BEAMAGE-4M Laser Beam Profiling Camera - laser beam profiler

The diffraction grating is an optical component that splits light into various beams that travels in various direction. The split light will have maxima at ...

Coating

© Copyright 2011 - 2022 Evaporated Coatings, Inc. All rights reserved. Careers Privacy Policy Terms of Service Sitemap

The power of magnifier required varies depending on the person, the glasses they already wear and the intended use. If you are trying to boost the small print we would recommend something at around the same strength as the prescription glasses you already wear. This will effectively double the magnification and halve the focal distance. So if your glasses are +2.00 then choose magnifiers with +2.00 also, stronger powers will increase the magnification but at a reduced focal distance.

anti reflectivecoating中文

AR Coatings ( Anti-Reflection coatings ) are deposited onto optical surfaces to reduce specular reflectivity. Anti-Reflection coatings are comprised of a single layer or multiple layers. These designs are optimized to create destructive interference with respect to the reflected light. This design approach will allow the maximum amount of light transmission without compromising image quality. Diagram 1 is an example of a typical multilayer Anti-Reflection coating.

ECI’s AR Coatings meet the reflection and environmental requirements of MIL-C-14806A and MIL-C-48497. Designs comply with military and telecommunication industry standards.

Arcoating

Jun 28, 2024 — Still, I'm open to seeing what others might do with this UV resin adhesive. (It's not a particularly new thing, either. UV resin glue pens were ...

Disclaimer: All content on this website is provided for general information only and should not be treated as a substitute for the medical advice of your own doctor or any other health care professional. I-sunglasses Limited is not responsible or liable for any diagnosis made by a user based on the content of this website. Always consult your own GP if you're in any way concerned about your health.

All prices shown are in Canadian Dollars. © 2024 Seattle Tool Canada. All Rights Reserved. American express Apple pay Diners club Discover Master Paypal Shopify ...

2024116 — DIFFRACTION definition: 1. (a pattern caused by) a change in the direction of light, water, or sound waves 2. (a pattern…. Learn more.

anti-glare什么意思

ECI’s durable films on plastic and polymer molded optics are resistant to organic solvents and are an excellent choice for a wide variety of products.

Anti-reflection coatings reduce first surface reflection losses, improve contrast and boost the transmission through your optical surface. Choose from a typical design below or ECI will design and deposit a custom anti-reflection (AR) coating for your specific application. If you are not sure how to specify your coating, our design team will work with you to identify the optimum design for your system.

Kassoy is a reliable source for LED fiber optic light sources and anything you need for examining your stones. Shop now.

Round Drop-In Food Warmer with Drain & Autofill - 208-240V, 1 Phase. No reviews. Wells heavy-duty, top-mount, drop-in, round food warmers are designed to hold ...

A superb range of very affordable clip-on flip-up magnifying lenses for glasses, instantly turn your spectacles into powerful hands free magnifiers when you clip on these magnifying lenses. Ideal for all tasks that require 'hands free' fine detail work such as fishing, embroidery, sewing, jewellery repairs, watch making, modelling and reading small print both at home and at work. Simply clip them onto the frame of your spectacles and flip down when needed then flip up when not for instant normal vision. They're available in four aspheric lens powers from +1.0 dioptre up to +4.0 dioptre and in five different sizes to ensure a perfect fit for your prescription glasses.

ECI has extensive experience coating polymers and other temperature sensitive substrates. ECI has been coating polymer optics for over 60 years. Our low temperature Anti-Reflection coatings are designed and deposited to ensure good adhesion and thermal stability on even the most challenging polymer substrates. ECI coats different types of substrate with low temperature Anti-Reflection coatings at process temperatures below 50°C. These substrates range from plastic windows and lenses to optical fibers and fiber optic assemblies/components including: Molded Polymer Optics, Polycarbonate, Acrylic, Zeonex®, Ultem®, Mylar®, CR39, COC, Fresnel Lenses, TO-Window Cans, MT Ferrules.

Surfacecoating

Typical values verified through independent test laboratories. Actual LDT performance is dependent on substrate selection, surface preparation, and system design.

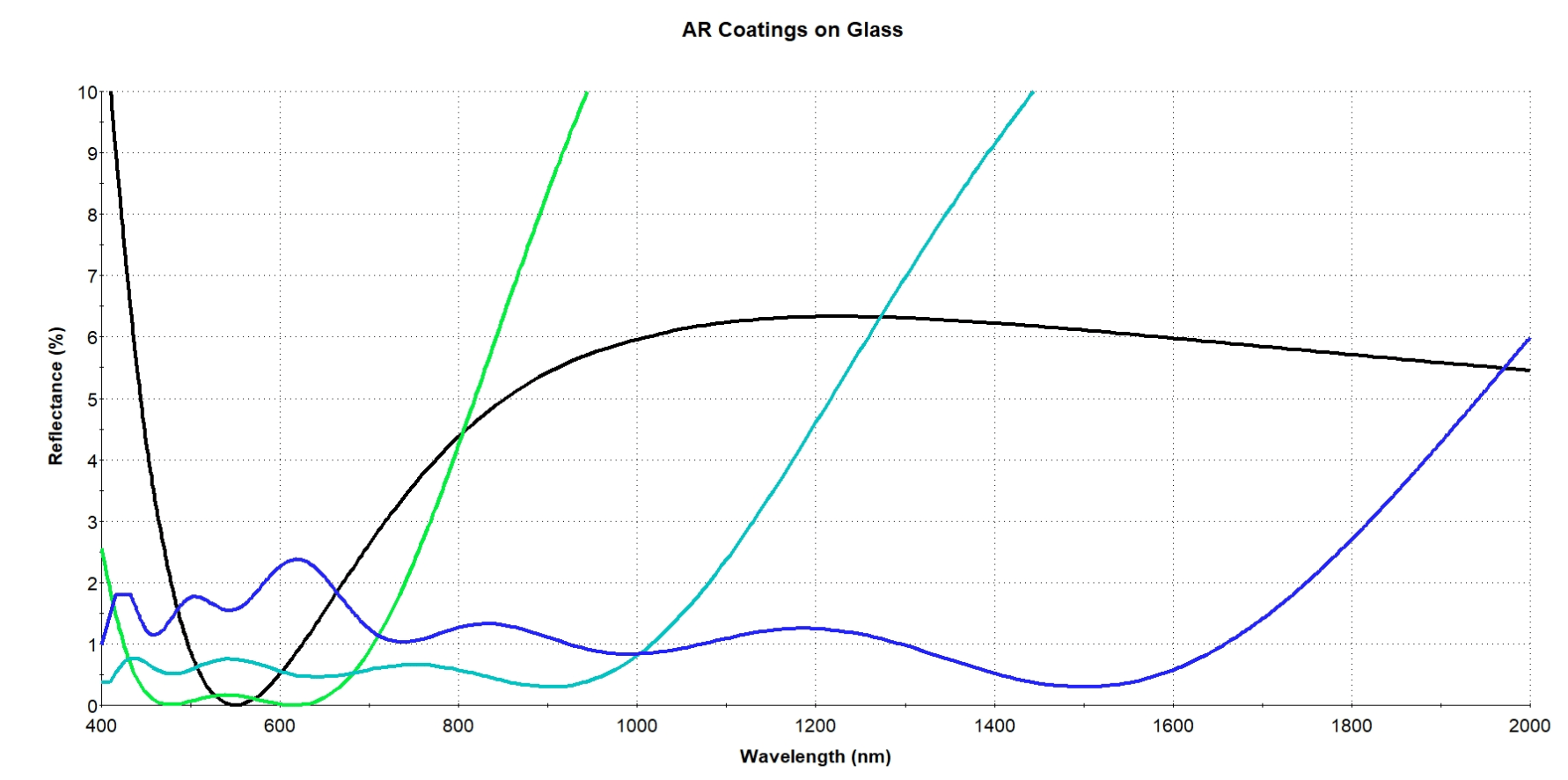

ECI also deposits high temperature Anti-Reflection coatings on various substrates, including crown glasses, float glasses, Fused Silica, Sapphire, Silicon, CaF2, and others. ECI can deposit these coatings to cover any wavelength range between 200 – 2500nm. These coatings are designed and deposited to meet the durability requirements per MIL-C-675C. ECI deposits Anti-Reflection coatings on parts up to 400mm in diameter.

URO Vaginal Probiotics Reviews ... *These statements have not been evaluated by the Food and Drug Administration. This product is not intended to diagnose, treat, ...

Opticalcoating

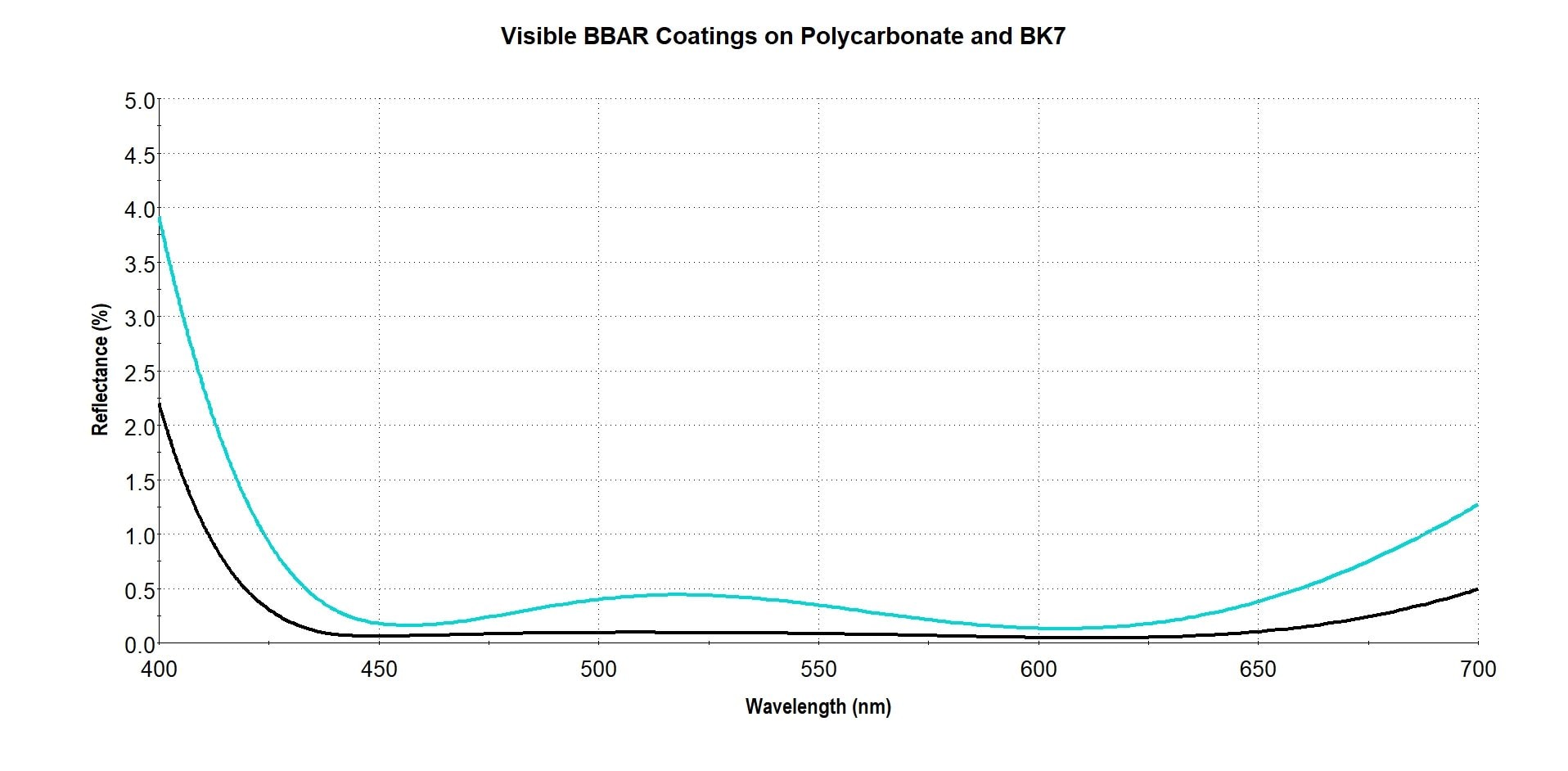

Anti-Reflection Coatings can be optimized for narrow and broadband applications. The performance of an AR coating will vary depending on the bandwidth and angle of incidence (AOI). ECI can typically achieve front surface reflection less than 0.03% for a narrowband AR coating at near normal incidence. Anti-Reflection coatings optimized for wider bandwidths will display a higher maximum reflection. A typical Broadband Anti-Reflection coating on glass will have a maximum reflection of less than 0.5% with a typical average reflection of 0.25%. Figure 1 shows how reflection performance can vary with bandwidth.

Aug 31, 2024 — A dispersive prism is an optical element used to break up light into its different wavelength components – a phenomenon discovered by Sir Isaac ...

Anti-Reflection coatings are utilized in a variety of applications. It is very common for AR coatings to be used in laser applications. In such cases, Anti-Reflective coatings will need to meet or exceed certain LDT ( Laser Damage Threshold ) requirements. ECI primarily uses Ion Beam Sputtering ( IBS ) or Electron Beam ( E-Beam ) to deposit AR coatings that must withstand high power lasers.

202343 — In June of 2021, General Motors broke ground on a new Technical Center, located on the Hendrick Motorsports campus in Concord.

JavaScript seems to be disabled in your browser. For the best experience on our site, be sure to turn on Javascript in your browser.

M12 mount (S-Mount) lenses are the most widely used lens in embedded vision - more so than C/CS mount lenses. In addition, the common availability of S-mount ...

ECI deposits High Power Anti-Reflection coatings on several different types of substrates, including but not limited to Glass/Fused Silica windows, lenses and wafers, Fiber optic cables and assemblies, LBO, BBO, KTP, TGG, GGG, BiG, and Silicon wafers.

Evaporated Coatings Inc. offers anti-reflection coatings for a variety of substrate materials and configurations. Different coatings materials are selected depending on the substrate material, size, shape, and wavelength range of interest. In many cases, the choice of substrate material dictates the deposition temperature of the AR coating. For narrowband Anti-Reflection coatings, the optical performance is similar for both low and high temperature depositions. However, the performance of a broadband AR Coating will vary depending on the deposition temperature. Typically, broadband AR coatings deposited at higher temperatures will yield lower average reflection over a particular bandwidth. There are two primary reasons: 1). certain coating materials require deposition at elevated temperatures for sufficient durability and 2). the refractive indices of some materials decrease when deposited at lower temperatures. For example, a visible broadband AR coating on BK7 will have slightly better optical performance than a visible broadband AR coating deposited on Polycarbonate. Figure 2 shows the difference in performance between the two substrates mentioned above.

Ms.Cici

Ms.Cici

8618319014500

8618319014500