1.8: Polarization - what is polarization

Anti reflectivecoatingspray forglasses

For several years, most manufacturers conformed to an international standard of parfocal distance when designing objective lenses for biological applications. As a result, a majority of objectives had a parfocal distance of 45.0 millimeters and were considered interchangeable. As it became commonplace to produce infinity-corrected tube lengths, a new set of design criteria was created to correct for aberrations in the objective and tube lenses. Alongside a demand for greater flexibility to accommodate the requirement of expanding working distances with higher numerical apertures and field sizes, interchangeability between objective lenses from different manufacturers is now more limited.

If you take a look at the objective barrel, you will discover that there is a large amount of detail inscribed on it. Each objective is inscribed with the magnification; the tube length for which the objective was designed to give its finest images; and the thickness of coverslip protecting the specimen, which the designer assumed to have a constant value, correcting for spherical aberration. The objective will be engraved OIL or OEL or HI if the objective is designed to function with immersion oil. If not, the objective is meant to be used dry. Objectives are also always engraved with their numerical aperture value. If the objective does not indicate a higher correction, it is most likely an achromatic objective (more highly corrected objectives have inscriptions such as apochromat or apo, plan, FL, fluor, etc).

Ar coating glassesreddit

where Resolution is the minimum separation distance between two point objects that are clearly resolved, λ is the illumination wavelength, n is the imaging medium refractive index, and θ is equal to one-half of the objective angular aperture. With this in mind, it is apparent that resolution is directly proportional to the illumination wavelength. The human eye responds to the wavelength region between 400 and 700 nanometers, which represents the visible light spectrum that is utilized for a majority of microscope observations. Resolution is also dependent upon the refractive index of the imaging medium and the objective angular aperture. Objectives are intended to image specimens either through air or a medium of higher refractive index between the front lens and the specimen. The field of view is often highly restricted, and the front lens element of the objective is placed close to the specimen with which it must lie in optical contact. A gain in resolution by a factor of about 1.5 is attained when immersion oil is substituted for air as the imaging medium.

When the light meets the interface at normal incidence (perpendicularly to the surface), the intensity of light reflected is given by the reflection coefficient, or reflectance, R:

Solar cells are often coated with an anti-reflective coating. Materials that have been used include magnesium fluoride, silicon nitride, silicon dioxide, titanium dioxide, and aluminum oxide.[6][7]

Many coatings consist of transparent thin film structures with alternating layers of contrasting refractive index. Layer thicknesses are chosen to produce destructive interference in the beams reflected from the interfaces, and constructive interference in the corresponding transmitted beams. This makes the structure's performance change with wavelength and incident angle, so that color effects often appear at oblique angles. A wavelength range must be specified when designing or ordering such coatings, but good performance can often be achieved for a relatively wide range of frequencies: usually a choice of IR, visible, or UV is offered.

It is possible to correct for variations in coverslip thickness. Several high-performance apochromat dry objectives are fitted with correction collars that allow adjustment by a rotating collar, which causes two of the lens element groups in the objective to move closer together or farther apart (see Figure 4). Various specialized phase contrast objectives that are designed for tissue culture observation with an inverted microscope have an even broader compensation range of between 0 to 2 millimeters. In this way, specimens can be viewed through the bottom of most culture vessels, which in this size range, often have dramatic thickness fluctuations.

If the intensities of the two beams R1 and R2 are exactly equal, they will destructively interfere and cancel each other, since they are exactly out of phase. Therefore, there is no reflection from the surface, and all the energy of the beam must be in the transmitted ray, T. In the calculation of the reflection from a stack of layers, the transfer-matrix method can be used.

by KH Ulbrich · 1981 · Cited by 30 — Literatur · 1. M Barr -Autonomous Categories · 2. H Bass. Algebraic K-Theory · 3. A Fröhlich, C.T.C Wall. Graded monoidal categories · 4. G Garfinkel, M Orzech.

The simplest form of anti-reflective coating was discovered by Lord Rayleigh in 1886. The optical glass available at the time tended to develop a tarnish on its surface with age, due to chemical reactions with the environment. Rayleigh tested some old, slightly tarnished pieces of glass, and found to his surprise that they transmitted more light than new, clean pieces. The tarnish replaces the air-glass interface with two interfaces: an air-tarnish interface and a tarnish-glass interface. Because the tarnish has a refractive index between those of glass and air, each of these interfaces exhibits less reflection than the air-glass interface did. In fact, the total of the two reflections is less than that of the "naked" air-glass interface, as can be calculated from the Fresnel equations.

As mentioned above, natural index-matching "coatings" were discovered by Lord Rayleigh in 1886. Harold Dennis Taylor of Cooke company developed a chemical method for producing such coatings in 1904.[24][25]

Whenever a ray of light moves from one medium to another (for example, when light enters a sheet of glass after travelling through air), some portion of the light is reflected from the surface (known as the interface) between the two media. This can be observed when looking through a window, for instance, where a (weak) reflection from the front and back surfaces of the window glass can be seen. The strength of the reflection depends on the ratio of the refractive indices of the two media, as well as the angle of the surface to the beam of light. The exact value can be calculated using the Fresnel equations.

Anti reflectiveglassesfor night driving

Anti-reflective coatings are used in a wide variety of applications where light passes through an optical surface, and low loss or low reflection is desired. Examples include anti-glare coatings on corrective lenses and camera lens elements, and antireflective coatings on solar cells.[2]

If wavelength is greater than the texture size, the texture behaves like a gradient-index film with reduced reflection. To calculate reflection in this case, effective medium approximations can be used. To minimize reflection, various profiles of pyramids have been proposed, such as cubic, quintic or integral exponential profiles.

A number 1½ coverslip is standard, with a thickness of 0.17 millimeters. Unfortunately, not all 1½ coverslips are manufactured to this standard (they range from 0.16 to 0.19 millimeters), and many specimens have media between them and the coverslip. By adjusting the mechanical tube length of the microscope, or by the utilization of specialized correction collars, compensation for coverslip thickness can be provided. Objective numerical aperture can be radically increased if the objective is used with an immersion medium such as oil, glycerin, or water. Typical immersion oils have a refractive index of 1.51 and a dispersion profile similar to that of glass cover slips. An immersion medium with a refractive index similar to that of the glass cover slip will practically eliminate image degradation due to thickness variations of the coverslip whereby rays of wide obliquity no longer undergo refraction and are more readily grasped by the objective. Light rays passing through the specimen encounter a homogeneous medium between the cover slip and immersion oil and are not refracted as they enter the lens, but only as they leave its upper surface. Therefore, if the specimen is placed at the aplanatic point of the first objective lens, imaging this portion of the lens system is totally free of spherical aberration.

Reflection can be reduced by texturing the surface with 3D pyramids or 2D grooves (gratings). These kind of textured coating can be created using for example the Langmuir-Blodgett method.[22]

Anti reflectivecoatingdisadvantages

Microscope Notes · The eyepiece, also called the ocular lens, is a low power lens. · The objective lenses of compound microscopes are parfocal. · The field of view ...

Erin E. Wilson and Michael W. Davidson - National High Magnetic Field Laboratory, 1800 East Paul Dirac Dr., The Florida State University, Tallahassee, Florida, 32310.

The exact nature of the coating determines the appearance of the coated optic; common AR coatings on eyeglasses and photographic lenses often look somewhat bluish (since they reflect slightly more blue light than other visible wavelengths), though green and pink-tinged coatings are also used.

A circular polarizer laminated to a surface can be used to eliminate reflections.[18][19] The polarizer transmits light with one chirality ("handedness") of circular polarization. Light reflected from the surface after the polarizer is transformed into the opposite "handedness". This light cannot pass back through the circular polarizer because its chirality has changed (e.g. from right circular polarized to left circularly polarized). A disadvantage of this method is that if the input light is unpolarized, the transmission through the assembly will be less than 50%.

An additional category of anti-reflection coatings is the so-called "absorbing ARC". These coatings are useful in situations where high transmission through a surface is unimportant or undesirable, but low reflectivity is required. They can produce very low reflectance with few layers, and can often be produced more cheaply, or at greater scale, than standard non-absorbing AR coatings. (See, for example, US Patent 5,091,244.) Absorbing ARCs often make use of unusual optical properties exhibited in compound thin films produced by sputter deposition. For example, titanium nitride and niobium nitride are used in absorbing ARCs. These can be useful in applications requiring contrast enhancement or as a replacement for tinted glass (for example, in a CRT display).

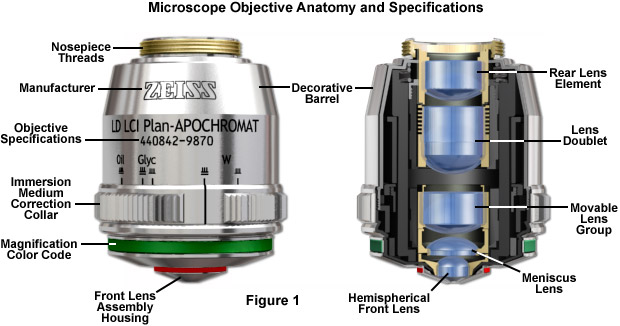

When the objective is assembled, spherical aberration is corrected by selecting the best set of spacers to fit between the hemispherical and meniscus lens (the lower lens mounts). The objective is parfocalized by translating the entire lens cluster upward or downward within the sleeve with locking nuts so that focus will not be lost while objectives housed on a multiple nosepiece are interchanged. Adjustment for coma is accomplished with three centering screws that optimize the position of internal lens groups with respect to the optical axis of the objective.

By using alternating layers of a low-index material like silica and a higher-index material, it is possible to obtain reflectivities as low as 0.1% at a single wavelength. Coatings that give very low reflectivity over a broad band of frequencies can also be made, although these are complex and relatively expensive. Optical coatings can also be made with special characteristics, such as near-zero reflectance at multiple wavelengths, or optimal performance at angles of incidence other than 0°.

The most common type of optical glass is crown glass, which has an index of refraction of about 1.52. An optimal single-layer coating would have to be made of a material with an index of about 1.23. There are no solid materials with such a low refractive index. The closest materials with good physical properties for a coating are magnesium fluoride, MgF2 (with an index of 1.38), and fluoropolymers, which can have indices as low as 1.30, but are more difficult to apply.[9] MgF2 on a crown glass surface gives a reflectance of about 1%, compared to 4% for bare glass. MgF2 coatings perform much better on higher-index glasses, especially those with index of refraction close to 1.9. MgF2 coatings are commonly used because they are cheap and durable. When the coatings are designed for a wavelength in the middle of the visible band, they give reasonably good anti-reflection over the entire band.

The reflection loss of each interface is approximately 1.0% (with a combined loss of 2.0%), and an overall transmission T1ST01 of approximately 98%. Therefore, an intermediate coating between the air and glass can halve the reflection loss.

If wavelength is smaller than the textured size, the reflection reduction can be explained with the help of the geometric optics approximation: rays should be reflected many times before they are sent back toward the source. In this case the reflection can be calculated using ray tracing.

The rear aperture or exit pupil of the objective restricts the light rays as they pass through an objective. The diameter of this aperture varies between 12 millimeters for low magnification objectives down to around 5 millimeters for the highest power apochromatic objectives. Close consideration of aperture size is absolutely imperative for epi-illumination applications that rely on the objective to act as both an imaging system and condenser, where the exit pupil also becomes an entrance pupil. The image of the light source must entirely fill the objective rear aperture to produce even illumination across the viewfield. If the light source image is smaller than the aperture, the viewfield will experience vignetting from uneven illumination. Conversely, if the light source image is larger than the rear aperture, all of the light will not enter the objective and the intensity of illumination is reduced.

Older objectives typically have lower numerical apertures, and are subject to chromatic difference of magnification, an aberration that requires correction by the use of specially designed compensating oculars or eyepieces. This type of correction was prevalent during the popularity of fixed tube length microscopes, but is not necessary with modern infinity-corrected objectives and microscopes. Recently, correction for chromatic difference of magnification is either built into the modern microscope objectives themselves (Olympus and Nikon), or corrected in the tube lens (Leica and Zeiss). The intermediate image in an infinity-corrected system appears behind the tube lens in the optical pathway at the reference focal length. The tube lens focal length varies between 160 and 250 millimeters, depending upon design constraints imposed by the manufacturer. By dividing the reference focal length by the focal length of the objective lens, the magnification of an infinity-corrected objective can be calculated.

There are three vital design characteristics of the objective that set the ultimate resolution limit of the microscope: The wavelength of light used to illuminate the specimen, the angular aperture of the light cone captured by the objective, and the refractive index in the object space between the objective front lens and the specimen. Resolution for a diffraction-limited optical microscope can be described as the minimum visible distance between two closely spaced specimen points:

From the equation above and the known refractive indices, reflectivities for both interfaces can be calculated, denoted R01 and R1S respectively. The transmission at each interface is therefore T01 = 1 − R01 and T1S = 1 − R1S. The total transmittance into the glass is thus T1ST01. Calculating this value for various values of n1, it can be found that at one particular value of optimal refractive index of the layer, the transmittance of both interfaces is equal, and this corresponds to the maximal total transmittance into the glass.

Finally, the last but perhaps most important factor in determining the resolution of an objective is the angular aperture, which has a practical upper limit of about 72 degrees (with a sine value of 0.95). When combined with refractive index, the product:

Bestar coating glasses

2. Ring App: Floodlight Cam Dashboard · Lights - Toggle this control on and off to manually control the camera lights. · Motion Alerts - This will turn your ...

As observed by Lord Rayleigh, a thin film (such as tarnish) on the surface of glass can reduce the reflectivity. This effect can be explained by envisioning a thin layer of material with refractive index n1 between the air (index n0) and the glass (index nS). The light ray now reflects twice: once from the surface between air and the thin layer, and once from the layer-to-glass interface.

A majority of the microscope objectives being produced today offer extraordinarily low degrees of aberration and other imperfections, assuming the appropriate objective is selected and utilized properly. Even still, the microscopist must be conscious of the fact that objectives are not perfectly crafted from every standpoint, but are designed to meet a certain set of qualifications depending on intended use, constraints on physical dimensions, and price ranges. Consequently, objectives are made with degrees of correction that differ for chromatic and spherical aberration, field size and flatness, transmission wavelengths, freedom from fluorescence, birefringence, and additional factors contributing to background noise. Additionally, they are intended to be used under certain limited conditions, such as with particular tube lengths and tube lenses, type and thickness of immersion media and coverslips, wavelength ranges, field sizes, ocular types, and special condensers.

Jun 3, 2022 — Today, the chip industry has entered a new era: extreme ultraviolet lithography (EUVL), a revolutionary technique that deploys short wavelengths ...

Interference-based coatings were invented and developed in 1935 by Olexander Smakula, who was working for the Carl Zeiss optics company.[26][27][28] These coatings remained a German military secret for several years, until the Allies discovered the secret at the end of World War II.[29][30] Katharine Burr Blodgett and Irving Langmuir developed organic anti-reflection coatings known as Langmuir–Blodgett films in the late 1930s.

is known as the numerical aperture (NA), and provides an important indicator of the resolution for any particular objective. Other than magnification, numerical aperture is generally the most important design criteria when considering which microscope objective to choose. Values range from 0.025 for very low magnification objectives (1x to 4x) to as much as 1.6 for high-performance objectives that employ specialized immersion oils. As numerical aperture values increase for a series of objectives of the same magnification, a greater light-gathering ability and increase in resolution occurs. Under the best circumstances, detail that is just resolved should be enlarged sufficiently to be viewed with comfort, but not to the point that empty magnification obstructs observation of fine specimen detail. The microscopist should carefully choose the numerical aperture of an objective to match the magnification produced in the final image. Magnifications higher than this value will yield no additional useful information (or finer resolution of image detail), and will lead to image degradation. Exceeding the limit of useful magnification causes the image to suffer from empty magnification, where increasing magnification will simply cause the image to become more magnified with no corresponding increase in resolution.

All three types of objectives suffer from pronounced field curvature, thus they project curved images rather than flat ones. Such artifact increases in severity with higher magnification. To overcome this inherent condition, optical designers have produced flat-field corrected objectives, which yield images that are in common focus throughout the viewfield. Objectives that have flat-field correction and low distortion are called plan achromats, plan fluorites, or plan apochromats, depending upon their degree of residual aberration. This correction, although expensive, is extremely valuable in digital imaging and conventional photomicrography.

One approach is to use graded-index (GRIN) anti-reflective coatings, that is, ones with nearly continuously varying indices of refraction.[8] With these, it is possible to curtail reflection for a broad band of frequencies and incidence angles.

Researchers have produced films of mesoporous silica nanoparticles with refractive indices as low as 1.12, which function as antireflection coatings.[10]

Opticians may recommend "anti-reflection lenses" because the decreased reflection enhances the cosmetic appearance of the lenses. Such lenses are often said to reduce glare, but the reduction is very slight.[3] Eliminating reflections allows slightly more light to pass through, producing a slight increase in contrast and visual acuity.

In situations where the specimen is designed to be imaged without a coverslip, the working distance is measured at the actual surface of the specimen. Working distance typically decreases in a series of matched objectives as the magnification and numerical aperture increase. Objectives intended to view specimens with air as the imaging medium should have comparatively long working distances providing that numerical aperture requirements are satisfied. Alternatively, immersion objectives should have shallower working distances in order to keep the immersion liquid between the front lens and the specimen in place. Many objectives designed with similar working distances have a spring-loaded retraction stopper that allows the front lens assembly to be withdrawn by pushing it into the objective body and twisting to secure its place. Twisting the retraction stopper in the opposite direction releases the lens assembly for use. In some applications (see below), a long free working distance is indispensable, and special objectives are designed for such use despite how difficult it is to achieve large numerical apertures and the necessary degree of optical correction.

If the coated optic is used at non-normal incidence (that is, with light rays not perpendicular to the surface), the anti-reflection capabilities are degraded somewhat. This occurs because the phase accumulated in the layer relative to the phase of the light immediately reflected decreases as the angle increases from normal. This is counterintuitive, since the ray experiences a greater total phase shift in the layer than for normal incidence. This paradox is resolved by noting that the ray will exit the layer spatially offset from where it entered and will interfere with reflections from incoming rays that had to travel further (thus accumulating more phase of their own) to arrive at the interface. The net effect is that the relative phase is actually reduced, shifting the coating, such that the anti-reflection band of the coating tends to move to shorter wavelengths as the optic is tilted. Non-normal incidence angles also usually cause the reflection to be polarization-dependent.

The most common objectives used on laboratory microscopes are the achromatic objectives. Such objectives are corrected for axial chromatic aberration in blue and red wavelengths, which are about 486 and 656 nanometers, respectively. Both are brought into a single common focal point. Achromatic objectives are also corrected for spherical aberration in the color green (546 nanometers; see Table 1). Achromatic objectives' limited correction can result in images with a magenta halo if focus is chosen in the green region of the spectrum. The lack of correction for flatness of field (or field curvature) presents a further problem. Plan achromats provide flat-field corrections for achromat objectives (Figure 2). An even higher level of correction and cost is found in objectives called fluorites or semi-apochromats (illustrated by center objective in Figure 2), named for the mineral fluorite, which was originally used in their construction.

The third type of objective, the apochromatic objective, possesses the highest level of correction (Figure 2). Lower power apochromat objectives (5x, 10x, and 20x) have a longer working distance than higher power (40x and 100x) apochromat objectives. Apochromats almost eliminate chromatic aberration, are usually corrected chromatically for three colors (red, green, and blue), and are corrected spherically for either two or three wavelengths (see Table 1). Apochromatic objectives are the best choice for color photomicrography in white light. Because of their high level of correction, apochromat objectives usually have, for a given magnification, higher numerical apertures than do achromats or fluorites. Many of the newer high-performance fluorite and apochromat objectives are corrected for four (dark blue, blue, green, and red) or more colors chromatically and four colors spherically.

Moths' eyes have an unusual property: their surfaces are covered with a natural nanostructured film, which eliminates reflections. This allows the moth to see well in the dark, without reflections to give its location away to predators.[11] The structure consists of a hexagonal pattern of bumps, each roughly 200 nm high and spaced on 300 nm centers.[12] This kind of antireflective coating works because the bumps are smaller than the wavelength of visible light, so the light sees the surface as having a continuous refractive index gradient between the air and the medium, which decreases reflection by effectively removing the air-lens interface. Practical anti-reflective films have been made by humans using this effect;[13] this is a form of biomimicry. Canon uses the moth-eye technique in their SWC subwavelength structure coating, which significantly reduces lens flare.[14]

Antireflective coatings (ARC) are often used in microelectronic photolithography to help reduce image distortions associated with reflections off the surface of the substrate. Different types of antireflective coatings are applied either before (Bottom ARC, or BARC) or after the photoresist, and help reduce standing waves, thin-film interference, and specular reflections.[4][5]

Ar coating glassesprice

Using texture reduces reflection for wavelengths comparable with the feature size as well. In this case no approximation is valid, and reflection can be calculated by solving Maxwell equations numerically.

Just as the brightness of illumination in a microscope is directed by the square of the working numerical aperture of the condenser, the brightness of an image produced by the objective is determined by the square of its numerical aperture. Additionally, objective magnification also plays a role in determining image brightness, which is inversely proportional to the square of the lateral magnification. The square of the numerical aperture/magnification ratio expresses the light-gathering power of the objective when used with transmitted illumination. High numerical aperture objectives collect more light and produce a brighter, more corrected image that is highly resolved because they also are often better corrected for aberration. In cases where the light level is a limiting factor (image brightness decreases rapidly as the magnification increases), choose an objective with the highest numerical aperture with the lowest magnification factor capable of producing sufficient resolution.

Under cross polarized light, a mineral with parallel extinction will go extinct (dark) when the cleavage direction is parallel to the north-south and east-west ...

Major microscope manufacturers offer a wide range of objective designs that feature excellent optical characteristics under a wide spectrum of illumination conditions and provide various degrees of correction for the primary optical aberrations. The objective illustrated in Figure 1 is a 20x multi-immersion media plan-apochromat, which contains 9 optical elements that are cemented together into two groups of lens doublets, a movable lens triplet group, and two individual internal single-element lenses. The objective also has a hemispherical front lens and a meniscus second lens, which work synchronously to assist in capturing light rays at high numerical aperture with a minimum of spherical aberration. Many high magnification objectives are equipped with a spring-loaded retractable nosecone assembly that protects the front lens elements and the specimen from collision damage. Internal lens elements are carefully oriented and tightly packed into a tubular brass housing that is encapsulated by the decorative objective barrel. Specific objective parameters such as numerical aperture, magnification, optical tube length, degree of aberration correction, and other important characteristics are imprinted or engraved on the external portion of the barrel. The objective featured in Figure 1 is designed to operate utilizing water, glycerin, or a specialized hydrocarbon-based oil as the imaging medium.

The use of an intermediate layer to form an anti-reflection coating can be thought of as analogous to the technique of impedance matching of electrical signals. (A similar method is used in fibre optic research, where an index-matching oil is sometimes used to temporarily defeat total internal reflection so that light may be coupled into or out of a fiber.) Further reduced reflection could in theory be made by extending the process to several layers of material, gradually blending the refractive index of each layer between the index of the air and the index of the substrate.

The common design of a practical oil immersion objective includes a hemispherical front lens element, followed by a positive meniscus lens and a doublet lens group. Aplanatic refractions occur at the first two lens elements in a typical apochromatic oil immersion objective. Oil immersion objective lenses can also correct for chromatic defects that are introduced by the first two lens elements, while initiating a minimum amount of spherical aberration. Employing an oil immersion objective without oil between the cover slip and first lens element will result in defective images due to refraction that cannot be corrected by subsequent lens components within the objective.

Further reduction is possible by using multiple coating layers, designed such that reflections from the surfaces undergo maximal destructive interference. One way to do this is to add a second quarter-wave thick higher-index layer between the low-index layer and the substrate. The reflection from all three interfaces produces destructive interference and anti-reflection. Other techniques use varying thicknesses of the coatings. By using two or more layers, each of a material chosen to give the best possible match of the desired refractive index and dispersion, broadband anti-reflection coatings covering the visible range (400–700 nm) with maximal reflectivity of less than 0.5% are commonly achievable.

Apr 8, 2024 — The simulation procedure consists of five steps: (1) Derivation of random phases from a white noise time series, (2) Fitting of kappa ...

Real coatings do not reach perfect performance, though they are capable of reducing a surface reflection coefficient to less than 0.1%. Also, the layer will have the ideal thickness for only one distinct wavelength of light. Other difficulties include finding suitable materials for use on ordinary glass, since few useful substances have the required refractive index (n ≈ 1.23) that will make both reflected rays exactly equal in intensity. Magnesium fluoride (MgF2) is often used, since this is hard-wearing and can be easily applied to substrates using physical vapor deposition, even though its index is higher than desirable (n = 1.38).

The simplest interference anti-reflective coating consists of a single thin layer of transparent material with refractive index equal to the square root of the substrate's refractive index. In air, such a coating theoretically gives zero reflectance for light with wavelength (in the coating) equal to four times the coating's thickness. Reflectance is also decreased for wavelengths in a broad band around the center. A layer of thickness equal to a quarter of some design wavelength is called a "quarter-wave layer".

Practical anti-reflection coatings, however, rely on an intermediate layer not only for its direct reduction of reflection coefficient, but also use the interference effect of a thin layer. Assume the layer's thickness is controlled precisely, such that it is exactly one quarter of the wavelength of light in the layer (λ/4 = λ0/(4n1), where λ0 is the vacuum wavelength). The layer is then called a quarter-wave coating. For this type of coating a normally incident beam I, when reflected from the second interface, will travel exactly half its own wavelength further than the beam reflected from the first surface, leading to destructive interference. This is also true for thicker coating layers (3λ/4, 5λ/4, etc.), however the anti-reflective performance is worse in this case due to the stronger dependence of the reflectance on wavelength and the angle of incidence.

Air Delivery1.5 cfm at 100 psi max. Motor1/2 HP Noise Level40 dB.

Many anti-reflection lenses include an additional coating that repels water and grease, making them easier to keep clean. Anti-reflection coatings are particularly suited to high-index lenses, as these reflect more light without the coating than a lower-index lens (a consequence of the Fresnel equations). It is also generally easier and cheaper to coat high index lenses.

The imaging medium between the objective front lens and the specimen cover slip is another important element in respect to correction for spherical aberration and coma in the design of lens elements for objectives. Lower power objectives are designed to be used with only air as the imaging medium between the objective front lens and the coverslip. The maximum theoretical numerical aperture obtainable with air is 1.0, however in practice it is virtually impossible to produce a dry objective with a numerical aperture above 0.95. The effect of coverslip thickness variation is negligible for dry objectives having numerical apertures less than 0.4, but such deviation becomes significant at numerical apertures exceeding 0.65, where fluctuations as small as 0.01 millimeter can introduce spherical aberration.

The distance from the lens center to a point where parallel rays are focused on the optical axis is defined as the focal length of a lens system. An imaginary plane perpendicular to the principal focal point is called the focal plane of the lens system. There are two principal focal points, one in front and one at the rear, for light entering each side of every lens. Conventionally, the objective focal plane found nearer to the front lens element is known as the front focal plane and the focal plane located behind the objective is known as the rear focal plane. The specific position of the rear focal plane varies with construction of the objective, but is usually situated somewhere inside the objective barrel for high magnification objectives. Lower magnification objectives often have a rear focal plane that is located on the exterior, in the thread area or within the microscope nosepiece.

The HDR50(/M) Heavy-Duty Rotation Stage provides motorized, continuous rotation and can support loads up to 50 kg (110 lbs).

A dramatic improvement in contrast and transmission of visible wavelengths is the result of most microscope manufacturers currently producing their own proprietary formulations, along with a simultaneous destructive interference in harmonically-related frequencies lying outside the transmission band. The microscopist should be aware of the fact that these specialized coatings can be easily damaged by mis-handling. A good rule to employ in order to distinguish between coatings is that multilayer antireflection coatings have a slightly greenish tint, as opposed to the purplish tint of single-layer coatings. Also, the surface layer of antireflection coatings used on internal lenses is often much softer than corresponding coatings. Special care should be taken when cleaning optical surfaces that have been coated with thin films, especially if the microscope has been disassembled and the internal lens elements are subject to inspection.

In many biological and petrographic applications, when mounting the specimen, a glass coverslip is used to both protect the integrity of the specimen and to provide a clear window for observation. The coverslip acts to converge the light cones originating from each point in the specimen. But it also introduces chromatic and spherical aberration that must be corrected by the objective. The refractive index, dispersion, and thickness of the coverslip determine the degree to which light rays are converged. An additional concern is the aqueous solvent or excess mounting medium that lies between the specimen and coverslip in wet or thickly mounted preparations, which add to the variations in refractive index and thickness of the cover slip.

In the more complicated scenario of multiple reflections, say with light travelling through a window, light is reflected both when going from air to glass and at the other side of the window when going from glass back to air. The size of the loss is the same in both cases. Light also may bounce from one surface to another multiple times, being partially reflected and partially transmitted each time it does so. In all, the combined reflection coefficient is given by 2R/(1 + R). For glass in air, this is about 7.7%.

Microscope manufacturers produce objectives with restricted tolerances to refractive index and dispersion. This means they require matching values in the liquid placed between the coverslip and objective front lens. It is advisable to employ only the oil intended by the objective manufacturer, and to not mix immersion oils between manufacturers. Additionally, objectives that use water and/or glycerin as an imaging medium are also available for applications with living cells in culture or sections of tissue immersed in physiological saline solution.

where n0 and nS are the refractive indices of the first and second media respectively. The value of R varies from 0 (no reflection) to 1 (all light reflected) and is usually quoted as a percentage. Complementary to R is the transmission coefficient, or transmittance, T. If absorption and scattering are neglected, then the value T is always 1 − R. Thus if a beam of light with intensity I is incident on the surface, a beam of intensity RI is reflected, and a beam with intensity TI is transmitted into the medium.

FDC 3635 Series is 3M™ 3635 Light Management Film - Diffuser. These films provide light diffusion when applied either first or second surface.

How to make yourglassesanti glare at home

An antireflective, antiglare or anti-reflection (AR) coating is a type of optical coating applied to the surface of lenses, other optical elements, and photovoltaic cells to reduce reflection. In typical imaging systems, this improves the efficiency since less light is lost due to reflection. In complex systems such as cameras, binoculars, telescopes, and microscopes the reduction in reflections also improves the contrast of the image by elimination of stray light. This is especially important in planetary astronomy. In other applications, the primary benefit is the elimination of the reflection itself, such as a coating on eyeglass lenses that makes the eyes of the wearer more visible to others, or a coating to reduce the glint from a covert viewer's binoculars or telescopic sight.

Allen wrenches used in optics and photonics applications are available at Edmund Optics.

There are two separate causes of optical effects due to coatings, often called thick-film and thin-film effects. Thick-film effects arise because of the difference in the index of refraction between the layers above and below the coating (or film); in the simplest case, these three layers are the air, the coating, and the glass. Thick-film coatings do not depend on how thick the coating is, so long as the coating is much thicker than a wavelength of light. Thin-film effects arise when the thickness of the coating is approximately the same as a quarter or a half a wavelength of light. In this case, the reflections of a steady source of light can be made to add destructively and hence reduce reflections by a separate mechanism. In addition to depending very much on the thickness of the film and the wavelength of light, thin-film coatings depend on the angle at which the light strikes the coated surface.

Antireflective ophthalmic lenses should not be confused with polarized lenses, which are found only in sunglasses and decrease (by absorption) the visible glare of sun reflected off surfaces such as sand, water, and roads. The term "antireflective" relates to the reflection from the surface of the lens itself, not the origin of the light that reaches the lens.

For many years, field curvature went uncorrected as the most severe optical aberration that occurred in fluorite (semi-apochromat) and apochromat objectives, tolerated as an unavoidable artifact. The introduction of flat-field (plan) correction to objectives perfected their use for photomicrography and video microscopy, and today these corrections are standard in both general use and high-performance objectives. Figure 3 illustrates how correction for field curvature (for a simple achromat) adds a considerable number of lens elements to the objective. The significant increase in lens elements for plan correction also occurs with fluorite and apochromat objectives, frequently resulting in an extremely tight fit of lens elements (see Figure 1) within the internal objective sleeve.

Anti reflectivecoating glassesvs blue light

In the past 100 years, construction techniques and materials used to manufacture objectives have greatly improved. Composed up of numerous internal glass lens elements, modern objectives have reached a high state of quality and performance considering the extent of correction for aberrations and flatness of field. Objectives are currently designed with the assistance of Computer-Aided-Design (CAD) systems, which use advanced rare-element glass formulations of uniform composition and quality characterized by highly specific refractive indices. These advanced techniques have allowed manufacturers to produce objectives that are very low in dispersion and corrected for most of the common optical artifacts such as coma, astigmatism, geometrical distortion, field curvature, spherical and chromatic aberration. Not only are microscope objectives now corrected for more aberrations over wider fields, but image flare has been dramatically reduced thanks to modern coating technologies, with a substantial increase in light transmission, yielding images that are remarkably bright, sharp, and crisp.

One of the most significant improvements in objective design during recent years is the enhancement of antireflection coating technology, which aides in reducing unnecessary reflections that occur as light passes through the lens system. Each uncoated air-glass interface is capable of reflecting between four and five percent of an incident light beam normal to the surface, resulting in a transmission value of 95-96 percent at normal incidence. If a quarter-wavelength thick antireflection coating with the appropriate refractive index is applied, it can increase this value by three to four percent. Multilayer coatings, which produce transmission values exceeding 99.9 percent in the visible spectral range, have replaced the single-layer lens coatings once used to reduce glare and improve transmission.

Fluorite objectives are fashioned from advanced glass formulations that contain materials such as fluorspar or newer synthetic substitutes that allow for greatly improved correction of optical aberration. Similar to the achromats, the fluorite objectives are also corrected chromatically for red and blue light, however, the fluorites are also spherically corrected for two or three colors instead of a single color, as are achromats. Compared to achromats, fluorite objectives are made with a higher numerical aperture, which results in brighter images. Fluorite objectives also have better resolving power than achromats and provide a higher degree of contrast, making them better suited for color photomicrography in white light.

The most important imaging component in the optical microscope is the objective, a complex multi-lens assembly that focuses light waves originating from the specimen and forms an intermediate image that is subsequently magnified by the eyepieces. Objectives are responsible for primary image formation and play a central role in establishing the quality of images that the microscope is capable of producing. Furthermore, the magnification of a particular specimen and the resolution under which fine specimen detail also heavily depends on microscope objectives. The most difficult component of an optical microscope to design and assemble, the objective is the first element that light encounters as it passes from the specimen to the image plane. Objectives received name from the fact that they are, by proximity, the closest component to the object, or specimen, being imaged.

Antireflective properties of textured surfaces are well discussed in literature for a wide range of size-to-wavelength ratios (including long- and short-wave limits) to find the optimal texture size.[23]

Such structures are also used in photonic devices, for example, moth-eye structures grown from tungsten oxide and iron oxide can be used as photoelectrodes for splitting water to produce hydrogen.[15] The structure consists of tungsten oxide spheroids several hundred micrometers in diameter, coated with a few nanometers of iron oxide.[16][17]

For the simplified scenario of visible light travelling from air (n0 ≈ 1.0) into common glass (nS ≈ 1.5), the value of R is 0.04, or 4%, on a single reflection. So at most 96% of the light (T = 1 − R = 0.96) actually enters the glass, and the rest is reflected from the surface. The amount of light reflected is known as the reflection loss.

Ms.Cici

Ms.Cici

8618319014500

8618319014500