Am I Trans Quiz - transgender quiz mtf

Laser powerdensity formula

With drop-in filters, rectangular filters and Rota-Pols for cine matte boxes, circular polarizing filters are labeled with “this side out”.

The classic problem in 35mm film production was the video tap. Using a linear polarizer on a film camera with a video tap, could and often would cause the video feed to go dark because the partially silvered mirror in the video tap would get cross polarized. A very similar cross polarization is used to create Variable Neutral Density Filters with ND values between ND 0.6 (2 Stops) and ND 2.4 (8 stops). 8 stops means that only about 0.39% of the light gets past the filter. A Neutral Density Filter with an ND Value of ND 2.4 can be used to allow opening the aperture in a lens for shallow depth of field, or slow a shutter for various effects . . . it is not a good thing to do accidentally in an optical system with a mirror.

There are a number of important challenges that must be addressed when it comes to measuring high power beams. Some of the main ones:

Laser PowerMeter price

The main problem that the circular polarizer addresses is cross polarization on other reflective surfaces in your system such as mirrors and beam splitters. Reflective surfaces polarize light . . . which is why a polarizer can reduce or eliminate those reflections. If you have a mirror or other reflective surface inside your camera, a linear polarizer can cross polarize the reflected image and possibly black out the image.

In order to provide better service and products, please provide the following brief information. Any future resource requests will be automatically available.

Choose products to compare anywhere you see 'Add to Compare' or 'Compare' options displayed. Compare All Close

Since cavemen first figured out how to throw rocks and shoot arrows, our ability to precisely deliver power has come a long way. High-power laser beams, by delivering a lot of power into a small and precisely controlled space, now help us manufacture components that would have been difficult - if not impossible - using purely mechanical means. Automotive and aircraft manufacture, shipbuilding, and similar heavy-industry applications have been dramatically changed by the ever-advancing capabilities of laser technology.

The application of new, advanced technology in measurement devices, can help both designers and users of high-power laser systems to optimize and control their processes, so they can confidently accomplish their goals and achieve consistently good results.

We mentioned the 120K-W sensor earlier; this is the first commercial sensor (read: small size, fast response time) for measuring up to 120 kW. It's designed for fiber lasers used in such applications as industrial material processing, military directed-energy applications, and similar. It's very small, considering what it does - 50 cm deep x 50 cm diameter, with a 200 mm aperture. Because of the way it works, it's in a sense almost like a blackbody - less than 1% backscatter, minimizing safety hazards.

Laser power measurementpdf

At powers above a few tens of watts, we usually add a fan to help remove heat from the sensor. Although Ophir offers 2 fan-cooled sensors rated for 1.1 kW, water cooling is the usual solution for sensors rated for more than a few hundred watts. Most "regular" thermopile type sensors use the water just to remove the heat; some examples are shown below:

So if you are asking the question: "Do I need a circular or linear polarizer?", we hope we've given you enough information to make that decision.

Laser power measurementtable

Yes, opt-in. By checking this box, you agree to receive our newsletters, announcements, surveys and marketing offers in accordance with our privacy policy

Several standard Ophir meters offer "Pulsed Power" mode, meaning they "do the math" automatically; the user is prompted to enter the "pulse width", and the readout is in units of power. "Pulsed Power" mode enables the use of standard, small and inexpensive thermal sensors to measure powers as high as 10 kW - since total amount of heat to be dissipated by the sensor is actually low.

Our Rota-Pol a circular polarizer made to fit in 4"x5.65" cine matte boxes and allow quick and easy rotation by hand or with a motor:

Processes requiring less dramatic power levels also benefit; a single high-power beam can be "shared" among multiple parallel processing stations – and because they all use what started as a single beam, there can be much better uniformity and process control across these multiple stations.

Laser power measurementunits

With a circular pol, the quarter wave plate on the rear of the polarizer spins the light before it enters the camera lens so that it doesn't get cross polarized on any reflective surfaces in the system, such as the partial mirror in a video tap or a DSLR mirror.

Earlier we said that, although the focus in this article has been power measurement, "we will say a few words about beam profiling solutions toward the end". Okay then…

Notice the Alarm and Interlock module on the 16K-W-BB-55; this protects the sensor from overheating in case there is a failure of the water cooling system. Some sensors use a somewhat different design: the temperature rise of the cooling water, and the water's flow rate, are combined to enable measurement of the power. Some sensors using this method are shown below, including a large-format 6 kW sensor, and a unique sensor for measuring up to 120 kW:

It's also worth mentioning that when using Fiber Adapters at these high powers, the adapters themselves also need to be cooled! Note that highest power sensor for which we have standard FO adapters is the 400 W FL400A-BB-50. The "regular" adapters are not rated for more than that. With high power lasers, the delivery fiber itself is water cooled, as must be the fiber connectors. Ophir offers several models of QBH water-cooled fiber optic adapters.

Ophir offers "Scatter Shields" as an optional accessory. They absorb some of the backscattered light, and reflect some of it back into the sensor's aperture, reducing backscatter by some 70%.

Laser power measurementformula

A given process is designed to bring the beam to the needed power density in a precisely controlled location. Consider the following sketch:

Ophir's Helios is a compact industrial laser power meter designed especially with factory automation in mind. It is based on the same "Pulsed Power" concept as above, except in this case even the pulse width measurement is automatic, using an integrated fast photodetector. It measures up to 12 kW using a short exposure and therefore no water cooling. There are models for Profinet and EtherNet/IP.

Power – at the sort of levels were talking about, from maybe a few hundred watts to tens of kilowatts – is normally measured using a thermal sensor. Absorbed light becomes heat, and the resulting heat flow is proportional to the beam's power and is measured. The output can be a numeric readout on the display screen of a handheld meter, or perhaps the sensor interfaces directly with software running on a host system…It all depends on the specific needs of a given application.

Lindsey Optics offers both circular and linear polarizers in professional cine sizes in 4.5" Round Drop-In, 138mm Round Drop-In, and 4"x5.65" and Rota-Pols in 4x5.65" and 6.6x6.6" all with anti-reflection coating.

In still photography, SLR cameras and DSLR cameras have a mirror, which a linear polarizer can cross polarize, causing the image to darken or go black.

The way to prevent this is to monitor the relevant parameters of the beam with an appropriate level of accuracy. That way, you can catch any drift before it becomes a problem, and deal with it proactively.

Beam power and focal plane location inevitably drift with time and use – a result of aging of components, contamination of the focusing lens by process debris, misalignment of delivery optics, etc. When that happens, the space in which the power density is high enough to affect the material can then move or change shape:

"Exotic" applications such as military directed-energy weapons, once of real interest only to sci-fi authors, are now reaching maturity. Experts often mentioned the "magic number" of 100 kW, the power level needed to make such things practical. Thanks largely to advances in fiber lasers and their scalability, industrial materials-processing systems operating at 50 kW and even 75 kW are almost standard items now.

We mentioned the need to minimize footprint. So, how do we make a small sensor that can still measure high powers without overheating? The trick is to use a sensor designed for lower powers so that it's small, and then expose the sensor to the high power beam only for a short time – short enough that the total absorbed heat is low, but long enough for the sensor to measure it. The truth is, though, that this would mean the exposure has to be really short – in fact, shorter than the response time for power measurement! Enter "Pulsed Power" mode. Here's the basic idea:

As we mentioned, a sensor needs to be able to withstand not only the total power it will face but also the power density. Some important ways to prevent damage:

Laser PowerMeter Thorlabs

Parameters that are not controlled can unexpectedly change what the process is doing and where it's doing it. That can make your process unpredictable; in the case of an industrial, commercial process - it can eat into the profits the process is supposed to be generating.

Laser powerMeter Ophir

The two laser parameters that are most typically the critical ones in high power laser processes are power density and focus location (and shape). Additional parameters sometimes become important and need to be measured, including pulse energy, actual beam profile (which determines the "focus-ability" of the beam), beam position and size (less than a full profile), and others.

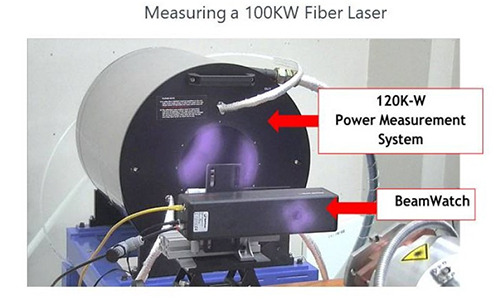

Here we see a 100 kW beam from a fiber laser, with its power being measured by a 120K-W sensor. The beam first passes through a "BeamWatch" non-contact high-power beam profiler. This unique instrument is based on a physical property of light known as Rayleigh Scattering, where the highly-concentrated light around the laser's beam waist is scattered off air molecules in its vicinity and captured by the camera. This allows for an analysis of the laser's waist without coming into contact with the beam. The result is a beam analyzer with no water cooling required, no moving parts, and no upper limit in the power of the laser being analyzed. And, since it is a camera-based system, it provides data at video rates; this allows the user to see more time-based characteristics of their laser system.

Of course the meter will need to "know" that the scatter shield has been added; there is a separate calibration factor ("Laser" or wavelength setting) for the "scatter shield in" condition.

Circular polarizers for cinematography are marked to show proper orientation, but mistakes happen. If you have no mirrors or reflective surfaces in your system, such as a mirror or a beam splitter . . . then the Linear-Pol will not cause you any trouble and you can’t put it in the matte box backwards, which might save you some time and trouble.

Focal spot analysis is done using various types of beam profiling technologies. In this article we'll focus mainly on power measurement, but we will say a few words about beam profiling solutions toward the end.

The linear polarizer element in a circular polarizer needs to be out front, pointed at the world, with the quarter wave plate on the rear side, the camera lens side. A circular polarizer doesn’t work if you get it in backwards. With a screw-in filter that’s no issue, there's only one way you can screw it on the lens..

Polarizers used in cinematography are often inserted in a matte box so there's an opportunity to insert a circular pol backwards and it doesn't polarize when inserted incorrect.

Circular Polarizers contains a Linear Polarizer component that does the main work of polarization, as well as a second layer inside the filter called a Quarter Wave Plate, which “spins” the light after it goes through the linear layer and before it enters the camera lens.

The short answer is that both Linear and Circular Polarizers do the same thing. The actual polarization effects such as reducing reflections on glass surfaces, increasing color saturation in foliage, darkening a blue sky are the same with both Linear and Circular polarizers.

Ms.Cici

Ms.Cici

8618319014500

8618319014500