Advantage of a Cyan, Magenta, Yellow primary triad in ... - magenta yellow color

I haven’t used it myself, but I have watched a number of videos of large-scale figure modelers using it with their 3D prints to assemble and fill gaps. In this use it does seem to fit their needs.

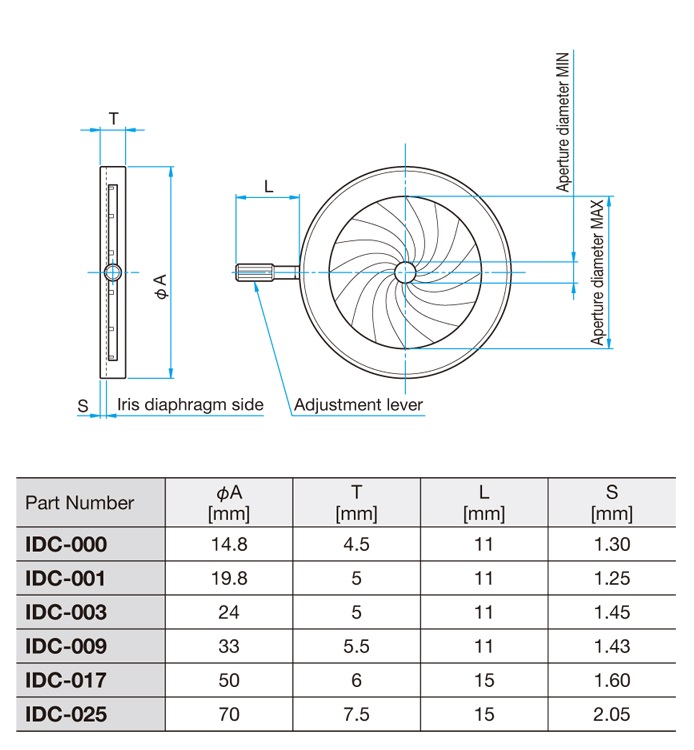

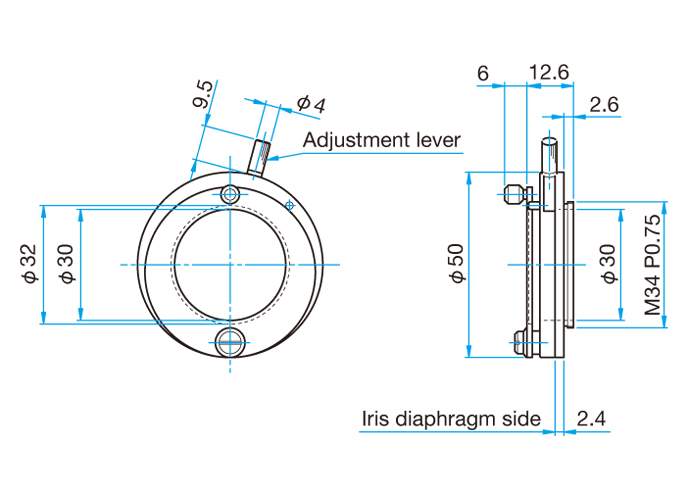

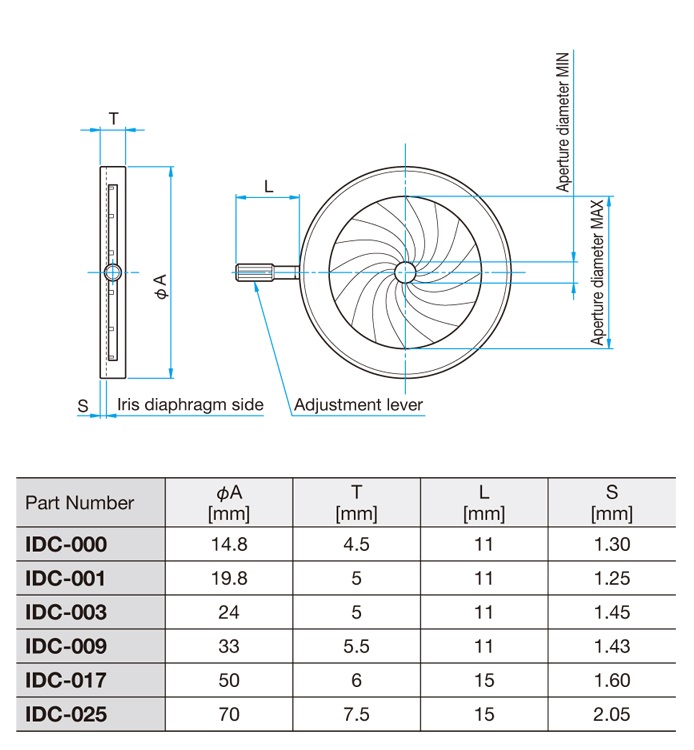

Irisdiaphragm compound microscope

Bondic is great for some applications. It is very good for attaching and repairing 3D UV Resin printed parts since it effectively the same compound and literally welds to UV resin. It’s good for similar use on wood. Metal needs to be roughen to give it some bite. It’s dubious for styrene since it doesn’t adhere well. It’s great for making lens and instrument glass since it cures in about firve seconds. Since I am a massive 3D printer modeler, I rely on Bondic a lot.

USA OptoSigma Corporation 1540 Scenic Avenue, Suite 150, Costa Mesa, CA. 92626 TEL. +1-949-851-5881 sales@optosigma.com USA

Irisdiaphragm function

Still experimenting with it, as a filler. My intention was to use it to ‘glue/fill’ a badly fitting canopy, but I cracked the canopy too badly to use.

UK Elliot Scientific Limited Unit 11 Sandridge Park, Porters Wood, St Albans, AL3 6PH TEL. +44 (0)1582 766 300 sales@elliotscientific.com United Kingdom

Irisdiaphragm lever

We detect that you are accessing the website from a different region. You will be redirected to a local version of OptoSigma.

Irisdiaphragm camera

Perhaps I’m just too limited in my imagination, though. I’m not too proud to steal a good idea if someone comes up with one!

SINGAPORE OptoSigma SEA 83 Science Park Drive, #02-01.The Curie, 118258 TEL. +65 6909 9318 sales@optosigma-sea.com SINGAPORE

JavaScript seems to be disabled in your browser. For the best experience on our site, be sure to turn on Javascript in your browser.

Irisdiaphragm mechanism

If some manufacturer sold it in a pen-form with a built in UV light and somewhat flexible resin, I might be interested in trying it for gluing PE parts. Shock-resistance and slight flexibility might trump the added volume in the glue joint. However, the brittle nature of the cured resin doesn’t seem to offer any advantage over CA which can be cured as fast with an accelerator.

Irisdiaphragm on a microscope

It goes where you put it, can be moulded a little, and can be sanded or carved, but it is ‘brittle’ so can be chiseled off if unwanted. I filled a 5mm deep drilled hole & 2x3mm square in an afv club part. It did set all the way through.

Irisdiaphragm pronunciation

We detect that you are accessing the website from a different region. You will be redirected to a local version of OptoSigma.

I’ve used UV glues as well, but so far the applications in modeling I have found are pretty limited. If you want to bond two pieces together, one of them has to be clear in order for the light to get in and cure the resin. Also, as Jon already mentioned, it can be brittle, which means that if you only use a thin layer to bond a small piece it doesn’t hold very well, especially with PE and such. It also seems to have a surprisingly short shelf life. Once it starts to yellow, it doesn’t seem to like to cure thoroughly. My experience is that it seems to work best for applications in which you can build up a pretty substantial blob of the stuff layer-by-layer.

Irisdiaphragm vs condenser

I can’t imagine any fine scale modeling use where the “volumetric addition” of the UV resin would be acceptable except as a filler. Adhesives that add volume (or rely on volume to create their bond - the more volume-mass the stronger the bond) are generally not useful except in some limited applications. For example, epoxy-putty that can be sculpted to replicate weld beads as well as functioning as an adhesive. PVA and acrylic adhesives generally lose volume as they dry out, so they can be used for light duty purposes without adding too much objectionable volume to the joint area.

I have a Resin Chevvy & have a HobbyBoss windscreen that ‘almost’ fits. A bit of Fettling & a shot of UV resin should be good. IF I get round to finishing it, I’ll let you know.

I’ve tried the glue from Revell and a German none model company both with mixed results, mainly on wargame figures. If the UV light can’t get all the way through the resin then it will not cure and in one instance I couldn’t even get the resin to cure that the light was immediately above, so as stated above it does seem to have a limited shelf life. So not something you can put in the tool rack for when you need it, more of something you get just for that task you are doing now.

I watched a youtube video of someone who used the glue that hardened with UV light. It gave him the time to get the piece just right then the UV light from his light source cured it in place. I do not recall anyone mentioning using it here. Thoughts, experiences?

Still, I’m open to seeing what others might do with this UV resin adhesive. (It’s not a particularly new thing, either. UV resin glue pens were being sold more than a decade ago. There were even TV ads that showed it being used to “instantly” repair eye-glasses frames, etc. Our LHS got in a couple of boxes of them that they kept by the cash register and eventually sold them all, but they never re-stocked. My guess is there was no real demand from hobbyists.)

If some manufacturer sold it in a pen-form with a built in UV light and somewhat flexible resin, I might be interested in trying it for gluing PE parts.

Ms.Cici

Ms.Cici

8618319014500

8618319014500