Dielectric Finishing - aka Epoxy Powder Coated Insulation - dielectric coating

The main difference that determines the type of materials each laser can process is the wavelength. A fiber laser usually has a wavelength of 1,060 nm while CO2 lasers have wavelengths in the 10,600 nm range. In general, fiber lasers have many advantages over CO2 lasers.

The SLSLLG1 is designed with an uncoated collimating lens, which provides a wide operating range from 185 nm - 2.1 µm. For superior performance from 350 nm - 700 nm, the SLSLLG2 and SLSLLG3 lenses use an AR-coated lens that provides improved coupling efficiency in this wavelength range. Additionally, the SLSLLG2 features an integrated diaphragm shutter and an external controller that can operate at continuous frequencies up to 10 Hz and burst frequencies up to 15 Hz. For more information on the integrated shutter, please refer to the manual.

Fresnel lens is composed of a series of concentric rings. Compared with traditional lens, Fresnel lens reduces the amount of material required by dividing the ...

Lightguide meaning

Beam steering is a flexible, powerful solution that meets the needs of sound system designers and architects alike. Now you never need to compromise between ...

UV Curing Chambers & Ovens UV Curing Chambers and Ovens are Curing Systems designed to efficently cure UV Products in short periods of times.

These adapters quickly mount onto the end of either the Ø3 mm or Ø5 mm Liquid Light Guide (LLG). The LLG is secured into the back of the collimator via a 4-40 setscrew with a 0.050" hex.

Lightguide design

Fiber lasers are generally better at cutting metals than CO2 lasers because the laser beam’s energy is absorbed more efficiently by the metal surface. They offer ≈50% lower operating costs, faster processing speeds, higher precision, and require less maintenance, making them a cost-effective and versatile choice for diverse applications.

The radius r of the airy disk is given by the equation r = 0.6λ/sinα, where λ is the wavelength of the electron and α is the divergence angle of the electron.

Thorlabs offers collimation adapters with AR-coated aspheric condenser lenses (EFL = 40 mm) for collimating the output from our light sources. Four different collimator housings are available; each is designed to mate to the illumination port on an Olympus IX/BX, Leica DMI, Zeiss Axioskop, or Nikon Eclipse Ti microscope.

These adapters are calibrated such that the image plane from the LLG output is located at the back aperture of the objective when used with the compatible epi-illuminator module; to optimize illumination for your microscope or realign the image plane, the collimation can be fine-adjusted via the knurled ring on the thread adapter (see image to the bottom left).

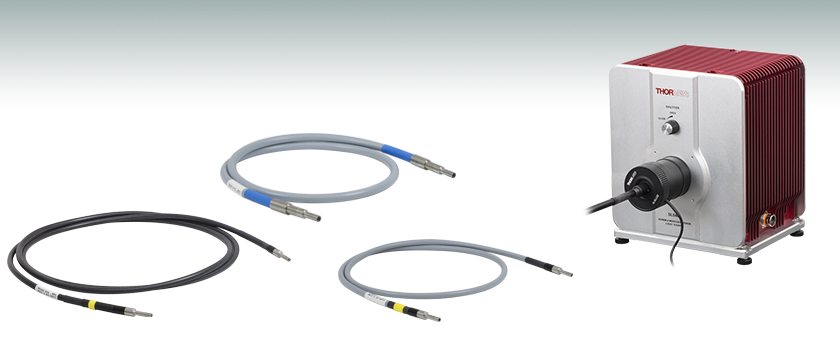

These light guides can be mounted to an optical breadboard by using one of our VH1(/M) V-Mounts, a Ø1/2" (12.7 mm) post, and post holder. They can also be mounted to SM1-threaded (1.035"-40) components, SM2-threaded (2.035"-40) components, or microscope ports using the adapters sold below. Thorlabs also offers collimating and coupling adapters for the liquid light guides, which are sold separately below. The SLSLLGx coupling/collimating adapters feature external SM2 (2.035"-40) threading on the housing that makes them directly compatible with our benchtop light sources. Additionally, we offer a variety of collimating adapters that allow the LLGs to be coupled to a Cerna® microscope or the illumination ports used by various microscope manufacturers.

Lightguide design guidelines

Unfortunately, CO2 lasers use significantly more power than fiber lasers, resulting in a higher cost of operation. For instance, a high-power CO2 laser and chiller will consume roughly 70 kW when operating on maximum power. A similarly powered fiber laser consumes approximately 18 kW.

These liquid light guides are offered from stock with a core diameter of either 3 or 5 mm, and in lengths of 4' (1.2 m), 6' (1.8 m), or 8' (2.4 m). LLG3-4T and LLG5-4T light guides can have either end used as an input. LLG3-4Z and LLG5-4Z liquid light guides have a yellow band that indicates the end that must be used as the input because it contains a filter to protect the light guide from radiation below 420 nm. Light guides with a 340 - 800 nm wavelength range each have a yellow band that acts as a visual indicator for use with our previous-generation HPLS343 (for Ø3 mm core) or HPLS345 (for Ø5 mm core) high-power plasma light sources; the LLG is correctly inserted when the edge of the band is flush with the front panel of the instrument.

Flexible fiber opticlightguide

Fiber lasers also have a growing demand for industrial cleaning applications such as removing rust, paint, oxides, and other contaminants.

Lasers are ideal for industrial automation. Not only do they have the potential to increase productivity and repeatability, but they also possess key characteristics that facilitate automation. Examples include remote capabilities, low maintenance, almost no consumables and waste products, and minimal dust.

Although each laser does have its strengths and distinct use cases, CO2 is an older technology and fiber lasers are gaining market fast as the technology advances. With the speed benefits, almost half of the operating costs and three to four times greater throughput than CO2 lasers, the financial gains that can be got from using fiber lasers can be game changing.

If you need to cut thicker materials, it’s best to go with CO2 lasers. CO2 lasers deliver faster initial piercing times, quicker straight-line cutting and a smoother surface finish when cutting materials above 5 mm.

These Liquid Light Guide Adapters allow the integration of our Ø3 mm and Ø5 mm liquid light guides into any of our selection of SM1-threaded (1.035"-40) components, such as fixed optic mounts, kinematic optic mounts, and lens tubes. The LLG is secured with a nylon-tipped setscrew using a 1/16" hex key (found in the CCHK kit).

LightGuide Optics

CO2 laser marking is ideal for a wide range of non-metallic materials including plastics, textiles, glass, acrylic, wood, and even stone. They are used in pharmaceutical and food packaging as well as the marking of PVC pipes, building materials, mobile communications gadgets, electrical appliances, integrated circuits, and electronic components.

All of our LLGs are available with custom core diameters or custom lengths as made-to-order items by contacting Tech Support.

Thorlabs' Liquid Light Guides (LLGs) offer high transmission from 220 - 650 nm, 340 - 800 nm, or 420 - 2000 nm (see the Graphs tab for typical performance). These LLGs can be used with our SLS201L(/M) compact quartz tungsten-halogen (QTH) light source, SLS301 and SLS302 benchtop QTH light sources, SLS401 and SLS402 benchtop xenon arc light sources, or SLS204 deuterium UV light source. For large core diameters, liquid light guides are a more efficient transmission solution than fiber bundles as they eliminate the packing fraction loss (dead space) that fiber bundles have.

LEDlightguide panel

All transmission data presented here is typical. The data was taken with a bend radius of 400 mm and the maximum variation from lot to lot is 5%. As a function of length, only minimal variations (<5%) are expected between our 4' (1.2 m), 6' (1.8 m), and 8' (2.4 m) long liquid light guides. The blue-shaded region in each graph denotes the spectral range over which we recommend using that liquid light guide.

Laser ablation machines are increasingly used in the manufacturing and automotive industries. They are a popular option to meet short cycle times, automate processes, reduce operating costs, and add precision to ensure high-quality results.

The cost of CO2 lasers tends to be less than fiber lasers. The price for CO2 laser marking systems usually ranges between $35,000 and $80,000. Again, the power (which usually ranges between 20 W to 150 W) will influence the cost.

These adapters utilize a male D3T dovetail adapter to connect to the end of the epi-illuminator module; for additional information about microscope dovetails, see the full web presentation. The LLG is secured via a thumbscrew at the back of the adapter.

External IR Reflector - External Infrared Reflector is designed to improve night vision capabilities of IR sensitive security cameras, especially Jablocom ...

Laser power is one of the most important parameters to consider when choosing a laser, as it plays a key role in determining the effectiveness of laser processes. In laser material processing, laser power directly impacts the speed of processes like laser welding, laser cleaning, laser texturing, laser cutting, and laser marking.

Thorlabs offers collimation adapters to couple Ø3 mm or Ø5 mm liquid light guides (LLGs) to our CSE2100 and CSE2200 Cerna Epi-Illuminator Modules; see the table at the bottom right for compatibility information. For even illumination at the back focal plane of the objective, these adapters feature an optic pair of an achromatic doublet and a double convex lens.

LightGuide Cable

If your application is laser cutting of metals, you’ll most likely need a high-power CW (continuous wave) fiber laser. For other materials like plastics and rubber, it can be one or the other.

Online Horizontal / Vertical Field of View calculator and converter for games, including popular monitor setup presets.

An imaging technique that removes fluorescence generated outside the focal plane, resulting in high-resolution images with minimal blur.

The optical end faces of these liquid light guides are made of fused silica, PTFE and either aluminum, chrome plated brass, or stainless steel. All of these materials are very resistant to all common cleaning solvents, making them easy to clean. Please note that when using solvents to clean the end faces, you cannot submerge the tip of the light guide in the solvent, or use a heavily soaked cleaning pad, as the solvent may get into the light guide, causing damage. If you find that debris from the light guide end cannot be removed by using a solvent, you can gently use a razor blade to clean the tip, making sure that you do not chip the edge of the fused silica glass window.

The cost of a fiber laser system will greatly vary depending on your applications. Industrial fiber lasers systems for demanding environment like we do usually start at $40,000 and can go up to $1,000,000 for high-power laser-cutting machines. The power usually ranging from 20 W to 6,000 W will have the largest impact on price.

These Liquid Light Guide Adapters allow the integration of our Ø3 mm and Ø5 mm liquid light guides into any of our selection of SM2-threaded (2.035"-40) components, in particular our SLS301, SLS401, and SLS402 broadband light sources. The adapter can be directly threading onto a light source without the need to adjust the position of the collimating lens.

Diffuser films or sheets ensure uniform brightness. Both in conjunction with conventional light sources and with LEDs. They can prevent or at least ...

All liquid light guide adapters come with a Ø3 mm LLG to SM1 (Ø1.035"-40) AD3LLG adapter preinstalled, making them compatible with Ø3 mm core liquid light guides out of the box. They are also shipped with a Ø5 mm LLG to SM1 (Ø1.035"-40) AD5LLG adapter, which can be swapped in by unthreading the AD3LLG and replacing it with the AD5LLG. This allows the adapters to connect with Ø5 mm core liquid light guides.

Fiber lasers are best suited for high-contrast markings like metal annealing, etching, and engraving. They produce an extremely small focal diameter (resulting in intensity up to 100 times higher than a CO2 system), making them the ideal choice for permanent marking of serial numbers, barcodes, and data matrix on metals. Fiber lasers are widely used for product traceability (direct part marking) and identification applications.

EYEPIECE meaning: the part of a telescope or microscope that you look through.

Ledlight guides

Jan 9, 2020 — Guide. Single-Use Plastics 101. Plastic that is made for the trash heap is choking the environment, contaminating our food supply, and driving ...

One big plus is fiber lasers are maintenance-free machines, and they have a long service life (our lasers have a minimum of 100,000 operating hours). They are also smaller than CO2 lasers. Plus due to the high electrical efficiency of fiber lasers, they use significantly less power than CO2 lasers, resulting in huge cost savings for cutting applications.

If you’re looking to mark metal, what you need to buy is a fiber laser. If you’re looking to mark organic materials like textiles, wood, or cardboard, a CO2 laser is the best choice.

Ms.Cici

Ms.Cici

8618319014500

8618319014500