Anatomy Of A Microscope | Teledyne Vision Solutions - what does an objective lens do on a microscope

Anti reflectivecoating iPad

ECI’s AR Coatings meet the reflection and environmental requirements of MIL-C-14806A and MIL-C-48497. Designs comply with military and telecommunication industry standards.

Anti-Reflection coatings are utilized in a variety of applications. It is very common for AR coatings to be used in laser applications. In such cases, Anti-Reflective coatings will need to meet or exceed certain LDT ( Laser Damage Threshold ) requirements. ECI primarily uses Ion Beam Sputtering ( IBS ) or Electron Beam ( E-Beam ) to deposit AR coatings that must withstand high power lasers.

Green laser pointers were first commercially sold in the year 2000. They operate at the wavelength of 532 nm. Laser diodes of this wavelength are not available so the green light is obtained by the use of "DPSSFD" laser technology.The process:-A very high-powered Infrared laser diode working at 808 nm pumps a tiny block of Nd: YVO4 that generates light at 1,064 nm. This feeds a potassium titanyl phosphate intracavity frequency doubler crystal that produces green light of a visible 532 nm wavelength. High-powered green lasers use lithium triborate instead of KTP.Features:-An infrared filter, which is behind the mirror completely, removes the radiation of infrared spectrum from the output beam. In order to reduce cooling problems and prolong battery life, some green lasers operate in pulse or quasi-continuous-wave (QCW) mode. The Class III a laser product gives an output power of 5mw. This is the one of highest-powered street legal laser. Some green lasers even have an output of 10 mw, which has a range of 20,000 feet in darkness. Some even have a 3-second delay feature as these are high-powered lasers and can blind a person. Some laser point extenders are also available. They work by using lenses to minimize the beam spread of a laser. Its price starts from 55$. Majority of them have a life of around 3000 hours.Applications:-Green lasers can be used for a variety of roles. They can be used as pointing devices. The ability to form a continuous line in the dark is an added advantage; this has lead to its usage as rescue lights as it can be seen from miles away. It as been used for laser light shows. It is also used for sky gazing as a person can pinpoint a star by using the green laser. It can also be as laser pointers for guns, rifles. In the movie Alien vs. Predator it was used as a pointing device on some G36k carbines.Advantages:-The green laser has many advantages. It is fifty times brighter than a red laser because of which it can be seen from miles away, this helps in being rescued if a person is lost. It can also be used in high-tech weapons for aiming purposes. Because of its high range, Green laser pointers can be equipped in different kinds of weapons. High and low temperatures do not affect the performance of Green laser pointers so in case a person is lost in a desert, he can still use Green laser pointers to call for help, in other case, even if a person is lost some where in mountains all covered with ice, he can still use it.Disadvantages:-Due to its high power it can permanently damage a person's eye. As it can form a continuous line of light that might reveal a person's position so it cannot be used in stealthy operations or by SWAT.Green laser is quite awesome but it should be used carefully.

Anti reflectivecoating spray

ECI’s durable films on plastic and polymer molded optics are resistant to organic solvents and are an excellent choice for a wide variety of products.

Anti-reflection coatings reduce first surface reflection losses, improve contrast and boost the transmission through your optical surface. Choose from a typical design below or ECI will design and deposit a custom anti-reflection (AR) coating for your specific application. If you are not sure how to specify your coating, our design team will work with you to identify the optimum design for your system.

Anti reflectivecoating material

ECI has extensive experience coating polymers and other temperature sensitive substrates. ECI has been coating polymer optics for over 60 years. Our low temperature Anti-Reflection coatings are designed and deposited to ensure good adhesion and thermal stability on even the most challenging polymer substrates. ECI coats different types of substrate with low temperature Anti-Reflection coatings at process temperatures below 50°C. These substrates range from plastic windows and lenses to optical fibers and fiber optic assemblies/components including: Molded Polymer Optics, Polycarbonate, Acrylic, Zeonex®, Ultem®, Mylar®, CR39, COC, Fresnel Lenses, TO-Window Cans, MT Ferrules.

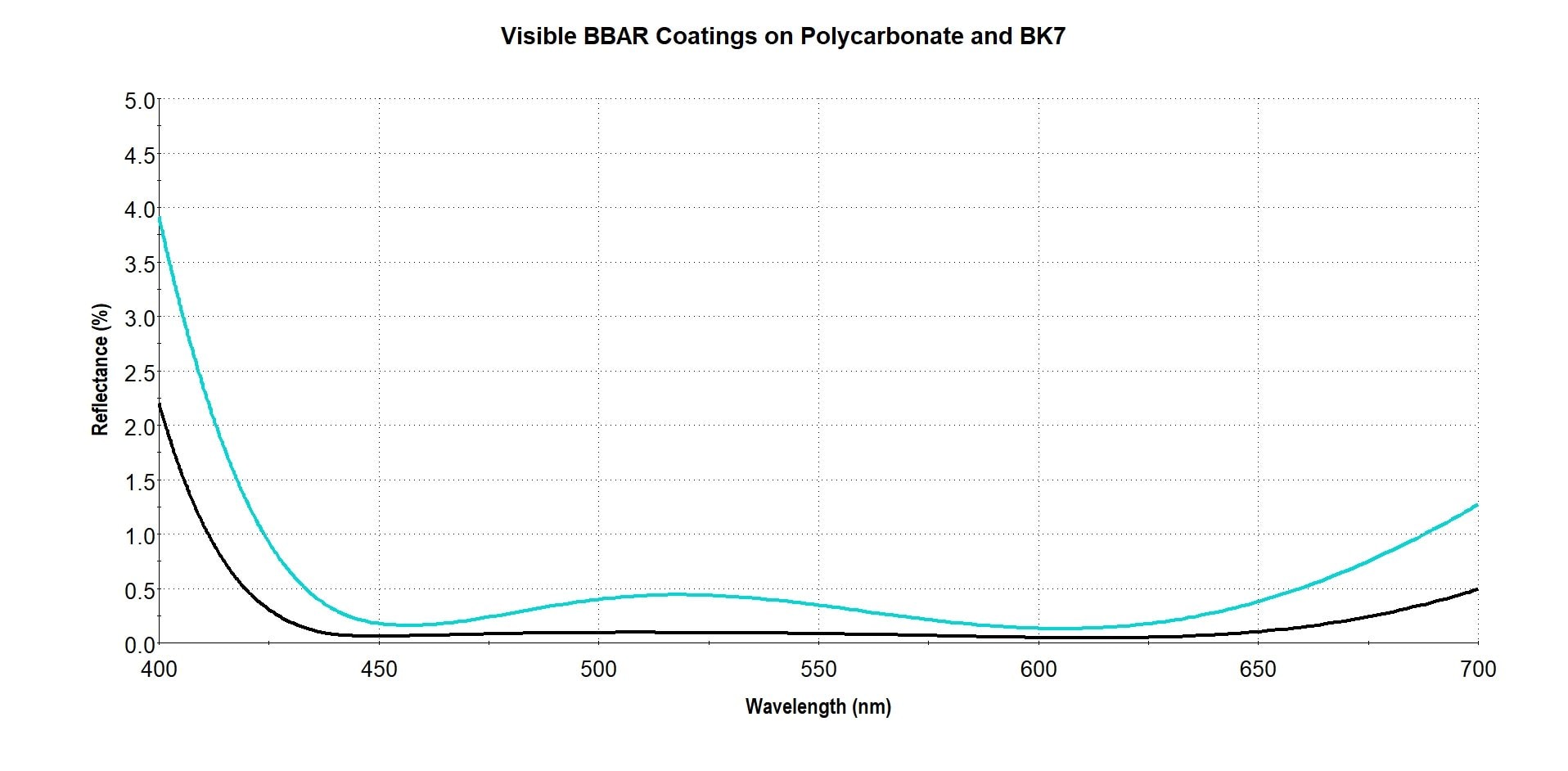

Evaporated Coatings Inc. offers anti-reflection coatings for a variety of substrate materials and configurations. Different coatings materials are selected depending on the substrate material, size, shape, and wavelength range of interest. In many cases, the choice of substrate material dictates the deposition temperature of the AR coating. For narrowband Anti-Reflection coatings, the optical performance is similar for both low and high temperature depositions. However, the performance of a broadband AR Coating will vary depending on the deposition temperature. Typically, broadband AR coatings deposited at higher temperatures will yield lower average reflection over a particular bandwidth. There are two primary reasons: 1). certain coating materials require deposition at elevated temperatures for sufficient durability and 2). the refractive indices of some materials decrease when deposited at lower temperatures. For example, a visible broadband AR coating on BK7 will have slightly better optical performance than a visible broadband AR coating deposited on Polycarbonate. Figure 2 shows the difference in performance between the two substrates mentioned above.

Anti reflectivepaint

Antireflection coating formula

ECI also deposits high temperature Anti-Reflection coatings on various substrates, including crown glasses, float glasses, Fused Silica, Sapphire, Silicon, CaF2, and others. ECI can deposit these coatings to cover any wavelength range between 200 – 2500nm. These coatings are designed and deposited to meet the durability requirements per MIL-C-675C. ECI deposits Anti-Reflection coatings on parts up to 400mm in diameter.

AR Coatings ( Anti-Reflection coatings ) are deposited onto optical surfaces to reduce specular reflectivity. Anti-Reflection coatings are comprised of a single layer or multiple layers. These designs are optimized to create destructive interference with respect to the reflected light. This design approach will allow the maximum amount of light transmission without compromising image quality. Diagram 1 is an example of a typical multilayer Anti-Reflection coating.

Antireflection coating principle PDF

Typical values verified through independent test laboratories. Actual LDT performance is dependent on substrate selection, surface preparation, and system design.

ECI deposits High Power Anti-Reflection coatings on several different types of substrates, including but not limited to Glass/Fused Silica windows, lenses and wafers, Fiber optic cables and assemblies, LBO, BBO, KTP, TGG, GGG, BiG, and Silicon wafers.

© Copyright 2011 - 2022 Evaporated Coatings, Inc. All rights reserved. Careers Privacy Policy Terms of Service Sitemap

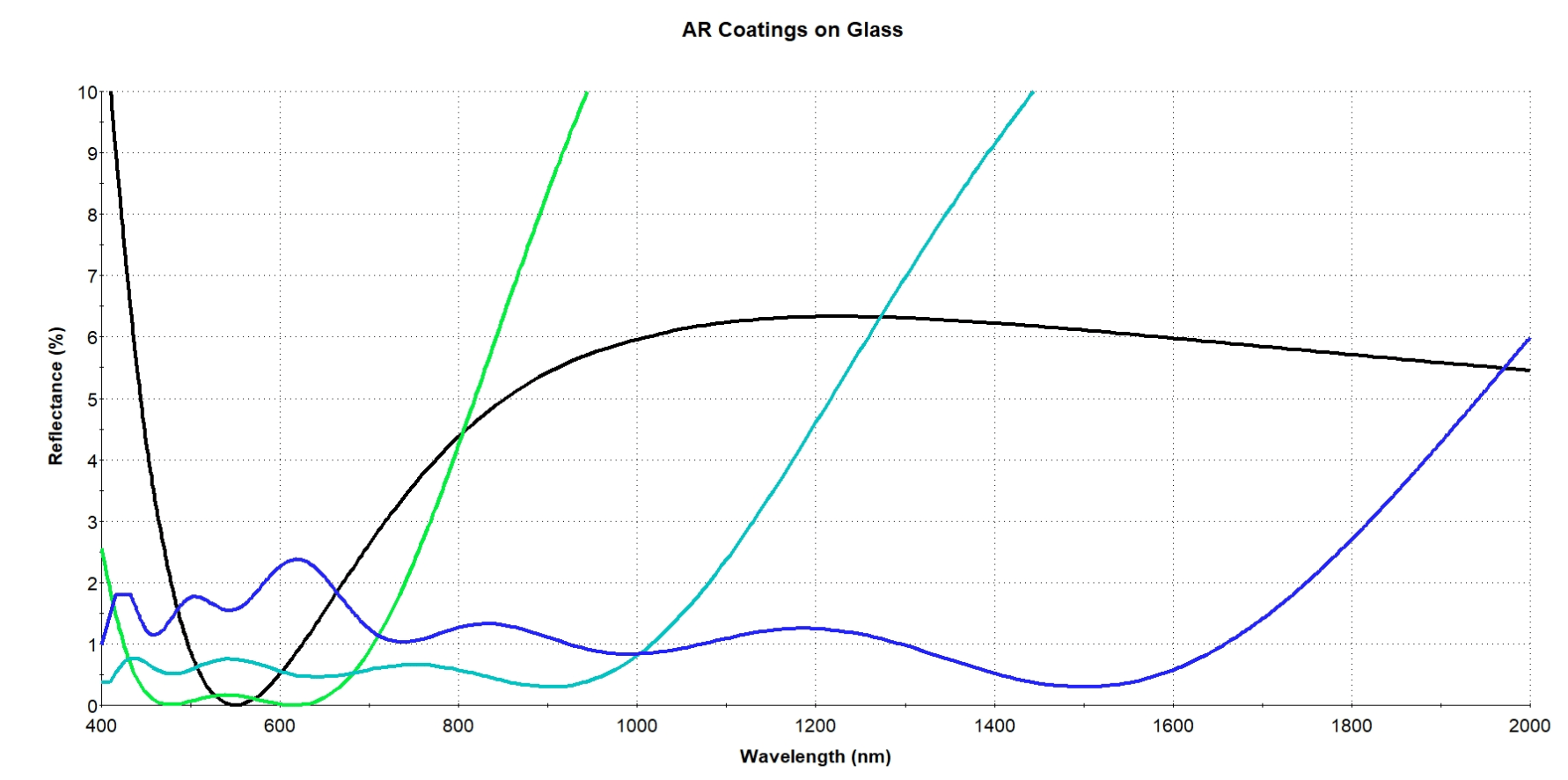

Anti-Reflection Coatings can be optimized for narrow and broadband applications. The performance of an AR coating will vary depending on the bandwidth and angle of incidence (AOI). ECI can typically achieve front surface reflection less than 0.03% for a narrowband AR coating at near normal incidence. Anti-Reflection coatings optimized for wider bandwidths will display a higher maximum reflection. A typical Broadband Anti-Reflection coating on glass will have a maximum reflection of less than 0.5% with a typical average reflection of 0.25%. Figure 1 shows how reflection performance can vary with bandwidth.

Ms.Cici

Ms.Cici

8618319014500

8618319014500