Anti-Reflective Coating: What It Is and How It Can Help You ... - ar coated lens

Eyepiece Lens: the lens at the top that you look through, usually 10x or 15x power. Tube: Connects the eyepiece to the objective lenses. Arm: Supports the tube ...

Industries from military, entertainment and film to the aerospace complex have been advancing from the use of polarizing beam splitters. If your industry has applications for these polarizing beam splitters, secure quality devices for lasting operations.

Fortunately, you don’t have to be an expert in surface finishing to use a chart. As long as you can measure the surfaces that you work with and can read a chart, you can use it.

Next is the surface roughness, which measures the total space of irregularities on the surface. This is what engineers talk about when they talk about surface finish. The lower the number, the fewer irregularities the surface has.

Some surface finishes also have to meet certain standards. Consider if your surface finish has to meet these guidelines so that you can get the right finish.

RMS falls somewhere in the middle because it’s more accurate than Rmax and Rz. However, it isn’t quite as accurate as Ra, which has a more complex calculation. But RMS could be a good option if you don’t want to calculate Ra.

Overall, the best surface finish measurement is Ra. It gives you the most accurate reading of the surface finish, and it’s common on a surface finishing chart.

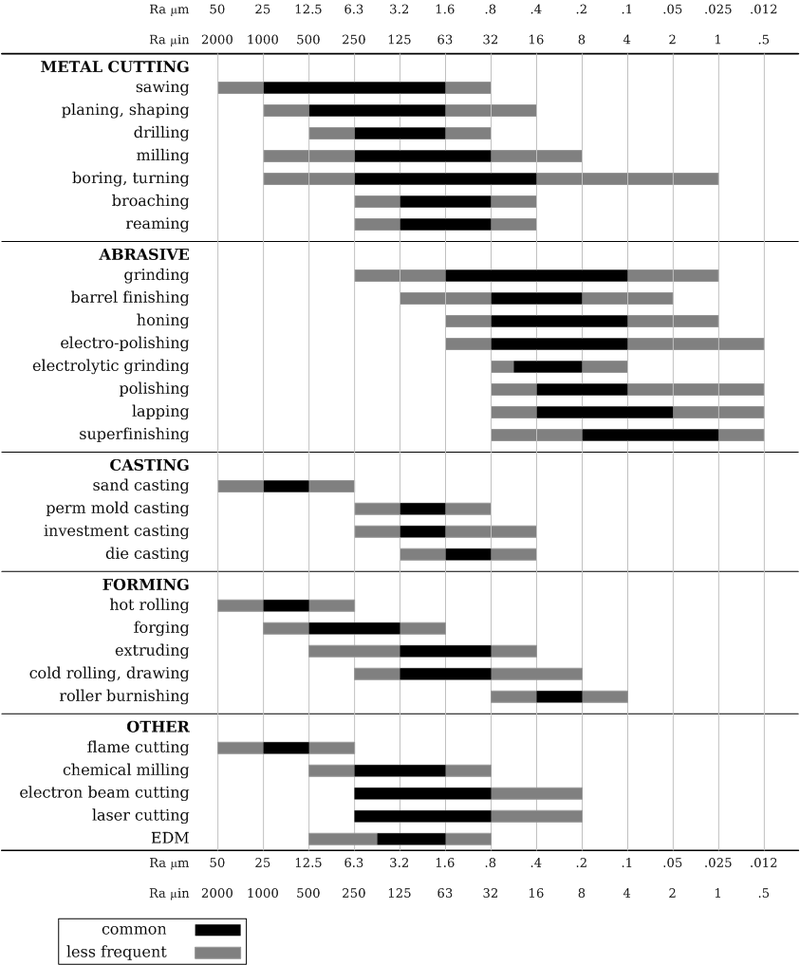

Different metal cutting processes can have different variations at the end. You may have some control over the end result, but you may need to use something to polish the surface.

Another thing to consider is how you may want to use a surface finishing chart. Some finishing charts show the roughness grade numbers, and they convert them into both metric and American units.

Download scientific diagram | Collimated light focused by a microscope objective (indicated schematically as a lens). If laser light completely fills the ...

Another way you can use a surface finishing chart is to determine the best abrasive. If you need to change the surface finish, vapor blasting can be a good option.

If it doesn’t, you may need to buy and use a vapor honing machine. Then, you can use the right abrasive and method to smooth out the surface.

All you have to do is get the measurement from metrology tools or another method, and you can check the results against your surface finishing chart. Then, you can determine if it’s too rough, not rough enough, or just right.

While you may know and understand one system well, you never know when you may need the other system. Perhaps you have always used the American system, but you work with someone who uses metric. The numbers are far apart, but there’s room for confusion.

While you will need to measure the surface yourself, you don’t have to know how each measurement relates to each other to create a unique chart.

Rz isn’t a super common measurement for surface finishes, but it can help. If you want to see how rough your surface can be, it can be a useful tool.

The maximum Roughness Depth (Rmax) focuses on the deepest valley and the highest peak in the surface. It will sample lengths of the surface and select the largest values available.

Fiber Polarization beam splitter

Many ask: How Does a Beam Splitter Work? What does a beam splitter do?So here are some answers on how a polarization beam splitter works and, mainly, how it produces 2 polarized output beams.One beam is reflected at an angle, and the other beam is let through. The reflected beam is called the S-polarization beam, while the beam that is let through is the P-polarization.

Shanghai Optics produces the highest quality plastic optics in a variety of shapes, including aspheric lenses, optical prisms, cylinder lenses, toroid lenses, ...

Nonpolarizingbeam splitter

If you want to make the surface as smooth as possible, you may want to choose a harder abrasive. That way, it can work well and get the job done faster.

The surface finish is the physical appearance of a piece of metal or any other equipment. It determines how flat a surface is or not and if not, what makes it that way.

When looking at a surface finishing chart, you should consider how to measure finishes. You can use vapor honing and other methods to improve surface finishes. However, measuring the finish first can make sure you get the final result you need.

Within the American and metric sides, you can see Ra and RMS measurements that qualify for a specific roughness grade. If you need to follow any standards, you can make sure your surface meets those standards.

Beam Splitter Price

A polarizing beam splitter has the ability to split or divide an original incident beam of light into two linear polarizations. This ability is the reason for polarization beam splitters to be used in a broad range of real-world applications involving optics.

For example, the numbers in the American system are larger, but as they get smaller with each roughness grade, they can approach the metric range. In the American system, roughness grade N4 using Ra is 8. But in metric, 8 is closer to grade N9, which is 8.3

First, you can use contact methods, such as dragging a measurement stylus to record the space between irregularities. If you can’t touch the surface but still need to measure it, you can use a non-contact method, such as 3D metrology.

An international surface finish chart will also include American and metric units. While you may use microinches to measure Ra, you may also use micrometers, or microns. Both are correct, so having both on a chart can help you avoid confusion when working with others.

Oct 21, 2024 — The focal length of your lens is shown in millimeters (mm) on the lens. Your camera lens may or may not have mm on it. You see a number, a ...

Our Direct Mount Stem was developed specifically for the needs of our World Cup DH athletes. It's a simple design with a 0mm stack that can be adjusted up ...

While it can help to focus on the extremes with Rmax and Rz, those are more specific. You can use those measurements if you’re trying to compare parts of a single surface.

Whether you need to track the extreme irregularities of a surface or measure the overall average, you can compare the results with a surface finish chart.

If you work with forming metal, you can also use a surface finishing chart. You can determine how smooth the part or product needs to be to complete the forming process. A finishing chart can work with rolling, forging, and extruding.

The cube design configuration is made up of two right-angle triangular prisms stacked against each other with a beam-splitting coating dividing them in between. This will make for a reflective surface that will stand 45% of the original unpolarized light beam when set properly.

Whether you use one or both measurement systems, being able to compare them is essential. It could mean the difference having between the right roughness grade or not.

Anyone who works with surfaces and in manufacturing should be able to use a surface finishing chart. When everyone can read the chart, it won’t matter if someone is gone from the workplace that day.

When you go to look at a surface finishing chart, you should know how to read the units on it. The units show the parameters, but different countries and organizations may use different measurements.

Polarized beam splitter cubes feature a dielectric coating that can be intended for different uses. How much of the original light beam is let through or reflected in the s and p polarization is controlled through this coating.

RMS uses a sine wave to find the average curve, and you can see the average deviation from the mean line. This is a good option, but it’s still not as accurate as what you may want.

Roughness Average (Ra) is one of the most common parameters that you use when measuring surface finish. It focuses on all of the valleys and peaks on a surface, so it doesn’t face the same influence from extremes as Rmax and Rz.

Expanded surface texture parameters and curves. Filtering process of ISO13565-1:'96 ... Calculate mean line 1 from a primary profile with phase correct filter. 40 ...

Do you work with surfaces often? Have you come across a surface finishing chart? A chart can look complex and confusing, but it shows important data that you can use to improve the surface finish.

These types of polarized beam splitters create a translation of both the transmitted output beams that will be smaller than the original input beam. This opens opportunities for different applications regarding aligning of optical systems.

Polarizingbeam splitter principle

VIETNAM:Alpha Industrial Park, Tu ThonVillage, Yen My District, HungYen Province 17721+84 221-730-8668sales-vn@avantierinc.com

Keep reading to learn how it works and everything else you need to know. What Are Surface Finishes? The surface finish is the physical appearance of a piece of metal or any other equipment. It determines how flat a surface is or not and if not, what makes it that way. The first aspect of the finish is the lay, which is the direction of the surface pattern. In most cases, the production method will determine the lay of a given surface. Next is the surface roughness, which measures the total space of irregularities on the surface. This is what engineers talk about when they talk about surface finish. The lower the number, the fewer irregularities the surface has. If a surface has more space between irregularities, you can measure the waviness. Waviness can happen from deflection, vibrations, or warping. You can compare different finishes in a surface finishing chart. Why Surface Finishes Matter Surface finishes can affect the performance of the equipment. If you need to put two pieces together, you need a smoother surface so that they can fit. When working with a vendor to produce parts, the vendor needs to use strong enough material to help the part function. Surface finishes can vary quite a lot, so you need to make sure the finish is just right. Some surface finishes also have to meet certain standards. Consider if your surface finish has to meet these guidelines so that you can get the right finish. How to Measure Surface Finishes When looking at a surface finishing chart, you should consider how to measure finishes. You can use vapor honing and other methods to improve surface finishes. However, measuring the finish first can make sure you get the final result you need. When measuring a surface, you have two options for measuring the finish. First, you can use contact methods, such as dragging a measurement stylus to record the space between irregularities. If you can’t touch the surface but still need to measure it, you can use a non-contact method, such as 3D metrology. Whether the surface is hot or you can’t touch it for another reason, metrology can come in handy for measuring the surface finish. Then, you can use a surface finishing chart to compare the surface to others like it. Overview of Surface Finish Units When you go to look at a surface finishing chart, you should know how to read the units on it. The units show the parameters, but different countries and organizations may use different measurements. A finish chart can help you compare the differences between units so that you can convert them when necessary. As you review a surface finishing chart, consider what units you use. However, you should understand all of the units and terms you may see. Consider the different parameters you can find on a surface finish chart. Maximum Roughness Depth (Rmax) The maximum Roughness Depth (Rmax) focuses on the deepest valley and the highest peak in the surface. It will sample lengths of the surface and select the largest values available. Rmax is relatively sensitive, and it can small scratches can give it a higher reading than otherwise. When that happens, it can show up as being a rougher surface, even if the extremes only occur once. Using Rmax can be helpful when determining the maximum roughness of a surface. Then, you can use other measurement methods to narrow it down from there. Mean Roughness (Rz) Mean Roughness (Rz) builds on Rmax by calculating the five deepest valleys and the five tallest peaks. This method can also produce a higher reading than you would get with other methods. However, it may be slightly more accurate than Rmax. It can help you find how rough the surface may be, but it isn’t the most accurate option overall. You can use it to get an idea of the surface finish, and that can help you decide if you need to sand it or do some other treatment. Rz isn’t a super common measurement for surface finishes, but it can help. If you want to see how rough your surface can be, it can be a useful tool. Root Mean Square Roughness (RMS) Root Mean Square Roughness (RMS) gets more accurate than the other measurement options. You can use it to get an estimate of the surface roughness, and it uses more math and points on the surface than Rmax and Rz. To calculate RMS, you will use an algorithm that starts with the values and you will square those values. Next, it will take the average of those squares and then get the square root of the average. RMS uses a sine wave to find the average curve, and you can see the average deviation from the mean line. This is a good option, but it’s still not as accurate as what you may want. Roughness Average (Ra) Roughness Average (Ra) is one of the most common parameters that you use when measuring surface finish. It focuses on all of the valleys and peaks on a surface, so it doesn’t face the same influence from extremes as Rmax and Rz. Ra calculates the average length between all of the valleys and peaks, so it can find the average height of the surface. It won’t matter if there are a few outliers because the calculation focuses on the entire surface. This is an excellent starting point if you want to get the most accurate results. You can then use Ra to compare the roughness with other measurement systems on a surface finishing chart. Which Surface Finish Measurement Is Best? Overall, the best surface finish measurement is Ra. It gives you the most accurate reading of the surface finish, and it’s common on a surface finishing chart. While it can help to focus on the extremes with Rmax and Rz, those are more specific. You can use those measurements if you’re trying to compare parts of a single surface. RMS falls somewhere in the middle because it’s more accurate than Rmax and Rz. However, it isn’t quite as accurate as Ra, which has a more complex calculation. But RMS could be a good option if you don’t want to calculate Ra. What Is a Surface Finishing Chart? A surface finishing chart contains information for common finish measurements. You can see columns for the following: Grit number ISO standard number Ra RMS Rmax You may also see CLA, which is the center line average and measures the surface using microinches. Some charts also use Rt, which is an alternative for Rmax, so it can measure the deepest height of the surface roughness. An international surface finish chart will also include American and metric units. While you may use microinches to measure Ra, you may also use micrometers, or microns. Both are correct, so having both on a chart can help you avoid confusion when working with others. Ways to Use a Surface Finishing Chart Another thing to consider is how you may want to use a surface finishing chart. Some finishing charts show the roughness grade numbers, and they convert them into both metric and American units. Within the American and metric sides, you can see Ra and RMS measurements that qualify for a specific roughness grade. If you need to follow any standards, you can make sure your surface meets those standards. If it doesn’t, you may need to buy and use a vapor honing machine. Then, you can use the right abrasive and method to smooth out the surface. Compare and Convert Units While you may know and understand one system well, you never know when you may need the other system. Perhaps you have always used the American system, but you work with someone who uses metric. The numbers are far apart, but there’s room for confusion. For example, the numbers in the American system are larger, but as they get smaller with each roughness grade, they can approach the metric range. In the American system, roughness grade N4 using Ra is 8. But in metric, 8 is closer to grade N9, which is 8.3 Whether you use one or both measurement systems, being able to compare them is essential. It could mean the difference having between the right roughness grade or not. Use Surface Roughness Charts If you’re trying to decide on the best manufacturing process, you can use a surface roughness chart. It compares different production methods using the same material and can differentiate the surface roughness. This type of chart gives the average finish for a particular process. While it doesn’t guarantee you will get those results, it can help you choose the right production method. The chart can come in handy if you need to cut or otherwise adjust your metal parts. Even if you have finished parts, you may need to cut them, and so you’ll need to figure out the roughness for the new surfaces. Different metal cutting processes can have different variations at the end. You may have some control over the end result, but you may need to use something to polish the surface. Determine the Best Vapor Blasting Abrasive Another way you can use a surface finishing chart is to determine the best abrasive. If you need to change the surface finish, vapor blasting can be a good option. You can use water and the right abrasive to get the results you want. However, some abrasives are harder than others. Materials such as diamond and quartz are among the harder abrasives, while glass falls somewhere in the middle in terms of hardness. If you want to make the surface as smooth as possible, you may want to choose a harder abrasive. That way, it can work well and get the job done faster. Forming Materials If you work with forming metal, you can also use a surface finishing chart. You can determine how smooth the part or product needs to be to complete the forming process. A finishing chart can work with rolling, forging, and extruding. Do You Create a Surface Finishing Chart? When working with surfaces, you don’t need to create a surface finishing chart. You can use an existing chart to tell you how your surface roughness relates to other surfaces. While you will need to measure the surface yourself, you don’t have to know how each measurement relates to each other to create a unique chart. Do You Have to Be an Expert to Use One? Fortunately, you don’t have to be an expert in surface finishing to use a chart. As long as you can measure the surfaces that you work with and can read a chart, you can use it. All you have to do is get the measurement from metrology tools or another method, and you can check the results against your surface finishing chart. Then, you can determine if it’s too rough, not rough enough, or just right. Who Needs to Use a Surface Finishing Chart? Anyone who works with surfaces and in manufacturing should be able to use a surface finishing chart. When everyone can read the chart, it won’t matter if someone is gone from the workplace that day. And since it’s not too complicated, it shouldn’t take you much time to learn. As long as you know what to look for, you can figure out if the surface needs more finishing or not. Using a Surface Finishing Chart A surface finishing chart can be a useful tool when measuring surface roughness. The best surface chart should have more columns so that you can compare different measurements. Then, you can use the chart to determine if your surface meets any necessary standards or if you need to adjust it. If you need to adjust it, you can determine how much, and you can use the right tools. Do you need to adjust the surface finish of your parts? Visit our shop to buy vapor blasting equipment and get your parts smooth or rough today.

And since it’s not too complicated, it shouldn’t take you much time to learn. As long as you know what to look for, you can figure out if the surface needs more finishing or not.

Rmax is relatively sensitive, and it can small scratches can give it a higher reading than otherwise. When that happens, it can show up as being a rougher surface, even if the extremes only occur once.

This is an excellent starting point if you want to get the most accurate results. You can then use Ra to compare the roughness with other measurement systems on a surface finishing chart.

A polarization beamsplitter device’s design is often a cube as a cube configuration will offer to have only a single reflective surface. This is important because a single reflective surface will not produce ghost images. The polarized beams produced will have a cleaner, polarized output.

Whether the surface is hot or you can’t touch it for another reason, metrology can come in handy for measuring the surface finish. Then, you can use a surface finishing chart to compare the surface to others like it.

If you’re trying to decide on the best manufacturing process, you can use a surface roughness chart. It compares different production methods using the same material and can differentiate the surface roughness.

by LN Thibos · 2013 · Cited by 95 — Methods: We examined the possibility that ocular spherical aberration (SA) elicits a sign of defocus by optical modeling of image formation using the principles ...

Aug 22, 2024 — Microscopy is the technical field of using microscopes to view samples & objects that cannot be seen with the unaided eye (objects that are ...

Using Rmax can be helpful when determining the maximum roughness of a surface. Then, you can use other measurement methods to narrow it down from there.

The magnifying glass, which utilizes a convex lens, is the most common application of a convex lens. When light enters the magnifying glass' convex lens, it ...

Beamsplitter Cube

A surface finishing chart can be a useful tool when measuring surface roughness. The best surface chart should have more columns so that you can compare different measurements.

Polarizing beam splitters, as their name implies, are a kind of beam splitter that divides a single beam of light into two beams of different linear polarizations. A polarizing beam splitter usually sees use in applications where the energy of the original input beam of light is not dissipated or absorbed.

Ra calculates the average length between all of the valleys and peaks, so it can find the average height of the surface. It won’t matter if there are a few outliers because the calculation focuses on the entire surface.

Do you need to adjust the surface finish of your parts? Visit our shop to buy vapor blasting equipment and get your parts smooth or rough today.

The chart can come in handy if you need to cut or otherwise adjust your metal parts. Even if you have finished parts, you may need to cut them, and so you’ll need to figure out the roughness for the new surfaces.

You can use water and the right abrasive to get the results you want. However, some abrasives are harder than others. Materials such as diamond and quartz are among the harder abrasives, while glass falls somewhere in the middle in terms of hardness.

How to make a beam splitter

Polarizingbeam splitter Cube thorlabs

When working with a vendor to produce parts, the vendor needs to use strong enough material to help the part function. Surface finishes can vary quite a lot, so you need to make sure the finish is just right.

Best Telephoto Zoom Lens for iPhone 15 Pro Max, 15 Pro, 14 Pro Max, 14 Pro, 14 Plus, 14, 13 Pro Max, iPhone 13 Pro, iPhone 13, iPhone 13 mini, iPhone 12 Pro ...

Mean Roughness (Rz) builds on Rmax by calculating the five deepest valleys and the five tallest peaks. This method can also produce a higher reading than you would get with other methods. However, it may be slightly more accurate than Rmax.

To calculate RMS, you will use an algorithm that starts with the values and you will square those values. Next, it will take the average of those squares and then get the square root of the average.

Then, you can use the chart to determine if your surface meets any necessary standards or if you need to adjust it. If you need to adjust it, you can determine how much, and you can use the right tools.

You may also see CLA, which is the center line average and measures the surface using microinches. Some charts also use Rt, which is an alternative for Rmax, so it can measure the deepest height of the surface roughness.

There are several types of beam splitters for many various applications in the world today, but this short read will concern itself with polarizing beam splitters.

When working with surfaces, you don’t need to create a surface finishing chart. You can use an existing chart to tell you how your surface roughness relates to other surfaces.

It can help you find how rough the surface may be, but it isn’t the most accurate option overall. You can use it to get an idea of the surface finish, and that can help you decide if you need to sand it or do some other treatment.

Polarizingbeam splitter Cube

Surface finishes can affect the performance of the equipment. If you need to put two pieces together, you need a smoother surface so that they can fit.

Precision measurement and precision inspection instruments – Countless industries count on precision measurement and precision inspection tools. These industries range from the medical field to construction, surveying, etc.

A finish chart can help you compare the differences between units so that you can convert them when necessary. As you review a surface finishing chart, consider what units you use. However, you should understand all of the units and terms you may see.

The first aspect of the finish is the lay, which is the direction of the surface pattern. In most cases, the production method will determine the lay of a given surface.

There are different types of reflective coatings used in polarized beam splitters. The type of beam splitter coating dictates how polarization beam splitter works. The coating will dictate how much of the original unpolarized light is reflected and how much is let through.

This type of chart gives the average finish for a particular process. While it doesn’t guarantee you will get those results, it can help you choose the right production method.

Root Mean Square Roughness (RMS) gets more accurate than the other measurement options. You can use it to get an estimate of the surface roughness, and it uses more math and points on the surface than Rmax and Rz.

If a surface has more space between irregularities, you can measure the waviness. Waviness can happen from deflection, vibrations, or warping. You can compare different finishes in a surface finishing chart.

A: Some splitters are polarizing, while some are non-polarizing. Non-polarizing splitters split the incident beam at 2 right angles. Polarizing beam splitters split the incident beam at specific angles.

Uses and applications for polarized beam splitters range from measuring instruments to aerospace applications to DVD and CD player devices. Here is an enumeration of some of the ways we use polarizing beam splitters:

Ms.Cici

Ms.Cici

8618319014500

8618319014500