Ring Light - lighting ring light

VisionSystem design

Benefit from our comprehensive training programs for all personnel levels, supported by an expert team of vision, controls, and automation engineers. Operators, maintenance staff, and engineers will gain valuable knowledge and access to a robust support network.

Meet your manufacturing deadlines with the quality you demand. Unify your production data and quickly identify and resolve issues. Our inspection machines automatically send data to your factory information system, database, or controller, ensuring your builds stay on track.

Transform your operations into a flexible smart factory with adaptable, automated quality control. Our vision systems offer precise guiding, inspection, and sorting, leveraging industrial automation to maximise quality and eliminate defects. Be Industry 5.0 ready.

Vision& Control gmbh

For the identification and traceability of products and components, codes are applied to them using various methods, such as laser marking, needling or printing.

User-friendly operator guidance systems combined with automated visual inspection. Augmented Reality, 3D vision and robotics.

Industrial machinevision

Rest easy. Our engineers handle the complete vision system integration and commissioning, freeing your team to focus on your busy manufacturing schedules. We deliver ready-to-run, fully integrated systems, machines, and cells.

Remove risk by using our experienced engineering team. Our expert vision engineers will get you automated quicker and faster.

Our systems inspect food packaging to ensure it contains accurate information about ingredients, nutritional information and allergens.

Gain swift insights into your production process with concise, traceable data and image records. Monitor real-time defect rates, spot quality issue spikes, and receive instant failure threshold alerts. Take proactive corrective action to ensure your products meet the highest standards.

Our vision systems and machines are used in a wide range of industries. Almost any manufacturing industry sector can benefit from IVS applying machine vision for automated quality control, identification, guidance or quality verification.

A vision system like no other, powered by advanced algorithms and enhanced intelligence. Our solutions feature extendable processing, robust artificial intelligence, deep learning, and traditional machine vision tools to tackle any application with precision and efficiency.

Explore our complete range of robot vision products and integrated solutions for flexible machine vision inspection and precision guidance.

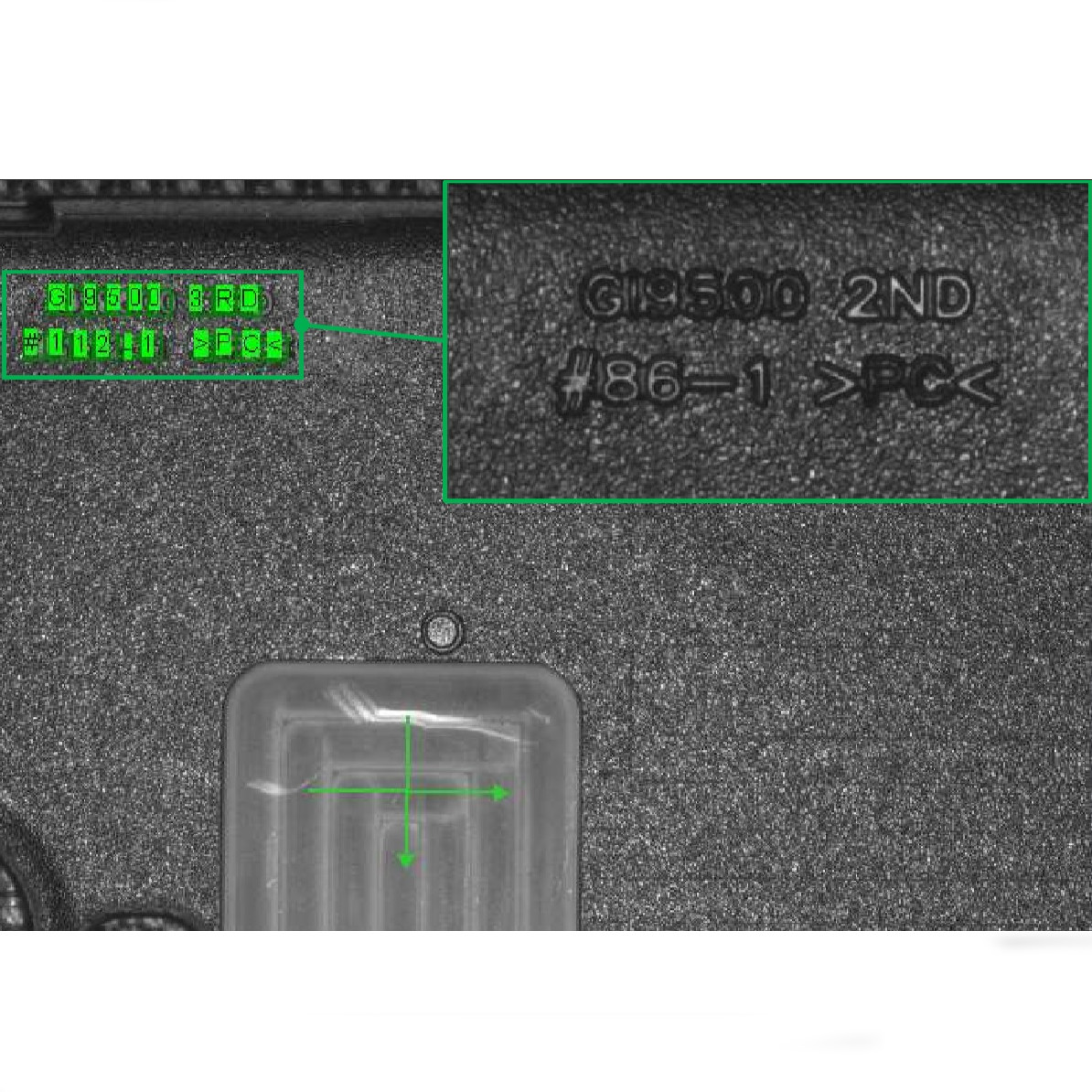

With the help of our machine vision systems, we guarantee texts on electronic products with correct information about safety warnings, batch numbers, etc.

Automatically save and archive Ultra HD photos of all your products, before they leave the factory. Save photos against part, serial and lot numbers for recall and warranty protection.

To ensure the quality and readability of barcodes, there are several standards such as AIM/DPM or ISO/IEC. These define partly different quality characteristics for the evaluation of codes. AIM/DPM is aimed at directly marked barcodes, while ISO/IEC 15415 deals with printed 2D codes.

Contact us today, and our knowledgeable engineers will find the best machine vision solution for your application. Benefit from our comprehensive AI inspection solutions, including 2D, 3D, confocal, and more. We have the right solution for you.

Semi-automatic inspection of pharmaceutical production. Detect flaws, defects and particulates at pace, providing convenient support for high-throughput operator inspection.

Our extensive machine vision laboratory enables rapid testing of your products. With skilled expertise, we deliver timely demonstration results and provide outcomes, parametric tests, and measurements at your fingertips.

Human visual system

Our Product family covers everything from vision system component supply up to fully customised machine vision systems designed, built, and installed by our expert engineers.

Integrated industrial automation solutions for automated non-contact inspection. Detect unanticipated defects, maximise quality and eliminate escapes. Inspection machines, benches, lines, robots, and cells – ready-to-run.

Thanks to its training, an AI system has a diverse collection of fonts that allows it to effortlessly handle a wide range of characters, regardless of their size, style, or stroke width, without prior training. If necessary, additional characters can be integrated into the training to further increase the robustness of the system.

Visionsystem examples

We deliver full automation and integration, incorporating third-party equipment such as conveyors, robots, sensors, pick & place systems, and other automation tools into our machine designs, boosting your efficiency.

Machinevision

Our machine vision systems combine leading-edge technology and high-performance image processing to solve a wide variety of automated inspection, identification, and quality control problems. Take a look at each of the areas we cover – the chances are we have a solution for your inspection requirement.

Discover our full range of high-speed quality control vision inspection products for contact lens and optical lens production.

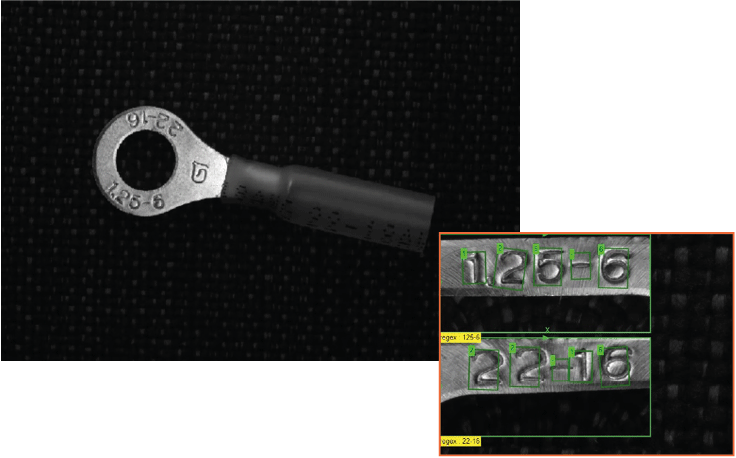

AI-based reading tools are adaptable and can easily handle different fonts, sizes, and layouts without the need for complex manual adjustments. Especially in the case of stamped or embossed fonts and inkjet printing (e.g. sell-by dates on food packaging), the character representation can vary considerably while the text remains legible to the human eye. This is where the strengths of AI come into play.

Segmentation has always been the biggest challenge with previous OCR systems. Fluctuating brightness or variable backgrounds could quickly lead to false reads. AI systems, on the other hand, are able to segment and classify characters even on inhomogeneous backgrounds. This significantly increases reliability and robustness in many industries.

Precision machine vision inspection for quality control in automotive, engineering, and related industries. Clever vision systems, easily deployed.

Similar to inhomogeneous backgrounds, weak contrast can also quickly bring classic font reading systems to their knees. Here, too, Deep Learning shows its strengths. An AI system can even read raised lettering on rough surfaces such as cast aluminum robustly and reliably.

Visionsystems inc

Leading vision inspection machines for medical devices and pharmaceuticals, from standalone benches to fully automated systems.

Easily inspect, sort, grade, and classify your manufactured components with 360-degree comprehensive analysis at speeds of up to 600 parts per minute.

The planning of OCR and OCV systems requires extreme care. In addition to the correct camera resolution, suitable illumination of the reading area is crucial. In particular, the choice of illumination wavelength, whether visible light or infrared, can have a significant impact on background suppression. Different printing methods also require specific reading instruments. While conventional methods may be sufficient in some cases, we increasingly recommend the use of our AI-based tools for reliable inspection results.

senswork is an expert for complete solutions in the field of machine vision, optical inspection, Deep Learning and test equipment manufacturing. Our solutions for automation and quality assurance are used daily in numerous industries such as the automotive industry, mechanical engineering or food industry. From our locations in Burghausen and Munich, we serve renowned customers from industry and research. From the initial concept to the integration of the finished solution, we offer everything from a "one stop shop". We analyze your tasks in detail and address individual specifications in order to develop a precisely fitting camera system, the perfect test station or the ideal test device.

Our experts have successfully implemented machine vision solutions in diverse industries around the globe. Discover how we can assist you with your vision inspection needs.

Ms.Cici

Ms.Cici

8618319014500

8618319014500