Calcium Fluoride Optics and Substrates - refractive index of calcium fluoride

Numerical apertureof microscope

Now that we have briefly explained what numerical aperture is, we can equate it to f/#. As explained here, f/# is also a measure of how much light can get through a lens. f/# of a simple lens is defined by the following equation, where f is the focal length of the lens and D is the diameter (or more specifically the entrance pupil diameter for more complex lens systems).

Please note that one CAB4000 TEC cable is included with the purchase of an ITC4002QCL or ITC4005QCL controller. The CON4001 connector kit is included with all of the controllers (see the Shipping List tab for specific details).

The software packages support LabVIEW 8.5 and higher. If you are using an earlier version of LabVIEW, please contact Tech Support for assistance.

For driver software, as well as programming reference guides for the Programmable Instruments (SCPI) standard, LabVIEW™, Visual C++, Visual C#, and Visual Basic, please see the Software tab.

Numerical apertureunit

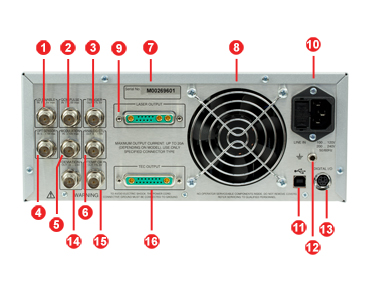

Depending on the application, the ITC4000 Series of laser drivers can be operated in Continuous Wave (CW) or Quasi-CW (QCW) mode. To demonstrate the performance of these controllers, a screenshot of an oscilloscope measuring the output current of an ITC4020 in QCW mode is shown to the right. The ITC4020 produces sharp and accurate 100 µs pulses with a peak current of 20 A without any unwanted overshoots. The ITC4002QCL and ITC4005QCL will provide similar performance within their respective current ranges. The integrated pulse generator can be triggered internally with an adjustable repetition rate or externally via a BNC jack at the rear of the unit.

This cable is made of a highly flexible flat cable and contains a 9W4 male connector on one end and 17W2 and 13W3 male connectors on the other end. The CAB4007A is designed for connecting an LCM100(/M) liquid-cooled mount to a Thorlabs ITC400xQCL series controller.

Numerical apertureof objective lens

Thorlabs offers recalibration services for our ITC4000 Series Combined Laser Diode and TEC Controllers. To ensure accurate measurements, we recommend recalibrating the devices every 24 months. The table to the right lists the controllers for which the CAL-ITC4 recalibration service is available.

In general the gains of P, I, and D will need to be adjusted by the user in order to best servo the system. While there is not a static set of rules for what the values should be for any specific system, following the general procedures should help in tuning a circuit to match one’s system and environment. A PID circuit will typically overshoot the SP value slightly and then quickly damp out to reach the SP value.

This cable is made of a highly flexible flat cable and contains a Flat 10-Pin HHL Female connector on one end and 17W2 and 13W3 male connectors on the other end. The CAB4007B is designed for connecting any laser with a standard 10-Pin HHL package to a Thorlabs ITC400xQCL series controller.

Please Note: To ensure your item being returned for calibration is routed appropriately once it arrives at our facility, please do not ship it prior to being provided an RMA Number and return instructions by a member of our team.

We also offer a variety of OEM and rack-mounted laser diode current & temperature controllers (OEM Modules, PRO8 Current Control Rack Modules, and PRO8 Current and Temperature Control Rack Modules).

This is an exact equation relating the NA to the f/#, but it is often convenient to have an approximation for this. When n = 1 (medium is air) and if we use a small angle approximation (sin α ≈ tan α) then:

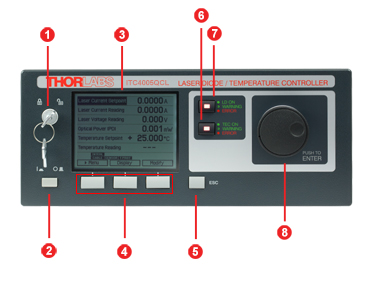

Current Source: If the connection between the current source and laser is interrupted, the current source automatically switches off the current output. The open current circuit condition is indicated by the “OPEN” indicator on the controller and a short acoustic warning. The separate laser ON key switches the laser current on and off. When switched off, an electronic switch within the device short circuits the laser for added protection. After being switched on, a soft start ensures a slow increase of the laser current without voltage peaks. Even in the case of line failure, the laser current remains transient free. Voltage peaks on the AC line are effectively suppressed by electrical filters, shielding of the transformer, and careful grounding of the chassis.

Through proper setting of the controls in a PID circuit, relatively quick response with minimal overshoot (passing the set point value) and ringing (oscillation about the set point value) can be achieved. Let’s take as an example a temperature servo, such as that for temperature stabilization of a laser diode. The PID circuit will ultimately servo the current to a Thermoelectric Cooler (TEC) (often times through control of the gate voltage on an FET). Under this example, the current is referred to as the Manipulated Variable (MV). A thermistor is used to monitor the temperature of the laser diode, and the voltage over the thermistor is used as the Process Variable (PV). The Set Point (SP) voltage is set to correspond to the desired temperature. The error signal, e(t), is then the difference between the SP and PV. A PID controller will generate the error signal and then change the MV to reach the desired result. For example, if e(t) states that the laser diode is too hot, the circuit will allow more current to flow through the TEC (proportional control). Since proportional control is proportional to e(t), it may not cool the laser diode quickly enough. In that event, the circuit will further increase the amount of current through the TEC (integral control) by looking at the previous errors and adjusting the output to reach the desired value. As the SP is reached (e(t) approaches zero), the circuit will decrease the current through the TEC in anticipation of reaching the SP (derivative control).

The CAB4007x connector cables for HHL laser packages are Hi-Flex™†, unshielded cables designed for high-current applications, where the laser diode (LD) and thermoelectric cooler (TEC) currents exceed most standard cable limits.

Current Limit: A precisely adjustable current limit ensures that the maximum laser current cannot be exceeded. Thorlabs has intentionally provided limited access to this feature to prevent accidental adjustment. An attempt to increase the laser drive current above the preset limit will result in a visible and short audible indicator. Even when utilizing the external modulation feature, the current limit setpoint cannot be exceeded.

Numerical apertureformula

The PID circuit is often utilized as a control loop feedback controller and is commonly used for many forms of servo circuits. The letters making up the acronym PID correspond to Proportional (P), Integral (I), and Derivative (D), which represents the three control settings of a PID circuit. The purpose of any servo circuit is to hold the system at a predetermined value (set point) for long periods of time. The PID circuit actively controls the system so as to hold it at the set point by generating an error signal that is essentially the difference between the set point and the current value. The three controls relate to the time-dependent error signal. At its simplest, this can be thought of as follows: Proportional is dependent upon the present error, Integral is dependent upon the accumulation of past error, and Derivative is the prediction of future error. The results of each of the controls are then fed into a weighted sum, which then adjusts the output of the circuit, u(t). This output is fed into a control device, its value is fed back into the circuit, and the process is allowed to actively stabilize the circuit’s output to reach and hold at the set point value. The block diagram below illustrates the action of a PID circuit. One or more of the controls can be utilized in any servo circuit depending on system demand and requirement (i.e., P, I, PI, PD, or PID).

To determine whether lens specifications are compatible, we need to find the resulting numerical aperture from the other three specifications. To do this we will first need to use the equation below to relate the image height h, focal length f and the half field of view Θ. This equation can be derived using simple geometry using the relationships shown in the red triangle in figure 3.2.

Now we can find the focal length of the lens by assuming that the customer wants entrance pupil diameter to stay at the specified 20mm.

These controllers offer many advanced features such as Quasi-Continuous Wave (QCW) operation mode, easy auto-tune PID, and diverse laser and TEC element protection (see the More Info tab). The controller design also provides silent and power-efficient operation. These features make the ITC4002QCL and ITC4005QCL ideal choices for safe and secure operation of medium- to high-power QCLs, ICLs, and laser diodes either in the lab or in production environments. Thorlabs recommends recalibrating these controllers every 24 months and offers a factory recalibration service. To order this service, scroll to the bottom of the page and select Item # CAL-ITC4.

Manual tuning of the gain settings is the simplest method for setting the PID controls. However, this procedure is done actively (the PID controller turned on and properly attached to the system) and requires some amount of experience to fully integrate. To tune your PID controller manually, first the integral and derivative gains are set to zero. Increase the proportional gain until you observe oscillation in the output. Your proportional gain should then be set to roughly half this value. After the proportional gain is set, increase the integral gain until any offset is corrected for on a time scale appropriate for your system. If you increase this gain too much, you will observe significant overshoot of the SP value and instability in the circuit. Once the integral gain is set, the derivative gain can then be increased. Derivative gain will reduce overshoot and damp the system quickly to the SP value. If you increase the derivative gain too much, you will see large overshoot (due to the circuit being too slow to respond). By playing with the gain settings, you can maximize the performance of your PID circuit, resulting in a circuit that quickly responds to changes in the system and effectively damps out oscillation about the SP value.

Please note that one CAB4005 cable and one CON4005 connector kit are included with the purchase of the ITC4002QCL and ITC4005QCL benchtop controllers (see the Shipping List tab for details).

Integral control goes a step further than proportional gain, as it is proportional to not just the magnitude of the error signal but also the duration of the error.

Numerical apertureof optical fiber

The controllers are compatible with all laser diode and monitor diode pin configurations, as well as our two-tab C-mount and HHL QCL and ICL packages. They feature a constant current (CC) or constant power (CP) mode. Most common temperature sensors can be used, and the contollers can be adapted to different thermal loads via a digital PID controller, which can operate through the built-in auto-tune PID function or separate control of the P, I, and D parameters. For more details about these features, please see the More Info tab.

These controllers provides a monitoring signal proportional to the difference between actual and set temperature. An oscilloscope or an analog data acquisition card can be connected to the rear panel BNC connector to monitor the settling behavior with different thermal loads.

Derivative control attempts to reduce the overshoot and ringing potential from proportional and integral control. It determines how quickly the circuit is changing over time (by looking at the derivative of the error signal) and multiplies it by Kd to produce the derivative response.

The CAB4005 cable connects our ITC4000 series dual current / temperature controllers to laser diode mounts. We also provide loose 13W3 connectors for customers who wish to make their own cables. Please see the Pin Diagrams tab for specific pinout information.

The download button below links to VISA VXI pnp™, MS Visual Studio™, MS Visual Studio.net™, LabVIEW™, and LabWindows/CVI™ drivers, firmware, utilities, and support documentation for Thorlabs' ITC4000 Series laser controllers, LDC4000 Series laser controllers, CLD1000 Series compact laser diode controllers, and TED4000 Series TEC controllers.

While manual tuning can be very effective at setting a PID circuit for your specific system, it does require some amount of experience and understanding of PID circuits and response. The Ziegler-Nichols method for PID tuning offers a bit more structured guide to setting PID values. Again, you’ll want to set the integral and derivative gain to zero. Increase the proportional gain until the circuit starts to oscillate. We will call this gain level Ku. The oscillation will have a period of Pu. Gains for various control circuits are then given to the right in the chart.

Numerical aperture meaningin optical

This cable contains a DB-9 male connector on one side and a 13W3 male connector on the other side. Both views shown below are looking into the connector.

Below are three sets of lens specifications that would result in the desired system NA. There is an infinite number of specifications that will give the desired NA if one is allowed to change more than one spec.

The tables below are designed to give a quick overview of the key specifications for our laser diode controllers and dual diode/temperature controllers. For more details and specifications, or to order a specific item, click on the appropriate item number below.

Often times when starting the design process one can inadvertently request conflicting specifications. This example will show how easy this is to do and how to avoid it when specifying a lens.

The ITC4002QCL and ITC4005QCL contain high-performance digital TEC controllers for currents up to ±15 A. They offer excellent temperature stability of 0.002 °C within 24 hrs together with the same enhanced safeguard and operation features of Thorlabs' TED4015. The digital PID controller can adapt to different thermal loads by individually adjustable parameters or by the auto PID function (for more details see the full presentation for the TED4015). The maximum control range of the temperature sensor input spans 100 Ω to 1 MΩ for thermistors and -55 to 150 °C for temperature sensing ICs or Platinum RTD sensors. The actual applicable temperature range is limited by the connected sensor and the thermal setup. For maximum TEC element protection, the ITC offers the same features as the TED4015. These protection features include an adjustable TEC output current limit and temperature sensor malfunction alerts.

Larger proportional gain results in larger changes in response to the error, and thus affects the speed at which the controller can respond to changes in the system. While a high proportional gain can cause a circuit to respond swiftly, too high a value can cause oscillations about the SP value. Too low a value and the circuit cannot efficiently respond to changes in the system.

This cable contains a DB-9 female connector on one side and a 17W2 male connector on the other side. Both views shown below are looking into the connector.

Numerical aperture meaningin physics

Note that when using the Ziegler-Nichols tuning method with some devices like the DSC1 digital servo controller, the integral and derivative terms must be normalized by the sample rate. To do this, the integral term determined from the table should be divided by the sample rate in Hertz and the derivative term should be multiplied by the sample rate in Hertz.

The ITC4002QCL and ITC4005QCL each offer two independent monitor inputs: one for photodiodes and one for thermopiles, either of which can be chosen for controlling the laser. The analog modulation via external input or the internal function generator allows modulation of the laser in CC and CP modes. A control output voltage proportional to the laser current is provided for monitoring purposes.

So what if the customer needs a numerical aperture of 0.25? To get this, at least one of the other specifications need to change. To do this, lets start with the initial specification for NA=0.25 and find what the f/# would be using this spec.

The ITC4002QCL and ITC4005QCL controllers can be controlled via front panel keys and intuitive operation menus on a large and easy-to-read graphic LCD display (see the Display tab for sample screens). Alternatively, these controllers can be controlled by a SCPI-compatible USB Interface. Higher settings and measurement resolution are offered via USB operation, since the front panel resolution is limited by the resolution and refresh rate of the front panel display. Various outputs and a digital I/O port offer many control and connectivity options. The built-in function generator allows analog modulation of the laser output out of the box.

The software download page also offers programming reference notes for interfacing with compatible controllers using SCPI, LabVIEW, Visual C++, Visual C#, and Visual Basic. Please see the Programming Reference tab on the software download page for more information and download links.

The lasers can be driven in either Constant Current (CC) mode, where the laser current is held precisely at the level adjusted by the user, or Constant Power (CP) mode, where an optical power sensor is used to monitor the output power of the laser for active power control. The CC mode is preferable when the lowest noise and highest response speed are required, but this mode generally requires temperature stabilizing as well. In CP mode, feedback from the internal photodiode integrated into most laser packages, an external photodiode, or other sensor is used to actively stabilize the laser's output power.

Integral control is highly effective at increasing the response time of a circuit along with eliminating the steady-state error associated with purely proportional control. In essence integral control sums over the previous error, which was not corrected, and then multiplies that error by Ki to produce the integral response. Thus, for even small sustained error, a large aggregated integral response can be realized. However, due to the fast response of integral control, high gain values can cause significant overshoot of the SP value and lead to oscillation and instability. Too low, and the circuit will be significantly slower in responding to changes in the system.

Please pay attention to the controller specifications when the CAB4007A or CAB4007B connector cables are used with a controller other than the ITC400xQCL controllers to ensure that the cables will safely connect to the controller(s).

Thorlabs' Combined Laser Current and TEC Controllers are designed with a high compliance voltages of 17 V (ITC4002QCL) or 20 V (ITC4005QCL), enabling support for our entire selection of Quantum Cascade Lasers (QCLs). These devices combine the functionality of an LDC4000 series current controller and a TED4015 temperature controller into a single controller. The ITC4002QCL and ITC4005QCL supply precise, stable currents for lasers with a maximum operating current of 2 A or 5 A, respectively. Both devices provide excellent temperature stabilization to within 0.002 °C over a period of 24 hrs. For optimal noise performance, choose a controller that has maximum current and voltage ratings as close as possible to, but still higher than, the required voltage and current needed to operate your laser.

Please note that a PID circuit will not guarantee optimal control. Improper setting of the PID controls can cause the circuit to oscillate significantly and lead to instability in control. It is up to the user to properly adjust the PID gains to ensure proper performance.

Thorlabs offers Laser Current and TEC connector cables to ensure safe and reliable connections between these controllers and the laser. The CAB4007A and CAB4007B dual LD / TEC connector cables are designed for use with HHL laser packages. The CAB4007A cable is designed specifically to connect the controllers to Thorlabs' LCM100(/M) Liquid-Cooled Mount for HHL Lasers. The CAB4007B cable is designed to be used to connect any standard 10-pin HHL laser package to our ITC400xQCL controllers. The CAB4005 LD Cable and CAB4000 TEC Cable are the standard, 5A connector cables that are shipped with each ITC4002QCL and ITC4005QCL. The CAB4001 TEC cable is a high-current cable rated for up to 20 A.

The CAB4007A cable connects the complete LCM100(/M) mount to ITC400xQCL series controllers via the 9W4 connector. The CAB4007B cable can connect any standard 10-Pin HHL laser directly to an ITC400xQCL series controller via the flat 10-Pin HHL female connector. The CAB4007B connector cable can be used with the LCM100(/M) mount when only the top cold plate is in use. For the pinout of the CAB4007A and CAB4007B cables, please see the Pin Diagrams tab.

Numerical apertureof lens

Numerical aperture (NA) refers to the cone of light that is made from a focusing lens and describes the light gathering capability of the lens (similar to f/# ). NA is defined by the following equation, where n is the index of refraction of the medium (often n=1 for air), and α is the half angle of the cone of light exiting the lens pupil.

These cables connect ITC4000 series dual current / temperature controllers to thermoelectric cooling elements. We also provide loose 17W2 connectors for customers who wish to make their own cables. Please see the Pin Diagrams tab for specific pinout information.

From here we can define the control units through their mathematical definition and discuss each in a little more detail. Proportional control is proportional to the error signal; as such, it is a direct response to the error signal generated by the circuit:

If the medium is not air, as is common for some microscope objectives, the approximation above can be multiplied by the index of refraction of the medium as shown below.

In order to equate NA and f/#, we can use simple geometric relationships. Figure 3.1 shows a simple lens focusing light rays (blue lines) from infinity to a point. This creates a cone of light that can be described by numerical aperture using the previous equation. The half angle, α, can now be defined by the following equation:

Unlike proportional and integral control, derivative control will slow the response of the circuit. In doing so, it is able to partially compensate for the overshoot as well as damp out any oscillations caused by integral and proportional control. High gain values cause the circuit to respond very slowly and can leave one susceptible to noise and high frequency oscillation (as the circuit becomes too slow to respond quickly). Too low and the circuit is prone to overshooting the SP value. However, in some cases overshooting the SP value by any significant amount must be avoided and thus a higher derivative gain (along with lower proportional gain) can be used. The chart below explains the effects of increasing the gain of any one of the parameters independently.

Ms.Cici

Ms.Cici

8618319014500

8618319014500