washing symbol: Wash and care for wool properly - symbol hand wash

Corrosive substances have the potential to corrode or deteriorate packaging materials over time. For this reason, secondary containment measures, such as using leak-proof inner containers, absorbent materials, or bunded pallets, should be considered to contain any potential leaks or spills and prevent their spread.

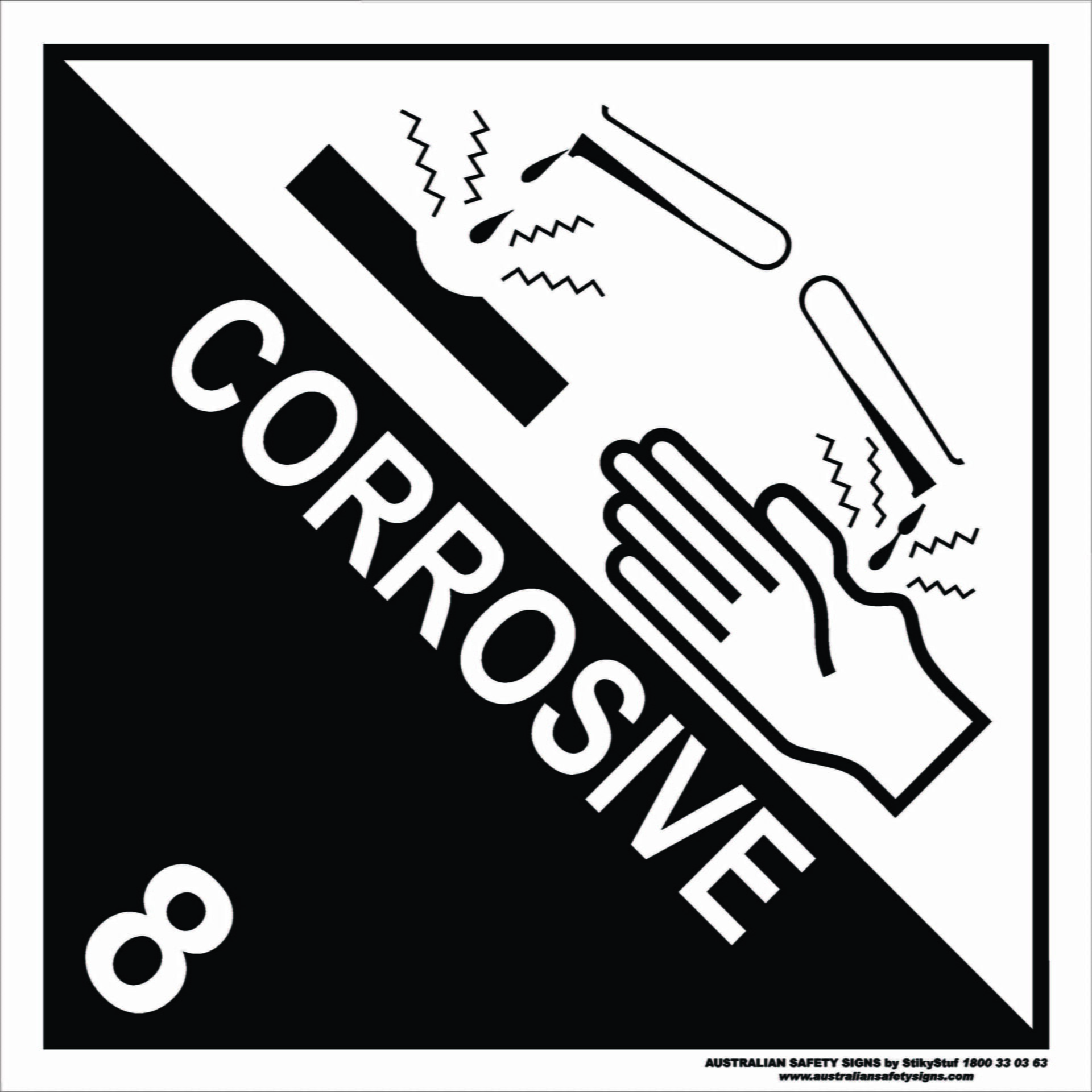

Class 8Corrosive UN Number

Corrosive substances and articles should be packaged in containers that are specifically designed and approved for the transportation of dangerous goods. These containers are constructed using materials that can withstand the corrosive properties of the substances being transported. Examples include high-density polyethylene (HDPE) bottles or drums, stainless steel containers, or glass bottles with appropriate thickness.

DG Class9

To minimise the risk of accidents, we recommended you utilise dedicated storage areas or containers specifically designed for corrosive substances. These storage solutions are constructed using materials that can withstand the corrosive properties of the substances being stored. Using a dedicated storage area, such as a depot for storing corrosive substances, offers a controlled environment that follows safety regulations and reduces the chances of accidents.

Regular inspections of storage areas and containers are crucial to identify signs of deterioration, leakage, or damage. Periodic checks ensure that the storage facilities remain in good condition and that containers are structurally sound. Any compromised containers or areas should be promptly addressed, repaired, or replaced.

The containers should be clearly labelled with recognised hazard symbols, such as the corrosive symbol (a pictogram of a test tube and a hand) or the GHS (Globally Harmonised System) pictograms. Additionally, appropriate warning signs, such as “Corrosive Substance” or “Corrosive: Handle with Care,” should be prominently displayed to indicate the hazardous nature of the contents.

HAZMATClass 8shipping requirements

Class 8dangerous goods transportation

Personnel should receive thorough training on how to properly use and maintain PPE. This includes instructions on how to correctly wear, remove, and store protective gear. Training sessions should emphasise the importance of regularly inspecting PPE for any signs of damage or degradation. Damaged or worn-out equipment should be replaced immediately.

Stop Sign for My Neighborhood · Stop Signs & 4-Way Stops. The City of Durham Department of Transportation installs and maintains traffic control devices, ...

Regular inspection of the packaging material is crucial to ensure its integrity throughout the transportation process. Containers should be checked for signs of degradation, such as cracks, corrosion, or weakening. Any compromised containers should be replaced immediately to maintain the safety and containment of the corrosive substance.

Handling and Personal Protective Equipment (PPE) Safe Handling Techniques Personnel involved in the transportation process should receive comprehensive training on the safe handling procedures for corrosive substances. This involves understanding the properties of the substances being handled and proper lifting and carrying techniques. Proper technique typically involves bending at the knees, using leg muscles to lift, and avoiding excessive strain on the back. Using appropriate lifting aids, such as trolleys or carts, can also reduce the risk of accidents and strain. Personal Protective Equipment (PPE) Personnel should be equipped with the necessary gear to minimise contact. This includes wearing chemical-resistant gloves made of materials such as nitrile or neoprene, along with eye protection in the form of safety goggles or a full-face shield. Full-body protective clothing, such as chemical-resistant coveralls or aprons, should be worn to shield the skin, while chemical-resistant boots or shoes with non-slip soles protect the feet. Depending on the situation, respiratory protection in the form of respirators with appropriate cartridges or filters may be necessary. PPE should be selected based on the specific corrosive substances being handled. Training and Familiarity with PPE Personnel should receive thorough training on how to properly use and maintain PPE. This includes instructions on how to correctly wear, remove, and store protective gear. Training sessions should emphasise the importance of regularly inspecting PPE for any signs of damage or degradation. Damaged or worn-out equipment should be replaced immediately.

A flammable gas (Division 2.1) means any material which is a gas at 20 °C (68 °F) or less and 101.3 kPa (14.7 psia) of pressure.

To prevent leakage or spills during transportation, it’s crucial to securely seal the containers. This can be achieved using suitable closures, such as screw caps, tamper-evident seals, or pressure relief devices, depending on the specific requirements of the substance and container.

Corrosive SubstancesCorrosive substances refer to chemical substances that have the ability to cause damage, destruction, or irreversible alterations to materials they come into contact with. They typically possess acidic or alkaline properties and can corrode metals, degrade organic matter, or cause burns to living tissues. Examples of corrosive substances include sulfuric acid, hydrochloric acid, sodium hydroxide, and potassium hydroxide.

Loss prevention is any actions taken to reduce the amount of theft, breakage, or wastage in a business. As the premier firm involved ...

Dg Class 8UN number

( There are no reviews yet. ) R 1,500.00 Original price was: R 1,500.00. R 850.00 ...

DG Class 8Label

Australian Dangerous Goods Code (ADG)The Australian Dangerous Goods Code (ADG), developed by the National Transport Commission, provides a comprehensive framework for the transportation of dangerous goods across Australia. The ADG outlines specific requirements for packaging, labelling, and handling of corrosive substances and articles, aiming to minimise risks during transportation.

Class 8dangerous goods examples

As an international symbol, it is used worldwide to indicate the presence of biohazard agent. It was developed in 1966 by Charles L. Baldwin of Dow Chemicals ...

The packaging material must exhibit excellent chemical resistance to the corrosive substance being transported. For example, corrosive acids may require containers made of materials like high-density polyethylene (HDPE), polypropylene (PP), or glass, which have a high resistance to corrosion. On the other hand, corrosive bases/alkalis might require containers made of materials like polyvinyl chloride (PVC) or stainless steel.

When we say “corrosive,” we mean that these substances have the potential to eat away or deteriorate other materials they come into contact with. They can be highly reactive and pose risks to both human health and the environment.

Class 8corrosive examples

Standard Regulatory Signs, Speed Limit Enforcement Signs, Turn Prohibition Signs, Lane-Use Control Signs, Center and Reversible Lane Control Signs.

Aug 6, 2024 — Police incident report software · Record management software · Computer-aided dispatch (CAD) software · Case management software · Incident mapping ...

Handling and Personal Protective Equipment (PPE) Safe Handling Techniques Personnel involved in the transportation process should receive comprehensive training on the safe handling procedures for corrosive substances. This involves understanding the properties of the substances being handled and proper lifting and carrying techniques. Proper technique typically involves bending at the knees, using leg muscles to lift, and avoiding excessive strain on the back. Using appropriate lifting aids, such as trolleys or carts, can also reduce the risk of accidents and strain. Personal Protective Equipment (PPE) Personnel should be equipped with the necessary gear to minimise contact. This includes wearing chemical-resistant gloves made of materials such as nitrile or neoprene, along with eye protection in the form of safety goggles or a full-face shield. Full-body protective clothing, such as chemical-resistant coveralls or aprons, should be worn to shield the skin, while chemical-resistant boots or shoes with non-slip soles protect the feet. Depending on the situation, respiratory protection in the form of respirators with appropriate cartridges or filters may be necessary. PPE should be selected based on the specific corrosive substances being handled. Training and Familiarity with PPE Personnel should receive thorough training on how to properly use and maintain PPE. This includes instructions on how to correctly wear, remove, and store protective gear. Training sessions should emphasise the importance of regularly inspecting PPE for any signs of damage or degradation. Damaged or worn-out equipment should be replaced immediately.

Personnel should be equipped with the necessary gear to minimise contact. This includes wearing chemical-resistant gloves made of materials such as nitrile or neoprene, along with eye protection in the form of safety goggles or a full-face shield. Full-body protective clothing, such as chemical-resistant coveralls or aprons, should be worn to shield the skin, while chemical-resistant boots or shoes with non-slip soles protect the feet. Depending on the situation, respiratory protection in the form of respirators with appropriate cartridges or filters may be necessary. PPE should be selected based on the specific corrosive substances being handled.

Corrosive ArticlesCorrosive articles, on the other hand, are objects or items that, due to their design or composition, have corrosive properties. These articles themselves may not contain corrosive substances but can cause corrosion or damage to other materials they come into contact with. For example, a battery may be classified as a corrosive article due to the corrosive properties of the electrolyte it contains.

Oct 28, 2024 — Police Body Cameras · Pro Arguments · Pro 1: Police body cameras improve police accountability and lower reports of police misconduct. · Pro 2: ...

Storing and transporting Class 8 dangerous goods requires careful attention to safety regulations to prevent accidents and protect the environment and public health. Among the various dangerous goods classes, Class 8 is dedicated to corrosive substances and articles. Following is a detailed summary of what these dangerous goods are and how to store and transport corrosives in Australia.

One of the victim photos that JJ is looking at (around the 3:10 mark) looks rather like Kelly Frye, who played Matt Simmons' wife in later seasons.

Personnel involved in the transportation process should receive comprehensive training on the safe handling procedures for corrosive substances. This involves understanding the properties of the substances being handled and proper lifting and carrying techniques. Proper technique typically involves bending at the knees, using leg muscles to lift, and avoiding excessive strain on the back. Using appropriate lifting aids, such as trolleys or carts, can also reduce the risk of accidents and strain.

The Private Security Certificate is designed to provide you with an entry-level education and hands-on training to enhance employability in the field of private ...

The packaging material should have low permeability to prevent the substance from escaping or reacting with the external environment. This is particularly important when dealing with volatile corrosive substances that can evaporate or react with moisture or air. Impermeable materials, such as certain plastics or glass, can help maintain the stability and containment of the corrosive substance during transportation.

To ensure the safe transportation of corrosive substances and articles, regulatory bodies in Australia play a crucial role in setting standards and guidelines. The key regulations involved are the ADG Code and Work Health and Safety regulations.

Remember, when dealing with dangerous goods, safety should always be the top priority. By staying informed and maintaining a proactive approach to safety, we can ensure the smooth and secure transportation of corrosive substances and articles across Australia.

It’s important to store corrosive substances and articles separately from incompatible materials, such as flammable or reactive substances. Keeping them in separate storage areas reduces the likelihood of accidental contact or interaction, which could result in dangerous chemical reactions. Alongside physical barriers, obvious signage should be displayed to clearly indicate the boundaries and warn personnel of the presence of corrosive substances. By establishing clear boundaries between corrosive substances and incompatible materials, the risk of fires, explosions, or the release of toxic fumes is significantly reduced.

Work Health and Safety (WHS) RegulationsUnder the Work Health and Safety (WHS) Regulations, employers and employees involved in the transportation of dangerous goods, including corrosive substances, have legal responsibilities to ensure the safety of themselves and others. These regulations cover various aspects such as training, risk assessment, emergency planning, and the provision of suitable safety equipment and facilities. Compliance with WHS Regulations helps protect workers and communities during the transportation process.

Ms.Cici

Ms.Cici

8618319014500

8618319014500