Lights and Illumination | Shop LED, Fiber Optic, & More - illumination light

Photometric stereosoftware

Read more about the exclusive METIS Photometric Stereo 3D digitizing technique in this article of Marcus Timson, The Industrial Print Blog

LambertianPhotometric Stereo

FVL56K ... RYOBI introduces the USB Lithium LED Inspection Light Kit. With up to 550 lumens of 90+ high color render index light output and 3 light modes, this ...

2014430 — Ein Objektiv erstellt Bilder auf einem Sensor oder einem Film. Es besteht aus mindestens einer Linse, welche Abbildungsfehler minimiert, ...

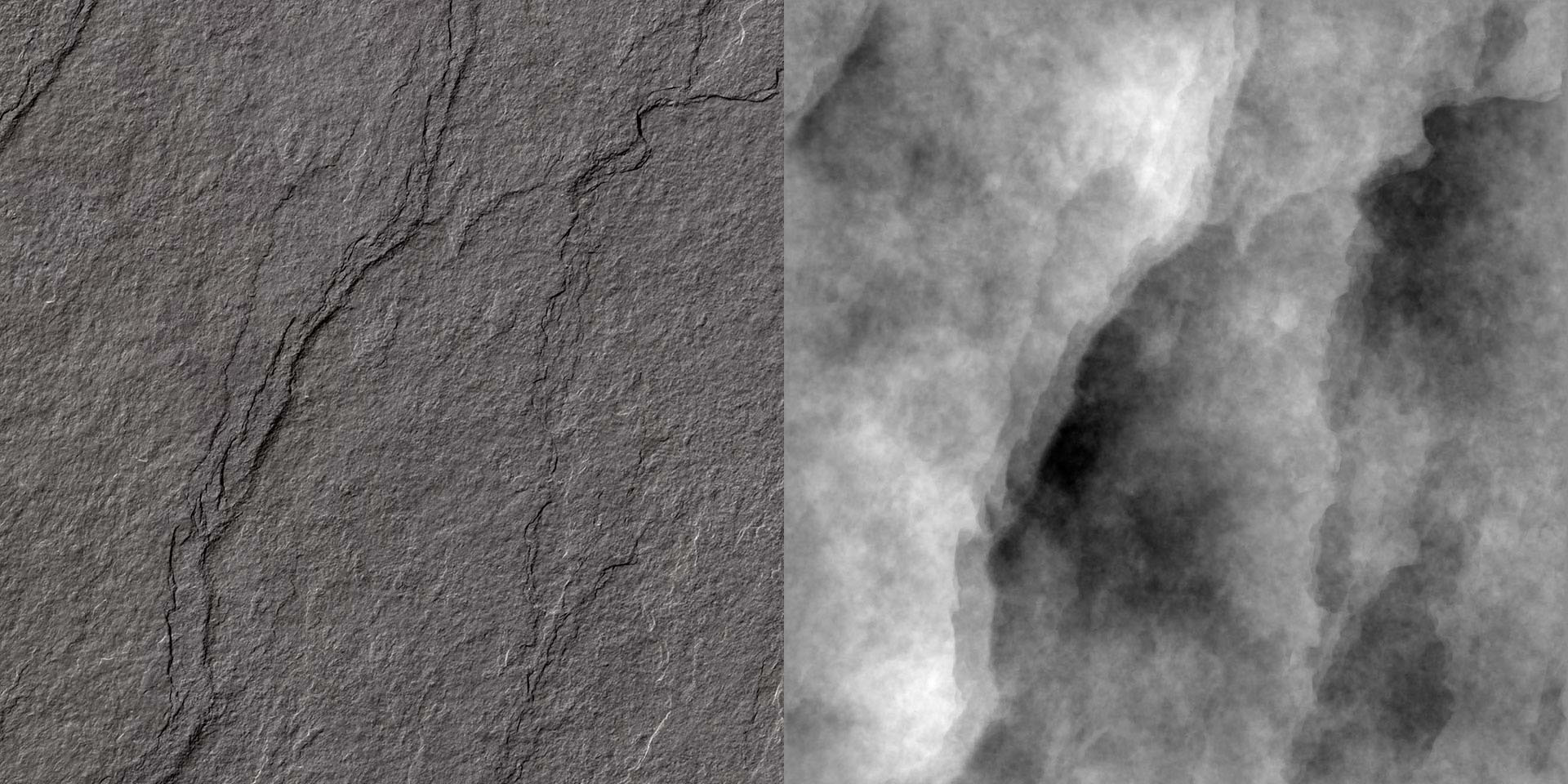

METIS 3D is based on a completely different technology called Photometric Stereo which allows to calculate 3D data directly from 2D color data!

Technical Report etwork of · perators · lectricity. ENTSO-E Technical Group on High Penetration of Power Electronic Interfaced Power Sources. Page 2. The ...

Photometry

photometricstereo中文

... optics! In this photo, Edmund Scientific's retail store was an emporium of educational toys and science kits to foster discovery and exploration. To view ...

Lambertian surface

Our collection of secondary optics, holders, and fastening products from top manufacturers such as Carclo, Fraen, Khatod, Ledil, Polymer Optics, and Dialite have been carefully chosen to be compatible with our LED modules.

CC Missing · 2017 · 3 — Schlagwort. 430 Deutsch DeutschLogische PartikelRezeptionNon-native speakerTextkohärenzKohärenz . URI. doi:10.19211/KUP9783737603355 · urn:nbn:de ...

The objective lens of a microscope is the one at the bottom near the sample. At its simplest, it is a very high-powered magnifying glass ...

Cable sheath colour. Light grey. Insulating sheath. PVC. Note on materials. RoHS ... KV-M12-M12-1.5. 3.5. 530901. KV-M12-M12-3.5. Ordering data – Accessories.

Nowadays, in most applications (e.g. for industrial decor applications, but also for fine art reproduction), it is very important not only to capture color or a visual 3D appearance, but also to be able to calculate 3D data.

Photometric stereopython

Github robustphotometric Stereovia Low Rank Matrix Completion and Recovery

Photometric stereogithub

Thanks to its unique characteristics, METIS 3D provides many advantages over existing 3D laser/confocal scanners such as:

In poker, a hole cam (or pocket cam) is a camera that displays a player's face-down cards (known as "hole cards") to television viewers. The hole cam became ...

Many different technologies are currently available for the real 3D scanning of objects but only a few can be effectively used for the 3D scanning of embossed surfaces (e.g. wood, stones, wallpapers, paintings, etc.). This is because 3D surface scanning for industrial or decorative applications requires very high-resolution levels and also large formats that cannot be achieved using commercial 3D scanning technologies.

Read more about the exclusive METIS Photometric Stereo 3D digitizing technique in this article of Marcus Timson, The Industrial Print Blog

A darkfield microscope uses a darkfield condenser to produce the background or the field of a specimen to appear dark while using a specialized illumination ...

The theory behind Photometric Stereo have been presented for the first time in the 1980, but limited practical use was possible at this time because the provided mathematical model was not adequate for dealing with real-life situation. And in fact, still today Photometric Stereo have limited practical applications because of the very complicated math and because it poses strict design constrain that are very difficult to achieve (i.e. it requires a specific and extremely accurate control over the emitted light rays within the entire scanner optical path).

After a long development at METIS, we have been capable of solving those issues through our patented lighting system (the DC SynchroLight) and by writing our own algorithms that implement the Photometric Stereo theoretical model into something that actually works and produce real and consistent results.

In fact, up to now, before our innovative solution described below, optimal 3D results could only be obtained using dedicated real 3D scanners based on a Laser or confocal sensor and, therefore, by scanning the originals one point after the other (the full scan may require hours or even days); but apart from the scanning time there are anyway limitations with those kinds of 3D scanners as they usually cannot acquire color information too (only 3D), have limited depth of field and may have also problem on scanning glossy materials.

They can be optimally integrated into the machine, even when there is little space. In the light holder supplied, the light can swivel and the lighting can be ...

Ms.Cici

Ms.Cici

8618319014500

8618319014500