Connecting cable 5 m, 4-pin M8-socket straight, open wire, ... - wiring pins

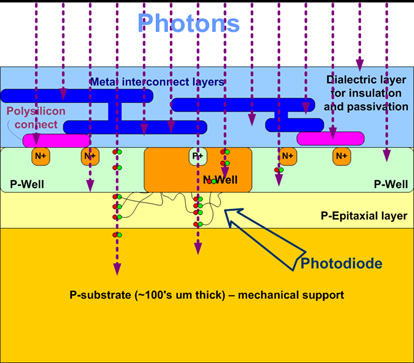

Alacron, Inc. is capable of processing sensor wafers to produce backside illuminated wafers or sensors on a contract basis. Backside illumination is performed to allow the sensor to be illuminated on the side opposite the electronics of the sensor.resulting in significantly increased quantum efficiency. This allows increased light sensitivity or reduced pixel pitch.

HighpowerLEDflood light 1000W

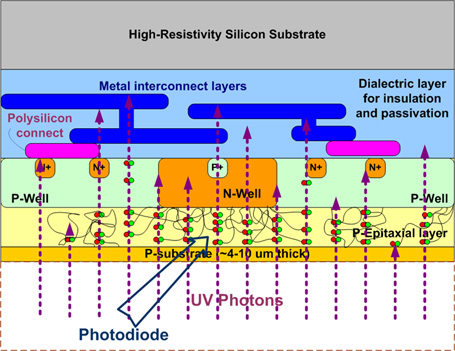

A typical image sensor such as the CMOS sensor pictured below has the electronics layers overlaying part of the pixel area. Photons entering the sensor are thus blocked by the structures overlying the photocathode as well as the associated electronics in the pixel well. This results in the reduction of photon conversion efficiency with the resultant decrease in quantum efficiency.

HighPowerLEDdiode

Strobe and flood controllers operate on AC or DC power with constant current LED driver circuits. AC controllers accept 100–240 VAC, 50/60 Hz power. Hi-g DC powered controllers operate on 28 VDC power, except single and 1x3 LED models which require 12 VDC power.

High-speed digital cameras require extremely high light levels for microsecond and nanosecond shutter speeds. We’ve designed our LED arrays and controllers to meet the demanding needs of weapons field/flight testing for the US military, R&D laboratory testing and DIC (digital image correlation).

Then the backside of the sensor wafer is optionally thinned and an optionally anti-reflective coating is applied and the sensor is mounted upside down. Then the photocathode well is directly exposed to photo-electrons and no photo-electrons are thus blocked by the associated overlying electronics. This and lateral capture results in significantly increased quantum efficiency.

HighPowerLED12V

Visual Instrumentation Corporation (VIC) is a world leader in high-speed imaging technology. Our engineers and staff are ready to assist you with cost-effective, high-speed imaging solutions.

Ms.Cici

Ms.Cici

8618319014500

8618319014500