Red Circuit Boards: Exploring Advancements and ... - circuit board red

The quality of your M12 connectors and cables directly impacts your connections’ performance and reliability. Metabee, a prominent connector manufacturer in China, is known for creating high-quality M12 connectors and cables. Ensure that the cables are specifically built for the application (e.g., power, data, etc.) and that the cable jacket material is appropriate for your environment.

M12 connectors, with their versatility and robust design, are employed in a wide range of industrial automation applications. Here, we’ll look at specific wiring diagrams for some of the most common uses of M12 connectors:

ZEB Metals specializes in the trading and recycling of non-ferrous metals within the scrap industry. The company offers services that include buying, processing, and selling scrap metal, with a focus on aluminum, ensuring competitive pricing and customer satisfaction. ZEB Metals operates a full-service scrap recycling facility to manage all processing needs. It was founded in 2021 and is based in Lewisport, Kentucky.

OmniSource is a multifaceted metals recycling company that operates in the scrap and secondary metals industries. The company specializes in collecting, processing, and reselling a wide variety of scrap metal, including ferrous and nonferrous materials and electronics scrap recycling services. OmniSource's primary customer segments include industrial scrap generators and manufacturing companies, to which it offers customized metal recycling programs and strategic partnerships. It was founded in 1943 and is based in Fort Wayne, Indiana.

M12 connectors are metric circular connectors that use a 12mm locking thread interface. They are the hidden heroes of industrial automation, quietly ensuring the consistent flow of data and power throughout complicated systems. They are made of high-quality materials such as nickel-plated brass or stainless steel, which provides outstanding durability and corrosion resistance. The strong shell protects the internal components from shock, vibration, and severe temperatures, which can be troublesome in industrial environments.

ReMatter provides software solutions for the scrap recycling industry, focusing on operations management and efficiency. The company offers tools for scale ticketing, inventory management, sales documentation, and dispatching, accessible via web and mobile applications. ReMatter primarily serves the scrap yard and recycling sector. It was founded in 2020 and is based in Palo Alto, California.

Dc power connector pinoutadapter

M12 connectors feature a threaded coupling that needs to be screwed together for a secure connection. This design provides the greatest strength and vibration resistance.

Consider working on a complex system that uses numerous M12 connectors. Pinouts and wiring diagrams serve as a road map, clearly illustrating how each connector should be wired. This saves you time and effort during installation, especially when working with various M12 coding types.

DCJack Femalepinout

I published a blog post about M12 connector types. You can learn more information about M12 connector coding in this post.

While this guide offers a general overview of M12 connector pinouts, color codes, and wiring diagrams, there can be variations between manufacturers. It’s crucial to read the manufacturer’s datasheets for your M12 connectors. These datasheets will provide the most accurate and up-to-date information regarding pinout, color code, and recommended wiring methods.

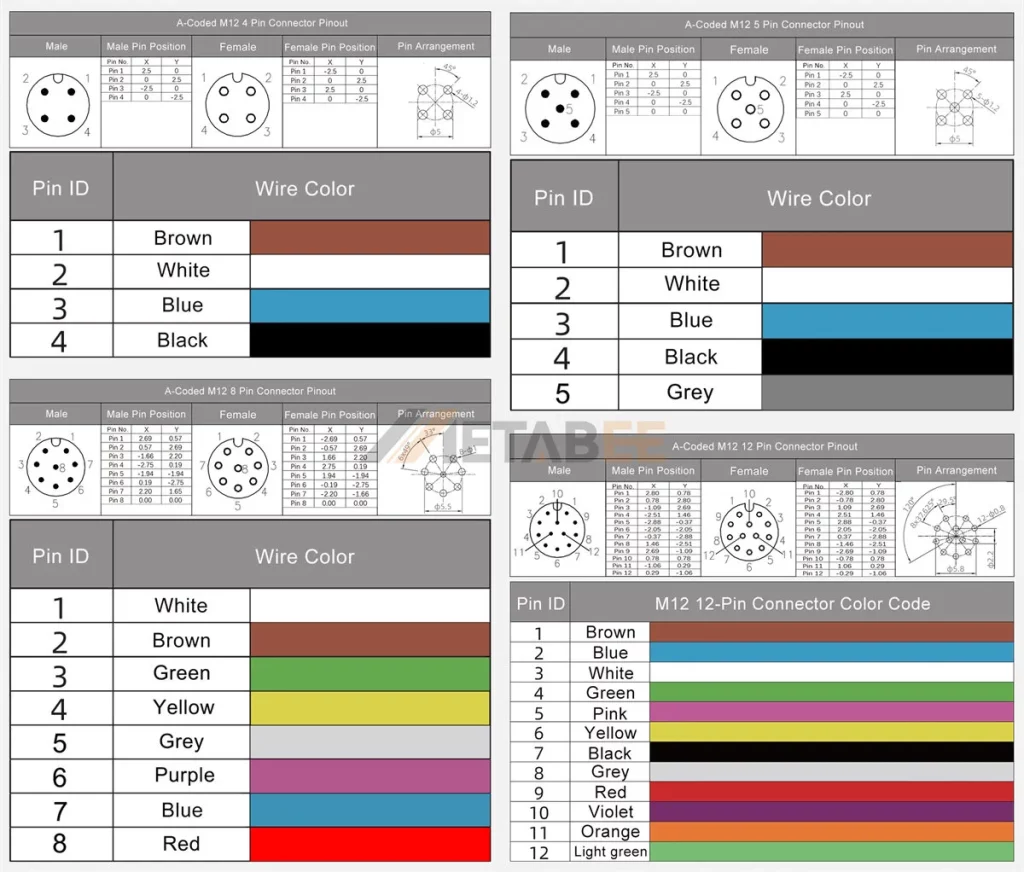

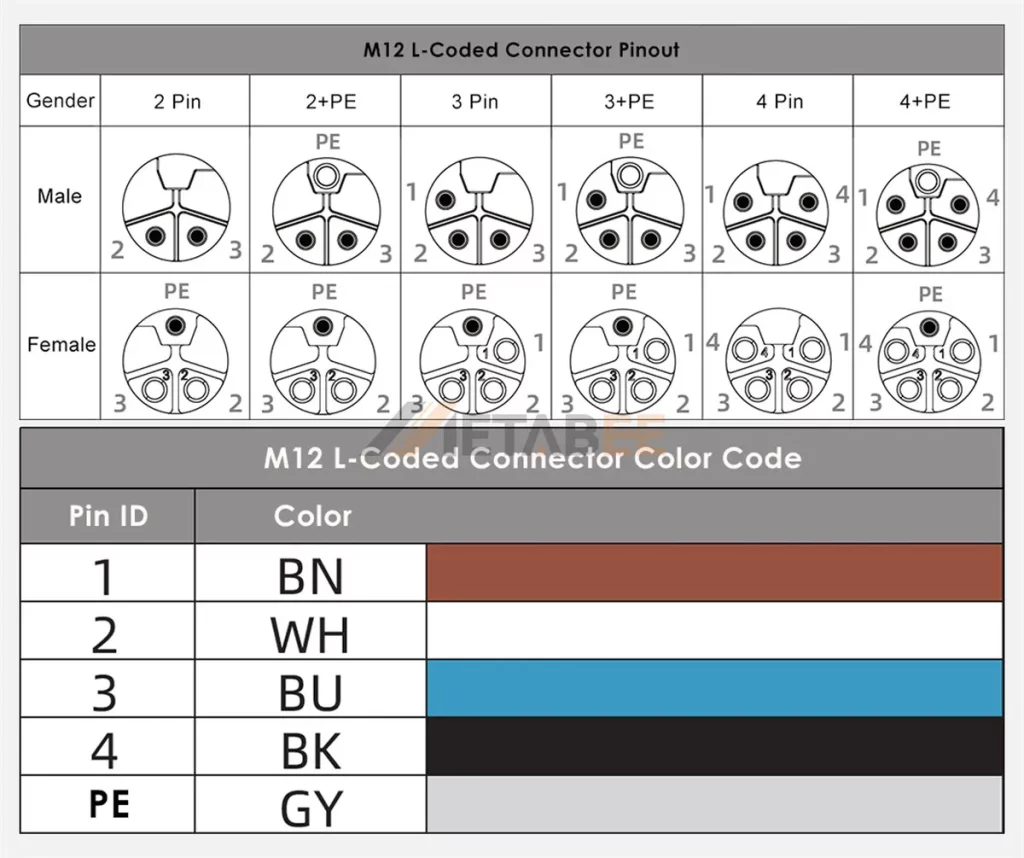

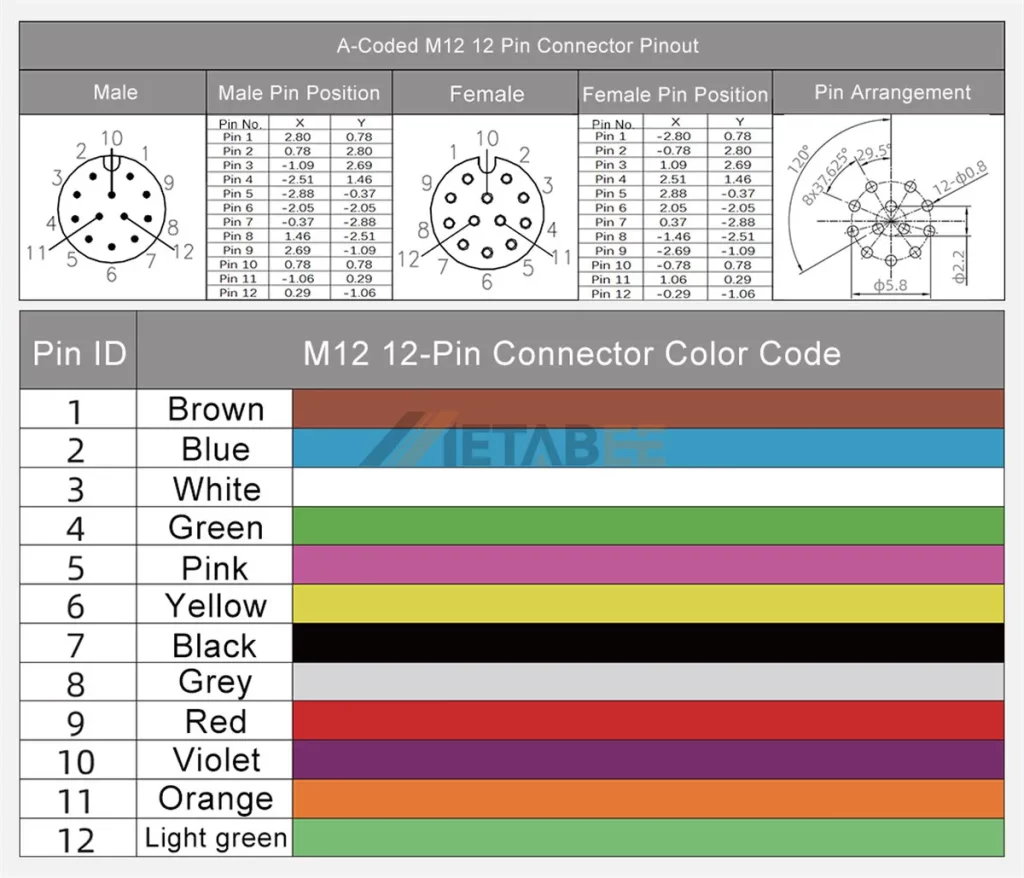

M12 connectors come in various codings, each with a unique pin configuration. Understanding the pinout, color code, and wiring diagram for your preferred coding type is critical for making correct connections. Here’s an overview of commonly used M12 connector types, along with their pinouts, color codes, and wiring diagrams:

M12 connectors are so important for industrial automation. They ensure the smooth flow of data and power in complicated systems. However, their functionality is dependent on making the correct connections. This is where pinouts, color codes, and wiring diagrams come in.

M12 connectors provide a strong and user-friendly solution for industrial connections. However, a few important considerations can ensure a smooth and successful experience:

ScrapWare is a specialized software provider focused on the recycling industry's unique operational needs. The company offers a suite of software modules designed to streamline processes such as purchasing, sales, inventory management, and compliance with anti-theft laws, all tailored to support recyclable materials businesses. While ScrapWare's software is customizable to meet the specific requirements of each client, it also provides web-based training and technical support to ensure users can maximize the benefits of their system. It was founded in 1989 and is based in Rockville, Maryland.

Barrelconnectorpolarity

M12 connectors come in various coding types, each with its pin configuration. Failure to identify the appropriate coding type for your application can result in incorrect connections and equipment damage. Always double-check the coding type (represented by letters such as A, B, C, D, and so on) before creating any connections.

CBI websites generally use certain cookies to enable better interactions with our sites and services. Use of these cookies, which may be stored on your device, permits us to improve and customize your experience. You can read more about your cookie choices at our privacy policy here. By continuing to use this site you are consenting to these choices.

Reliable connections are the backbone of any robust industrial automation system. Pinouts, color codes, and wiring diagrams let you make secure and error-free connections. This reduces downtime caused by incorrect connections while ensuring your system runs smoothly.

M12 connectors rely on a secure screw mechanism to provide a waterproof seal. Improper tightening can cause loose connections, corrosion, and signal integrity issues. Tighten the connector according to the manufacturer’s guidelines, which are normally hand-tight for M12 connectors.

Industrial automation systems rely heavily on the hidden heroes: M12 connectors. Their compact size, durability, and versatility make them ideal for establishing secure and reliable electrical connections in harsh environments. However, with various coding types, navigating the world of M12 connectors can be overwhelming.

12vdc power connector pinout

DCbarrel jackpinout

One of the distinguishing features of M12 connectors is their coding system. Unlike general plug-and-play connectors, M12 connectors come in various coding types, represented by letters like A, B, C, D, X, etc. Each coding scheme has a distinct pinout configuration that determines the function of each pin in the connector. For example, a M12 4-pin A-coded connector is designed for sensor signals, while a M12 4-pin D-coded connector is used for industrial Ethernet. This coding system prevents unintentional mismatches and ensures the proper flow of data or power within your system.

By following these important considerations, you can ensure that your M12 connector installations are safe, dependable, and perform efficiently inside your industrial automation system.

Ward specializes in metal recycling and waste management services within the waste management and recycling industry. The company offers a range of services including scrap metal processing, commercial and household waste disposal, skip hire, and recycling solutions. Ward primarily serves sectors such as construction, manufacturing, healthcare, retail, offices, demolition, facilities, public sector, and utilities. It was founded in 1946 and is based in Swadlincote, England.

M12 connectors are reliable and adaptable for industrial applications, but their true power lies in their versatility. Understanding the pinouts, color codes, and wiring diagrams relevant to each M12 coding type allows you to unlock the potential of these connectors. In addition, you’ll ensure error-free connections within your system.

News Provided By Share This Article Emergen Research Logo Rising aluminum demand in construction, packaging, and EV production drives market growth, despite environmental concerns. Discover key insights & market trends VANCOUVER, BC, CANADA, June 19, 2024 / EINPresswire.com / -- The global aluminum market size was USD 156 Billion in 2023 and is expected to register a rapid revenue CAGR of 5.9 % during the forecast period. The global aluminum market is experiencing significant growth due to rising demand in the construction and packaging industries. Aluminum, known for its versatility and durability, is now the second most widely used metal in construction, only behind steel. It is extensively utilized in various construction applications, including external facades, roofs, walls, windows, and doors. To Receive A PDF Sample Of The Report, Visit @ https://www.emergenresearch.com/request-sample/2529 Urbanization and Construction Boom The growth in urban populations is a major factor driving the demand for aluminum. According to the United Nations, 55% of the global population currently lives in urban areas, with this figure expected to rise to 68% by 2050, adding 2.5 billion urban residents. This rapid urbanization is fueling the need for modern, efficient building materials like aluminum, which is favored for its lightweight, corrosion-resistant properties and ease of maintenance. Aluminum Packaging Gains Popularity Another significant driver of market growth is the increased use of aluminum in packaging. Aluminum foil is a preferred choice in the consumer goods and food & beverage industries due to its ability to protect products from light, oxygen, and moisture, thereby extending shelf life. It is also widely used in pharmaceutical packaging to ensure the safety and longevity of medicinal products. Rising Demand in Electric Vehicle Production The surge in electric vehicle (EV) production also contributes to the growing aluminum market. The International Energy Association (IEA) reports that EV sales tripled from 4% in 2020 to 14% in 2022. Aluminum is crucial in EV manufacturing, helping to reduce vehicle weight, enhance energy efficiency, and extend driving range, thus improving overall vehicle performance. Environmental Concerns as a Market Restraint Despite these growth drivers, the aluminum market faces challenges, particularly environmental concerns. The processing of aluminum emits significant amounts of carbon dioxide (CO2). According to the IEA, aluminum production accounted for 270 million tons of direct CO2 emissions in 2022, roughly 3% of global industrial CO2 emissions. These environmental impacts may restrain market growth due to increasing regulatory pressures. To Get A Discount On The Latest Report, Visit @ https://www.emergenresearch.com/request-discount/2529 Market Segmentation Insights Product Types: Cast Products: Dominating the market with the largest revenue share in 2022, cast products such as alloys and pistons are in high demand, especially in the transportation industry due to their strength and conductivity. The aerospace industry also relies heavily on aluminum for aircraft components. Aluminum Sheets: Expected to see steady growth, aluminum sheets are crucial in food packaging, automobile manufacturing, and construction. Their corrosion resistance and antibacterial properties make them ideal for various applications. Alloy Types: Cast Alloys: Forecasted to maintain a significant market share, cast alloys are essential in industrial applications, including aircraft and engine manufacturing, due to their ability to reduce weight and enhance fuel efficiency. Technological advancements in the wheel industry also drive demand for cast alloys. Wrought Alloys: These alloys are used extensively in transportation, civil engineering, and electrical applications. Representing about 85% of aluminum alloys, wrought alloys are versatile, being used in extrusion, forging, and rolling processes to reduce vehicle weight and improve efficiency. Browse Detailed Research Report @ https://www.emergenresearch.com/industry-report/aluminum-market The global aluminum market is fragmented, with several key players accounting for the majority of market revenue. Major players are deploying various strategies, entering mergers & acquisitions, strategic agreements & contracts, developing, testing, and introducing new products and solutions. RusAL Aluminum Latest Industry News On 13 July, 2023, Norsk Hydro ASA acquired Alumetal S.A., a Polish recycled-content aluminum producer, a move that widens its product offering in the low-carbon and scrap-based foundry alloy market. The global aluminum producer's tender offer for Alumetal applies to over 97% of the company shares. Hydro will increase its competence in the recycling of aluminum scrap materials. On 24 Feb 2023, Glencore, a Switzerland-based commodities trading company partnered with Kentucky-based Zeb Metals to build an aluminum dross and scrap recycling plant in South Carolina. Zeb Metals is a buyer and trader of nonferrous scrap with a full-service scrap recycling facility, and is engaged in the shredding, sorting, screening, shearing and torching of scrap metal. Aluminum Market Segment Analysis For the purpose of this report, Emergen Research has segmented the global aluminum market on the basis of product type, alloy type, processing, end-use, and region: Product Type Outlook (Revenue, USD Billion; 2019-2032) Sheet About Us: Emergen Research is a market research and consulting company that provides syndicated research reports, customized research reports, and consulting services. Our solutions purely focus on your purpose to locate, target, and analyse consumer behavior shifts across demographics, across industries, and help clients make smarter business decisions. We offer market intelligence studies ensuring relevant and fact-based research across multiple industries, including Healthcare, Touch Points, Chemicals, Types, and Energy. We consistently update our research offerings to ensure our clients are aware of the latest trends existent in the market. Emergen Research has a strong base of experienced analysts from varied areas of expertise. Our industry experience and ability to develop a concrete solution to any research problems provides our clients with the ability to secure an edge over their respective competitors. Eric Lee

3 pinDC powerjackpinout

Imperial Group provides services such as scrap metal recycling, metal processing, and manufacturing, as well as trading and supplying a variety of metal products. Imperial Group caters to a range of industries with customized recycling programs and integrated services combining the capabilities of its various businesses. The company was founded in 1962 and is based in Chicago, Illinois.

In industrial settings, safety is important. Improper connections with M12 connectors can lead to potential overheating or sparking, generating security risks. Following the specified pinout and wiring diagram prevents such scenarios and supports a safe working environment.

M12 connectors are essential parts of industrial automation systems. These circular connectors provide a durable and reliable solution for making electrical connections. They are small, versatile, and can withstand dirt, moisture, and vibrations. As a result, they are perfect for factories, power plants, and other industrial environments. M12 connectors are available in various coding schemes, each with a specific pin configuration tailored for different applications. This guide will cover everything you need about the M12 connector pinout, color code, and wiring diagram.

Understanding the pinouts, color codes, and wiring diagrams of M12 connectors can help you make reliable connections in your industrial automation systems. This tutorial will help you navigate the world of M12 connectors and ensure they perform optimally in your applications.

DCJack FemaleConnector

M12 connectors come in two genders: male and female. M12 male connectors have protruding pins, while M12 female connectors have corresponding sockets. When connected, the pins fit tightly into the sockets, establishing an electrical connection. The coding system dictates the pin layout and ensures proper functionality.

Proper cable management is critical for ensuring long-term reliability. Avoid excessive cable tension and severe bends, which might harm the internal wires. Use cable ties or other cable management methods to arrange and secure the cables for maximum performance.

DCJack Malepinout

Miswiring an M12 connector can lead to disastrous results. Incorrect pin arrangement can cause device damage, disrupt system communication, and possibly constitute a safety risk. Following the designated pinout and color code ensures each wire connects to the correct pin, avoiding costly mistakes.

Metabee (Chengdu) Technology Co., Ltd. is a leading manufacturer of electronic connectors and industrial cables based in Sichuan Province, China. We are committed to providing high-quality connectivity solutions for a wide range of industries, including automotive, industrial, defense, and so on.

Understanding the pinout, color code, and wiring diagram for your chosen M12 connector type will enable you to build secure and dependable connections within your industrial automation system. The following section will explore common applications for M12 connectors and provide more information about M12 connector pinout.

Color codes are mainly used for M12 cables and bulkhead connectors. For some industries and applications, the color code has default rules. For example, for an M12 A-coded 4-pin connector, pin 1 is connected to the brown wire, pin 3 to the blue wire, and pin 4 to the black wire.

M12 connector coding serves as a language, dictating the functionality of each pin within the connector. Different coding types, represented by letters (A, B, C, D, X, etc.), have different pinout configurations that cater to various applications. Here are some popular M12 coding schemes and their applications:

M12 connector color codes indicate the color of the wires connected to the pins. Each pin in the connector is assigned a color, and the matching wire on the cable must match that color. This visual cue reduces the possibility of errors during installation, particularly when working with several M12 connectors.

Imagine a factory floor bustling with activity. Machines whir, sensors collect data, and signals travel seamlessly between devices. M12 connectors are essential for keeping things running smoothly. But how do these connectors know what kind of data to carry or how much power to deliver? The answer lies in their unique coding system.

This comprehensive guide has provided you with the knowledge to demystify M12 connectors. You’ve looked into their benefits, explored the different coding schemes, and acquired a strong understanding of pinouts, color codes, and wiring diagrams.

Before connecting any M12 connectors, check them for physical damage, such as cracks in the housing, bent pins, or worn-out threads. Connectors that have been damaged should be replaced to ensure the integrity of the connection.

A wiring diagram is a blueprint for M12 cables, splitters, and M12 to RJ45 cables. It uses the pinout information from each connector to visually represent how the associated pins should be wired together. Consider it a step-by-step guide to ensure data or power flows properly across connected devices.

Each M12 coding type has a specific purpose. A-coded connectors are created for low-power applications, whereas D-coded connectors are suitable for Ethernet connections. Following the pinout and wiring diagram related to the coding type ensures that data or power flows as expected.

Erzkontor Group is a company focused on reshaping the raw materials industry through procurement, processing, and trade. The company specializes in sourcing and trading minerals and chemicals, offering services in raw material processing, recycling, supply chain management, and quality laboratory services. Erzkontor Group primarily serves various industrial sectors, including the chemical, refractory, feed, foundry, rubber, ceramics, plastics, food, leather processing, oil and gas, abrasive, welding, and construction materials industries. It is based in Lubeck, Germany.

Imagine a roadmap for an electrical connection. That is exactly what an M12 connector pinout looks like. It describes the pin configuration of an M12 connector, indicating which pins are pins 1 and 2 and their positions. Pinout configurations for M12 connectors vary depending on the coding type. Before attaching any device to an M12 connector, check the pinout to ensure it is compatible with the device.

Ms.Cici

Ms.Cici

8618319014500

8618319014500