Wide Bar Silver Dollar Info Thread - widebar

White Light is a trading name of d&b solutions UK Ltd. Registered Office: 20 Merton Industrial Park, London SW19 3WL Registered Company No. 01031687

100-240 VAC 50/60 Hz powerCON power in and thru 28 A at 120 V (First half-cycle) 46 A at 240 V (First half-cycle) 9 fixtures (15 A power thru connector) or 10 fixtures (R20 module or similar) 147 W / 1.87 W at 120 V 1.24 A at 120 V

Spectrum illumination

Swappable lens tubes between 5-90 degrees 79-24 mm Gate size 6.25”-14” (depending on lens tube) aperture size Pattern projection A or B Pattern size 1,200 Hz (default) and 25,000 Hz (via RDM) Can be used with Source Four LED CYC and Fresnel adapters

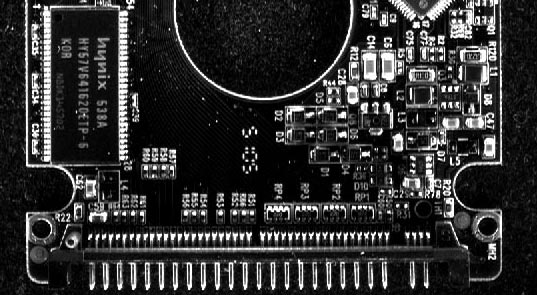

Only if it is possible to visualize the desired test characteristics or errors with enough contrast, these can then be evaluated with the image processing software. Usually the object is illuminated by an external light source. This principle sounds very trivial, but the practice reveals that it is one of the main difficulties of industrial machine vision to make the error in the object visible at all for the camera.

Tplvision

EFFILUX

Get to know ETC’s ColorSource® Spot luminaire, which boasts the same Red+Green+Blue+Lime LED mix as the ColorSource PAR washlight, bringing natural color and bright white light within reach of every budget.

The ColorSource Spot outperforms other four-color LED profiles, thanks to its precise combination of red, green, blue and lime emitters. ETC applied its extensive color-mixing knowledge to the fixture to ensure that it can achieve brighter, richer and more believable colors than other budget LEDs. And it accepts all the Source Four LED accessories, zoom and fixed-focus lens tubes, and CYC and Fresnel adapters.

SmartvisionLights

60 Lumileds LUXEON® Rebel LED 6,932 Max lumens 42.4 Lumens per watt L70 rating (hours to 70% output): 54,000 hours (both variants)*

Lighting plays a major role for industrial machine vision: Not the object itself, but only the visual image of the object is checked! It follows that only homogeneous lighting conditions result in a consistent image of the same inspection object. Fluctuating light conditions are therefore to be avoided at all costs!

Advanced illumination

Direct frontlight illumination Surface partly very bright but overexposed, partly dark due to total reflection. Diffuse dom light illumination Surface smoothly illuminated due to homogeneous incident light. Dark field illumination Lateral edges are very bright. Scratches and dust are visible. Backlight illumination Part appears only as black silhouette. No surface information, contures ideal for measurement applications.

The key role plays the light with its interaction in a functional chain of illumination, test object, filter, lens and camera:

As the object characteristics of inspected part cannot or can only hardly be influenced, the object determines the illumination and the camera! The camera, in turn, defines the optics due to its working distance and mount, due to its data format and data rate it also determines the image acquisition card.

Ms.Cici

Ms.Cici

8618319014500

8618319014500