Alltest Surplus - alltest instruments

LEDlightguide panel

There are not many constraints that limit our liquid light guides' use. One of the few is that their cross sections have to be circular; another is that they can only tolerate extreme temperatures for short periods. Apart from the end fittings, which are very robust, they work best in environments that people find comfortable.

Liquid light guides are clearly superior to light guides made of silica fiber bundles by the very nature of their design. A liquid light guide is much like a single silica fiber with a very large diameter. It has the cross-section of an open pipe, transmitting light with total reflectance using all the space available. Silica fiber bundles, in contrast, are like many small tubes in a larger pipe with spaces between the individual strands remaining unused. These dead spots do not transmit light. This is why our liquid light guides are able to deliver light with much greater intensity to the target object.

Lightguide meaning

Users should follow safety guidelines provided by the equipment manufacturer, which often include wearing gloves, protective eyewear, and working in a clean environment to prevent the introduction of new contaminants during cleaning. Additionally, users should be cautious when handling cleaning solutions and chemicals.

Yes, Elma precision optic cleaning equipment is suitable for a wide range of optical components, from laboratory-grade optics used in research and scientific applications to commercial optics found in cameras, telescopes, microscopes, and eyeglasses.

Lightguide design guidelines

Yes, precision optical cleaning equipment is compatible with Jayco Chemical optical cleaning solutions that are designed specifically for cleaning precision optics. The solutions are gentle on delicate optics while effectively removing contaminants.

Flexible fiber opticlightguide

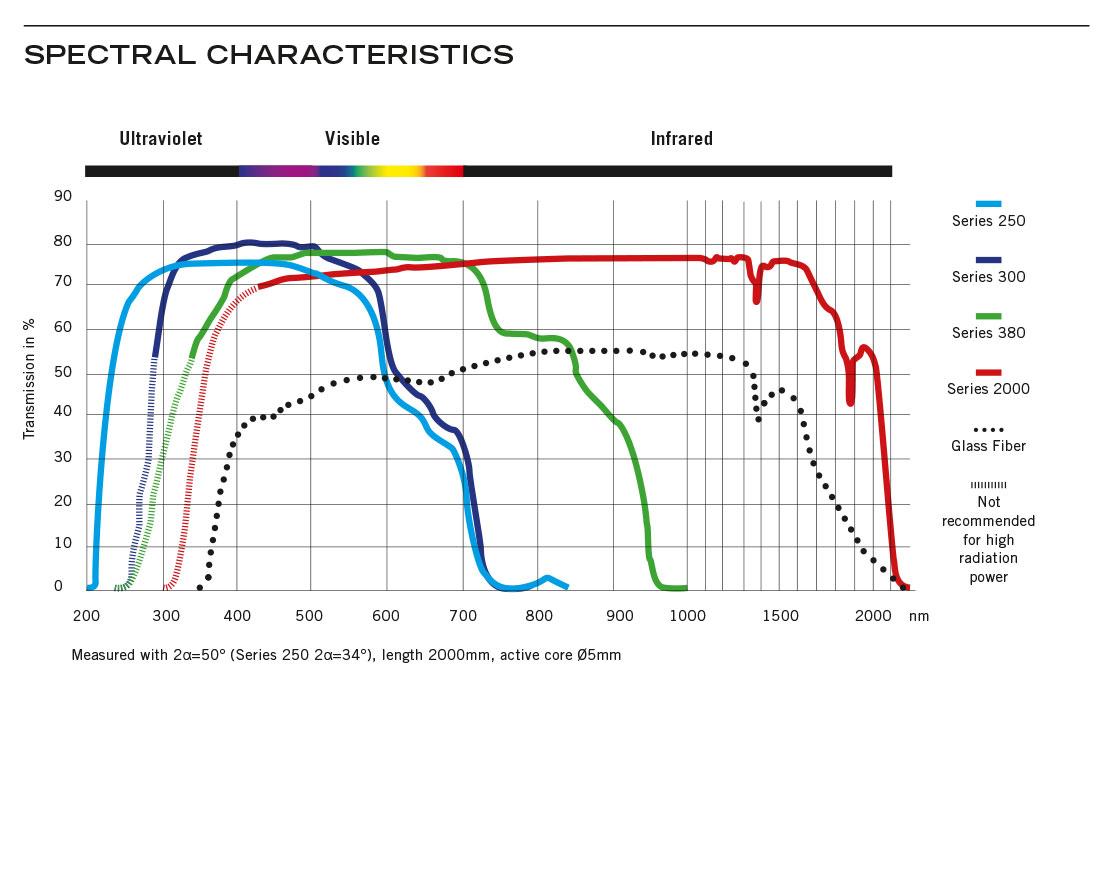

To date, we have developed four types of liquid light guides that differ mainly in terms of their liquids' optical properties. The charts and tables below show the various transmission spectra and other specifications of our light guides. Our light guides are available in various cross-sections and with a range of sleeve types to fit your needs. We also offer a selection of connectors with up to four poles.

We've cleaned practically all traditional and emerging manufacturing process soils used to produce lenses, mirrors, and other optical components.

LightGuide Optics

Feel free to talk to us if you wish to learn more about our liquid light guides. We'll be happy to discuss which options are best suited for your purposes. The possibilities are many, and we're always exploring fascinating new applications with our customers.

Precision optical cleaning equipment is a specialized system designed to clean optical components, such as lenses, mirrors, and prisms. These systems are crucial because even minor contaminants can degrade the performance of optical systems, leading to reduced clarity and accuracy.

We understand that in industries like medical, optics, aviation and hydraulics, high performance and precision cleaning are critical. When you have the reliable equipment you need, you don’t have to worry about falling behind on production, inefficient cleaning and other negative consequences that are beyond your control. With JAYCO Cleaning Technologies, you can depend on precision, knowledge and service that goes beyond expectations. Our expertise in industrial parts washing exceeds any other company in the market.

Our deep understanding of precision optical parts cleaning provides the best solution for you - no guesswork, just results.

The Jayco system uses ultrasonic cleaning which implodes bubbles, cleaning dirt and other contaminants off of optics like lenses and mirrors.

Jayco has been delivering certified cleaning systems for over 15 years to some of the leading OEM and Tier 1 optical component manufacturers in North America.

Lightguide design

Common contaminants on optical components include dust, fingerprints, smudges, oils, and environmental particles. The Elma X-tra precision optical cleaning system employs methods such as ultrasonic cleaning to remove these contaminants without scratching or damaging the delicate surfaces of optics.

Ledlight guides

Our liquid light guides consist of a polymer tube with a liquid core. They do not break. Bundles of optical fibers, in contrast, will fatigue if they are frequently bent and eventually break. LUMATEC liquid light guides have much larger apertures, are more efficient and serve many different applications. They are the perfect solutions for applications that demand uniform, high-intensity light. We offer devices designed for diverse spectra ranging from ultraviolet to infrared and a broad selection of end fittings.

Jayco has experience with providing proven cleaning solutions that meet strict specifications for final clean before coating application and assembly.

Edmund Optics chose Jayco to invest in a fully automated & validated final cleaning processes for their lenses and mirrors.

Ms.Cici

Ms.Cici

8618319014500

8618319014500