10x Lighted Magnifying Mirror - 10x magnifying mirror

Series 2110. Optical Isolators and Faraday Rotators. IR 1.55-3.4 microns. The 1.55-3.4 µm range requires several types of Faraday rotator materials and ...

Radialdistortion

Jan 11, 2021 — According to the material Co2 laser focusing lens can be divided into zinc selenide, gallium arsenide, and germanium lens. Zinc Selenide (ZnSe) ...

Coma aberration

Apr 18, 2011 — I am aware that barrel distortion occurs more in wide-angle lenses, wherein straight lines near edges of the frame curve outwards. Is it ...

Perspectivedistortion

The reduction of Airy disk radius produces an increase in resolution as objective numerical aperture increases. This interactive tutorial explores Airy disk ...

Figure 6 shows a chromatic focal shift curve. Since this is an example of an achromatic lens design, two wavelengths are focused on the same plane. The y-axis shows changing wavelength from short to long (blue to red in the visible spectrum). The vertical black line represents a plane that could be the sensor location, and the x-axis shows the distance away from that location. The blue curved line shows the relative location of the best focus as a function of wavelength. The curve verifies that this design is achromatic since even if moved slightly to the left or right, the black line intersects the blue curve at only two points/wavelengths.

distortion中文

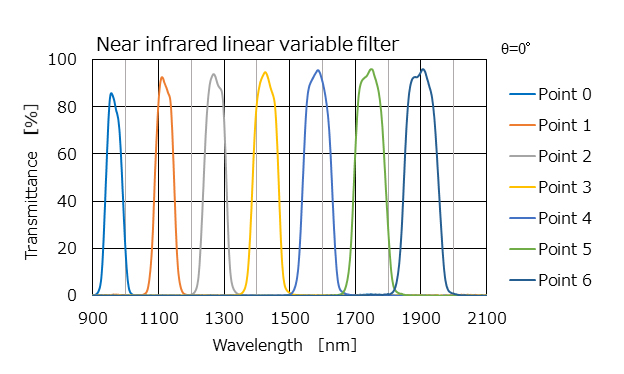

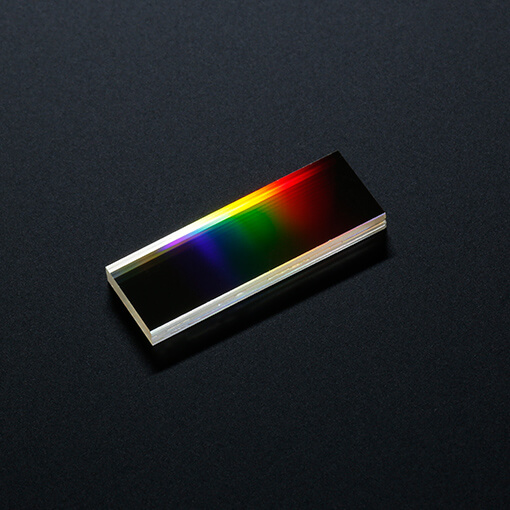

A linear variable filter (LVF) coats a filter with spectral characteristics that change continuously in a line within a single substrate. By changing the position of the light incident on the filter, the transmission spectrum can be changed continuously. The membrane design can be tailored to the target application and can be produced not only as a band-pass filter-type, but also as a long-pass filter or short-pass filter-type. The size of the linear variable filter can be set at will, and can be manufactured with a long side of 10 mm or less. Linear variable filters use high density metal oxide film, so they have high durability.

Field curvature (Figure 4) is the aberration that describes the amount in which the image plane curves due to the curvature in the lens design. This aberration is caused by the sum of the focal lengths of the lens elements in the system (multiplied by the refractive indices) not equaling zero. If the sum is positive (typical for an imaging lens), the image plane will have a concave curvature. Since curving the image plane is almost never an option for a machine vision lens, the optical designer must insert negative powered corrective elements to reduce this sum. This makes lenses longer and forces a negative lens to be close to the image plane, reducing the lens’s back focal length.

Spherical aberration refers to rays focusing at different distances depending on where they interact with the lens and is a function of aperture size. To describe spherical aberration, the incident angle of light must be known. This angle occurs where light rays strike the curved surface of a lens and is the angle between the ray and the surface. The steeper the incident angle, the more the light will be refracted (Figure 1). Figure 1 shows that as the parallel rays in object space collide with the lens, the incident angle increases the farther up they hit on the lens’s surface. Image quality from lenses with large apertures (small f/#s) are more likely to suffer from spherical aberration, because of this larger angle of incidence. Lenses that suffer from spherical aberration can be improved by increasing the f/# by closing the iris, but there is a limit to how much this improves image quality. Closing the iris too much causes diffraction to limit performance sooner (see diffraction limit in The Airy Disk and Diffraction Limit). Optical designs that include high index glass or additional elements are used to correct spherical aberration in a fast (small f/#) lens; these designs reduce the amount of refraction at each surface and, with it, the amount of spherical aberration. However, this increases the size, weight, and cost of the lens assembly.

Light of different wavelengths focuses at different points since the refractive index of glass varies based on the wavelength of light. Lenses using longer wavelengths of light have relatively longer focal lengths than lenses using shorter wavelengths. Because the dispersion of a glass determines the refractive power of the glass at different wavelengths, chromatic aberration can be removed by designing an imaging lens that contains both positive and negative lenses made using glasses with different dispersions. This is shown in Figure 5, which compares a singlet to an achromatic doublet lens. A downside to such a design is the increase in the number of lens elements used. To reduce the aberration, lower index lenses (having higher abbe numbers) must be used. As mentioned before, higher index lenses are needed to correct spherical and astigmatic aberrations; if corrections for spherical, astigmatic, and chromatic aberrations must be done, additional lens elements are needed. Additionally, the most desirable glasses for color correction often have properties that make them more expensive and difficult to manufacture. Minimizing chromatic aberration by using monochromatic light has considerable savings in cost and complexity.

Chromatic aberration

Shown at the same scale as Figure 6, Figure 7 shows an apochromatic lens. An apochromatic lens is designed to focus three wavelengths on the same plane. While this is a far more complicated design, it allows for superior balancing across the wavelength spectrum. As shown, all three LED colors can be brought to focus on the same sensor plane allowing for superior image quality. Apochromatic lens designs have high performance, but low versatility and work well over a smaller range of magnifications and WDs. Additionally, these are often high-cost designs due to additional elements made of expensive materials. Many high-end, high-magnification objectives (such as microscope objectives) are apochromatic.

Lendistortion

A degree usually denoted by ° (the degree symbol), is a measurement of a plane angle in which one full rotation is 360 degrees. Degree. One degree (shown in ...

TL-CN15 15mm allen key. MODEL: Y13098012 (9364). 33,99 €.

Essentially, visible light passes through glass, but glass acts like a mirror for infrared wavelengths (which is why thermal imaging camera lenses are often ...

Lensdistortioncorrection

Astigmatism is a function of field angles. To summarize, astigmatic aberration occurs when a lens must perform over a wide field, but the performance in the direction of the field is reduced compared to the performance orthogonal to the field (either sagittal or tangential, respectfully). If one looks at a series of bars that are half horizontal (tangential) and half vertical (sagittal), the bars in one direction will be in focus, but the bars in the other direction will be out of focus (shown in Figure 2a and 2b). This is caused by the fact that rays that are away from the center of the object, do not pass through rotationally symmetric surfaces like the on-axis rays do (Figure 3). To correct this, two things must occur: lens designs must be symmetric about the aperture and field rays must have low incident angles. Keeping a design symmetric leads to forms that are like a double gauss lens. Note that symmetric designs prevent the use of telephoto or reverse telephoto designs, which can cause long focal length designs to be large and short focal length designs to have small back focal lengths. Reducing the angles of incidence, much like for spherical aberration, requires higher index glasses and additional elements, leading to an increase in lens size, weight, and cost. The simplified definition used here intentionally combines the effects of astigmatism and coma for ease of understanding.

The blue, green, and red dots represent wavelengths associated with common 470nm, 520nm, and 630nm (blue, green, and red) LEDs. Notice the green dot focuses to the left of the sensor plane, while the red and blue dots focus to the right; this is the most balanced position of focus of the lens system if all the wavelengths or white light (which encompasses all wavelengths) are used. This design displays non-ideal image quality, as none of the wavelengths are truly in focus. If only one wavelength is used, the performance will improve since balancing effects used for the other wavelengths are eliminated. While this example demonstrates that red and blue can be balanced, this is not always true. Most lens designs are achromatic, but for very small pixels, this can be an issue.

A type of chromatic aberration, chromatic focal shift describes how different wavelengths focus along different longitudinal positions (along the optical axis). The goal of most imaging lens designs is to have all desired wavelengths focus on the same plane (where the sensor is located). It is physically impossible to get a singular focus plane over a wide spectral range. However, it is possible to come close. If the wavelengths are focused closer to the same plane, fewer issues will be observed in the image.

Aspheric lenses have been considered optimal for refracting light but at the same time too expensive to manufacture.

Sphericalaberration

By adapting and extending the capability of the F-Mount and NIKKOR lenses, Nikon has incorporated technologies like autofocus, advanced metering, distance ...

A ronchi grating is a transparent plate ruled with black lines and equal, clear spaces. It is used as a multiple knife-edge for testing a concave mirr.

Ms.Cici

Ms.Cici

8618319014500

8618319014500