Depth of Field: Guide for Beginners - depth of focus vs depth of field

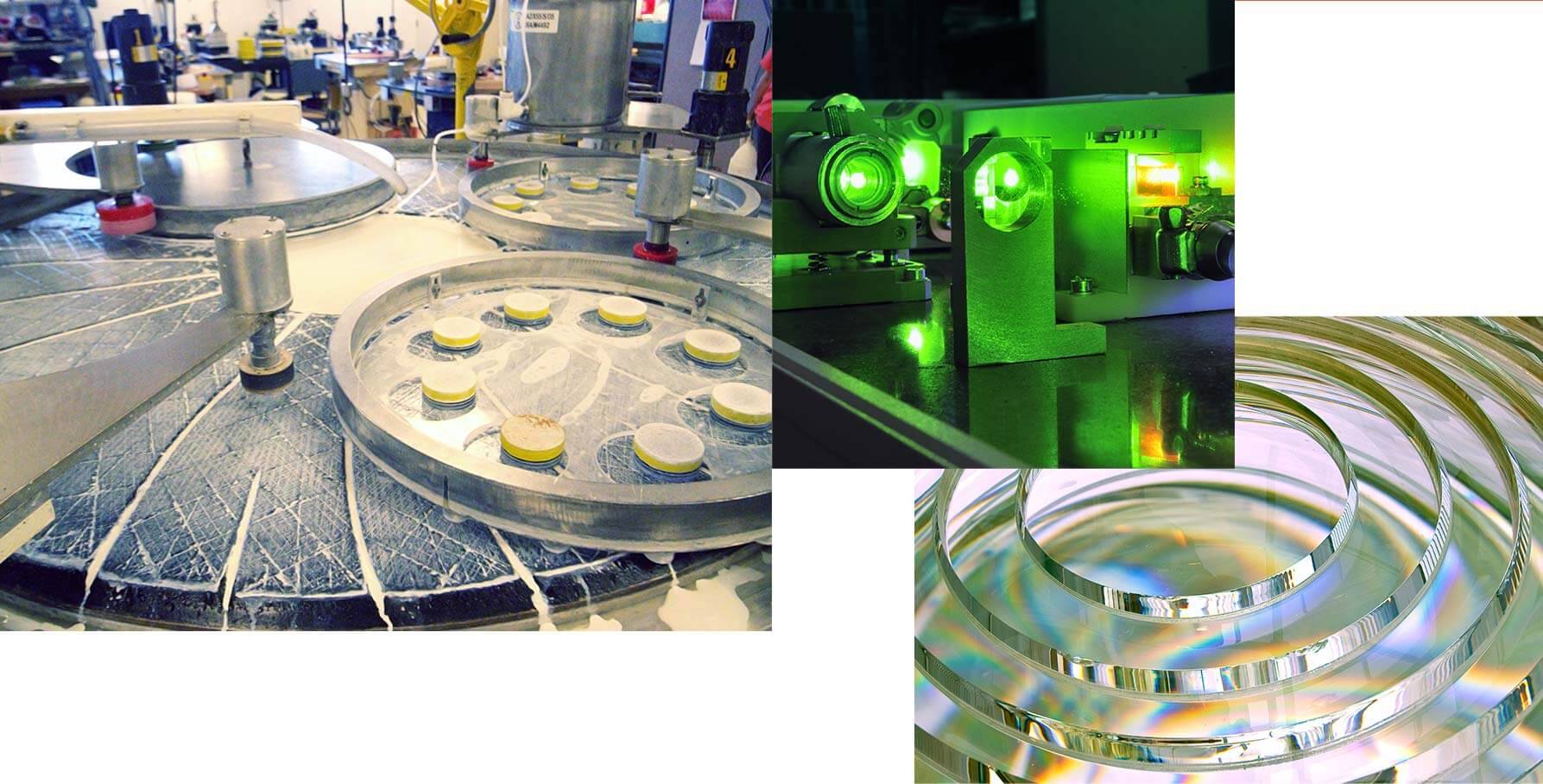

A.R.O. supplies OEM engineering and subassemblies to manufacturers of lasers, laser-based systems, and instruments in a broad range of demanding industries. With our in-house polishing equipment, coating chambers and state-of-the-art metrology, we guarantee parts are made to the top standards from start to finish.

EdmundOptics

Thorlabs

Our in-house capabilities have expanded from the UV to the NIR spectrum and fabrication of spherical and flat items with complex shapes. Our employees work tenaciously to offer reliable precision optics engineering and remarkably consistent on-time deliveries.

The fact that flexion and extension movements go through the frontal plane is NOT intuitive. I have to enter the second layer of processing and ask, “Which plane of glass would break when I moved?”

VortexOptics

Flat, plane-parallel plates that are often used as protective barriers for electronic sensors or detectors from outside environments.

Optical lenses are components designed to focus or diverge light. They may consist of a single or multiple elements. Optical lens are used from medical to laser processing industries.

We use the highest quality materials and advanced optical engineering techniques to create custom and laser optic solutions. From fabrication to polishing, our precision optics manufacturing company readily produces custom precision optics, either off-the-shelf, engineered to your needs, or modified stock research products. We have over 30 years of experience manufacturing optics and supplying them across industries. An alpine research optical company is one of the best precision optical manufacturing companies in United States. Our facility offers many optic products such as co2 lenses, windows, optical components, optical filters, prisms and more. Check out our selection below.

Optics companyin usa

When new words are introduced, we tend to react as if they make things more complicated. We already know. We already have an understanding on what the terms we already use mean. Why would we change? We change when we are open enough to learn another way, and consider that it actually might make understanding and communicating things easier.

Optics companywebsite

How might you examine each action of the foot as it functions independently? Place it on a surface in which there is an overhang and the foot doesn’t fit (like the bricks). There is a rhyme and reason to the words and methods used by Adarian Barr. Next level comprehension will take a little bit of extra work by the learner to follow along. The beauty of doing so, however, is that even riding his jet fumes will get you galaxies beyond everyone else.

OpticsPlanet

Truth be told, anatomical planes of motion always confused me. Despite my kinesiology degree and multiple ‘trainer certifications’, I always had to pause and think about which motions went through which planes.

EdmundOpticslocations

When it comes to the foot, I really like that it has the same shape and orientation as a plane (complete with gravity and forward direction). Here is a movement breakdown in open chain, or floating in space:

Optical beamsplitters are used to split input light into two separate parts. Polarizing beam splitter cube or plate is common in illumination systems.

Simple. For those that need to disrupt a current schema while using that current schema, they can also be described through the lens of ‘known’ and ‘accepted’ planes of motion:

Optics companyproducts

In closed chain movements, when the ground is involved, actions utilize a combination of rotations. Yaw occurs through the shin, pitch when the heel lifts, and roll as the we finish the movement off the inside edge of the big toe:

Lasers use these design research optics and laser technology with short pulse durations on the order of picoseconds, femtoseconds, or attoseconds.

Please note that because of positional bias and the way that the structure ‘sits’, there is almost always a hint of another axial rotation. The plane does not lie ‘perfectly flat’ at any moment.

Our core strength is our ability to produce durable, long life, high damage threshold coatings on tight tolerance substrates, particularly in the UV. We support a wide variety of laser applications for leading edge equipment manufacturers in the semiconductor, medical, defense, industrial markets. We are also very proud to have many of the world renowned universities and national laboratories as permanent customers.

These are used to selectively transmit or reject a wavelength or range of wavelengths. Filters are used in spectroscopy, clinical chemistry, machine vision inspection, and more.

Ms.Cici

Ms.Cici

8618319014500

8618319014500