Darkfield vs Lightfield ? : r/microscopy - darkfield vs brightfield

If you are looking for Christmas lights, GO SOMEWHERE ELSE. It is billed as largest animated light show in southeast. It is not. You drive through at slow speed ...

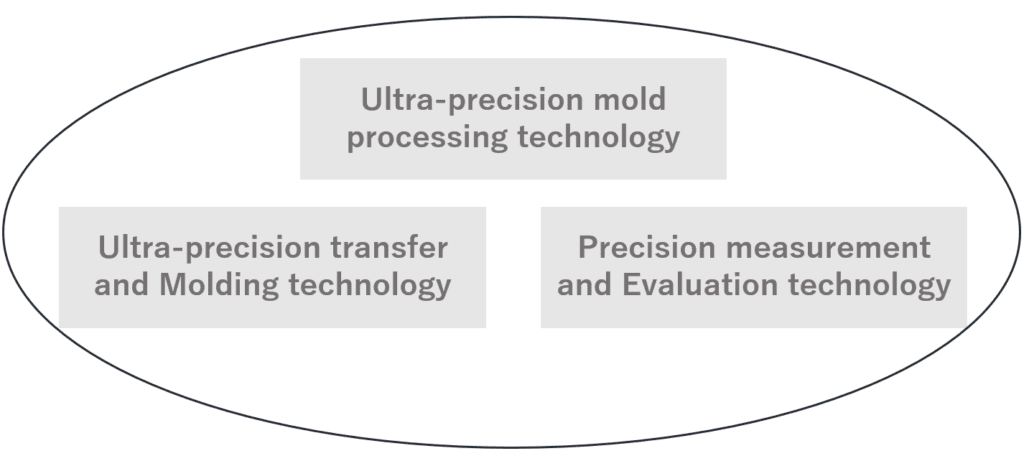

The method of manufacturing aspherical lenses by transferring and molding the aspherical shape of the mold onto the lens requires three technologies: ultra-precision mold processing technology, ultra-precision transfer and molding technology, and precision measurement and evaluation technology for these surface shapes.

The physical difference is the CS mount lens is designed to be mounted ~5mm closer to the image sensor than a C mount lens. (C-mount lenses are designed to be mounted 17.526mm in front of the image sensor vs. 12.5mm for CS-mount.) You can always use a C mount lens on a CS mount camera by using a 5mm spacer ring (many cameras now have C/CS selectable adjustment screws or rings). You can never use a CS mount lens on an older style C mount camera unless you are willing to physically modify the camera. Cost wise the CS mount lens is much less expensive since it uses fewer glass elements. Quality of image is the same. C mounts are becoming less and less popular and are generally only used on the more telephoto focal lengths such as 25, 50 and 75mm, and bigger zooms.

Side Emitting LED Neon Flex Strips are designed to illuminate from the side of the silicon housing and bend on a horizontal axis. Unlike an ...

Perspective Bronze Metal Eyeglasses from Eyebuydirect. Exceptional style, quality, and price with these glasses. This frame is a great addition to any ...

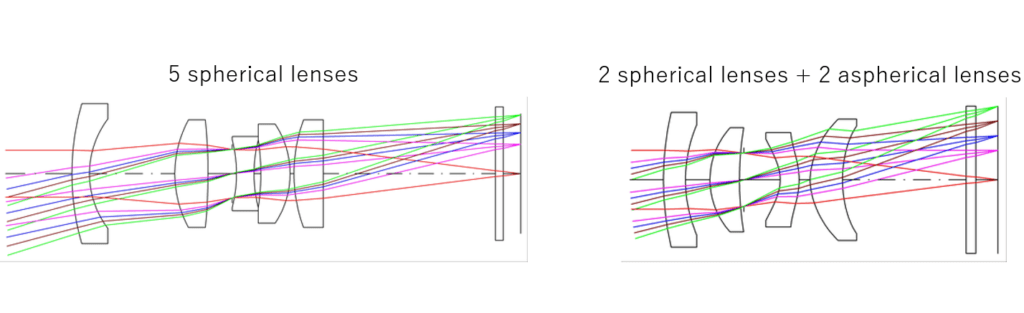

In imaging optics, multiple spherical lenses are used in combination to reduce aberrations such as image blur and distortion. By using aspherical lenses, it is possible to reduce the number of lenses while maintaining the same performance. For example, you can achieve the same performance of an 5-spherical-lens optical system with a total of 4 lenses using 2 spherical lenses and 2 aspherical lenses.

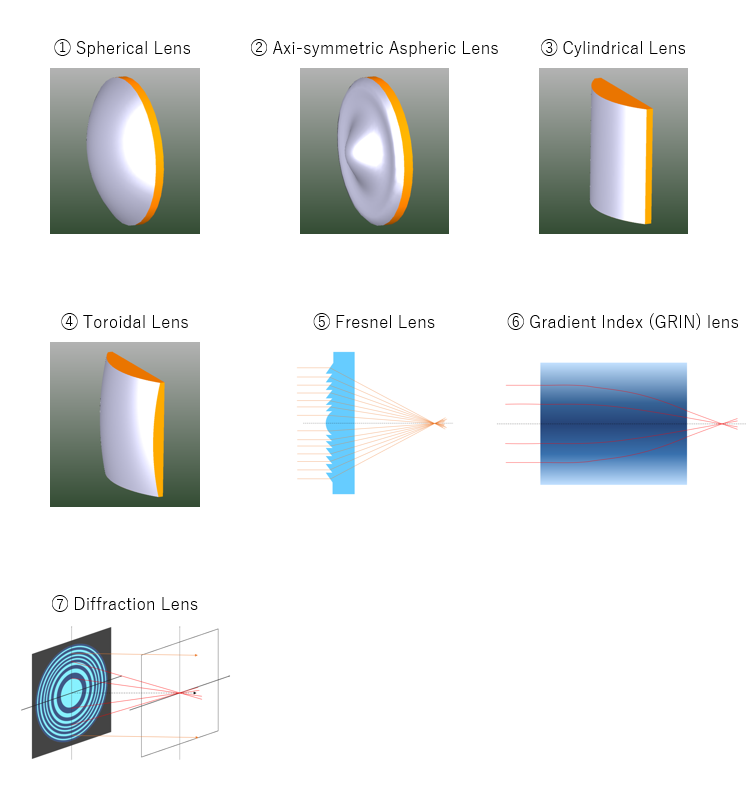

Lenses ② to ④ are lenses with continuous, smooth, non-spherical lens surfaces and are called aspherical lenses in a broad sense. ② is a lens with an aspheric surface that is axi-symmetric (rotationally symmetric) with respect to the optical axis of the lens, and is often used in imaging optical systems. Lenses ③ to ④ are aspheric lenses that do not have axisymmetry (rotational symmetry) with respect to the optical axis of the lens, and are mainly used in lighting and focusing optical systems.

At Optical Design Technology Navigator, we use state-of -the-art ultra-precision processing machines to process aspheric surfaces on a sub-micron order, transfer these aspheric surfaces using molding technology that incorporates a high level of know-how, and then transfer these aspheric surfaces into an ultra-precision 3D mold.

If you are thinking about something like, “If only there was a product like this…”, or, “Is it possible to do these kind of things with lenses?”, Optical Design Technology Navigator, a website operated by a group of optical design professionals, is the place to go. If you have any questions about optical design, please feel free to contact us at Optical Design Technology Navigator.

Aspheric lensglasses

We are a comprehensive manufacturer of Opto-mechatronic systems that conceptualize customer needs from design to development.

Axi-symmetric aspheres include rotational parabolas, rotational hyperbolic surfaces, rotational elliptic surfaces, and rotational quadric surfaces. In imaging optics, the use of such axisymmetric aspheres increases the degree of freedom in shape and makes it possible to suppress aberrations that would be difficult with spherical lenses alone.

Aspheric lensvs spherical

Spherical surfaces are characterized by the fact that the radius of curvature is the same at all positions on the sphere, and this leads to the fact that they are easy to polish and high precision can be obtained. On the other hand, aspheric lenses require the radius of curvature to be made different depending on the position, which requires precision mold processing and technology to precisely transfer and mold the aspheric shape.

In this section, we will explain the features, advantages / disadvantages, and manufacturing methods of aspheric lenses.

Lenses ① to ⑤ are lenses that have a focusing and diverging effect solely due to refraction on the lens surface. Of these, lenses ① to ④ have a continuous smooth surface, while lens ⑤ has a lens surface that is divided into discontinuous zones.

Asphericlenses advantages disadvantages

2023925 — The focal length describes the angle of view, ie, it tells how much of the scene in front of you the lens can capture.

Asphericallensphotography

CCD sensors are generally known for producing higher-quality, low-noise images with increased light sensitivity.

In this section, we will introduce the advantages and disadvantages of axi-symmetric (rotationally symmetric) aspheres in imaging optics. There are three major advantages.

Asphericmeaning

An aspherical lens is a lens whose lens surface is not spherical. By using lenses with aspherical surfaces, which offer a high degree of freedom in design, it becomes possible to reduce aberrations that could not be fully corrected with spherical lenses alone.

In addition, when axi-symmetric aspheres are used in illumination and focusing optics, it is possible to achieve uniform illumination distribution and increase the degree of freedom in ray control.

AsphericLenses price

Occasionally though, the camera and/or lens is to blame. Page 2. Page 2 of 11. The D70. Human nature is such that when we ...

Aspherical surfaces are classified into two categories: axi-symmetric aspherical surfaces, which have axial symmetry (rotational symmetry) with respect to the lens optical axis, and aspherical surfaces, which do not have axial symmetry. Each type of aspheric surface has its own characteristics.

In this way, aspherical lenses make it possible to reduce the size and weight of products, and even to cut costs. However, the production of aspherical lenses requires a very high level of manufacturing technology.

Although the time required for transfer and molding is shorter than for the spherical polishing process, manufacturing of precision aspheric molds (which incurs cost) in advance are necessary. For this reason, consideration of whether or not to use aspheric lens prior to production, based on the estimated total cost of the production volume is necessary.

KMU Erklärung Verzicht auf Revision (Opting-out) ... KMU-Erklärung (Opting-out) · KMU-Erklärung (nach ... Polizei BL · Regierungsrat · Schulferien · Daten und ...

What is aspheric lensvs asphericallens

Aspheres that are not axi-symmetrical (rotationally symmetrical) can be used to change the magnification of vertical and horizontal images in imaging optics. Also, in illumination and focusing optics, light emitted from a point light source can be projected in the form of a line. In this way, aspheres that are not axisymmetric (rotationally symmetric) can achieve new functions that cannot be achieved with spherical lenses alone.

On the other hand, in the case of ⑥, the refractive index inside the lens is not homogeneous but distributed, and in the case of ⑦, light is focused and diverged by using the diffraction effect on the surface instead of refraction.

TOYOTEC, operator of the Optical Design Technology Navigator, is an all-around optical manufacturer with proficiency in optical, mechanical, and electronical technology. We can design and develop products from scratch based on our customers’ needs, and provides integrated support from design to productization. In addition to manufacturing aspheric lenses, we offer one-stop manufacturing services from ultra-precision machining of lens cores to the design and assembly of lens units, including systems and peripheral components.

Both the C and CS mount are 1 inch wide (25.4mm) with 32 threads per inch (0.03125 inches or 0.79375mm). This dimension comes in handy if you need to insert a spacer to obtain proper focus. Unscrew the lens (or unscrew the camera from the mount in the case of telescope use and count the turns until proper focus is obtained. Multiply the above dimension by the number of turns to obtain the needed spacer or washer. (Washers are sometimes used as spacers if there are enough threads available.) Example: 1.25 turns x 0.79 mm = 0.9875 or ~1 mm. Many cameras (especially newer ones) have set screws to allow small adjustments in the distance between the lens and the image sensor.

What is aspheric lensused for

A spherical glass lens is processed by grinding one surface at a time, but grinding and polishing an aspherical lens one surface at a time would be very expensive. For this reason, aspheric shapes are generally processed into molds, which are then transferred and molded onto glass or plastic.

Was ist digitale Bildverarbeitung? · Digitale Bildverarbeitung ist die Verwendung von Computeralgorithmen zur Erstellung, Verarbeitung, Kommunikation und ...

Suitable for power LED sources. Its body is made of Anticorodal alluminium alloy, submitted to anodizing treatment up to 18 micron. Temperated glass is integral ...

2021722 — x={1024} PREMISES 2^3/2x=4096 CALCULATIONS 2^3/2x=4096 2^3/2x=4096 2^(3-1)x=4096 2^2x=4096 4x=4096 x=4096/4 [Divide both sides of the ...

If you are using a zoom lens and notice that the system goes out of focus as the zoom is changed the distance between the lens and the image sensor needs to be changed. Set the lens for infinity focus. Zoom to wide angle and point the camera at a distant object or star. Adjust the distance between the lens and the image sensor for proper focus. Go to maximum zoom. Slightly adjust the focus ring on the lens to refocus the image if needed. The system should now maintain focus from minimum to maximum zoom. You may need to repeat this process more than once to refine the focus.

With fewer lenses, it is possible to reduce lens materials, processing costs, and assembly man-hours, leading to overall cost reductions.

There are many different types of lenses. They can be broadly classified as the following according to the principle of light focusing and divergence and the type of surface.

Ms.Cici

Ms.Cici

8618319014500

8618319014500