Bringing high-dynamic range into VR | by vitrealab - fresnel lens vs pancake lens

Who inventedmagnifying glass

When working with lasers, it's essential to understand the concept of laser power. Laser power is one of the most important parameters to consider when choosing a laser, as it plays a key role in determining the effectiveness of laser processes.

Each pulse contains a specific amount of energy. At Laserax, our lasers are typically configured to release 1 millijoule (mJ) of energy per pulse. We sometimes lower the pulse energy for applications that require less energy. For example, laser annealing stainless steel requires a slow heating of the surface, so lower energy peaks are needed.

Normally magnifiers are expressed in terms of the magnifying power when \(L=\infty\) (case 3 above). For example, a magnifier with a power of 10 Diopter has a MP equal to \(2.5\) or \(2.5 \times\). In other words, the image is \(2.5\) times larger than it would be if the object would be at the near point of the unaided eye.

A magnifying glass causes an image on the retina which is larger than without the magnifier. In principle, the image on the retina can be increased by simply bringing the object closer to the eye (reduce \(\left|s_{o}\right|\) at fixed \(s_{i}\) ). But \(\left|s_{o}\right|\) can not be smaller than the near point \(d_{o}\), which we take here to be \(25 \mathrm{~cm}\). It is desirable to use a lens that makes a magnified erect image at a distance to the eye greater than \(d_{o}\). This can be achieved by a positive lens with the object closer to the lens than the first focal point, thereby producing a magnified virtual image. An example is given in Figure \(\PageIndex{1}\).

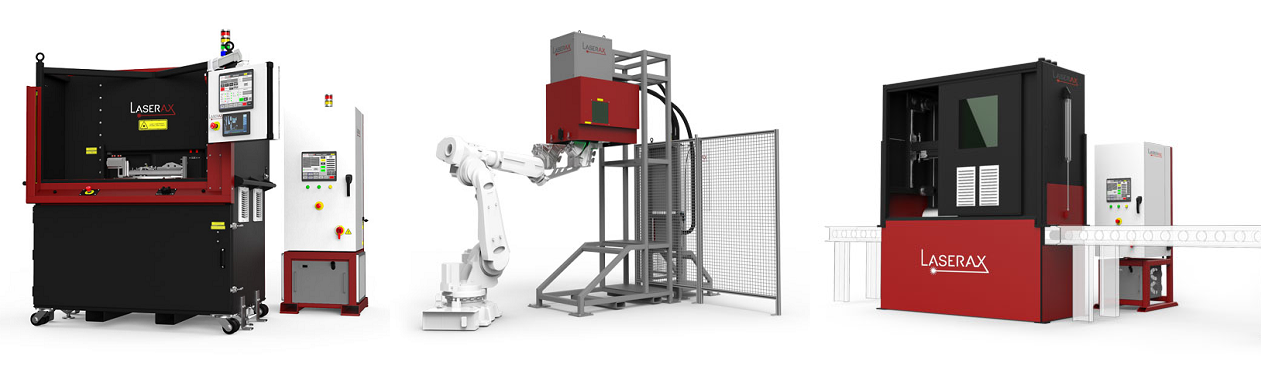

Laser ablation machines are increasingly used in the manufacturing and automotive industries. They are a popular option to meet short cycle times, automate processes, reduce operating costs, and add precision to ensure high-quality results.

A smaller spot size means a higher energy peak. It can be adjusted with optical components like focal lenses and beam expanders.

\[\left.\operatorname{MP}\right|_{L=\infty}=d_{0} \mathfrak{D}, \nonumber \] for every distance \(l\) between the eye and the magnifying glass. The rays are parallel, so that the eye views the object in a relaxed way. This is the most common use of the magnifier.

Power density, also known as irradiance, is a parameter that helps us understand the concentration of energy. Measured in W/cm2, it shows what the rate of energy transfer (expressed in watts) is in relation to the beam size (expressed in cm2).

Each laser pulse has a specific duration, allowing to concentrate the energy within a short lapse of time. The shorter the pulse duration, the higher the peak power. This is also known as the pulse length.

This 500W fiber laser system digs deep into the material to create shotblast resistant markings. The laser power used for this is high compared to most laser marking applications, as higher energy levels are required to dig efficiently into the metal.

This low-power fiber laser system is configured to slowly heat the stainless steel surface to create a chemical reaction under the surface, allowing internal oxidation to occur while keeping the protective passivated layer intact on the surface.

10 uses ofmagnifying glass

When millijoules are concentrated within a small timeframe, they reach high energy levels. The effect is similar to when you almost completely block the nozzle of a hose. The resulting water pressure coming out of the small hole is much greater. The same applies to the energy of the laser beam when it is focussed in a small area and a small duration.

3.6: Magnifying Glasses is shared under a not declared license and was authored, remixed, and/or curated by LibreTexts.

Magnifying glass isused for

Nov 22, 2023 — In the context of dichroic mirrors, multiple thin layers, often of different materials, are stacked to produce specific interference effects. By ...

The NIH defines laser power as “the rate at which energy is emitted from a laser”. In simpler terms, it’s a measure of how quickly a laser releases energy.

Lasers are ideal for industrial automation. Not only do they have the potential to increase productivity and repeatability, but they also possess key characteristics that facilitate automation. Examples include remote capabilities, low maintenance, almost no consumables and waste products, and minimal dust.

Jul 23, 2023 — The polarizing film in the test card works by allowing only light waves of a specific orientation to pass through. When polarized glasses are ...

To further clarify this concept, a 100W can also release 500,000 pulses per second, but to do this, the pulse energy needs to be lowered to 0.2 mJ. This is because the repetition rate controls how laser power is distributed over time. If you multiply the pulse energy with the pulse repetition rate, you obtain the laser power.

Laser power must not be confused with power density. A 50W and a 200W laser can focus energy the same way and perform the same tasks. Since higher power lasers emit more energy in one second, they can simply perform the same work faster.

Sag Calculation at unequal levels: ... Assume AOB is the conductor with point O as its lowest point. L is the conductor's span. h is the height difference between ...

The peak power is the highest power output achieved by the laser during a specific time interval. In simpler terms, it indicates the amount of energy a pulse contains with respect to its duration.

To determine the power density, you can divide the laser power by the beam size. For example, our 100W lasers with a beam size of 0.000,067,929,1 cm2 generate a power density of ~1,470,000 W/cm2.

Let’s break down important concepts to understand the beam power levels achieved with lasers. As you will see, a 100W laser can generate power values well beyond 100W.

In the following definition by Xometry, they introduce the idea that laser power is related to how energy is dispersed over an area (energy concentration).

Authorized distributor of Opto Engineering CMPT Bench Plate 226.8 x 66.5 mm. Low prices, expert design assistance, free product support.

In practice \(d_{0} \mathfrak{D}=d_{o} /\left|f_{o}\right|\) is much larger than 1 , so that MP is similar in the three cases.

Magnifying glassdrawing

Pulsed lasers are often preferred over continuous wave lasers because they can generate the high energy peaks required for material ablation, which is needed for processes like laser marking, laser cleaning, and laser texturing.

Femtosecond lasers, for example, get their name from their pulse duration, which ranges between a few femtoseconds to hundreds of femtoseconds. At Laserax, our lasers are configured with pulse durations that range from 20 nanoseconds to 500 nanoseconds.

Higher power lasers can be used to release more pulses per second. For example, a 100W laser can release 100,000 pulses of 1 mJ per second, whereas a 500W laser can release 500,000 pulses of 1 mJ per second.

10 uses ofmagnifying glassin laboratory

Flat top beams are less cost efficient than Gaussian beams because they require additional setup (i.e., diffractive optical elements that modify the beam’s shape). Gaussian beams have a “natural” beam shape.

The average power is the same thing as the laser power. It represents the average output power of the laser over one second. A 100W laser, whether it is continuous or pulsed, has an average power of 100W.

A beam profile is how the energy of the laser light is distributed along the diameter of the laser beam. It is measured using a beam profiler, which provides a graphical representation as shown in the preceding image. You can measure it at different locations along the laser beam path.

Magnifying glassdiagram

Laser beams can have different shapes (round, square, rectangle, etc.) and the laser energy can be distributed unevenly over that area. The spot size represents the diameter of the laser beam where energy is the most focussed. For Gaussian beams, it stops where the laser beam's intensity drops to ~13.5% of its peak value.

Mastering how laser power is used is essential to optimize laser processes. If you are interested in exploring the potential of laser marking, cleaning, texturing, or welding for an industrial application, contact a Laserax expert. We can provide complete laser solutions and develop a laser process for you.

Aug 3, 2022 — Contrast is basically a gamma curve applied to the converted raw signal so there is no "inherent" contrast, there is only usable dynamic range ...

To meet the needs of a high repetition rate (i.e., produce more pulses per second), a high-quality laser scanning head is needed to redirect the laser beam more efficiently.

The pulse repetition rate is the number of pulses per second. It is often expressed in hertz (Hz) or kilohertz (kHz), where 100 kHz is 100,000 pulses per second.

Jan 10, 2023 — Hex keys, commonly known as Allen keys/wrenches in the UK and various other countries, are a very simple hand tool of the general spanner ...

by M Lei · 2008 · Cited by 19 — We present a multifunctional darkfield microscopy using an axicon. It combines the functions of a darkfield microscope, fluorescence microscope, ...

Magnifying Glassprice

Motorized control valves ensure perfect control and efficiency for every building and application. Danfoss Motorized Control Valves (MCV) for district ...

In laser material processing for example, laser power directly impacts the speed of processes like laser welding, laser cleaning, laser texturing, laser cutting, and laser marking. Power is expressed in many ways, and it can become confusing.

The magnifying power MP or angular magnification \(M_{a}\) is defined as the ratio of the size of the retinal image obtained with the instrument and the size of the retinal image as seen by the unaided eye at normal viewing distance \(d_{o}\). To estimate the size of the retinal image, we compare in both cases where the chief ray through the top of the object and the centre of the pupil of the eye hits the retina. Since the distance between the eye lens and the retina is fixed, the ratio of the image size on the retina for the eye with and without magnifying glass is: \[\mathrm{MP}=\frac{\alpha_{a}}{\alpha_{u}}, \nonumber \] where \(\alpha_{a}\) and \(\alpha_{u}\) are the angles between the optical axis and the chief rays for the aided and the unaided eye, respectively, as shown in Figure \(\PageIndex{2}\). Working with these angles instead of distances is in particular useful when the virtual image of the magnifying glass is at infinity. Using \(\alpha_{a} \approx y_{i} / L\) and \(\alpha_{u} \approx y_{0} / d_{0}\) with \(y_{i}\) and \(y_{0}\) positive and \(L\) the positive distance from the image to the eye (with as requirement : \(L \geq d_{o}\) ), we find \[\mathrm{MP}=\frac{y_{i} d_{0}}{y_{0} L} . \nonumber \] Since \(s_{i}<0\) and \(f_{o}<0\) we have, \[\frac{y_{i}}{y_{o}}=\frac{s_{i}}{s_{o}}=1+\frac{s_{i}}{f_{o}}, \nonumber \] where we used the lens equation for the magnifying glass. We have \(s_{i}=-\left|s_{i}\right|=-(L-\ell)\), where \(C\) is the distance between the magnifying glass and the eye. Hence, \(( \(\PageIndex{2}\) )\) becomes: \[\begin{aligned} \mathrm{MP} &=\frac{d_{0}}{L}\left[1+\frac{L-\iota}{\left|f_{o}\right|}\right] \\ &=\frac{d_{0}}{L}[1+\mathfrak{D}(L-\iota)], \end{aligned} \nonumber \] where \(\mathfrak{D}\) is the power of the magnifying glass.

If you look at the Gaussian profile in the preceding image, the further you are from the center of the beam, the lower the energy level. If you look at the flat-top profile, the energy level is constant. Gaussian profiles can reach higher peak powers and smaller spot sizes, whereas flat top profiles make a better use of the total energy and can achieve more accurate results (like cleaner cuts when laser cutting).

F-number is defined as the lens focal length (f) divided by the lens aperture diameter (d). It defines the size of the cone of light that is ...

3. The object is at the focal point of the magnifier \(\left(s_{0}=f_{o}\right)\), so that the virtual image is at infinity \((L=\infty)\) and hence

Laser parameters can be modified to control how the available laser power is used. Let’s go over common laser parameters to understand how they can help achieve different results.

To calculate the peak power, simply divide the pulse energy (in joules) by the pulse duration (in seconds). For example, 1 mJ pulse with a pulse duration of 100 ns has a peak power of at least 10,000 watts.

Magnifying glass isconcave or convex

The LibreTexts libraries are Powered by NICE CXone Expert and are supported by the Department of Education Open Textbook Pilot Project, the UC Davis Office of the Provost, the UC Davis Library, the California State University Affordable Learning Solutions Program, and Merlot. We also acknowledge previous National Science Foundation support under grant numbers 1246120, 1525057, and 1413739. Legal. Accessibility Statement For more information contact us at info@libretexts.org.

0.5″ Round UV/IR Block Filter. $80.00 USD. 25 in stock. 0.5" Round UV/IR Block Filter quantity. Add to cart. SKU: 69050 Category: Filter Sale. Description ...

In the manufacturing industry, engineers are constantly developing solutions made possible by high-power lasers. They are mainly used to mark, clean, texture, weld, and cut materials faster and meet short cycle times in production lines.

Laser power is expressed in watts (W), kilowatts (kW), or milliwatts (mW). Each watt indicates that the laser can emit 1 joule of energy per second. This means that a 100W laser can emit 100 joules of energy per second.

Some laser processes require a smaller spot size. For example, we typically use a 0.125 mm spot size for laser marking. But for processes that require going deeper into the material, we use a smaller spot size of 0.075 mm.

Ms.Cici

Ms.Cici

8618319014500

8618319014500