Parallel Beam: Definition, Analysis & Light Waves Effects - what is meant by light rays being divergent

So long as the adhesive bond is illuminated by the light, the reaction carries on. However, if the light is removed too early, the reaction pauses. Consequently, it is important to cure a light curing adhesive the correct amount of time. Too short curing time leads to incomplete cure (which is why a safety factor is incorporated) and too long cure time can cause degradation of the adhesive. Degradation will weaken the bond and cause discoloration. Exposing the adhesive to 2-3 times the recommended dose is usually ok.

BestUV glue

Probably, two materials (‘substrates’) are being bonded together. This means that at least one of these materials must transmit the light so that it can reach the bond line. All materials do not have 100 % transmission of UV/Vis light and a transparent material is required. In addition, some plastics, for example, can be UV blocking, even though they are transparent. In some cases, the plastic can be cured with blue light (405 nm).

BondicUV glue

Light Meters are measurement devices that feature photodiodes to determine the level of light transmitted from a source.

Electrically conductive adhesives are used in many different types of industries and applications. Some examples are electronics, solar cell, medical, aerospace, space and automotive applications.

Light absorbing black out materials used in optics and photonics applications are available at Edmund Optics.

UVcuringGluefor Plastic

UV curing adhesives, or light curing adhesives, cure quickly when exposed to light. We will discuss advantages and disadvantages.

When a linearly polarized beam is incident on a half-wave plate, and the polarization of this beam does not coincide with one of these axes, the output ...

Our brightest Flexible LED Solid Color light Strips soft and easy bent for installation. Available in 5 meters (197 in) Non-weatherproof flexible light strips ...

There are, as mentioned, several different types of light curing adhesives and they are based on different chemistries. What they have in common is that the adhesive formulations contain monomers and oligomers (building blocks for the adhesive) and some type of photoinitiator (small molecule that initiates the curing reaction with the help of light).

Light curing adhesives are first and foremost used when a fast cure speed is desired. Often, a full cure is achieved in seconds and that is also the main advantage of this type of adhesive.

UVcure Adhesive

Smart Vision Lights is the leading designer and manufacturer of LED lighting solutions for any type of machine vision or automation camera application.

20241121 — Table 1: The useful magnification range (UMR) for an optical microscope depends on the wavelength of light used for illumination and the ...

UV Gluefor acrylic

2024131 — This artistry finds expression in landscape lighting techniques, particularly shadowing and silhouetting, which create visually appealing and emotionally ...

Parts of the Microscope ... Ocular lenses: These eye pieces are lenses that magnify the image of the specimen. The magnification of the ocular lenses is often ...

When choosing an adhesive for your application, it is advantageous if you consider the adhesive viscosity to best suit your application and process.

A light curing adhesive is not really a type of adhesive, but a curing mechanism. There are for example light curing acrylics, epoxies, silicones and cyanoacrylates.

When the photoinitiator absorbs light of a certain wavelength and intensity, it starts a polymerization reaction – the adhesive cures. It is important to make sure that the adhesive matches the UV lamp meant to be used: Intensity, wavelength of light, LED or broad spectrum, and the configuration of the lamp are all important aspects to consider.

UVadhesive for Glass

Medical grade adhesives are commonly biocompatibility tested according to ISO 10993 standard. Choose Epoxy, UV-curing adhesive or silicone.

The light from a lamp must have an intensity over 50 mW/cm2. Sun light, which has an intensity around 2-5 mW/cm2 will thereby not suffice.

Silicone rubber is one of the most difficult-to-bond rubbers. We will give you options for adhesives that can help you bond silicone.

USA: 10410 Corporate Drive, Sugar Land, TX 77478, USA China: 9, 19-20/F, Building 7A, 9F Building 7D, Shenzhen International Innovation Valley, Dashi 1st Road, Nanshan District, Shenzhen, Guangdong, China

The extended Mobile phone mount is an accessory included in our 10'' & 12'' ring light product series. With the Flex Arm, adjusta.

Camera lights provide the much-needed illumination when filming video footage or taking photos in low-light conditions. External flashes and on-camera lights ...

Compared with the general halogen lamp optical fiber cold light source, has the advantages of high light efficiency, energy saving, low calorific value, especially the service life is much higher than the halogen lamp. LED optical fiber cold light source adopts high-power single chip package LED as the light source, and specially designed kohler lighting concentrator system composed of 5 optical lenses, which can effectively couple the strong light of high-power LED to the fiber bundle, which has many advantages such as high light efficiency, energy saving, low calorimeter, long service life, low noise (<42db) and so on

Removing a cured adhesive can be tricky and the type will determine the method. The main methods are heat, chemicals and mechanical force.

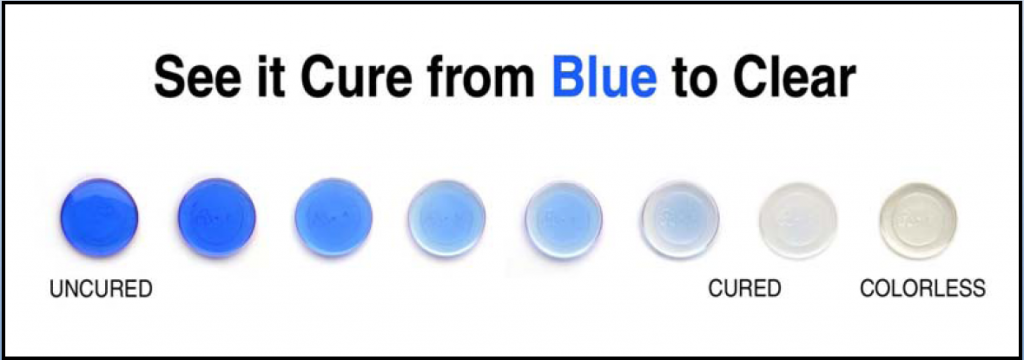

UV curing adhesives, often called light curing adhesives, are adhesives that cure when illuminated with light. But not just any light – different adhesives are adapted to cure at different wavelengths. Usually it is within the spectrum of UV-A or ‘blue light’, i.e. approximately 365 nm to 405 nm, which is why the term UV curing adhesive has been developed.

Ms.Cici

Ms.Cici

8618319014500

8618319014500