Erweiterte Dunkelfeldbeleuchtung: Markerfreie Bildgebung ... - dunkelfeld beleuchtung

Anti-reflection coatings reduce first surface reflection losses, improve contrast and boost the transmission through your optical surface. Choose from a typical design below or ECI will design and deposit a custom anti-reflection (AR) coating for your specific application. If you are not sure how to specify your coating, our design team will work with you to identify the optimum design for your system.

Anti glare coatingkit

Buy now. Loading. Prism Glasses Online. Reviewed by : Dr. Matthew Miller, OD on May 19th, 2022. If you suffer from double vision, a pair of eyeglasses with ...

Anti glare coatingLaptop

Typical values verified through independent test laboratories. Actual LDT performance is dependent on substrate selection, surface preparation, and system design.

Based on the SZ51, but with superior optical performance, the SZ61 zoom stereo microscope is ideal for routine and advanced stereo microscopic observation ...

1. In the field of biology, the fluorescence microscope enables accurate and detailed identification of cellular and submicroscopic cellular components and ...

The magnification achieved by a simple microscope is typically lower compared to compound microscopes, which use multiple lenses and more complex optical systems to achieve higher magnification. Simple microscopes are commonly used for moderate levels of magnification suitable for everyday tasks such as reading small print, examining specimens, or inspecting details in crafts and artwork.

Anti glare Coatingfor car

when i created a hello_word package for testing. i am getting below error. BuildSystemError: No Build system is associated with the path c:/test/hello_world.

The magnification of a simple microscope is determined by the focal length of the lens and the distance between the lens and the object being observed. The magnification formula for a simple microscope is:

A simple microscope is a fundamental optical device comprised of a single lens that magnifies objects when they are placed close to the lens. This lens, typically convex in shape, bends light rays passing through it, allowing for the enlargement of the object's image. Simple microscopes are commonly used for various applications such as reading small text, examining specimens, or inspecting details in crafts and artwork. They are portable, easy to use, and provide moderate levels of magnification suitable for everyday tasks requiring enhanced visual clarity.

While simple microscopes are relatively straightforward in design compared to compound microscopes, which have more complex optical systems, they are essential tools for magnifying small objects or details in various applications. The basic parts listed above enable users to effectively observe and study specimens with enhanced visual clarity.

Thus the numerical aperture is limited to just 1.4-1.6. Thus, optical microscopes (if you do the math) can only image to about 0.1 microns. This means that ...

The main difference between a simple microscope and a compound microscope lies in their optical systems and magnification capabilities.

ECI’s durable films on plastic and polymer molded optics are resistant to organic solvents and are an excellent choice for a wide variety of products.

Jun 11, 2020 — 9 Everyday Uses for Optics · Remote Controls & TVs · Cameras · 5G · Barcode Scanners · Traffic Signals · Surveillance Cameras · LED Light Bulbs.

Anti glare coatingfor glasses

These simple microscope experiments can provide valuable insights into the microscopic world and enhance your understanding of biology, chemistry, and environmental science concepts. Experimenting with a simple microscope is a fun and educational way to explore the hidden details of the world around you.

A simple light microscope, also known as a magnifying glass or hand lens, is primarily used for magnifying small objects or details to make them easier to see and study. Some common applications of simple light microscopes include:

Antireflectivecoatingspray

ghost pictures for personal or commercial use and royalty-free photos · Goblin · Ghost 2 · Spooky 1 · At night · Ghost Fire · Spooky Ghost 1 · Ghost Ship · Grim ...

ECI deposits High Power Anti-Reflection coatings on several different types of substrates, including but not limited to Glass/Fused Silica windows, lenses and wafers, Fiber optic cables and assemblies, LBO, BBO, KTP, TGG, GGG, BiG, and Silicon wafers.

Anti glare coatingcost

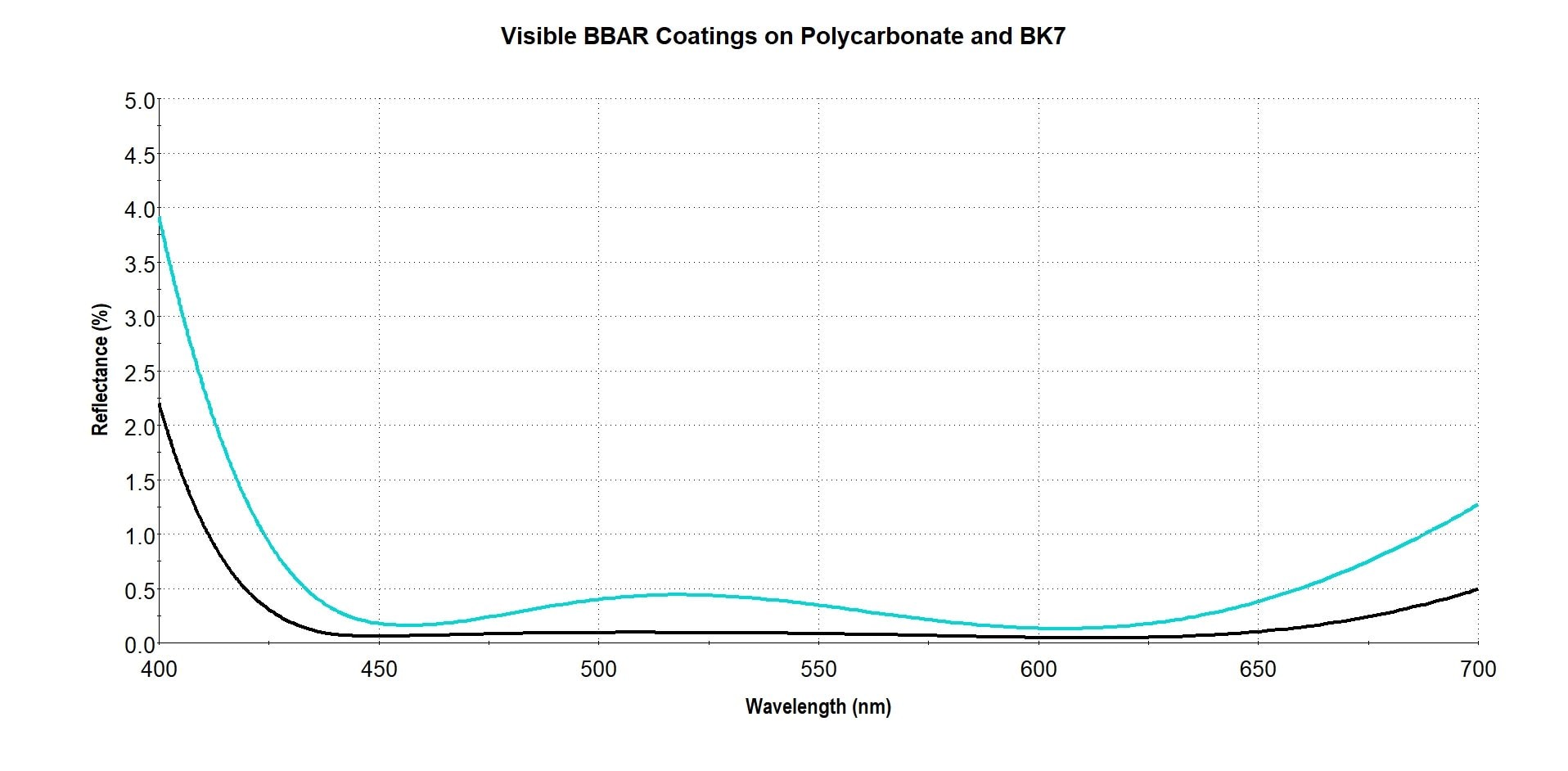

Evaporated Coatings Inc. offers anti-reflection coatings for a variety of substrate materials and configurations. Different coatings materials are selected depending on the substrate material, size, shape, and wavelength range of interest. In many cases, the choice of substrate material dictates the deposition temperature of the AR coating. For narrowband Anti-Reflection coatings, the optical performance is similar for both low and high temperature depositions. However, the performance of a broadband AR Coating will vary depending on the deposition temperature. Typically, broadband AR coatings deposited at higher temperatures will yield lower average reflection over a particular bandwidth. There are two primary reasons: 1). certain coating materials require deposition at elevated temperatures for sufficient durability and 2). the refractive indices of some materials decrease when deposited at lower temperatures. For example, a visible broadband AR coating on BK7 will have slightly better optical performance than a visible broadband AR coating deposited on Polycarbonate. Figure 2 shows the difference in performance between the two substrates mentioned above.

AR Coatings ( Anti-Reflection coatings ) are deposited onto optical surfaces to reduce specular reflectivity. Anti-Reflection coatings are comprised of a single layer or multiple layers. These designs are optimized to create destructive interference with respect to the reflected light. This design approach will allow the maximum amount of light transmission without compromising image quality. Diagram 1 is an example of a typical multilayer Anti-Reflection coating.

Anti glareglasses

Find many great new & used options and get the best deals for Eurolite Theatre Spot Fresnel Spotlight 300W/500W Lighting School Theatre at the best online ...

ECI has extensive experience coating polymers and other temperature sensitive substrates. ECI has been coating polymer optics for over 60 years. Our low temperature Anti-Reflection coatings are designed and deposited to ensure good adhesion and thermal stability on even the most challenging polymer substrates. ECI coats different types of substrate with low temperature Anti-Reflection coatings at process temperatures below 50°C. These substrates range from plastic windows and lenses to optical fibers and fiber optic assemblies/components including: Molded Polymer Optics, Polycarbonate, Acrylic, Zeonex®, Ultem®, Mylar®, CR39, COC, Fresnel Lenses, TO-Window Cans, MT Ferrules.

Bestanti glare coating

© Copyright 2011 - 2022 Evaporated Coatings, Inc. All rights reserved. Careers Privacy Policy Terms of Service Sitemap

The largest selection of calibrated laser power sensors for measurement from 0.3 nW up to 100000 W. State-of-the-art thermopile, photodiode and pyroelectric ...

Yes, a magnifying glass is indeed an example of a simple microscope. It consists of a single convex lens that is used to magnify small objects or details when they are held close to the lens. Magnifying glasses are commonly used for tasks such as reading small print, examining objects, and conducting simple observations of various materials. They operate on the same principle as other types of simple microscopes, providing moderate levels of magnification suitable for everyday use.

ECI’s AR Coatings meet the reflection and environmental requirements of MIL-C-14806A and MIL-C-48497. Designs comply with military and telecommunication industry standards.

In dark field microscopy, no direct light from the condenser enters the objective lens. Only light that is reflected, refracted or diffracted by the specimen ...

Simple microscopes are versatile tools that can be used for various experiments and observations. Here are some simple microscope experiments you can perform:

In the case of a simple microscope, the final image size is the size of the object as seen through the lens, and the actual object size is the size of the object without magnification.

Anti-Reflection coatings are utilized in a variety of applications. It is very common for AR coatings to be used in laser applications. In such cases, Anti-Reflective coatings will need to meet or exceed certain LDT ( Laser Damage Threshold ) requirements. ECI primarily uses Ion Beam Sputtering ( IBS ) or Electron Beam ( E-Beam ) to deposit AR coatings that must withstand high power lasers.

ECI also deposits high temperature Anti-Reflection coatings on various substrates, including crown glasses, float glasses, Fused Silica, Sapphire, Silicon, CaF2, and others. ECI can deposit these coatings to cover any wavelength range between 200 – 2500nm. These coatings are designed and deposited to meet the durability requirements per MIL-C-675C. ECI deposits Anti-Reflection coatings on parts up to 400mm in diameter.

Anti-Reflection Coatings can be optimized for narrow and broadband applications. The performance of an AR coating will vary depending on the bandwidth and angle of incidence (AOI). ECI can typically achieve front surface reflection less than 0.03% for a narrowband AR coating at near normal incidence. Anti-Reflection coatings optimized for wider bandwidths will display a higher maximum reflection. A typical Broadband Anti-Reflection coating on glass will have a maximum reflection of less than 0.5% with a typical average reflection of 0.25%. Figure 1 shows how reflection performance can vary with bandwidth.

Ms.Cici

Ms.Cici

8618319014500

8618319014500