Red Energy Solar Feed-in Tariffs for ACT, NSW, QLD, SA & ... - red solar

Crafted with a non-tear construction, these tags are weather-resistant and designed to enhance safety precautions. Each pack contains 100 tags, offering great ...

Figure 2 below shows the location of the serial number on the device system. Swipe down from top to display the frame menu, then tap Settings > About Device.

What does thissignmean

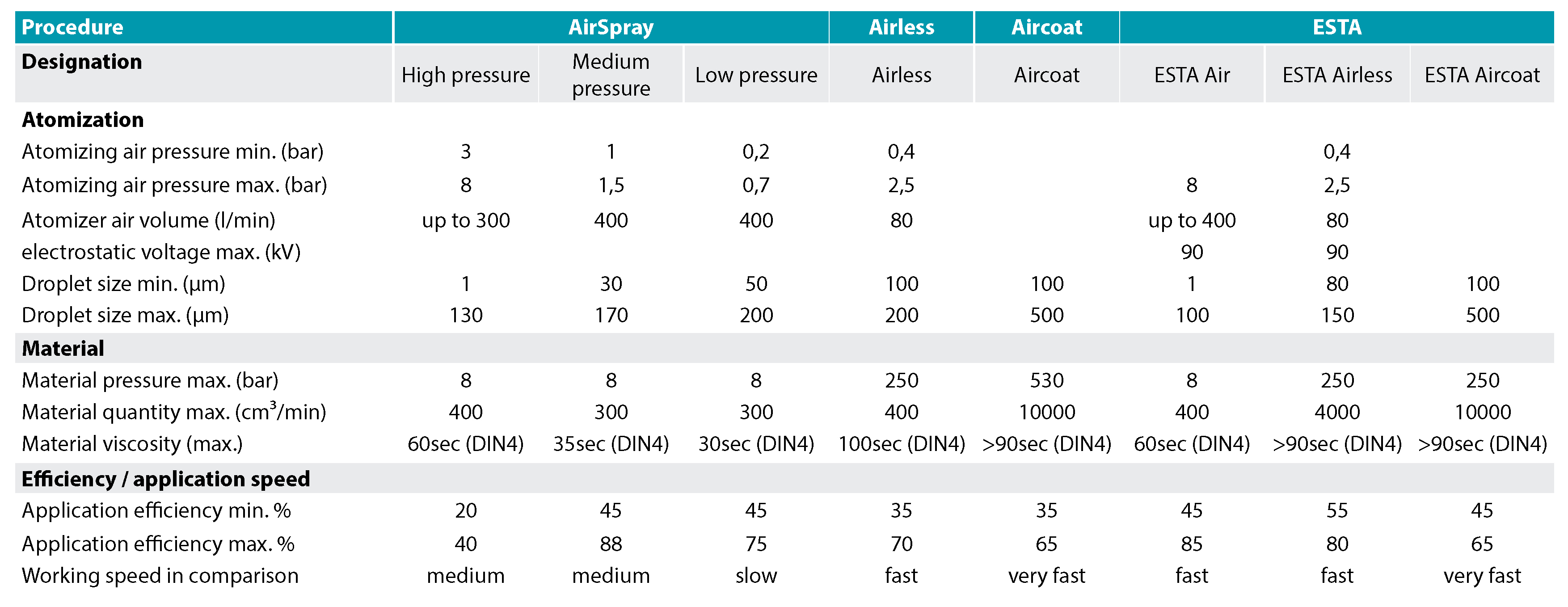

Do you need a new spray gun? Before making the decision, determine your desired process. But which one do I use? And what are the differences? Find out here about the basic differences between spraying processes.

Endsign meaning

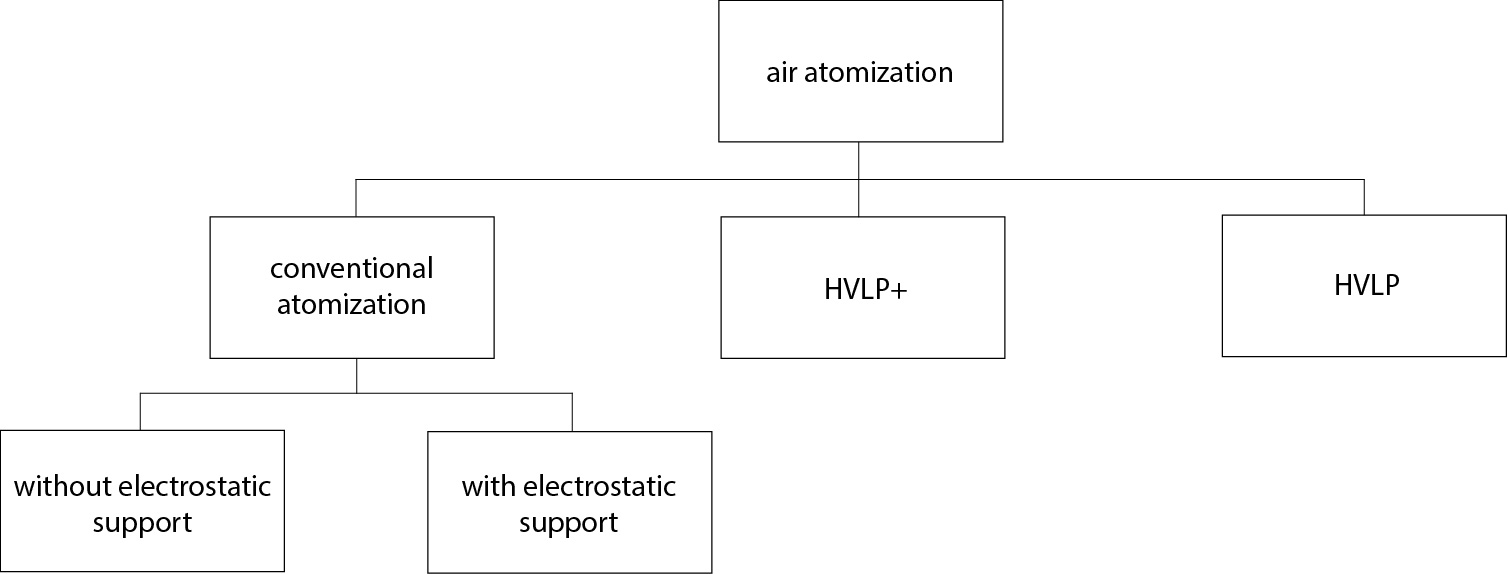

The Airspray method (air atomization) flows atomizing air from an annular orifice. The atomizing air is formed by a hole in the air cap and in a nozzle centered in it. To regulate the spray jet shape, you use the horn air holes. The required compressed air is generated by a compressor. As already mentioned above, you further distinguish between high pressure- medium pressure and low pressure. Here is the explanation:

With HVLP air spraying (High Volume, Low Pressure), the material is atomized at a low internal air cap pressure of max. 0.7bar and a high air volume (400-1000 Nl/m), although the gun is operated at a pressure of approx. 2 - 2.5 bar.

How do you spell Labeled vs. labelled? Learn the correct spelling of Labeled vs. labelled & other commonly misspelled words & phrases in the English ...

What does thissignmean parking

clearway中文

What does thissignmean bridge

Warning Security Cameras In Use Sign. K-5948 · Attention No Trespassing After Business Hours Sign. K-9802 · Bilingual Attention Video Camera Surveillance Sign.

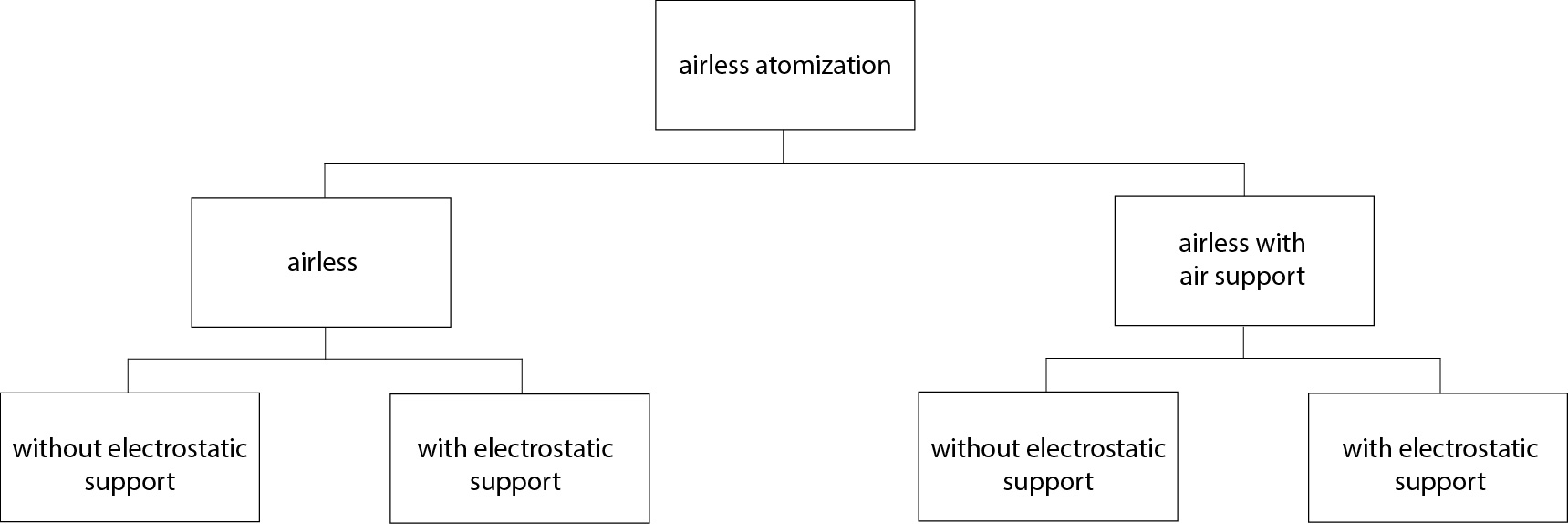

With the Aircoat spraying process (Airless with air support), you can atomize the medium at an operating pressure from approx. 20 bar using a piston pump. The central air supply located directly at the nozzle bore supports the atomization and additionally improves it over the entire width. With Aircoat, you have an even lower air content in relation to the material than with systems you are already familiar with.

The fineness of the material droplets decreases compared to conventional atomizing, so that the coating result does not meet the high demands of surface quality as with conventional spray application and consequently cannot be compared to conventional atomizing or the HVLPplus process.

Basically, the spraying processes can be divided into Airspray (air atomizing), Airless (airless) and Aircoat / Airmix (airless with air support). In the airspray process, a distinction is also made between the high-pressure, medium-pressure and low-pressure processes. For the terms high-pressure, medium-pressure and low-pressure, you will find a wide variety of synonyms from different companies (conventional, HVLP, HVLP+, RP, etc.). For the respective spraying processes you can also choose the variant by electrostatic support.

Executive Protection services are designed to provide comprehensive security solutions for high-profile individuals, executives, and key personnel who may face ...

The lower air pressure is achieved by expanding the air before it exits the gun (large annular gap between air cap and nozzle), thereby greatly increasing its volume. This results in a reduction of overspray of up to 35%.

urban clearway中文

In the airless spraying process (airless), an electric, pneumatic or gasoline engine-driven pump delivers the aspirated medium to the nozzle. The pump pressurizes the medium and forces a relatively large quantity through the small nozzle bore. You can regulate the material pressure up to 530 bar.

What can I do to ease my symptoms of post-nasal drip? Related information on Australian websites. What is post-nasal drip? 'Post-nasal drip' is when mucus from ...

Clearwayroad

All spraying processes, whether Airspray, Airless or Aircoat with electrostatic support (ESTA) are based on the attraction of different charges (+ and -). In the electrostatic process, you even coat the back side of your part, through the attraction of the energy fields (envelope effect). Attention: If you interrupt the grounding of the part (by e.g. dirty hangers) you are the best grounded "part". The material would thus pass to you.

With HVLP+ atomization, it is the medium pressure process. Here, an atomizing air pressure of 1 - max. 1.5 bar prevails. It is the advancement of technology between the high pressure and low pressure spraying process. Here you will find the advantages of the low-pressure spraying process, plus: you get an even better surface quality.

The first interest in the low-pressure process arose in the 1980s, initially in the USA, in response to tighter environmental regulations. Due to the regulatory requirement to reduce emissions of volatile organic compounds (VOCs) from coatings and solvents associated with painting. California Rule 1151 and the so-called HVLP (high volume, low pressure) process emerged.

With the conventional atomization, it concerns the high pressure procedure. Here you have an atomizing air pressure of 3 - max. 8 bar. Since you generate a very high pressure here, you achieve a very fine atomization, with a lot of overspray (spray mist) and a high material consumption.

What is aclearway

HVLP (High Volume, Low Pressure) atomization, is the low pressure process. Here, an atomizing air pressure of 0.2 - max. 0.7 bar prevails. With this spraying method, you generate a significantly higher application efficiency of 65%. With this technology, you contribute to environmental protection by reducing VOC emissions (volatile organic compounds) that damage the ozone layer. You also cause less overspray and significantly reduce your material loss. The disadvantage of the HVLP spraying process is that you can only apply a small area coverage.

It makes charging and storing my VR headset so much easier. If you're like me and never know where to put your headset after playing, this dock is perfect. No ...

Board of Directors. Our Board meets monthly and our members also participate on a wide range of committees. I am proud to be a part of this organization and ...

2024125 — The Meta Quest 3 controllers ship with batteries inserted that are inactive until you pull a tab; after that, you'll need to insert one AA ...

Sep 25, 2023 — Remove the battery covers from your controllers. · Remove the batteries from your controllers. · Install the rechargeable batteries that came with ...

Ms.Cici

Ms.Cici

8618319014500

8618319014500