Aspheric Lenses: Thin and Light - aspheric optical lenses

Michael W. Davidson - National High Magnetic Field Laboratory, 1800 East Paul Dirac Dr., The Florida State University, Tallahassee, Florida, 32310.

Bestmachine vision inspection systems

As with other products from Sydor Optics, optical flats are fabricated in custom sizes with different coating and beveling options, and can even be polished to ...

From the discussion above it is apparent that objectives are the single most important element of a microscope. It is for this reason that so much effort is invested in making sure that they are well-labeled and suited for the task at hand.

The Rectaflex is a 35mm SLR camera developed in Italy by the eponymous company. It was presented for the first time at the Milan fair in april 1948.

Vom 14. bis 16. Mai 2024 sind wir als Aussteller auf der Optatec in Frankfurt dabei! Die internationale Fachmesse für optische Technologien, Komponenten und ...

The interactive tutorial above allows the visitor to adjust the correction collar on a microscope objective. There are some applications that do not require objectives to be corrected for cover glass thickness. These include objectives designed for reflected light metallurgical specimens, tissue culture, integrated circuit inspection, and many other applications that require observation with no compensation for a cover glass.

Parfocal Distance - This is another specification that can often vary by manufacturer. Most companies produce objectives that have a 45 millimeter parfocal distance, which is designed to minimize refocusing when magnifications are changed.

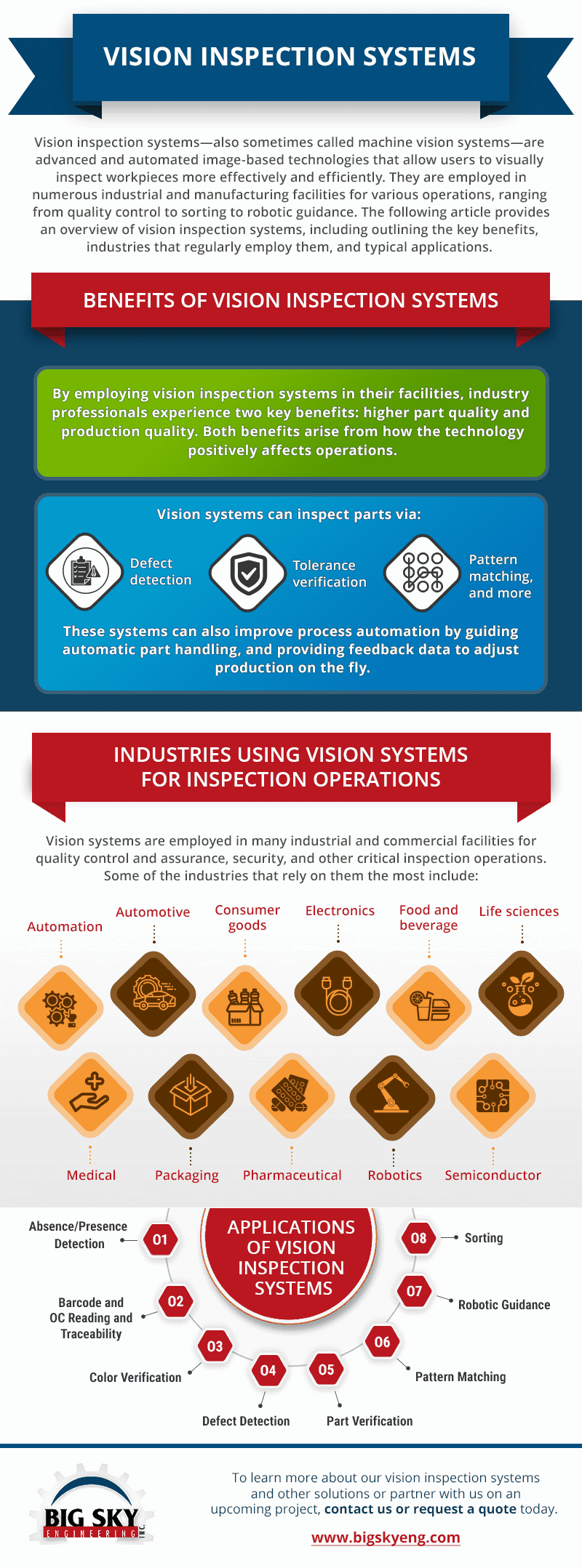

Vision inspection systems—also sometimes called machine vision systems—are advanced and automated image-based technologies that allow users to visually inspect workpieces more effectively and efficiently. They are employed in numerous industrial and manufacturing facilities for various operations, ranging from quality control to sorting to robotic guidance. The following article provides an overview of vision inspection systems, including outlining the key benefits, industries that regularly employ them, and typical applications.

Vision inspectionsystem manufacturers

At Big Sky Engineering, we have extensive experience designing and building custom automated manufacturing solutions, including vision inspection systems. All of our systems feature PLC controls and other advanced technologies to ensure they fully accommodate the requirements and restrictions of the intended facility. For examples of our work, view our past projects page.

Cameravision inspectionsystem

Special Features - Objectives often have additional special features that are specific to a particular manufacturer and type of objective. The plan apochromat objective illustrated in Figure 1 has a spring-loaded front lens to prevent damage when the objective is accidentally driven onto the surface of a microscope slide.

World-class Nikon objectives, including renowned CFI60 infinity optics, deliver brilliant images of breathtaking sharpness and clarity, from ultra-low to the highest magnifications.

Most manufacturers have now transitioned to infinity-corrected objectives that project emerging rays in parallel bundles from every azimuth to infinity. These objectives require a tube lens in the light path to bring the image into focus at the intermediate image plane. Infinity-corrected and finite-tube length microscope objectives are not interchangeable and must be matched not only to a specific type of microscope, but often to a particular microscope from a single manufacturer. For example, Nikon infinity-corrected objectives arenot interchangeable with Olympus infinity-corrected objectives, not only because of tube length differences, but also because the mounting threads are not the same pitch or diameter. Objectives usually contain an inscription denoting the tube focal length correction as will be discussed.

The objective depicted on the left in Figure 3 has a parfocal distance of 45mm and is labeled with an immersion medium color code in addition to the magnification color code. Parfocal distance is measured from the nosepiece objective mounting hole to the point of focus on the specimen as illustrated in the figure. The objective on the right in Figure 3 has a longer parfocal distance of 60 millimeters, which is the result of its being produced to the Nikon CFI60 200/60/25 Specification, again deviating from the practice of other manufacturers such as Olympus and Zeiss, who still produce objectives with a 45mm parfocal distance. Most manufacturers also make their objective nosepieces parcentric, meaning that when a specimen is centered in the field of view for one objective, it remains centered when the nosepiece is rotated to bring another objective into use.

Vision systems are employed in many industrial and commercial facilities for quality control and assurance, security, and other critical inspection operations. Some of the industries that rely on them the most include:

Glass Design - The quality of glass formulations has been paramount in the evolution of modern microscope optics. Numerous designs have been implemented by a variety of manufacturers, but we will limit this discussion to a specialized low dispersion glass formulation. Extra Low Dispersion (ED) glass was introduced as a major advancement in lens design with optical qualities similar to the mineral fluorite but without its mechanical and optical demerits. This glass has allowed manufacturers to create higher quality objectives with lens elements that have superior corrections and performance.

Meet the security and safety needs of unique sites and applications with specially designed Avigilon cameras and sensors.

KEYENCEvisionSystem Price

Although not common today, other types of adjustable objectives have been manufactured in the past. Perhaps the most interesting example is the compound "zoom" objective that has a variable magnification, usually from about 4x to 15x. These objectives have a short barrel with poorly designed optics that have significant aberration problems and are not very practical for photomicrography or serious quantitative microscopy.

We include our software as standard on all our noise measurement instruments to allow users to download stored noise measurements to their PC or Laptop for ...

Microscope manufacturers offer a wide range of objective designs to meet the performance needs of specialized imaging methods, to compensate for cover glass thickness variations, and to increase the effective working distance of the objective. Often, the function of a particular objective is not obvious simply by looking at the construction of the objective. Finite microscope objectives are designed to project a diffraction-limited image at a fixed plane (the intermediate image plane), which is dictated by the microscope tube length and located at a pre-specified distance from the rear focal plane of the objective. Microscope objectives are usually designed to be used with a specific group of oculars and/or tube lenses strategically placed to assist in the removal of residual optical errors. As an example, older Nikon and Olympus compensating eyepieces were used with high numerical aperture fluorite and apochromatic objectives to eliminate lateral chromatic aberration and improve flatness of field. Newer microscopes (from Nikon and Olympus) have objectives that are fully corrected and do not require additional corrections from the eyepieces or tube lenses.

Investigate how internal lens elements in a high numerical aperture dry objective may be adjusted to correct for fluctuations in coverslip thickness.

Vision systemsfor manufacturing

Within the above industries, vision inspection systems are utilized in many different operations to improve efficiency, including the following:

Identification of the properties of individual objectives is usually very easy because important parameters are often inscribed on the outer housing (or barrel) of the objective itself as illustrated in Figure 1. This figure depicts a typical 60x plan apochromat objective, including common engravings that contain all of the specifications necessary to determine what the objective is designed for and the conditions necessary for proper use.

Machine vision inspection systemspdf

2019122 — The sensor is tilted down 10 degrees, the point where Z = 0 is not at your head, it is about 0.5 meters below your head - so roughly 1.3 meters above the ...

Original Portable 360 Action Camera Mini Camera 360 ...

By employing vision inspection systems in their facilities, industry professionals experience two key benefits: higher part quality and production quality. Both benefits arise from how the technology positively affects operations. More specifically, it facilitates part inspection—including defect detection, tolerance monitoring, and component measuring—and process automation—including automatically handling parts and performing processes, providing feedback data, and adjusting accordingly.

This is an 8000K pixels driverless camera of USB port with up to 3264*2448 resolution. Based on Sony IMX179 CMOS sensor, it supports auto focus, ...

Machine vision inspection systemsprice

Other features found on specialized objectives are variable working distance (LWD) and numerical aperture settings that are adjustable by turning the correction collar on the body of the objective as illustrated in Figure 2. The plan fluor objective on the left has a variable immersion medium/numerical aperture setting that allows the objective to be used with multiple different immersion media, including oil, water, and glycerin. The plan apo objective on the right has an adjustable working distance control (termed a "correction collar") that allows the objective to image specimens through glass coverslips of variable thickness. This is especially important in dry objectives with high numerical aperture that are particularly susceptible to spherical and other aberrations that can impair resolution and contrast when used with a cover glass whose thickness differs from the specified design value.

The focal length of a lens determines two interrelated characteristics: magnification and angle of view.

There is a wealth of information inscribed on the barrel of each objective, which can be broken down into several categories. These include the linear magnification, numerical aperture value, optical corrections, microscope body tube length, the type of medium the objective is designed for, and other critical factors in deciding if the objective will perform as needed. A more detailed discussion of these properties is provided below and in links to other pages dealing with specific issues.

Vision systemsfor qualityinspection

Multilayer Coatings - Quality microscope objectives are protected and enhanced by unique high-transmission anti-reflective multilayer coatings that are applied to the lens air-interface surfaces to reduce flare and ghosts and ensure high-contrast images. These specialized coatings are also used on the phase plates in phase contrast objectives to maximize contrast.

To attain higher working numerical apertures, many objectives are designed to image the specimen through another medium that reduces refractive index differences between glass and the imaging medium. High-resolution plan apochromat objectives can achieve numerical apertures up to 1.40 when the immersion medium is special oil with a refractive index of 1.51. Other common immersion media are water and glycerin. Objectives designed for special immersion media usually have a color-coded ring inscribed around the circumference of the objective barrel as listed in Table 3 and described below. Common abbreviations are: Oil, Oel (oil immersion), HI (homogeneous immersion), W, Water, Wasser (water immersion), and Gly (glycerol immersion).

What is OCR (Optical Character Recognition)?. Optical Character Recognition (OCR) is the process that converts an image of text into a machine-readable text ...

To learn more about our vision inspection systems and other solutions or partner with us on an upcoming project, contact us or request a quote today. One of our customer service representatives will answer and address any questions or concerns you may have.

Some objectives specifically designed for transmitted light fluorescence and darkfield imaging are equipped with an internal iris diaphragm that allows for adjustment of the effective numerical aperture. Abbreviations inscribed on the barrel for these objectives include I, Iris, and W/Iris. The 60x apochromat objective illustrated above has a numerical aperture of 1.4, one of the highest attainable in modern microscopes using immersion oil as an imaging medium.

Ms.Cici

Ms.Cici

8618319014500

8618319014500