Lesson 1.1: How Do Cameras Work? - how to cameras work

In thespotlight

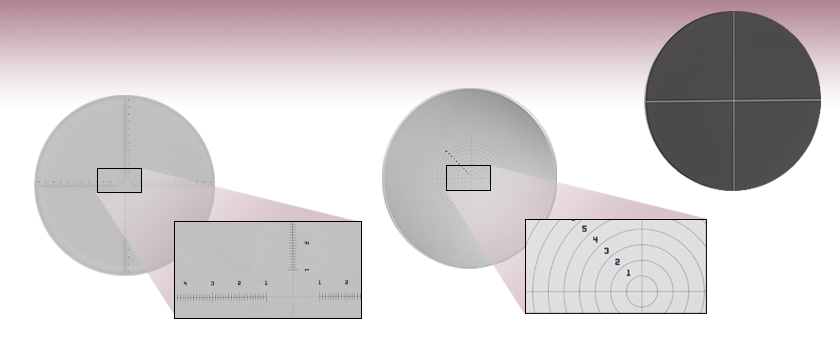

In addition to our catalog test targets and reticles offered from stock, we can provide custom chrome patterns on soda lime, UV fused silica, or quartz substrates from 8 mm by 8 mm up to 85 mm by 85 mm. Substrates can be cut to shape for your application. Our photolithographic coating process allows us to create chrome features down to 1 µm. A few sample patterns are shown below, which can be made positive or negative, as shown in the image directly below.

Spotlightsynonym

Our crosshair (crossline) reticles are used to superimpose a reference pattern on an object being imaged. The crosshairs span the entire diameter of the optic with lines that are 25 µm or 10 µm (Ø1" optic only) thick. Made by plating chrome onto one side of a 1.5 mm thick UV fused silica substrate, these optics provide greater than 90% transmission in the 200 - 1200 nm spectral range.

Because they are intended to be used in transmission, Thorlabs' line of reticles is made from a UV fused silica substrate, unlike our test targets, which are made from soda lime glass. UV fused silica provides excellent transparency from the infrared down into the ultraviolet.

The Ø19.0 mm reticle can be adapted to Ø1" mounts by inserting it into an AD19T or SM1AD19 Mounting Adapter. The AD19T adapter has a smooth outer perimeter, making it compatible with any standard Ø1" mount, while the SM1AD19 adapter has external SM1 (1.035"-40) threading, providing the ideal match for Thorlabs' line of SM1-threaded optomechanics.

Spotlightaustralia wikipedia

Our concentric circles reticles consist of a centered crosshair and concentric circles increasing in diameter by 0.5 mm, 1 mm, or 5 mm. The diameters are labeled in 1 mm increments (0.5 mm and 1 mm pitch circles) or 5 mm increments (5 mm pitch circles). The pattern is formed from lines that are 10 µm wide (0.5 mm and 1 mm pitch circles) or 250 µm wide (5 mm pitch circles). Made by plating chrome onto one side of a 1.5 mm thick UV fused silica substrate, these optics provide greater than 90% transmission in the 200 - 1200 nm spectral range.

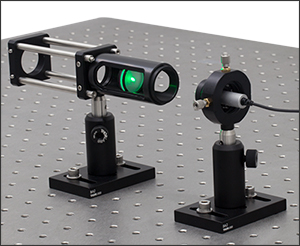

Reticles are optics that can superimpose a pattern onto an image or spatially filter light through a pattern. The reticle pattern provides a reference location and allows an imaged object or beam to be centered or measured. Many of our reticles are available as both positive and negative patterns. Positive reticles consist of high-reflectivity, vacuum-sputtered chrome patterns plated on clear substrates and are often placed in an image plane of an imaging system to superimpose the pattern onto an image. Negative reticles use the same chrome coating to cover the substrates, leaving the patterns clear and are often used as alignment targets for beams (see Figures 1-3) and in back-lit or highly illuminated applications. When backlit, the pattern of a negative reticle can be projected onto a dark image. Please see the Specs tab for a comprehensive list of options.

Our in-house photolithographic design and production capabilities enable us to create a range of patterned optics. We manufacture test targets, distortion grids, and reticles at our Thorlabs Spectral Works facility in Columbia, South Carolina. These components have served a wide variety of applications, being implemented in microscopes, imaging systems, and optical alignment setups.

The Ø19.0 mm reticle can be adapted to Ø1" mounts by inserting it into an AD19T or SM1AD19 Mounting Adapter. The AD19T adapter has a smooth outer perimeter, making it compatible with any standard Ø1" mount, while the SM1AD19 adapter has external SM1 (1.035"-40) threading, providing the ideal match for Thorlabs' line of SM1-threaded optomechanics.

All the parts shown here are manufactured at Thorlabs Spectral Works in Columbia, South Carolina. Our extensive production capabilities enable us to provide solutions for imaging system calibration and measurements. We use contact photolithography with a mask aligner to define the pattern on the glass substrate. Once the pattern is defined, we chemically etch the substrates and clean them in a class 100 cleanroom.

We do not suggest using a towel, rag, or wipe to dry the surface. If contamination persists, soak the reticle or target in a detergent and water solution for 1 hour, repeating as necessary.

The Ø19.0 mm reticle can be adapted to Ø1" mounts by inserting it into an AD19T or SM1AD19 Mounting Adapter. The AD19T adapter has a smooth outer perimeter, making it compatible with any standard Ø1" mount, while the SM1AD19 adapter has external SM1 (1.035"-40) threading, providing the ideal match for Thorlabs' line of SM1-threaded optomechanics.

Our scaled crosshair (crossline) reticles are used to superimpose a graduated reference pattern on an object being imaged. The crosshairs span the entire diameter of the optic with a graduated scale of tick marks that go up to 12 mm from center. The first set of tick marks are 2 µm thick and are spaced every 10 µm up to 1 mm from the center (the crosshair is also 2 µm thick within this radius). The next set of tick marks are 10 µm thick and spaced every 100 µm, extending from 1 mm to 12 mm from the center (the crosshair is also 10 µm thick from 1 mm from the center to the edge of the optic). Made by plating chrome onto one side of a 1.5 mm thick UV fused silica substrate, these optics provide greater than 90% transmission in the 200 - 1200 nm spectral range.

This tab details an optimal cleaning technique developed by our engineers for cleaning reticles, test targets, distortion targets, and calibration targets.

Ms.Cici

Ms.Cici

8618319014500

8618319014500