Breadboards, Tabletops, Rails & Carriages - optical breadboard

Lateralchromatic aberration

Synopsys is accelerating the adoption of photonic IC technologies with a unified solution, which includes the OptoCompiler electro-optical IC design solution, the OptSim simulation solution, and Photonic Device Compiler for photonic device design and PDK development. Synopsys Photonic Solutions offer a unified design platform to help IC designers and photonic engineers innovate consumer, health and industrial applications.

Like electronic integrated circuits, they are fabricated in foundries using photolithography to pattern wafers for etching and material deposition. PICs are used in a wide range of applications, thanks to their small size and robust nature. These include: high-speed data transmission for the telecoms and datacoms sectors; optical sensing for the environment, medicine and life sciences; various imaging and scanning systems for civil security and industry; and lidar systems in the automotive sector.

VLC Photonics operates using the fabless business model to offer independent pure-play services, and collaborate with a global network of foundries, packagers and providers. The company can assess the feasibility of integrating any optical system into a photonic chip, and provide cost estimates, expected performances and foreseeable limitations. The whole integration process is covered, from the photonic modelling, simulation, design and layout, to the prototyping, packaging, die and wafer level testing or certification if needed. Stand-alone outsourced design services, foundry process design kit development, and fab reports can be provided.

Freedom Photonics is a manufacturer of photonic components, modules and subsystems. Its photonic integration platforms and semiconductor laser and photodetector technologies allow its products to be used in applications such as optical sensing, high-performance optical interconnects and fibre optic communications applications. Core photonic technology is available in indium phosphide, gallium arsenide and silicon.

Vendors that produce PICs include Ams, which acts as a foundry partner, offering semiconductor manufacturing capabilities. A number of industry process technologies are used such as 0.18µm and 0.35µm digital and mixed signal CMOS, high-voltage CMOS and BICMOS processes. The company’s ‘More than Silicon’ initiative meant that it moved from electronic to photonic integrated circuits, using a silicon nitride process. The foundry now also offers optical waveguides and functional building blocks in a PIC library

Ligentec manufactures PICs for customers in high-tech areas such as communication for ground and space applications, quantum technologies, lidar, and biosensors. The company leverages all-nitride-core technology, and offers a foundry service for its fabrication technologies in silicon nitride, which is operated by the firm’s process engineers.

As PICs are not as mature as electronic circuits, it is still critical to do extensive characterisation and testing for validating PIC designs towards production. To this aim, wafer level testing is strongly needed, and needs to be compatible to both vertical and edge emitting types of PICs.

Chromatic aberrationin lenses

White light is made up of a full spectrum of colors, as observed in rainbows or when light is split through a prism. Each different color has a different wavelength and is refracted at a slightly different angle.

iC-Haus develops and manufactures application-specific integrated circuits (ASICs) and has expertise in monolithic mixed-signal circuits and microsystems. It has in-house wafer backend, chip assembly and test facilities, as well as global subcontracted wafer foundry and assembly partners. Assembly is performed in standard plastic packages and, for the Opto and power ICs, in the chip-on-board/flex and flip-chip technique. Packaging can be customised, for example with multi-chip-modules; furthermore, the chip layout and circuit topology is tailored to customer’s individual requirements.

Sphericalaberration

Unsightly fringing can spoil fine detail in an image, but clumsy corrections can be too heavy-handed. DxO’s meticulous corrections ensure that images are corrected without any unwanted consequences.

Because chromatic aberration varies according to the focal length and distance, DxO algorithms factor in these two key parameters to correct chromatic aberration in RAW and JPEG images more effectively. As a result, the software removes colored outlines without degrading a photo’s color and detail.

Bright Photonics is an independent design house for PICs in silicon, III-V, SiN, silica and polymers. The company supports businesses and research establishments in PIC development from application ideas to prototypes and design for volume production. Bright also commercially supports the PIC design platform ‘Nazca-Design’ for lowering barriers to photonic technologies. Applications include sensing, data and telecoms, microwave photonics, bio-photonics and quantum technology.

Chromatic aberrationPhotoshop

PICs are similar to electronic integrated circuits, with the main difference being that PICs can perform functions for information signals imposed on optical wavelengths typically in the visible spectrum or near infrared 850 to 1,650nm

The company said that the global PIC market was valued at $5,790m in 2020, and predicted that it will be worth $21,649m by 2026, registering a compound annual growth rate of 22.4 per cent during the forecast period of 2021 to 2026.

Chromatic aberrationeffect

DxO algorithms correct chromatic aberrations by removing colored outlines without degrading the photo’s color and details.

The first transmitter PIC was the electroabsorption-modulated laser (EML), which was developed in 1987. Today, this cost-effective photonic hardware is also seeing high demand in applications such as data centres, according to the latest data from research firm, ResearchAndMarkets.com

Applied Nanotools is an integrated photonics foundry that specialises in rapid turnaround prototyping and low-to-mid volume production. The company uses electron beam lithography to achieve feature sizes of 60nm. An online design submission system is available, alongside a process design kit for the fabrication service.

The phenomenon of chromatic aberration occurs when the lens is unable to converge all the colors upon the same point. Chromatic aberration appears as red or purple fringing and is especially visible in areas of high contrast.

Chromatic aberrationin games

The second type of chromatic aberration is called longitudinal — or axial — aberration. This is when the different wavelengths of light are focused at points in front or behind the surface of the camera sensor.

Partow Technologies develops photonics and electronic technologies for communication and sensing applications, such as advanced photonic and electronic substrates and components. Its core technology is ultra-high vacuum surface activated bonding capability, which allows a variety of materials to be bonded at room temperature. The company provides a bonding service, and custom thin film and thick film fabrication services. It is developing advanced photonic components based on thin film lithium niobate and lithium tantalate bonded substrates.

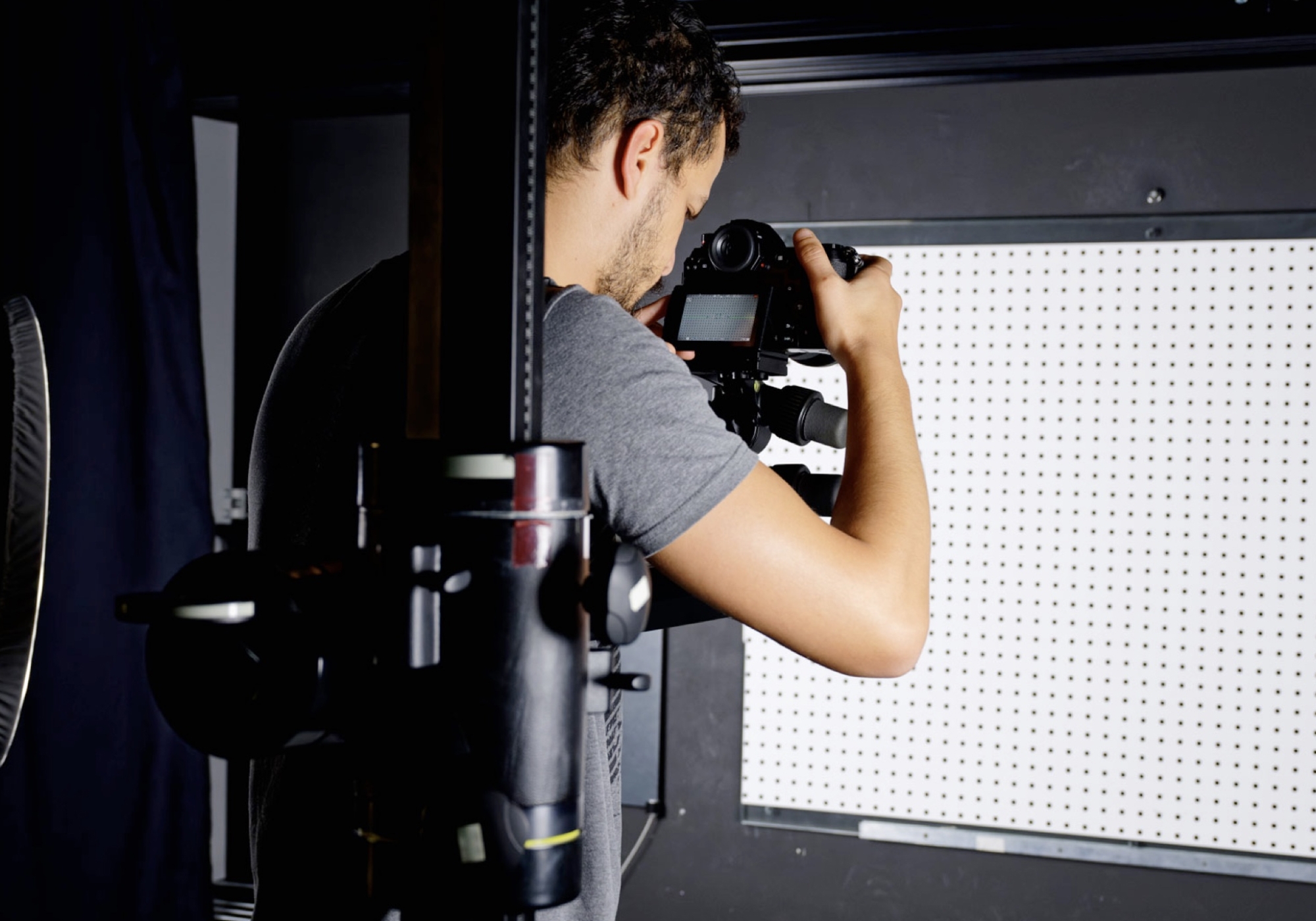

To assess the lateral chromatic aberration of a lens, images of a dot chart are taken with different focal lengths and distances. At different points in the field, DxO’s engineers calculate the maximum pixel distance between the different color components (red, green, and blue) of the same dot.

Chromatic aberrationexample

The resulting measurement makes it possible to establish a maximum chromatic aberration value on a precise scale. When the value is under 0.03 mm, it is not perceptible. Between 0.03 and 0.06 mm, it is visible. When the value is over 0.07 mm, it becomes problematic.

With the new VLC Photonics Wafer level testing services, companies can close design loop from fabricated to measured devices with massive data, allowing for statistical parameter modelling. Moreover, these massive data provide feedback for fab yield improvement, to accelerate product development and volume ramp up, as well as automate the identification of known good dies (KGDs) to sort dies wafers in production, and towards packaging. Find out more about wafer level testing services on the VLC Photonics website.

chromaticaberration中文

The amount of chromatic aberration in a photo depends on the type of lens used as well as other parameters: aperture value, focal length, and focal distance.

There are two types of chromatic aberration. The first is lateral — or transverse — chromatic aberration. This occurs when different wavelengths of light are dispersed across the surface of a camera’s imaging sensor.

Most lenses do a pretty good job of bringing the different colors together at roughly the same point, but sometimes, especially towards the edges of an image where there are strong transitions between light and dark, chromatic aberration can appear as red or purple fringing.

LioniX International offers PIC modules based on silicon nitride waveguides. Customised solutions are available for OEMs and system integrators, from design to fully assembled modules. PIC enabled modules are based on the company’s proprietary waveguide technology (TriPleX).

Eospace manufactures high-performance electro-optic integrated circuits and components for the designers and builders of next-generation optical telecommunication and photonic systems. Products use proprietary lithium niobate integrated optics devices to produce exceptionally low insertion loss and broad bandwidth devices.

VLC Photonics offers worldwide independent testing services for both vertical and edge emitting photonic integrated circuits (PICs) at wafer level. Photonic integration is gaining momentum and more people are looking at developing PICs for many applications, including optical transceivers, LiDAR, quantum and sensing among others.

DxO algorithms correct chromatic aberration by aligning the geometric position of each color in the scene being photographed.

A photonic integrated circuit (PIC) is a device that can integrate multiple photonic components such as interconnect waveguides and optical amplifiers, to form one photonic circuit.

This is not an exhaustive list. If you provide photonic integrated circuits and related products and solutions, and would like your company to be included, please let us know at editor.electro@europascience.com.

Infinera introduced the first large-scale PIC in 2005 and today offers the sixth-generation PIC in ICE6. Leveraging high-performance indium phosphide, Infinera’s PICs integrate a wide range of optical functions on a single chip. This reduces cost, footprint, and power consumption while improving performance and reliability. In addition, Infinera has invested heavily to build its own indium phosphide PIC fabrication facility.

Phix Photonics Assembly offers assembly services and contract manufacturing for photonic integrated circuits and MEMS. The company builds optoelectronic modules based on major PIC technology platforms, such as indium phosphide, silicon photonics, silicon nitride, and planar lightwave circuit. It specialises in chip-to-chip hybrid integration, coupling to fibre arrays, and interfacing of DC and RF electrical signals.

Sondrel is a provider of high-quality, complex system-on-chip designs across a number of markets, offering a turnkey ASIC service from system to silicon supply. Its designs have appeared in a variety of products including mobile phones, cameras, security systems, AR/VR systems and many more.

VPIphotonics integrates simulation techniques and professional design functions for integrated photonic devices, components, optical transmission system and network applications. Designed PICs cover applications such as coherent transmitters and receivers for advanced modulation formats, optical interconnects, recirculating optical buffers and reconfigurable delay lines, multi-ring filters and arrayed waveguide gratings, and other monolithically integrated or hybrid PICs based on silicon, indium phosphide or gallium arsenide substrates.

Interconnect is Lumerical’s PIC simulator. It verifies multimode, bidirectional, and multi-channel PICs. Creating a project in the hierarchical schematic editor provides an extensive library of primitive elements, as well as foundry-specific PDK elements, to perform analysis in the time or frequency domain.

Ms.Cici

Ms.Cici

8618319014500

8618319014500