Introduction to the Case of Bottle Cap Inspection

With the improvement of living standards, food quality and safety have become the focus of social attention. People's requirements for food safety are getting higher and higher. The production date code is an important basis for judging the validity period of food. Therefore, ensuring the correct and clear marking of production dates and other related information is an important link in the food production process.

Food production has the characteristics of high speed and large output, and has high requirements for appearance quality. Such highly repetitive and large-scale work, if relying on manual inspection, will bring huge labor management costs. Manual inspection is slow and inefficient, and there are problems such as fatigue misjudgment after long-term work.

The use of machine vision technology for production information code collection and detection is an inevitable development trend. It has high accuracy and high work efficiency, and can significantly reduce production costs. Machine vision technology detection has a very broad application prospect in the production and manufacturing process.

LOTS AUTOMATION has been deeply involved in the machine vision industry for many years and has extensive experience in bottle cap inspection (such as production date character detection, logo recognition, scratches, etc.). Below, we will share some cases in the food industry regarding character recognition on beverage bottle caps and surface defect detection.

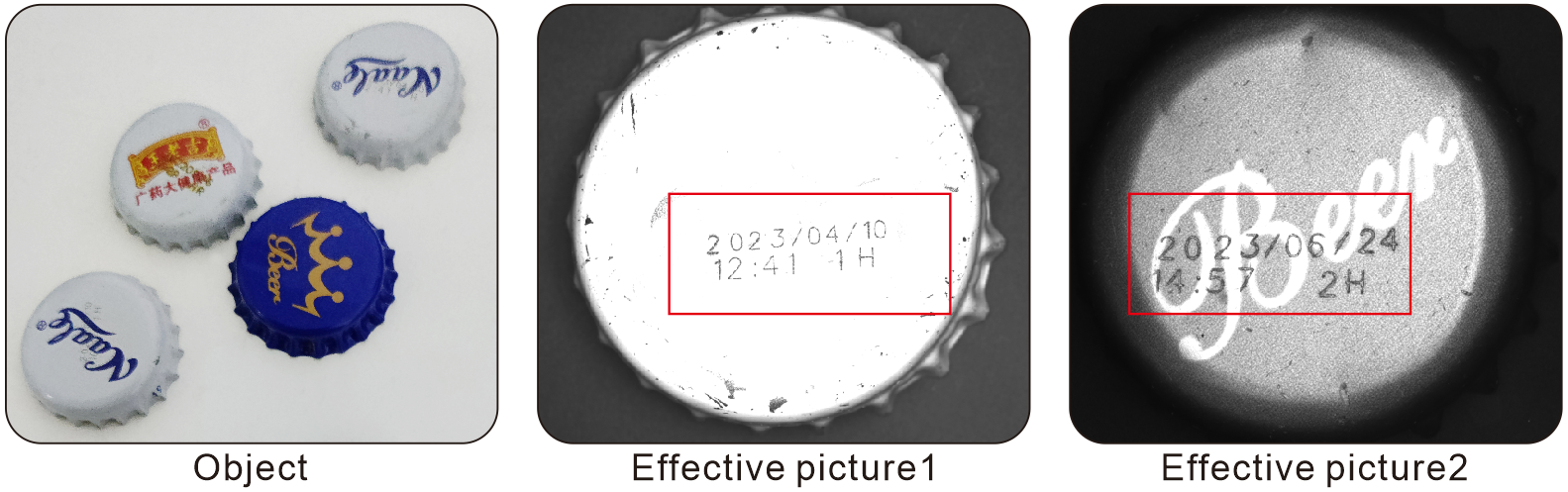

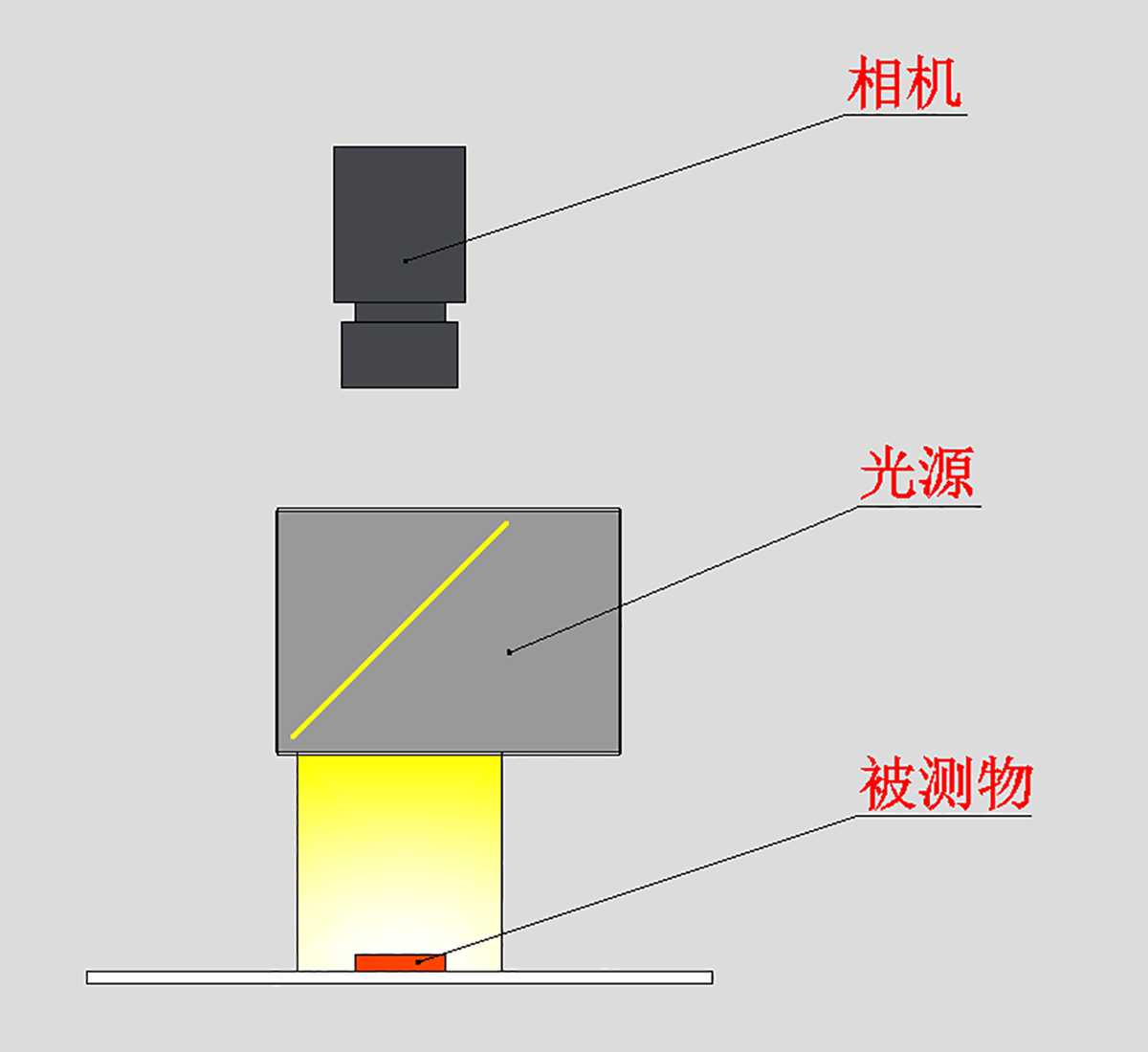

Case 1: Character Detection of Production Dates on Metal Beverage Bottle Caps

The task is to detect the date characters on different colored bottle caps. The challenge lies in the wide variety of colors and the significant background interference. After testing with various types of light sources, it was finally determined to use a coaxial light source with a vertical optical path.

Effective picture 1: The product has a white background which is highly reflective. Using high-intensity illumination, the background and the pattern appear white, while only the black characters stand out clearly against the background.

Setup |

Light |

Effective picture 2: The product surface is frosted and has slight deformation. If it is too bright, both the background and the characters will be overexposed. A digital controller is used to automatically adjust the brightness to an appropriate level. Although the background does not have a more obvious contrast compared to the first image, there is still a certain contrast effect, ensuring stable detection and determination.

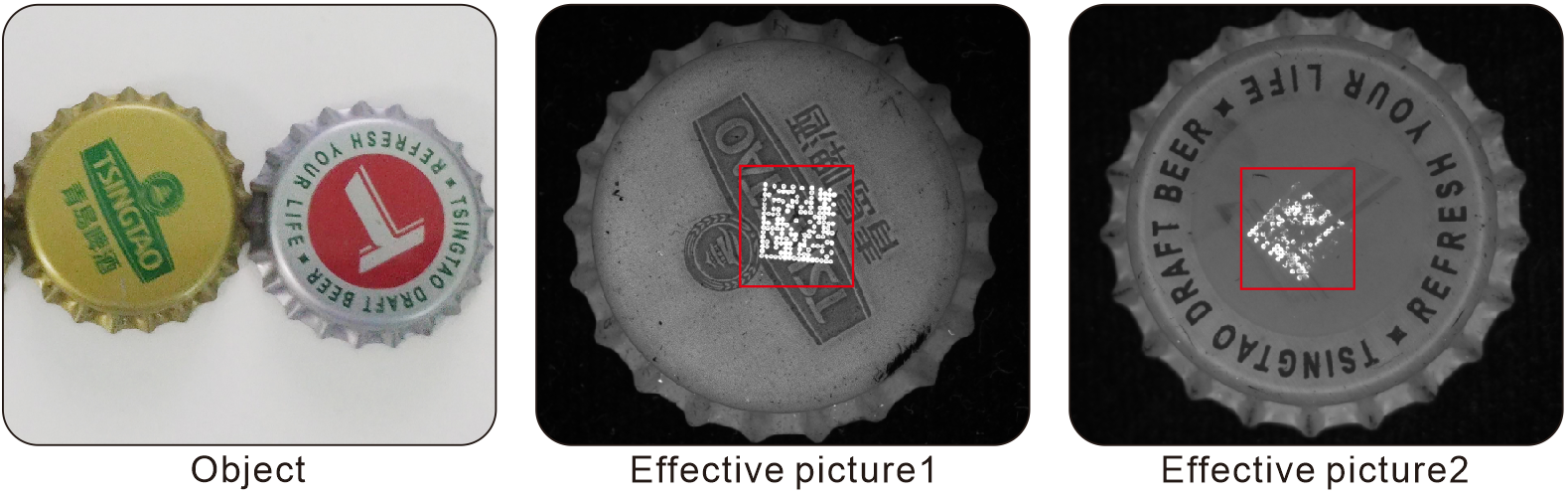

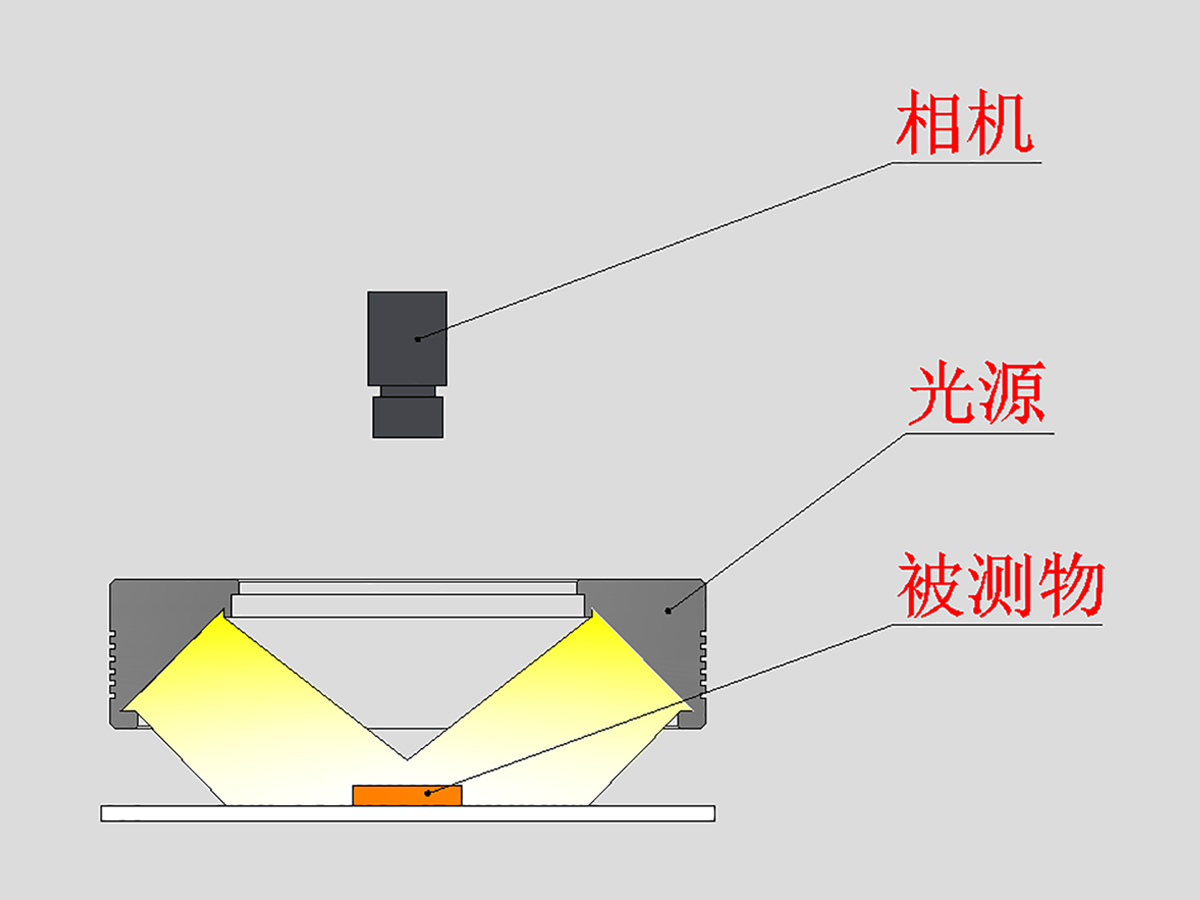

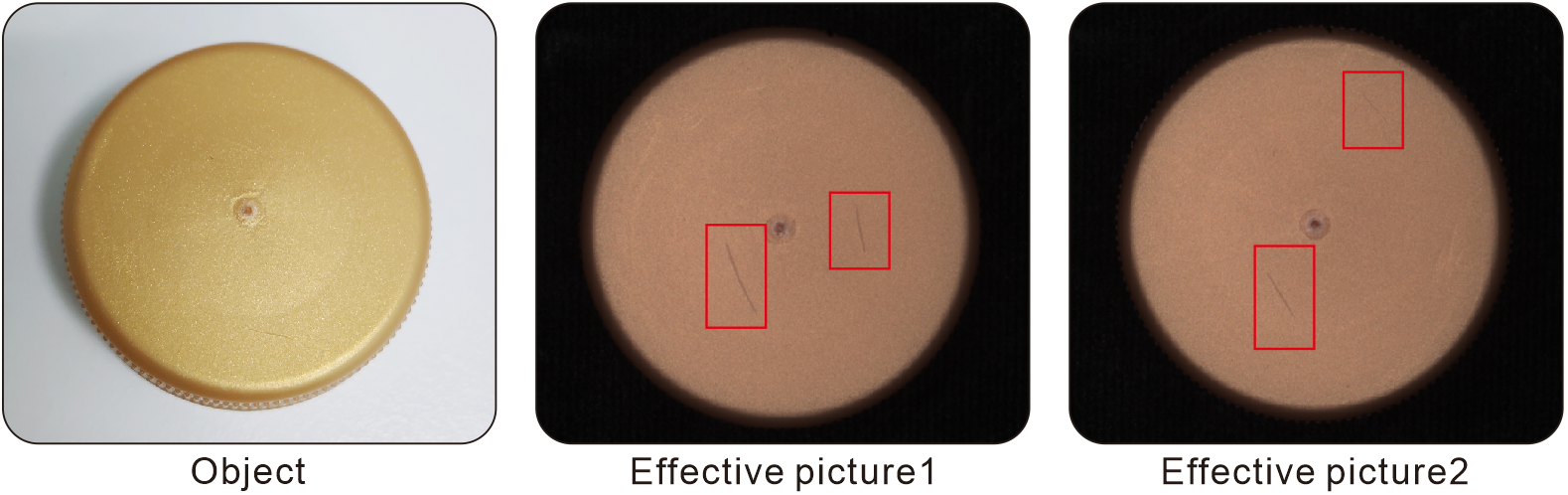

Case 2: Detection of QR Codes and Character Patterns on Beer Bottle Caps

The requirements for this project are to accurately detect the anti-counterfeiting QR code and the green printed character patterns. If only the anti-counterfeiting ink code is detected, a green light source can be used to filter out the background of the character patterns, but both need to be detected simultaneously. This increases the difficulty of the shooting process because the character patterns also need to be detected. Therefore, the character patterns cannot be eliminated. If the differences are not significant, the two will interfere with each other and affect the detection judgment.

After comprehensive analysis, a low-angle circular light source with a color of yellow is used for shooting, making the background gray-white, the character patterns gray, the anti-counterfeiting QR code white. The overall contrast effect is obvious.

Setup |

Light |

Case 3: Inspection of Character Printing on Plastic Beverage Bottle Caps

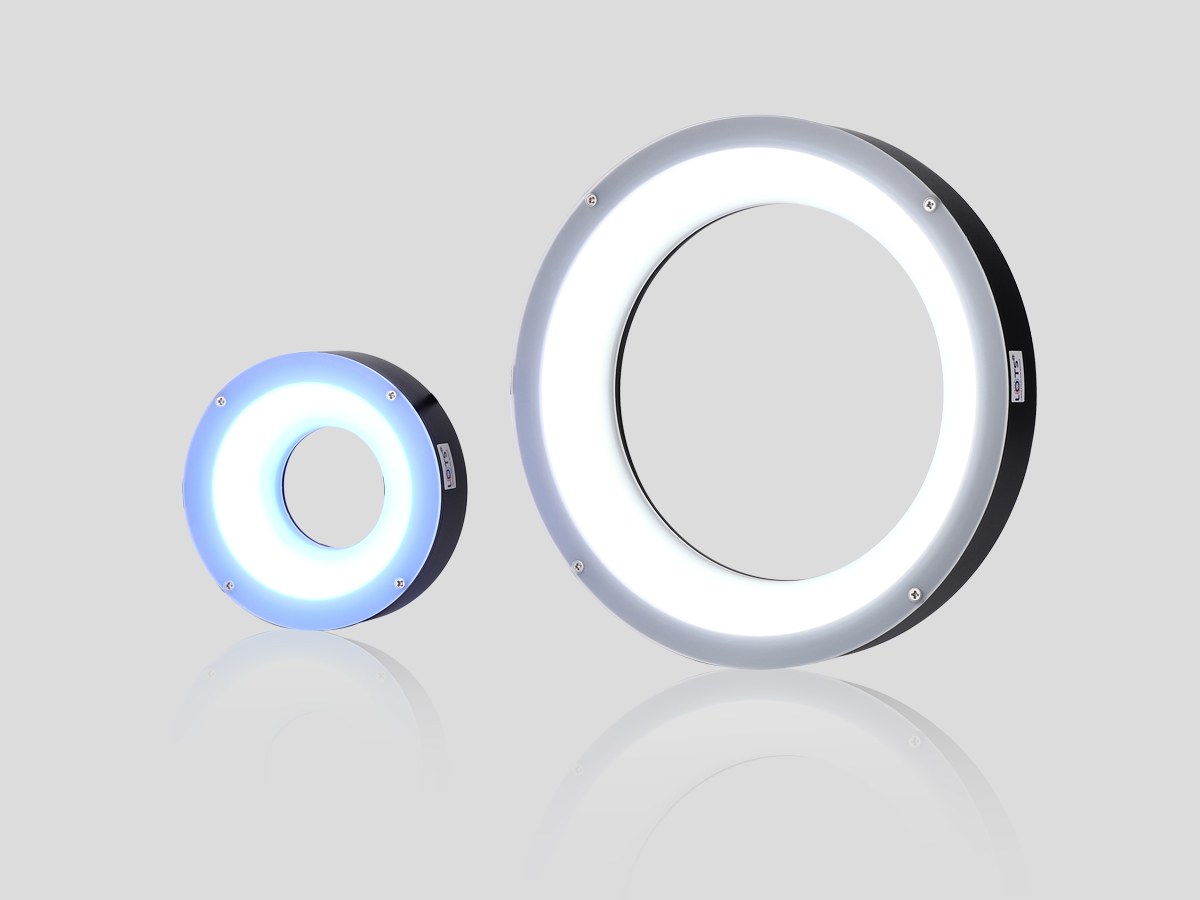

The requirement is to detect whether the printed characters on the bottle cap are present or not. This type of detection is relatively simple. From the pictures, an unqualified product is one without any printed characters and white with no features, while a qualified product is one with color and printed characters. After testing and judgment, using a circular shadowless light source for shooting ensures that the detection surface is uniform and there is a good contrast effect.

Figure 1: The product is shot with uniform light source and the LOGO contrasts clearly with the background; Figure 2: The product lacks the printed LOGO and is completely white with no features, which is judged as an unqualified product.

Setup |

Light |

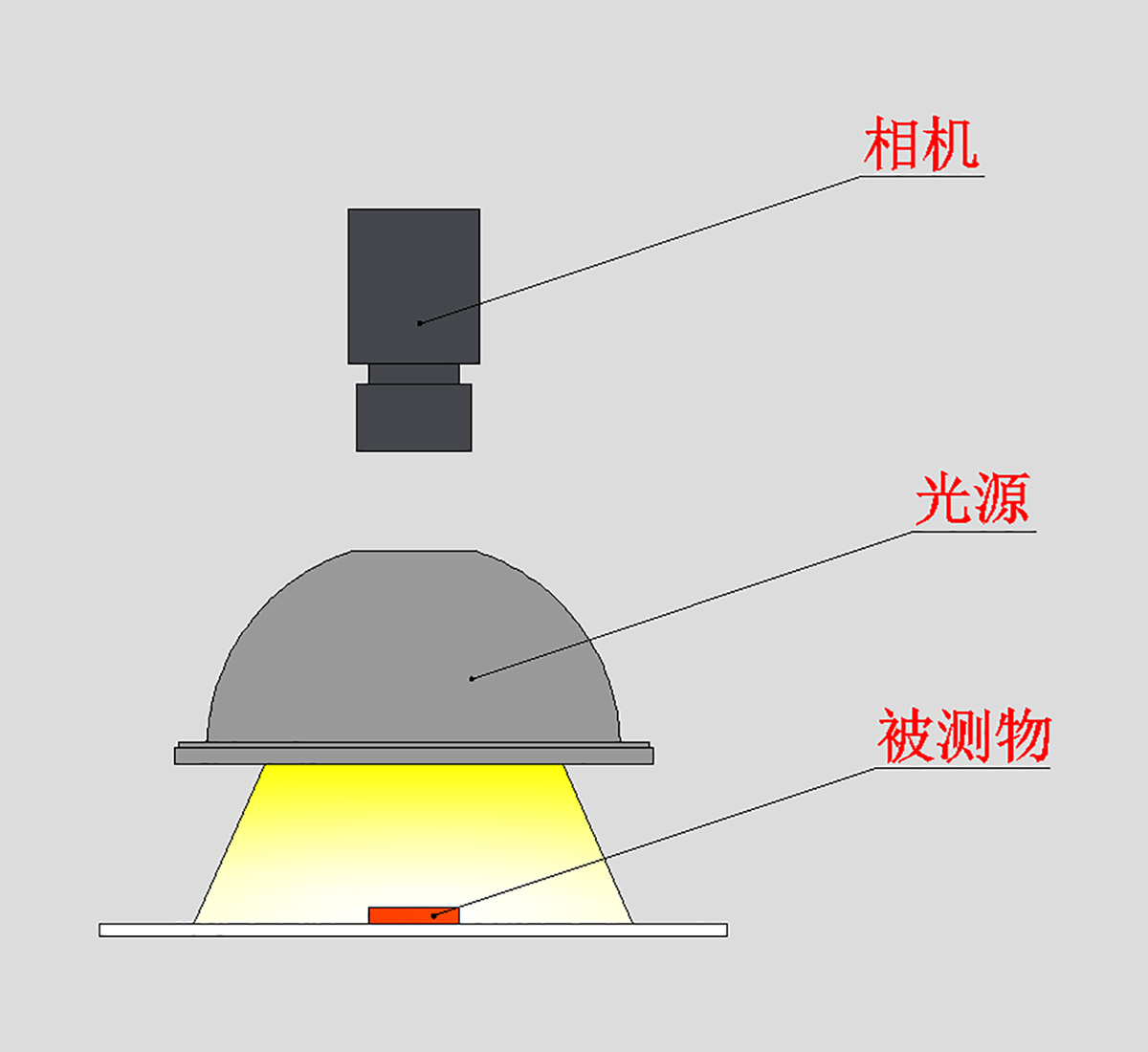

Case 4: Detection of Surface Defects on Plastic Bottle Caps

To detect defects such as scratches, dents and dirt on the surface of plastic covers, a high-angle vertical light path type light source is generally used, such as a high-angle ring light or coaxial light source. However, the product surface has a slight curvature and is a frosted surface. Using such a light source will be uneven, resulting in a significant difference in gray levels and affecting the detection results.

After comprehensive analysis, our company's dome light source is adopted, with an appropriate increase in the working distance, approaching the type of high-angle light source irradiation. This not only ensures the uniformity of imaging but also has the effect of a vertical light path, with a very obvious contrast effect.

Setup |

Light |

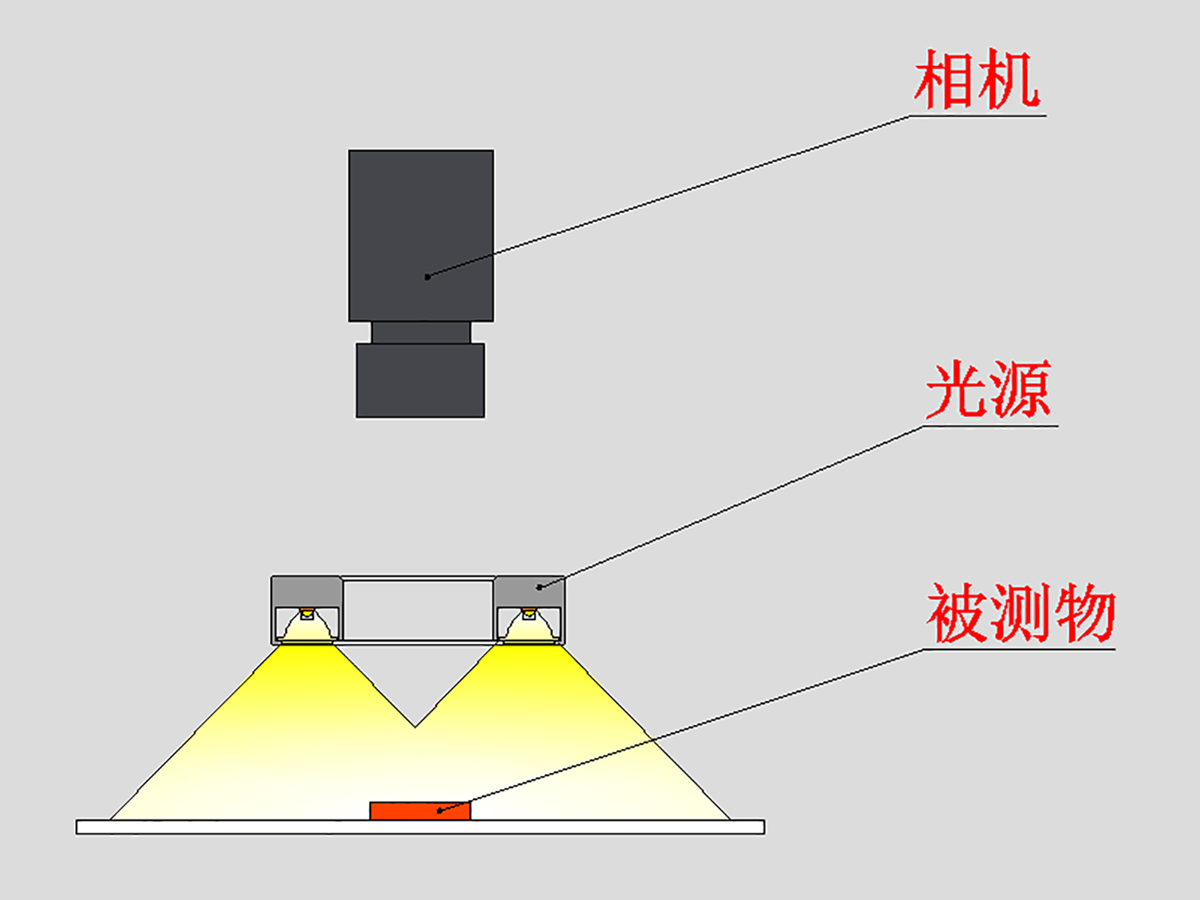

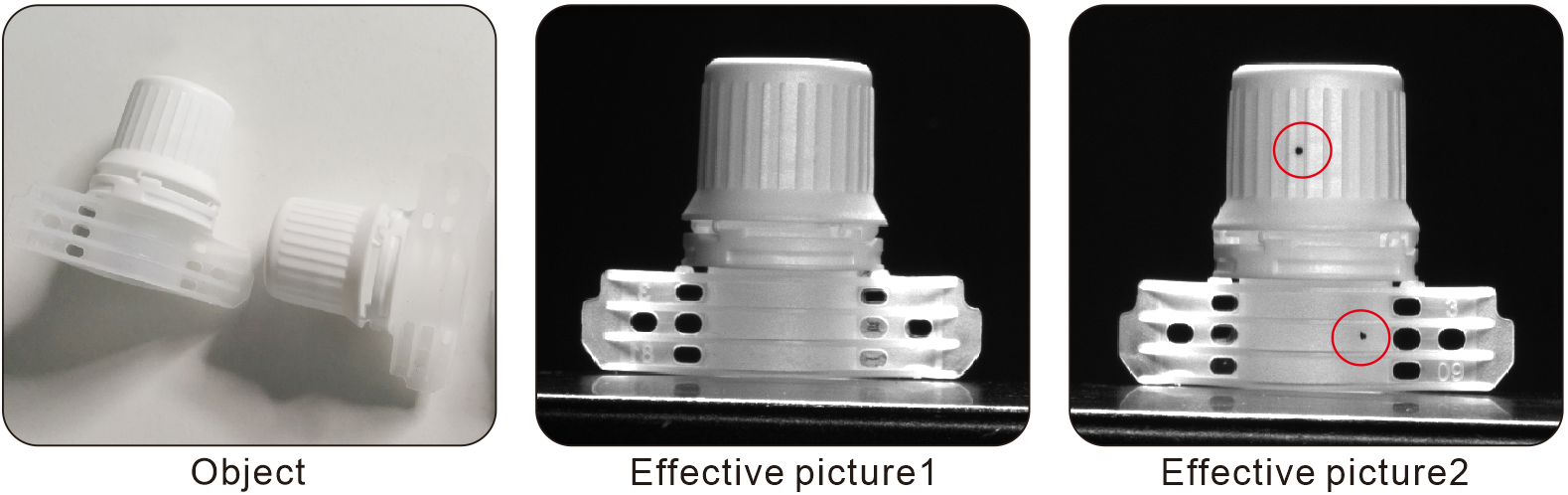

Case 5: Detection of Dirt on the Surface of Beverage Suction Cap

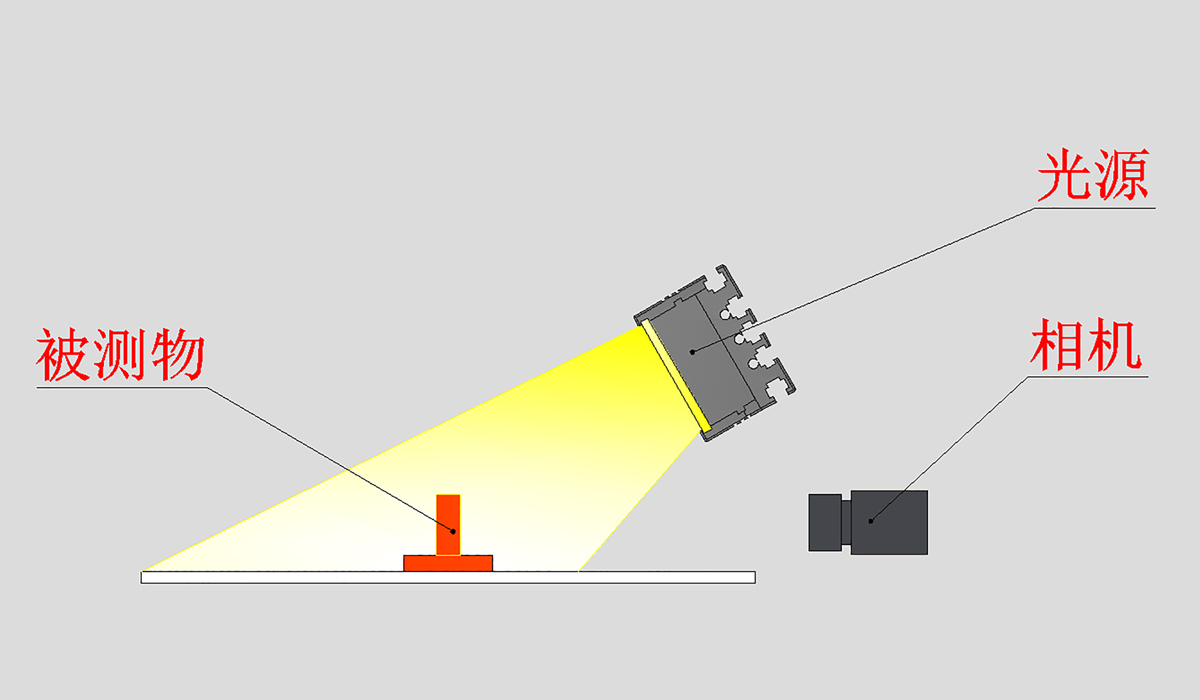

The requirements for the suction cap of children's beverages are extremely high. Not only in terms of hygiene, but also the material of the product itself is very particular. For visual inspection, only the characteristics such as dirt and defects need to be detected. Since the suction cap needs to be inspected in a full circle of 360 degrees, this also increases the difficulty of the inspection. This project adopts two cameras to take 1/2 of the shooting surface on the side each time, and a strip light is tilted slightly above to take pictures, which not only maintains the low-angle type surface inspection but also can maximize the uniform irradiation area as much as possible.

Effective picture 1: The surface of the product is clean and tidy, indicating it is an "OK" product. Effective picture 2: The surface of the product is dirty, indicating it is a "NG" product. It is very easy to identify the target that needs to be inspected.

Setup |

Light |

The above are some case studies of bottle cap inspection in the food industry. There are still many other inspection items required by the entire industry. If you have any related lighting requirements, you can contact our company to obtain case studies or send samples for lighting.

Thank you for watching. See you in the next episode.

Ms.Cici

Ms.Cici

8618319014500

8618319014500