Allen Wrench - 5/64 - 5 64 allen wrench

For wavelength division multiplexing your 100 different wavelengths could each be produced by an individual laser. They could then be sent through a single mode optical fiber and then your could collect the light coming out of the optical fiber. That ligh does each wavelength will be fairly nice almost Gaussian spot that will diverge. You could put a collimating lens where the spot is 5 mm and get a collimated beam. It would act pretty much like a Gaussian beam.

After completion of the cutting job, you will receive a message that your materials are ready to be picked up. If you need us to deliver the materials to your site we will make those arrangements.

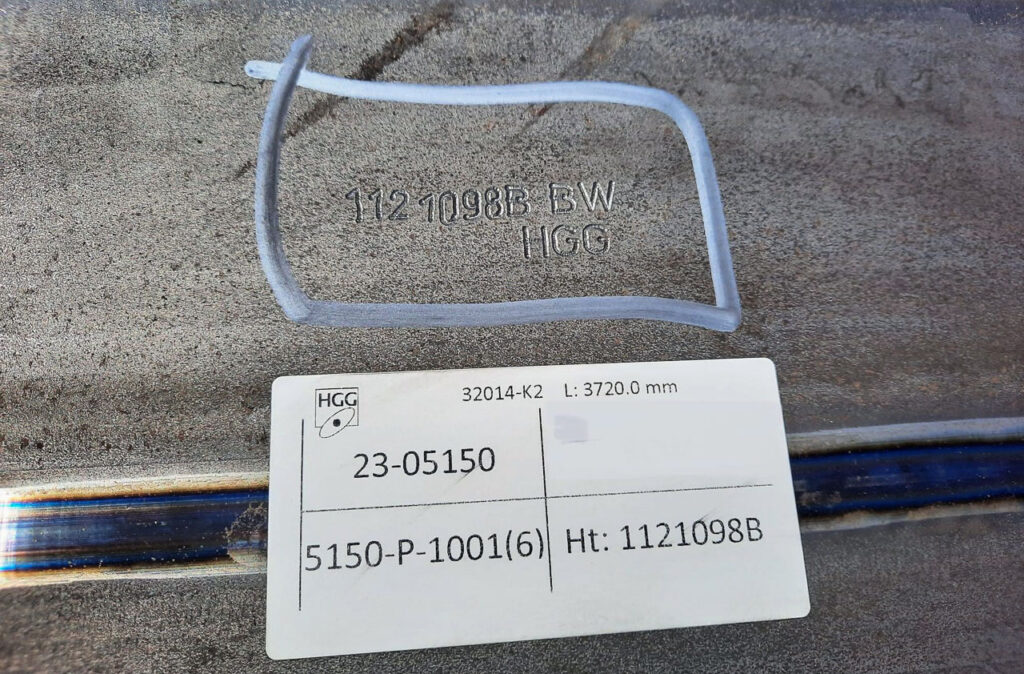

We are certified by Lloyd’s Register Nederland B.V. to transfer markings and numbers and issue inspection reports 3.1 and 3.2 in accordance with EN 10204:2004.

We specialize in profiling beams for both welded and bolted connections, serving a wide range of industries including infrastructure, offshore wind, process industries, and steel construction. Our advanced profiling process ensures exceptional accuracy, and we offer additional features such as welding edges, ratholes, holes, and slots for increased versatility.

But in the big picture, if you start out with a nice beam, you can usually use a lens or a set of lenses to collimate the beam, and each wavelength can be treated as a slightly different problem.

In addition to the final cuts, we can add holes and slots for various applications. These can also be prepared with the desired welding preparations, such as a ½ V-groove or X/K-groove.

We are flexible with our drawing guidelines; however, we do prefer the options listed below for a speedy process. If you have a different file format or need assistance in preparing your files, feel free to contact our team.

Before collimating, the beam will have diverged a bit to a radius of 5cm, the range of the wavelengths is 1400-1600nm and I don't want to lose more than 30% of initial power.

Laguerre Gaussbeam

I'm asking in general how to collimate it, but my idea was use a parabolic mirror, then focus all wavelengths into a very short optical fiber, then get the light back into vacuum. Would this work? Is there a better way?

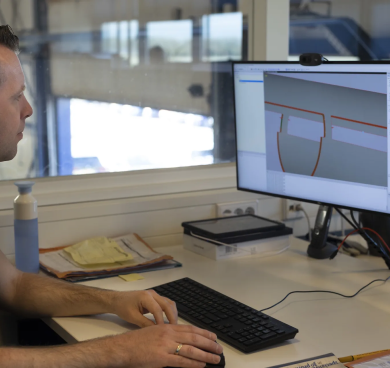

We convert STEP files into cutting files with HGG’s ProCAM. Our system reads STEP files in freeform shapes without relying on macros, providing you with design freedom.

There are some details, each wavelength will travel at a slightly different speed through the fiber due to waveguide dispersion and material dispersion.

Gaussianbeam

Based on your data, preferably in STEP format, we send you a tailored project quote within a few days of your request. If you regularly outsource projects with us, we are eager to take it a step further by establishing a partnership. Assuring you with production capacity and price stability.

With our modern machinery with a large range, HGG takes care of all your profile cutting work within the requested delivery time. Due to our large storage area and machinery, HGG has a large capacity.

With our advanced software, we cut any desired shape, resulting in less fit time, welding volume and welding time. You will receive a complete construction kit from us, including the desired welding pre-treatment and any markings and fit lines.

Laser M2

No extra post-processor is required because HGG’s ProCAM can import and read data for DSTV (NC/NC1) files. Enriched files, with a 3rd party post-processor are also possible.

Various beam profiles, including UNP, HEA, and HEB, can be efficiently handled in a variety of sizes and lengths up to 24 meters.

Laser cutting

HGG is active in various industries and takes a lot of manual work off your hands by cutting a wide variety of profiles, making it an extension of your workshop.

Our machines can apply reference lines and footprint markings using either a needle or plasma. This not only speeds up fitting time but also ensures higher quality. By incorporating these markings into your engineering plans beforehand, we can replicate them directly in our production process.

Beamdivergence

Each wavelength will have a little bit of chromatic dispersion due to the lens, unless you choose to use a special lens.

From our 40 years of 3D profiling experience, we know that every cut can be different. We assist you in the preparation of your project. From engineering, to welding details to optimizing material usage.

Good lasers have Gaussian beams. Gaussian beams are never perfectly collimated, but larger diameter beams have a small beam divergence. To get a larger diameter beam, use a beam expander.

Stack Exchange network consists of 183 Q&A communities including Stack Overflow, the largest, most trusted online community for developers to learn, share their knowledge, and build their careers.

Beamquality

We take the weight of your shoulders with a simple and clear 4-step process that ensures quick delivery and meets the highest industry standards.

After receiving your final models and material we will prepare cutting files using our ProCAM software. Once these files are ready production will be started at our production facility using the machine which suits best to the materials that need to be cut.

HGG has been cutting profile steel, such as tubes, beams and tubes, for decades with its own developed machines and software.

If instead you have incoherent light, rather than having nice electromagnetic modes to propagate, it is a little different. For example you wouldn’t get much light into the single mode optical fiber. But you could do something like put two apertures separated by a distance and have a roughly collimated light. The diffraction angle will depend slightly on the wavelength, but could still put a lens or set of lenses to expand or focus the light or to collimate the light. Same as before the chromatic aberration of the lenses and type of lenses can matter some, but big picture it would work.

Materials are usually delivered to us by you or your supplier. We have a large storage area capable of accommodating large-diameter and long-length material. However, we can also arrange transportation for you, ensuring materials are picked up and returned to the desired location. We partner with a transportation provider who offers daily services both within the Netherlands and internationally.

Ms.Cici

Ms.Cici

8618319014500

8618319014500