As you move the flashlight (magnifier) closer to the wall, you are reducing its distance (focal length). As you move the flashlight back from the wall, the distance (focal length) increases. Unfortunately, you can't have lots of magnification and lots of room below the lens (focal length). If you need lots of space to work, you won't have as much magnification available. If you don't need much working space, you can get stronger magnification, and in fact, magnifiers with higher power are generally reserved for close-in inspection and measurement... 3 diopter = 1.75x magnification at 13” focal length 5 diopter = 2.25x magnification at 8” focal length 7 diopter = 2.75x magnification at 5.5” focal length As a general rule of thumb, when your magnification gets larger, your lens and focal length get smaller.

What is meant by 'Field-Of-View' (FOV)? The field of view is the size of the magnified area that is in focus under the lens. The higher your magnification, the smaller your field-of-view. Lets go back to our flashlight example. As you move the flashlight closer to the wall (stronger magnification), the spot of light (field-of-view) will shrink.

JavaScript seems to be disabled in your browser. For the best experience on our site, be sure to turn on Javascript in your browser.

On the technical side, a machine vision system consists of a sensor that acquires information, an illuminator, a lens, as well as a data acquisition device and the software that enables data processing. Such a system forms the most efficient image processing system based on machine vision.

At KSM Vision, we implement vision systems, starting from production processes to logistics processes. For many years, we have been installing these systems in distribution centers, warehouses and sorting centers in various industries: food, pharmaceutical, cosmetics and construction. By using the services of our company, you can count on comprehensive service by thoroughly familiarizing yourself with the needs that the system is to meet, analyzing the production process, programming specific algorithms, selecting components, conducting tests and, as a result, assembling the finished system. We cooperate with leading producers of the highest quality components and, combined with our knowledge and experience, you receive the highest quality solutions.

Do I need "HANDS-FREE" viewing? One of the main benefits of a magnifying glass is the ability to use both hands to work with the object while under magnification. When repairing electronics or other close-in work, hands-free operation is absolutely essential.

Ms.Cici

Ms.Cici

8618319014500

8618319014500