Edmond O'Brien - edmund film

Hotmirror

Dielectric mirrors can be used for laser or ultra-high reflectance applications. This mirror can be designed for maximum reflection at one specific wavelength or range of wavelengths. Dielectric mirrors typically feature very low loss, >99% reflection at most common laser wavelength and can withstand moderate to high laser powers.

Whether you require custom optical fabrication or one of our many off-the-shelf IR optical mirrors, let us provide you with a prompt competitive quotation today!

IRsensormirror

For S-Mount or M12 Lenses, a mechanical comparison is needed between the lens, the lens mount, and the camera housing. The mechanical design for each M12 lens is different, as this mount type is not standardized.Industrial machine vision manufacturers can use S-Mount when referencing M12x0.5 thread specifications. This is a result of using C / CS mount terminology for several decades. The S-Mount term is less accurate and does not specify a maximum/minor thread diameter tolerance. The term "M12 Lens" or M12x0.5 can include tolerances such as M12x0.5-6H or M12x0.5-6G, for example. The M12x0.5 specification is not included in ISO724, or common 3D modeling software, because the camera industry needed a smaller thread pitch to achieve accurate focusing.Please note that this table assumes that your CS-mount or C-mount camera do not have artificial MBFL constraints. The Teledyne/FLIR/PointGrey Blackfly CS / C mount cameras are not compatible with all CS and C mount lenses unless the IR filter is removed.The back focal length and diameters of M12 / S Mount lenses are frequently incompatible with CS and C Mount cameras, resulting in a lens-to-mount combination which cannot be focused. This incompatibility can also occur with other M12 lens mounts.

Matching a lens type with mount type can be frustrating if you've purchased a lens and discovered that it cannot focus on your camera. If you are running into this problem, you're not alone! Check this lens mount compatibility chart to help you determine if you accidentally chose an incompatible lens for your camera.

Infrared reflector material

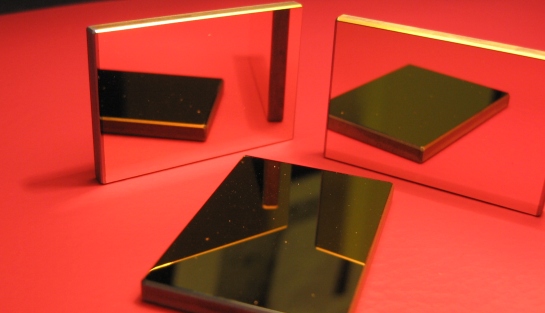

Gold mirrors are effective for applications requiring high reflectance requiring high refelctance in the NIR and IR reflections. Reflection in visisble spectrum is poor. Since a durable coating is necessary for handling purposes, we offer gold coated mirrors with protective overcoat. Please indicate your work wavelength to choose proper protection layer material.

Alkor Technologies provide a large variety of optical mirrors optimized for specific wavelength ranges. We produce custom high precision infrared optical mirrors: flat mirrors, concave mirrors, high reflectivity dielectric mirrors and more. We use a lot of different optical materials as a substrate for mirror: Fused Silica, optical glass, Zerodur, Sapphire, Silicon.

Infrared reflectormirror

Alkor Technologies produce IR Gold optical mirrors coating on various substrates: Fused Silica, Silicon and other optical crystals.

Standard protected aluminum is our most popular optical mirror coating for application in the visible and near infrared. SiO is typically used as an overcoat to protect delicate aluminum mirror coating. This treatment provides an abrasion-resistant surface while maintaining the perfomance of aluminum mirror. For 200-250nm wavelength it is recommended to use MgF2 protective layer. It gives higher reflection values in UV spectrum than SiO.

One of the first questions inevitably asked when designing vision systems is a variant of the following: - Will my CS Mount Lens work with my C Camera Mount? - Will my C Mount Lens work with my CS Camera Mount? - What is the difference between a S Mount lens and a M12 lens? If you've asked one of these questions, have run into an incompatibility, or just want to learn, you've found the right page! We've found that there are few simple answers to this frequently asked question and put together this brief summary. We can also help you check the compatibility of our lenses with your camera.

Ms.Cici

Ms.Cici

8618319014500

8618319014500