Catalase Activity in Keratinocytes, Stratum Corneum, and ... - biomass skin care

Not an “eyepiece” in the usual sense of the word, a Cheshire is a sight tube with a small hole at the top that you look through, and a shiny surface tilted at 45° and aimed at a large hole in the side of the tube. The version Orion (and others) sell also has a set of cross-hairs at the bottom of the tube for aligning the secondary mirror. This “all-in-one” collimation tool is excellent. Indeed, if you have one of these, you need nothing else.

The five options described above cover those most commonly available and frequently used. With varying ease, all of them can help you accurately collimate scopes — even those with fast (under f/5) focal ratios. There are other tools and systems, but mostly they are either variations of those covered here, or devices that increase the complexity of the operation without a corresponding improvement in accuracy.

Do you have any questions or comments? Then please contact us. We will get back to you as soon as possible. To help us process your request, please fill out all fields marked with *.

Best features: You can do it without spending a single dollar. No centre dot is needed on the primary mirror. Worst features: The method takes some experience and isn’t the best choice for absolute beginners. It’s also usually more time consuming than other methods and requires a star (or point-source light). It’s also not the best way to ensure the secondary mirror is correctly placed. Accuracy: Dead accurate. Ease of use: For the highest accuracy you’ll need a night of good, steady seeing. Experience will make the method more reliable and effective.

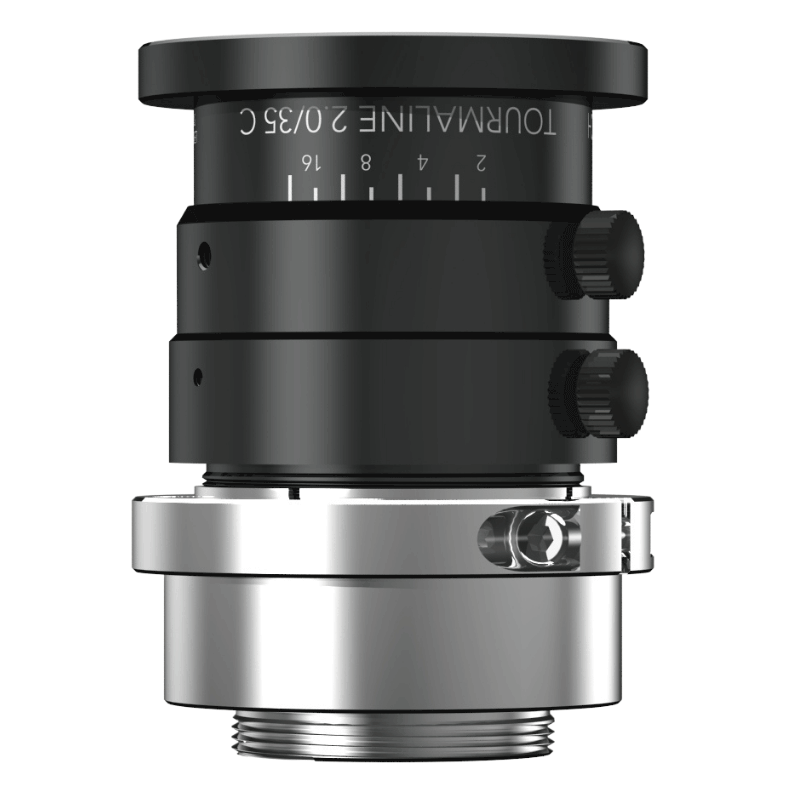

C-Mount adapter

Best feature: Works well in the dark. Worst features: Can be relatively expensive. Requires the centre of the primary mirror be marked. Accuracy. Very accurate. Ease of use: Very easy.

Our in-depth application knowledge and proven optical expertise enable us to provide customized solutions that combine mechanical robustness, reliability and the highest imaging accuracy. This is the result of our decades of experience with extremely tight tolerances. We even go so far as to design and build our own manufacturing and metrology systems if there is no equipment available on the market that is accurate enough. Our customers value us not only for our technical expertise, but also for the dedicated and customer-focused advice we provide. We listen. We answer questions and make recommendations. It is important to us that our customers have all the information they need so that they can make the right decisions and achieve the best possible results. Contact us - we will be happy to advise you.

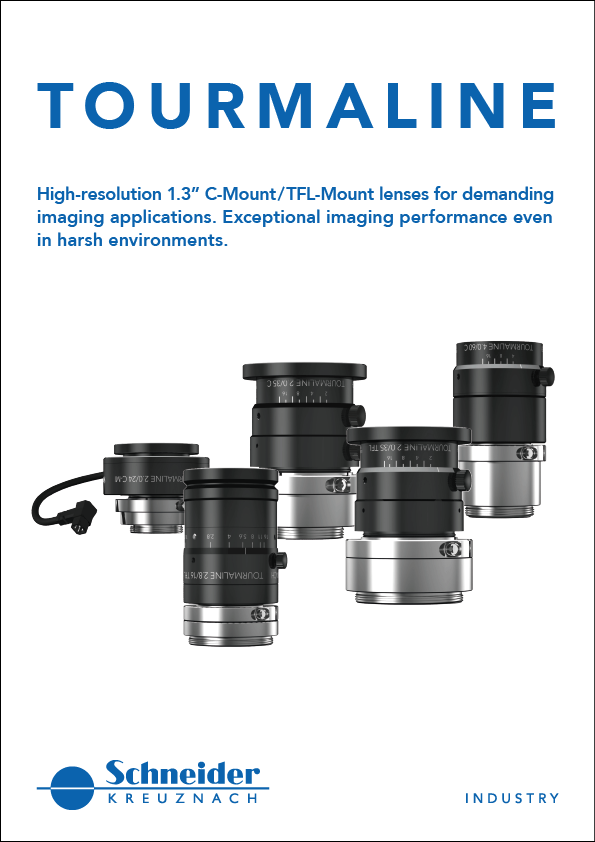

With a maximum sensor size of 1.3" (24 mm) and a resolution of up to 2.4µ pixel size, the TOURMALINE lenses offer impressive performance. For one, the flat main beam angle makes them suitable for all SONY Pregius™ generations. TOURMALINE lenses are available as C-Mount and TFL-Mount lenses in 8 different focal lengths from 16 mm to 50 mm. With starting apertures from F2 to F2.8, TOURMALINE lenses allow precise control of the amount of light reaching the sensor. Some models are also available in a ruggedized version for use in harsh environments. In addition, a number of models are available with a motorized iris. TOURMALINE compact lenses are ideal for industrial and demanding imaging applications. With their wide magnification range, high resolution and low distortion, they deliver excellent imaging results. Certain TOURMALINE models were formerly sold under the XENOPLAN name.

The technical characteristics of the TFL-Mount are based on this standardized thread and diameter, which allows high compatibility between different lenses and cameras. This mount is widely used in industrial vision systems and other applications where precision and consistency are important.

I’m purely a visual observer and mostly use scopes that are shade over f/4. For collimation I use either a Cheshire or laser to position the secondary mirror (something that rarely needs adjustment) and a simple collimation cap for tweaking the primary. That’s it. My scopes are always perfectly aligned, something I can quickly verify with a star test. Collimation rarely takes me more than a minute and most nights all I do is check to see that everything is okay since I last used my scope. There’s really no reason to spend any more time on it than that.

Machine vision enables machines to recognise objects, patterns and other visual features through the integration of lenses and image processing.

Yes, it is possible to collimate your reflector without any tools. It’s called the “star test.” The detailed ins and outs of this method are beyond the scope of this article, but essentially you centre a bright star in the eyepiece, throw it out of focus, and note where the shadow of the secondary mirror is positioned within the expanded disk of light. It should be centred. The test becomes progressively more sensitive the nearer you get to focus. Regardless of what other collimation method you use, the star test is the final arbiter of optical alignment. If it looks right in the star test, it is right.

C-MountLensVintage

If you want to read more about collimation, I can recommend Nils Olof Carlin’s excellent piece, Some Collimation Myths and Misunderstandings That article should fill in most of the gaps arising from the brevity of this overview.

By protecting the lens, eliminating unwanted wavelengths and enhancing contrast, optical filters improve the image quality of your lens in industrial applications.

Best features: Can be used in the dark. Useful for adjusting the secondary mirror. Worst features: Can lead to miscollimation. Batteries required. Expensive relative to benefits. Requires centre of primary to be marked. Accuracy: Potentially accurate if used correctly. Accuracy dependent on mechanical alignment of the laser within its housing and how the device seats in the focuser. Accuracy highly dependent on positioning of the secondary mirror. Ease of use: Relatively difficult to use successfully.

Quality and reliability are top priorities at Schneider-Kreuznach. Our lenses undergo rigorous quality control to ensure maximum reliability. Before a lens leaves our factory, it is carefully inspected and tested. This ensures that it meets our high quality standards. We use only high quality glass from reputable manufacturers to achieve very low manufacturing tolerances. As a result, our filters are of consistently high quality. Their use allows you to accurately reproduce results, as the lenses will perform nearly identically even after years of use.

Optics We demand the highest standards of materials and manufacturing processes to ensure excellent image quality, starting with the production of the optics. Our standards go beyond the production of individual components. We master the entire production process from raw glass to finished lenses and are able to process all common types of glass. Our special coating technologies give the optics or lenses the desired optical properties.

Any Schneider-Kreuznach standard lens can be modified to meet your needs. However, there are some applications that require new, customized lenses. Our product development department can develop custom lenses for your needs. This can even result in cost savings by tailoring the lens to your needs, thus avoiding unnecessary complexity.

c-mountlensmicroscope

Assembly Our lenses are assembled in dedicated clean rooms that provide a clean and controlled environment and ensure they are free of contaminants. Our qualified staff with many years of experience and expertise perform precise adjustments and calibrate the optics to the highest quality with the lowest tolerances.

Ever since the foundation in 1913 our staff have been perfecting our knowledge and technologies to bring you the best products in optics. Our manufacturing facilities in Bad Kreuznach, Germany, guarantee outstanding quality – Made in Germany. We continuously invest in our state-of-the-art machinery and in the education and training of our staff. Select your perfect lens from our large portfolio. If you need a customized solution, we are your partner from the kick-off to the Project completion. Our extensive experience and in-depth knowledge of a wide range of applications enables us to provide you with solutions that are perfectly tailored to your needs. As a family owned company, we are passionate and committed to our customers and their success. You can expect long-term relationships based on trust and shared goals with us.

C-mount connectors provide a robust and proven solution for connecting lenses to cameras. The standardization of C-mount also makes it easy to change lenses to meet the changing needs of different applications.

A C-mount is a specific mechanical connection widely used in the industry for cameras and lenses. It is defined by a diameter of 1 inch (25.4 mm) and 32 threads per inch (C-mount thread). This mount allows lenses to be easily and securely attached to cameras and is widely used in machine vision and other applications.

Discover the compatibility of TOURMALINE lenses with top sensor brands Check out the optimal sensor compatibility for TOURMALINE lenses. Our selection includes a variety of compatible sensors from leading manufacturers such as Sony, OnSemi, GPixel, Teledyne e2V, ams. Improve your imaging efficiency and accuracy with the ideal lens-sensor combination.

C-MountLensholder

Laser collimators have been around for many years now and seem to be especially attractive to those who equate lasers with precision. Unfortunately, it’s been my experience that beginners all too often end up de-collimating their scopes when using one of these. Why? The Achilles heel of the laser collimator is that its accuracy depends on how carefully you’ve adjusted your scope’s secondary mirror — a procedure that is far more difficult than it is important to image quality. In other words, if your scope’s secondary mirror isn’t set correctly, you can actually achieve a “pass” by putting your primary mirror out of alignment — a situation that can have disastrous consequences when it comes to image quality. That said, I have a laser collimator and find it a useful tool for adjusting the tilt of the secondary mirror. I don’t recommend it for adjusting the primary, however.

Completely free of charge and without obligation. I am aware that my data/ usage behavior is stored electronically. You can unsubscribe this service at any time in any newsletter, or your consent to the Jos. Schneider Optische Werke GmbH.

C-Mountlenssize

Visit us at any tradeshow or event we attend worldwide! Come with your challenge and let our experts help you find the perfect solution for your apllication.

A TFL-Mount is a specific mechanical mount used in the industry for cameras and lenses. The term "TFL" stands for "Treaded Filter Lens" and describes the thread system used with this mount. TFL-Mounts are also known as "M30.5x0.5" because they have a thread with a diameter of 30.5 mm and a pitch of 0.5 mm.

With exceptional shock and vibration resistance, our ruggedized lenses are ideal for harsh environments. They offer longer life, greater ruggedness and lower maintenance costs. They are used in aerospace, automotive, automated optical inspection and other industries where high reliability and durability are critical.

All specifications of the TOURMALINE lens can be modified to meet your needs because we control every aspect of the design and manufacturing process. Discover the versatility of our TOURMALINE lenses, available in a variety of configurations. If our standard does not meet your needs, we fit them to your specifications. To take customization a step further, we also work with customers to develop entirely new, tailor-made lenses. Your vision, our commitment – contact us.

Aligning the optics of your reflector telescope is crucial for optimal performance — all the more so if you have a telescope with a focal ratio of f/5 or less. A good tool can make the difference between successful collimation, and an exercise in frustration that encourages you to settle for “good enough.” But selecting the right tool can be more confusing than actually using it. On-line discussions offer a bewildering array of opinions and experiences — some of which posted by people who make and sell the products they (naturally enough) recommend. So what do you really need to collimate your scope? Here is a rundown of the various collimation tools commonly available, and their relative strengths and weaknesses. My evaluations are based on several decades of making and using reflector telescopes. All the devices discussed below can produce satisfactory collimation. What generally distinguishes one from another is not accuracy, but rather, ease of use and cost.

C-mountlenson full frame

Possibly your telescope came with one of these. Orion Telescopes supplies them with their reflectors, as do some other manufacturers. The device is simply a plastic cap with a small hole in its centre and a reflective underside. If your telescope didn’t come with one, you can make one with an old plastic film canister. For 90% of the collimation I do, this is the tool that I use. The only time I usually need something more is when I’m assembling a scope from scratch.

Our sales and engineering professionals provide customers with a high level of expertise and responsiveness. We understand that the needs of our industrial customers can be diverse and complex. Whether it's technical specifications, the exact application environment, special customizations, or other unique requirements, we take the time to understand each customer's unique needs and provide customized solutions. Our advice ranges from selecting the right lens to assisting with integration into existing systems. You can count on our experts to provide the best support and find the perfect solution.

Our industrial lenses are tough and durable by design. But we offer even more: Ruggedized and stabilized lenses. These lenses are exceptional. They offer superior performance and durability. Even in the harshest conditions, you can count on our lenses to deliver reliable, accurate results.

Maximise the potential of your industrial lens with our high-quality accessories including camera adapters, extension tubes, filter holders and UNIFOC.

Download the TOURMALINE lens product sheet for details of the lens family. It provides a comprehensive overview of the features, specifications and capabilities of each lens in the family.

For most people, a simple collimation cap is fine. The Barlowed laser is also a good option, especially if you already have a Barlow lens in your eyepiece box. If you do most of your collimation in the dark when you arrive at an observing site, this is the way to go. Nearly as convenient and useful is the Cheshire eyepiece. The important thing to remember is that you don’t have to get a bunch of tools — one chosen with care is all you need. Take the time to learn how to use it well and you won’t need another.

Schneider-Kreuznach offers high-quality lenses with motorized iris for industrial applications. They offer precision and flexibility in changing lighting conditions. The motorized iris adjusts to the lighting conditions by an electric control and offers maximum precision in various industries such as transportation and aviation.

Our custom lenses offer user-friendly integration into existing systems. The adaptability of our product designs allows engineers to seamlessly integrate lenses. We are a trusted partner because of our commitment to research and development and our decades of experience in the optical industry. With our custom lenses, we help our customers overcome challenges, open up new possibilities and take their technical applications to the next level.

Ruggedized Lenses Our ruggedized lenses are ideal for harsh environments. Ruggedized C-mount lenses resist shock and vibration. With shock resistance up to 100g and robust mechanics and optics, they offer exceptional durability in extreme conditions such as rocket launches into space.

Mechanics We do mechanical manufacturing in-house. We use the latest technologies and machinery to develop robust and durable filters. With our high-end 5-axis CNC milling machines, we have world-class machining capabilities that give us exceptional precision and flexibility. These powerful milling machines allow us to realize complex geometries and sophisticated contours in the mechanical components of our lens houses while maintaining high reproducibility. Electroplating is performed in-house under strict environmental conditions, allowing us to customize the surface coatings of our products to meet the specific requirements of our customers.

Our industrial lenses are rigorously tested to DIN and ISO standards to ensure they meet stringent environmental requirements. These include extreme temperature testing from -25°C to +70°C, humidity testing from 80% to 95% relative humidity, and shock testing at 50 g / 11 ms and sinusoidal vibration testing to ensure robustness, shock and vibration resistance. Of course, we can also design and manufacture lenses to meet even more demanding requirements. Contact us for more information.

All Schneider-Kreuznach industrial lenses are designed for total flexibility and adaptability. Not only are they available in a range of standard designs, but they can also be completely customized to meet your needs. The possibilities are virtually unlimited. Whether you want to adjust working distances, require specific housing dimensions, or are looking for custom coatings for specific wavelengths, we can make it happen. We understand that every project is unique and we will do our best to provide you with the perfect solution.

The Barlowed laser is the newest approach in the collimation game. Most people heard about it the first time when Nils Olof Carlin’s article appeared in the January 2003 issue of Sky & Telescope (page 121). As editor of the telescope-making department, I had the privilege of working with Nils to bring this to the pages of the magazine. Essentially the setup consists of an ordinary laser collimator used in conjunction with a Barlow fitted with a target attached in front of the lens. You can also purchase Barlowed lasers from commercial sources such as Howie Glatter and Kendrick Astro Equipment. Unlike a plain laser, the Barlowed version works very well and avoids the pitfalls of the former. This is my favourite method for collimating in the dark.

Best features: One tool that does it all. Relatively inexpensive. Worst features: In the dark you’ll probably need a red flashlight to illuminate the shiny surface of the collimation eyepiece. Requires a centre-dotted primary mirror. Accuracy: Very accurate if your mirror’s centre dot is correctly positioned. Ease of use: Easy to use.

Automated optical inspection (AOI) uses cameras and software to inspect and analyze components for defects in a manufacturing process.

Did you find this article interesting or helpful? If so, consider using this link the next time you shop at Amazon.com. Better yet, bookmark it for future use. Thanks to Amazon’s associates program, doing so costs you nothing yet helps keep this site up and running. Thanks!

We are proud of our technical expertise, which we consistently apply to the production of our lenses and optical filters through our high level of vertical integration at our Bad Kreuznach site. Each of the Schneider-Kreuznach products is manufactured with the utmost care and precision to provide you with the best possible performance and reliability.

Our focus on quality and innovation is evident in every industrial lens we modify. By working closely with our customers, we ensure that we can make your requirements a reality. Discover the possibilities of our custom industrial lenses and rely on our years of experience and expertise in the optical industry. Here are just a few examples of the modifications that can be made to our industrial lenses:

C-mount camera

Stabilized Lenses Stabilized lenses are specifically designed for precise measurement applications such as 3D measurement and complex triangulation systems to avoid image shift. With their secure mechanical design, these lenses ensure a stable image position and minimize image shift during movement. They provide highly accurate and reliable results without having to constantly re-calibrate. Stabilized lenses are ideal for robotic applications, especially robot vision.

C-MountLensebay

Our TOURMALINE compact lenses are tested to DIN standards to ensure they meet stringent environmental requirements. These tests check the durability of the compact lenses, their resistance to temperature changes and their ability to withstand shock tests and sinusoidal vibration. This ensures that the industrial lenses are up to the task in demanding industrial applications such as machine vision or automated optical inspection, providing consistent performance and reliability over time.

Testing and Quality Assurance Our test technology and quality assurance reflect our high quality standards. We use state-of-the-art technologies such as interferometers and 3D coordinate measurement technology to test the lenses we manufacture to ensure they meet the highest standards. Our ISO 9001 certified processes, metrology rooms and procedures ensure consistent and reliable production to meet our customers' high expectations.

Best features: Cheap and effective. Worst features: Not the best tool for aligning the secondary mirror (though it can be done). Requires the centre of the primary mirror to be marked. Accuracy: Very accurate if your mirror’s centre dot is correctly positioned. Ease of Use: Very easy to use.

Discover our wide range of high quality lenses, optical filters and accessories in our interactive eBrochure. Find the detailed compilation of all standard products currently available from Schneider-Kreuznach. Our product brochure gives you a comprehensive overview of our entire product range, including all technical information. Whether you are looking for specific products or want to compare different options, our eBrochure has it all in one place. Click on the link below to download our product brochure.

Our range of C-Mount or TFL-Mount compact lenses. They're compact, robust and available in ruggedized, stabilized or motorized versions. Ideal for demanding applications like automated optical inspection, 3D measurement and machine vision in industrial environments.

Ms.Cici

Ms.Cici

8618319014500

8618319014500