Dispersion-Compensating Prism Pairs for Ultrafast Lasers - dispersion prism

Everixname

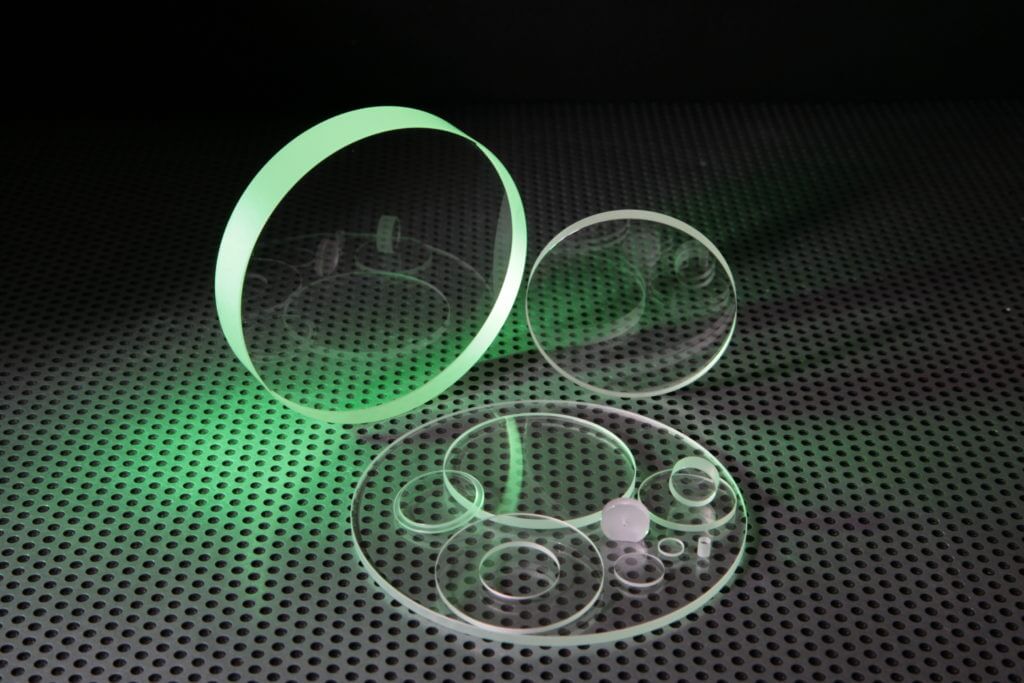

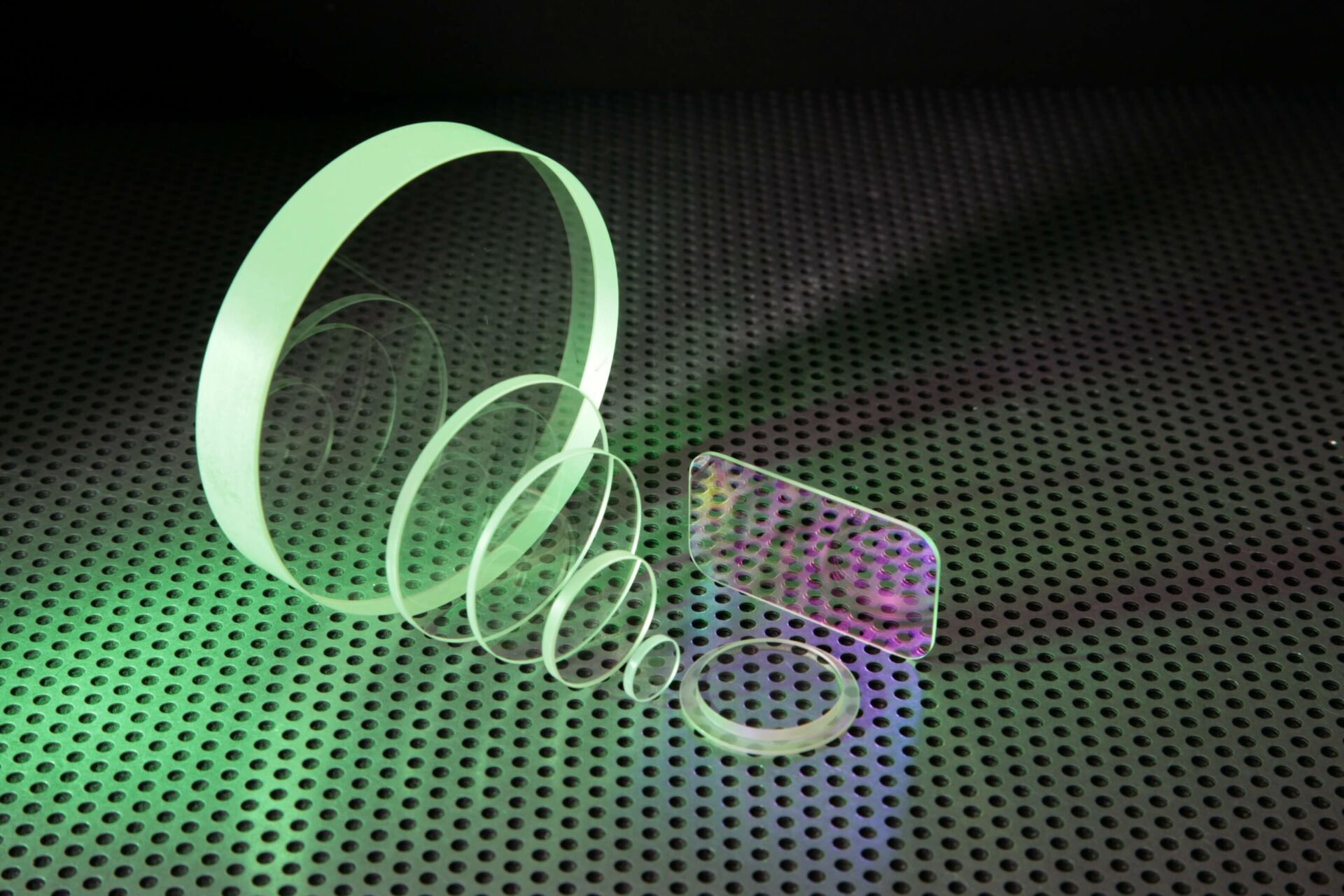

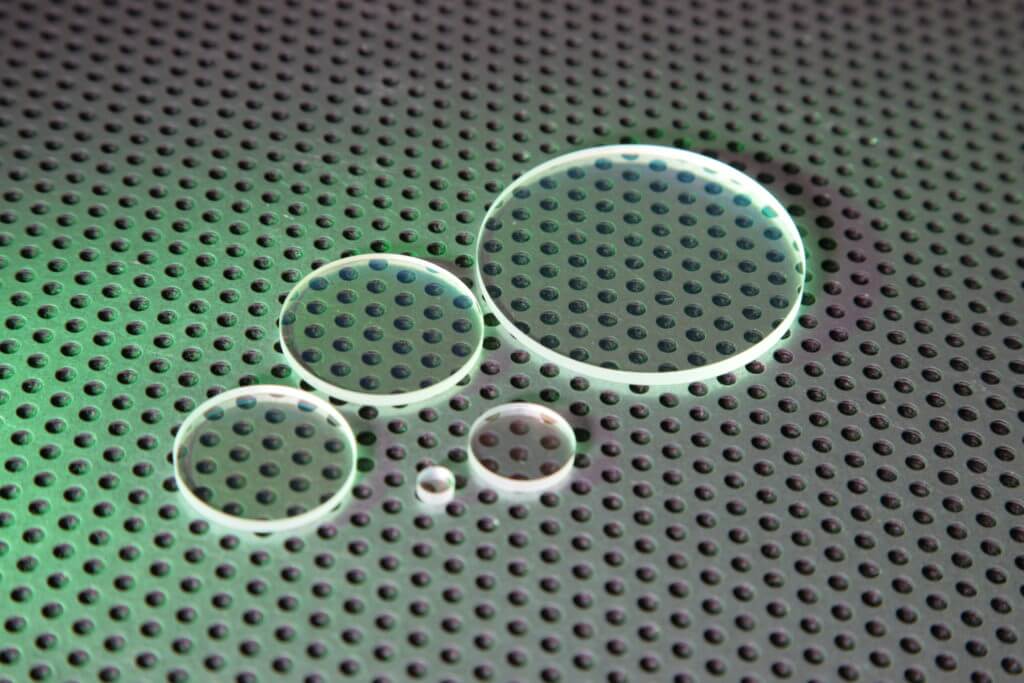

Here at UQG we provide sapphire windows and plates in a range of standard shapes and sizes as well as manufacturing custom solutions when required. In some cases, the sapphire windows or sapphire plates might have additional coatings applied to deliver necessary effects, such as reducing reflection or protecting the component from light at the infra-red or ultra-violet ends of the spectrum.

Here at UQG we offer sapphire windows and plates which are AR coated on one or both sides, cut to a random orientation, or cut to ‘C’ axis.

Everixoptical filters

“C”-cut sapphire windows have the added benefit of reducing any birefringence that may exist in sapphire windows cut to a random axis. Birefringence refers to the fact that a ray of light passing through an optical plate or window splits into two rays, and while it is only a slight effect in sapphire windows cut to a random orientation it is reduced further in ‘C’ cut sapphire windows.

Everixproducts

Welcome to UQG Optics! It looks like you are visiting from the US. Select your preferred currency below to see appropriate pricing. Contact us for additional support or to discuss specific requirements.

EverixEdge review

Posted by Kelvin Biggs, Managing Director | 14th February 2023 | Optical Products

The primary reason why sapphire is often chosen as the material for optical windows rather than other materials such as silica and quartz is that it is the hardest oxide material in existence, and one of the hardest crystals available, second only to diamond.

Additionally, they offer great transmission, high strength, and temperature resistance properties. Due to this, they are frequently used in optical instrumentation and equipment deployed in tough environmental situations where excessive temperatures, pressures, moisture, chemicals, or other factors must not impair optical performance because to their thermal stability features.

EVERIXINVESTMENTS LIMITED

We use optional cookies to review analytics that help us to improve our website experience. By clicking accept, you are giving consent for us to do this. You can find out more and manage cookies in our privacy policy.

Standard AR coatings of this kind include UV 250nm-400nm, visible range 400nm-700nm and IR 700nm-1100nm, and 3-5 microns. AR coatings can also be applied to apply to a single specified wavelength and coatings of this kind – on one or both sides of a sapphire window or plate – are often utilised in imaging applications, cameras and lasers.

EverixInc

Sapphire windows and plates are optical components that can be utilised in a wide range of applications. Their ability to transmit light with a specific wavelength at the same time as protecting the rest of the system from the impact of the environment makes them particularly useful. Sapphire windows and plates used for optical products can be supplied in several ways including, ‘C’ cut, random orientation, and AR coated – we review the key differences and benefits between them.

Due to their properties, sapphire windows are often used in difficult environments that involve factors such as high temperatures or pressure or the presence of corrosive substances.

Sapphire windows and plates that are optically AR coated on one or both sides maximise the transmission of light. Sapphire windows and sapphire plates that have been treated in this manner are extremely transparent in a range running from UV visible to mid IR.

When supplied as standard, sapphire windows and sapphire plates are cut to a random optical axis, which offers all of the advantages listed above in terms of durability, strength, and versatility, while the sapphire windows can also be AR coated on one or both sides.

EverixEdge

Welcome to UQG Optics! It looks like you are visiting from outside the UK. Select your preferred currency below to see appropriate pricing. Contact us for additional support or to discuss specific requirements.

The durability, precision, and strength of sapphire windows and plates make them the solution of choice across a range of sectors and industries, including the following:

Hardness of this kind means that sapphire windows are highly resistant to wear and tear and scratching, no matter how potentially damaging the environment in which they are utilised is.

This is one of the things that makes sapphire windows and plates of this kind particularly useful within camera systems, optical equipment, and medical components.

While Sapphire windows cut to random orientation still involves a high degree of precision and tolerance, it may not be exact enough for particular optical components, which is why some sapphire windows are cut to C axis.

In technical terms, sapphire windows or sapphire plates that have been cut to ‘C’ axis have been cut to provide an optical axis that runs perpendicular to the plane of the sapphire substrate itself. It is also referred to as a ‘Z’ cut or 0° plane cut.

Sapphire windows have exceptional surface hardness, acid, alkali, and other chemical endurance and scratch resistance, and they are frequently employed in the UV, visible, and near infrared bandwidth ranges.

To find out more about Sapphire Windows and Plates from UQG Optics, or any of our other optical products call us on 01223 420329 or email our sales team at info@uqgoptics.com

The strength of sapphire is also an advantage because it enables sapphire windows to be manufactured to extremely tight tolerances and thicknesses, therefore meeting the requirements of high-precision optical components across a wide range of different industries.

Ms.Cici

Ms.Cici

8618319014500

8618319014500