DLC Coatings - dlc coated

Harmful effects ofinfraredrays on humans

Schwank high-intensity heaters are used in industrial and commercial buildings, logistics facilities, and workshops with medium to high ceilings (up to 180 feet (55m)). They can handle the toughest job for you and get comfort right down to floor level in an instant because the infrared heat waves they emit are absorbed by objects rather than the air. This lowers the cost of operation and the environmental impact. The core component of our infrared gas heaters is the Schwank ceramic tile, invented by the company’s founder Günther Schwank. It is still manufactured by us in Germany.

The high heat radiation up to 1742°F (950℃) and the unique surface structure of the ceramic tiles make them and the burners suitable for almost any application–from high-power infrared heating systems and de-icing equipment to condensing boilers to overhead heat grills and infrared broilers. Our ceramic tiles ensure maximum performance and efficiency as well as clean, low-emission combustion.

How to useinfraredlamp for muscle pain

These ceiling-mounted radiant heaters are the most advanced line of infrared heaters in our collection of high-intensity heaters. They are low maintenance gas infrared heaters that provide superior comfort while delivering up to 65% energy savings—even when mounted 180’ up.

The surfaces absorb the thermal energy and, in turn, re-emit it into the environment. This results in a balanced micro-climate made of air and radiation heat, which is very comfortable for people. The energy costs are reduced significantly and the feeling of comfort is enhanced for the people. As compared to conventional systems, savings generally amount to between 30% to 50%.

Laser power detector for measurement up to 50 000 W that traps > 97 % of the incident light and handles high intensities of small beams.

Nonluminous infraredlamp

The high heat radiation up to 1742°F [950℃] and the unique surface structure of the ceramic tiles make them and the burners suitable for almost any application–from high-power infrared heating systems and de-icing equipment to condensing boilers to overhead heat grills and infrared broilers. Our ceramic tiles ensure maximum performance and efficiency as well as clean, low-emission combustion.

In addition to their high longevity, Schwank ceramic burner tiles are characterized by their industry-leading performance.

Our Schwank heaters combine gas (use either natural gas or propane) with air in a mixing chamber, then direct it through the approximately 3,500 combustion channels of the specially developed ceramic tiles. The mixture is ignited just before its outlet. Thanks to the extremely close-knit combustion channels, the ceramic tile is heated to approximately 1800°F (950°C). This results in the formation of radiation energy, which is directed, by means of highly reflective reflectors, to the exact location where it is required. The infrared rays are converted into heat at the point of contact, for example, on our skin but also on the floor, machines, stored goods, and products. Heating, therefore, takes place only where it is required, which is incredibly efficient.

Take a look at other types of light sources: incoherent light sources (light bulbs, LED, stars). These sources produce radiation by spontaneous emission in all directions, with a spread of wavelengths and no interrelationships among individual photons. Spontaneous emission is a random process. On the other hand, lasers use stimulated emission, producing photons with identical properties (all photons move at the same wavelength and direction).

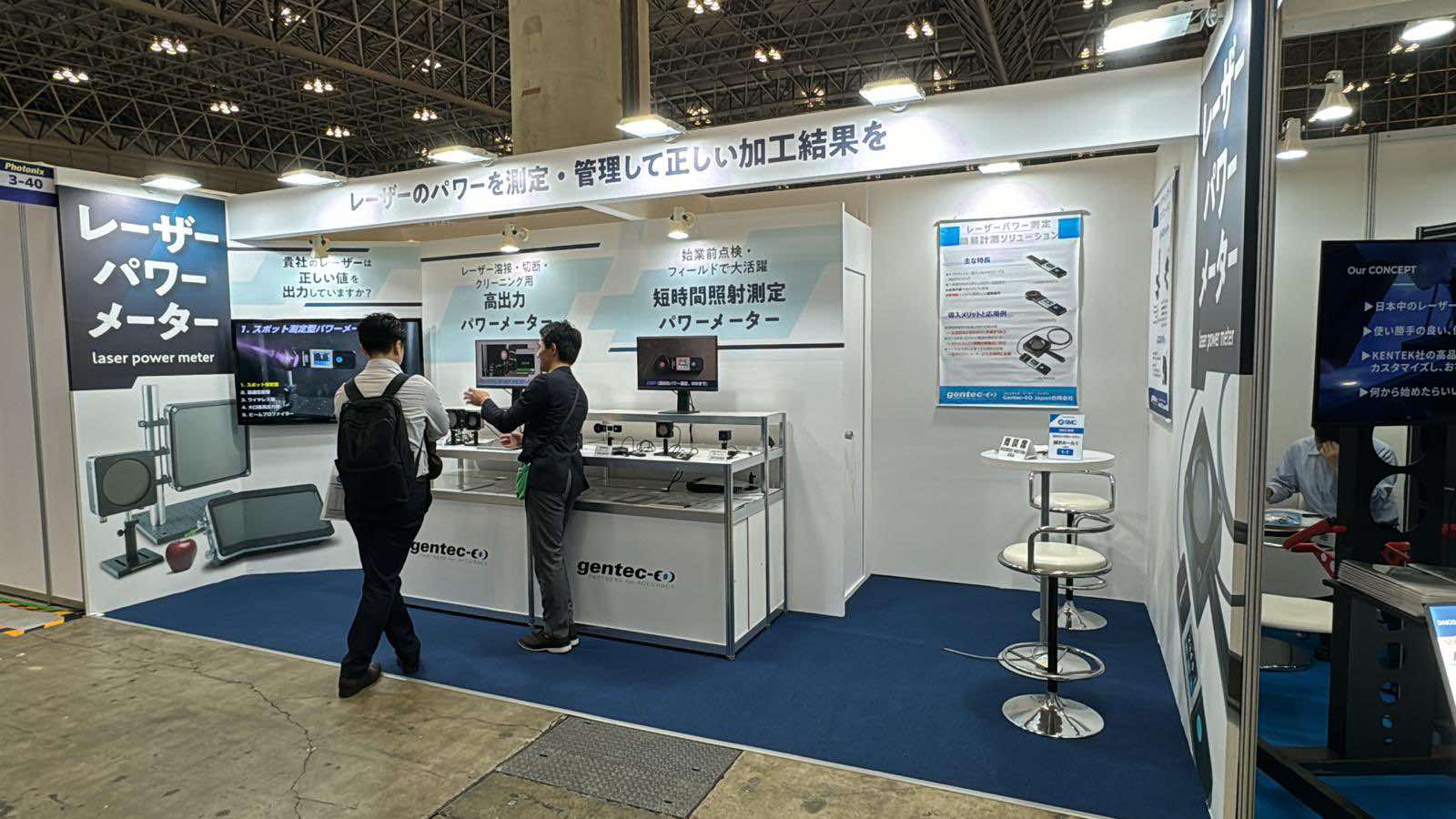

Since the discovery of the laser, more than 30 Nobel Prizes have been awarded in the field of natural sciences for scientific discoveries directly related to lasers. In 2018, Donna Strickland became the second woman to receive a Nobel Prize in physics, which she was awarded for her work on ultra-short and high-intensity laser pulses. Measuring the laser's properties with precision and accuracy is key to such research, which is why Gentec-EO develops and manufactures high-accuracy laser power meters and laser energy meters.

The surfaces absorb the thermal energy and, in turn, re-emit it into the environment. This results in a balanced micro-climate made of air and radiation heat, which is very comfortable for people. The energy costs are reduced significantly and the feeling of comfort is enhanced for the people. As compared to conventional systems, savings generally amount to between 30% to 50%.

When we talk about highly monochromatic lasers, we consider that the beam linewidth is very narrow. You can use these lasers especially for applications such as laser spectroscopy or coupling with optical fibers in fiber communications.

Infraredtherapy in physiotherapy

The surfaces absorb the thermal energy and, in turn, re-emit it into the environment. This results in a balanced micro-climate made of air and radiation heat, which is very comfortable for people. The energy costs are reduced significantly and the feeling of comfort is enhanced for the people. As compared to conventional systems, savings generally amount to between 30% to 50%.

Laser specifications change over time for many reasons and it causes problems accross all industries. Learn about how laser output measurement solves numerous problems in YOUR industry. Download the guide below.

Portable laser power meter for up to 250 W with flexible calibration options so the customers only pay for what they use. Includes 3 measurement modes : SSP, CWP and SSE.

You can be surprised by the fact that measured linewidths of real solid-state lasers, such as diode-pumped YAG lasers, are <1 kHz. This is not the bottom line. In fact, linewidths less than 1Hz are also achievable by suppression of external noise influence. Narrow-linewidth lasers are used in holography, frequency metrology and light detection and ranging (LIDAR).

The sun, stars and fire are natural sources of ordinary light. We recognize the light received by the human eye as white, whether it is the light of a lamp or the sun. However, we do not notice the spectrum of colors that make white, except through a prism by which light can be decomposed into different components.

ecoSchwank infrared gas heaters produce clean, efficient heat in industrial/warehouse settings. By converting up to 52%* of the gas input into radiant heat, ecoSchwank heaters offer great performance on a tight budget.

Laser (Light Amplification by Stimulated Emission of Radiation) is an artificial source of light radiation that emits a coherent beam of photons, as the source is stable in frequency, wavelength, and power. Unlike the light emitted by common sources, such as light bulbs, laser light is mostly monochromatic, i.e. only one specific wavelength (color).

Infraredlamp for physiotherapy side effects

Specific properties of artificial light obtained by lasers are advantageous for transmitting data for hundreds of miles, up to terabits per second, by a convenient, single wavelength coherent source. Nowadays, you can transmit data with laser beams through free-space optics technology over moderate distances with many Gbit/s data rates.

The laser beam is highly coherent, which means that the electromagnetic waves are in the same phase with each other and propagate in the same direction. You can get a laser beam of high intensity and directivity by superposition of electromagnetic waves that are in phase. Such a highly directional beam can be focused on a very sharp point, which is not possible with ordinary light.

It all started with ceramic burner tiles and burners. In 1939, company founder Günther Schwank invented the world’s first gas-operated ceramic burner tile. Today we are still the leader in this technology. Thanks to intensive research & development as well as constant quality controls, Schwank ceramic tiles and gas burners are second to none.In addition to their high longevity, Schwank ceramic burner tiles are characterized by their industry-leading performance.

All three models of Schwank luminous heaters deliver superior performance thanks to our proprietary technology and strict production standards: supraSchwank: 81.2% IR efficiency, primoSchwank: 67.7% IR efficiency, and ecoSchwank: 52% IR efficiency. This performance is verified by independent lab testing to ANSI Z83.6 standard (ANSI Z83.19b/CSA 2.35b) and by DVGW when tested to EN 419-2 standard.

The laser has also become an important research instrument and has found its application in many fields, such as the correction of vision, the sharpening of the astronomical image from space, testing the DNA molecule and in obtaining pure energy by laser fusion of atoms.

The principle of ceiling-mounted infrared gas heatersThe way high-intensity heaters work just like the sun: the heat rays of the sun travel through the air without heating it and emit their thermal energy only when they fall on contact surfaces.

The principle of ceiling-mounted infrared gas heatersThe way high-intensity heaters work just like the sun: the heat rays of the sun travel through the air without heating it and emit their thermal energy only when they fall on contact surfaces.

Ordinary light sources mainly emit polychromatic light and their emission is spatial. The source of ordinary light emits many rays in all directions, randomly. Ordinary light consists of a mixture of rays with different wavelengths, where each wavelength corresponds to one color that your eyes register.

Luminous infraredtherapy

The high heat radiation up to 1742°F [950℃] and the unique surface structure of the ceramic tiles make them and the burners suitable for almost any application–from high-power infrared heating systems and de-icing equipment to condensing boilers to overhead heat grills and infrared broilers. Our ceramic tiles ensure maximum performance and efficiency as well as clean, low-emission combustion.

In addition to their high longevity, Schwank ceramic burner tiles are characterized by their industry-leading performance.

The principle of ceiling-mounted infrared gas heatersThe way high-intensity heaters work just like the sun: the heat rays of the sun travel through the air without heating it and emit their thermal energy only when they fall on contact surfaces.

Infraredtherapy side effects

Luminous infraredlamp

Gentec-EO's high-accuracy laser beam measurement instruments help engineers, scientists and technicians in all sorts of laser applications from the factory to the hospital, laboratory and research center. Learn about our solutions for these measurement types:

Laser specifications change over time for many reasons and it causes problems accross all industries. Learn about how laser output measurement solves numerous problems in YOUR industry. Download the guide below. Gentec-EO's high-accuracy laser beam measurement instruments help engineers, scientists and technicians in all sorts of laser applications from the factory to the hospital, laboratory and research center. Learn about our solutions for these measurement types: Laser power meters Laser energy meters Laser beam profilers Terahertz power meters

Website portal for distributors, reps, retailers, contractors, engineers, and more. Log in with your Schwank ID to access your additional valuable resources.

However, real laser light is not purely directional because some propagation effects can distort the laser beam, especially if it is interacting with nonlinear media. When you propagate laser beam it gets broadened with distance. In order to achieve an adequate beam size and directivity you need to additionally precisely control, measure and direct laser beam with lenses and mirrors.

Our Schwank heaters combine gas (use either natural gas or propane) with air in a mixing chamber, then direct it through the approximately 3,500 combustion channels of the specially developed ceramic tiles. The mixture is ignited just before its outlet. Thanks to the extremely close-knit combustion channels, the ceramic tile is heated to approximately 1800°F (950°C). This results in the formation of radiation energy, which is directed, by means of highly reflective reflectors, to the exact location where it is required. The infrared rays are converted into heat at the point of contact, for example, on our skin but also on the floor, machines, stored goods, and products. Heating, therefore, takes place only where it is required, which is incredibly efficient.

Our Schwank heaters combine gas (use either natural gas or propane) with air in a mixing chamber, then direct it through the approximately 3,500 combustion channels of the specially developed ceramic tiles. The mixture is ignited just before its outlet. Thanks to the extremely close-knit combustion channels, the ceramic tile is heated to approximately 1800°F (950°C). This results in the formation of radiation energy, which is directed, by means of highly reflective reflectors, to the exact location where it is required. The infrared rays are converted into heat at the point of contact, for example, on our skin but also on the floor, machines, stored goods, and products. Heating, therefore, takes place only where it is required, which is incredibly efficient.

Ms.Cici

Ms.Cici

8618319014500

8618319014500