Taser Certification - taser course

DG Class 8Label

Protected places refer to places like shops, warehouses, offices, workshops, factories, and any other buildings often visited by people every day. Considering their harsh nature that can harm people, animals, and properties, the AS 3780 has lined up minimum separation distances to ensure you save your substances safely.

Materials like vermiculite can control moisture and absorb shock when used to fill the void in the package, while jerricans and pails can protect the goods during transit. Remember that labeling is also super important!

DG Class9

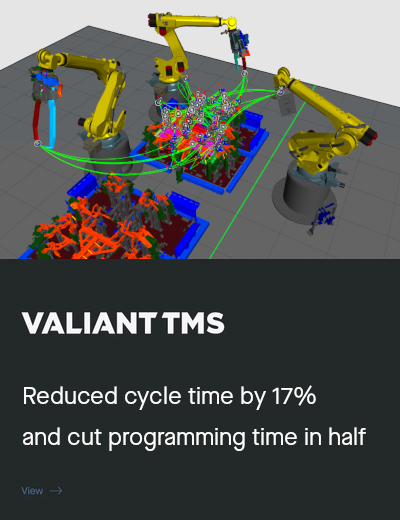

Our proprietary software and industrial automation expertise is the difference maker that can take your projects and performance to new heights.

Storing and handling corrosive materials in Class 8 is outlined in AS 3780—2008 – The storage and handling of corrosive substances, which is available for download for free on the Internet. Some we already sum up here include:

Dg Class 8UN number

Many other substances don’t work well with materials in Class 8 and can lead to harsh chemical reactions or fires when placed together. Even some in Class 8 can’t also be put into the same mix! Have them sit at least 5 meters apart or store them in segregated chemical storage containers with their own spill containment system.

Class 8dangerous goods examples

Always refer to the US DOT Hazmat tables for detailed instructions on shipping the corrosive materials in Class 8. Generally, these substances aren’t mailable via international mail. You or your employees who handle the shipping procedures should also be equipped with proper response procedures in case of leakage and emergency.

The United Nations’ Globally Harmonized System of Classification and Labelling of Chemicals (GHS) has ruled out the inner or single packaging and labeling standard of hazardous chemicals. There are three packing groups based on the degree of hazard in transport:

Oxidizing substances and organic peroxides are put in the same group, albeit as different divisions. The two... continue reading

Class 8dangerous goods transportation

We can’t overlook accidents. Having eyewash stations and emergency showers within 10 meters will be the first assistance whenever someone gets hurt from the corrosive substances.

Realtime Robotics’ innovative technology generates and runs robots through optimized motion plans and interlocks to achieve the shortest possible cycle time in multi-robot cells. Our automated collision-free motion planning software and expertise enables you to:

Class 8corrosive examples

We will help you creating your forwarder account using your current shipper account in second by clicking button below.

The easier programming is, the more time you’ll save. The more projects you’ll complete. And the more complex applications you can tackle. Learn how we can reduce downtime, increase efficiency and improve overall workcell performance.

Class 8Corrosive UN Number

The formal classification of Dangerous Goods Class 2 consists of flammable gases, nontoxic and nonflammable gases, and... continue reading

Categorized in the Dangerous Goods Class 8 is the corrosive materials with no subdivisions like the other classes. These substances are capable of causing acute injuries once exposed to living tissue like skin or organs. They can also corrode any other materials like aluminum and steel in case of leakage, which in turn hinders the means of transport. Read more to find out what goods belong in this class and general shipping rules applicable to them.

After Class 6, there's the dangerous goods Class 7 featuring radioactive materials, which are comprised of unstable... continue reading

Realtime’s Optimization-as-a-Service uses a combination of proprietary optimization software and industrial automation expertise to help you reach your cell’s target cycle time in days or weeks, not months.

Our software generates collision-free motion paths during runtime. Enable high throughputs and pick-rates for multiple robots while quickly reacting to changes in the market and supply chain.

Ms.Cici

Ms.Cici

8618319014500

8618319014500