0.375 inches to mm - Inches to Calculator - 0.375 mm

Dlc coatingsreview

488nm blue laser diode module projects high brightness sky blue laser light of beam aperture, and gets peak wavelength of 488nm. It provides users continuous wave mode of operation and high stability blue laser beam emission. Supported by constant power source supply, ultra compact structure made 488nm blue laser within 30mW to 100mW fulfills a large variety of applications, including laser medical imaging, biomedical and high tech fields, etc.

Key features: Direct diode emission made 488nm blue laser diode module with inner metal heat sink cooling ensures increasing laser beam stability and no dazzling blue light emission in continuous use.AC/DC adapter support wide output power of 5mW to 100mW, it assures continuous blue laser light emission. Extending electric wires within 3 meters ensures convenient installation, and highly stable blue dot projection under increasing temperature. Adjustable focus optic lens ensures immediate and high stability blue laser light concentration, and converts into increasing accuracy blue laser dot projection for both long time and long distance use.APC, ACC driving circuit board made 488nm blue laser provides users constant output power and electric current supply, and reduced possibility of tube burning out or damage. Laser beam stability keeps up to 85% within 8 to 10 hours.

Dlc coatingsnear me

DLCcoating application

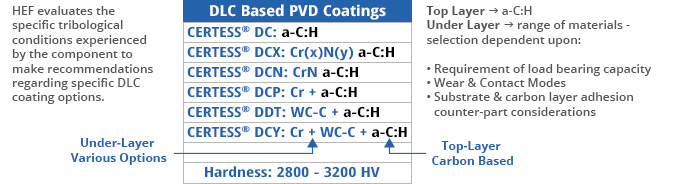

The properties of DLC coatings in terms of hardness; coefficient of friction; roughness; adhesion level; load carrying capacity; resistance to humidity influenced degradation; fatigue tolerance, etc. can be tailored over a wide range depending upon deposition parameters, deposition technology and the combination of materials constituting the coating. Some of the more common commercial variants of WCC and DLC coatings from HEF are shown below.

Ship in confidence on Berinlasers.com. We guarantee all laser pointers, laser alignments, laser modules, laser diodes are being sold with equal power as its guaranteed quality and performance.We accept Visa, Mastercard cards, Western Union, Bank Transfer as well as Paypal......

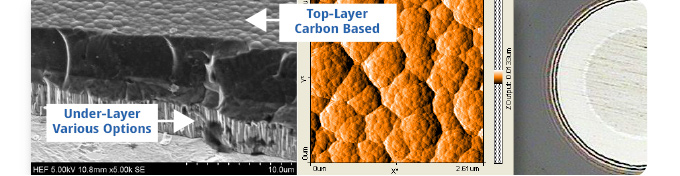

Diamond-like carbon coating process

In order to meet the diverse operating conditions encountered by engineered components used for automotive and other generic industrial applications, HEF has developed a family of diamond-like-carbon DLC coatings. These coatings usually include several layers of different materials such as Cr, CrN, W, WC-C, Si with a top layer of amorphous carbon, with hydrogen. The selection of the under-layer is based upon several factors such as: adhesion requirements, wear mode and contact mode, friction regimes encountered during operation, load carrying capacity, and other metallurgical considerations. These coatings have a unique combination of high hardness and low friction coefficient, compared to conventional PVD coating (TiN, CrN, ALTiN etc) and soft coatings (such as solid lubricants like Molybdenum di-sulfide).

Liquid nitriding is a subcritical surface enhancement process with one of the longest track records of success of any case hardening technology.

HEF bushings are recognized worldwide for their excellent frictional and anti-seizure properties, and ability to withstand high loads.

DLCcoating colors

DLCcoating price

Besides this unique combination of properties, this new generation of coatings has high load-bearing capabilities, making them an ideal choice for improving the performance of engineered components. Moreover, these coatings are usually bio-compatible and hence suitable for food-contact and medical applications. The lubricious surface also has good release properties, making these coatings a good choice for plastic processing applications.

DLCcoating at home

Other DLC coatings can be customized based upon the unique combination of wear mode, contact mode and the friction regime under which the component in operating.

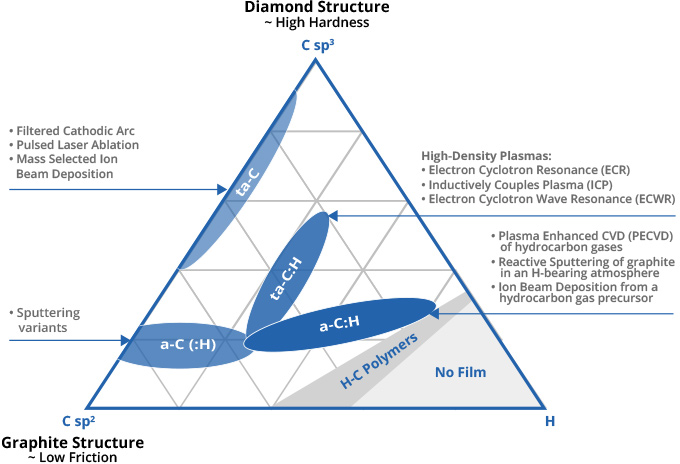

In recent years, a new generation of PVD + PACVD (plasma-assisted CVD) coatings has gained widespread commercial success. As is well known, carbon can exist in three allotropic forms. Carbon, in a diamond crystal structure, is one of the hardest know materials. Carbon, in a graphite crystal structure, is very soft and lubricous. Carbon-based coatings, referred to as Diamond-like-Carbon (DLC) coatings, combine these two different properties of diamond and graphite - hence possess high hardness levels - in the range of conventional tribological PVD coatings (1500 - 3200 HV), coupled with a coefficient of friction which is 200-500% lower than that of conventional PVD coatings.

Bestdlc coatings

As shown below, DLC coatings can be deposited using a diverse range of technologies and alloyed with elements such as hydrogen and metals such as chromium. These constituent elements and deposition technique can have a significant impact on the properties and structure of the DLC coating.

Packing list: 1 ea 488nm blue laser diode module and 1 ea AC/DC adapterNote: Any direct eye exposure to powerful blue laser light up to 50mW to 100mW brings users thermal energy hurt to eyes. Do remember to wear correct laser safety goggles so as to assure free and safe dot alignment constantly.

JavaScript seems to be disabled in your browser. For the best experience on our site, be sure to turn on Javascript in your browser.

High level of wavelength stability and high brightness sky blue laser light emission for various precise dot projecting work fieldsEmployed by an import 488nm blue laser diode, qualified glass coated lens, 488nm blue laser diode module always provides users increasing stability blue laser light emission, and highly clear blue reference dot projection. It emits high optical output power within 5mW to 100mW, and provides users the most reliable blue laser light source and gets wide range operating temperature as well. It gets featured advantages of ultra compact structure, good beam quality, low production cost and long lifetime.

PVD coatings involve the deposition of thin (2-10 microns; 0.0001" – 0.0004") films on the surface of tools and components.

Ms.Cici

Ms.Cici

8618319014500

8618319014500