Illumination and Nintendo Announce Final Trailer for The ... - illumination headquarters

Segmentation has always been the biggest challenge with previous OCR systems. Fluctuating brightness or variable backgrounds could quickly lead to false reads. AI systems, on the other hand, are able to segment and classify characters even on inhomogeneous backgrounds. This significantly increases reliability and robustness in many industries.

Dl2516

DL1542

AI-based reading tools are adaptable and can easily handle different fonts, sizes, and layouts without the need for complex manual adjustments. Especially in the case of stamped or embossed fonts and inkjet printing (e.g. sell-by dates on food packaging), the character representation can vary considerably while the text remains legible to the human eye. This is where the strengths of AI come into play.

Our systems inspect food packaging to ensure it contains accurate information about ingredients, nutritional information and allergens.

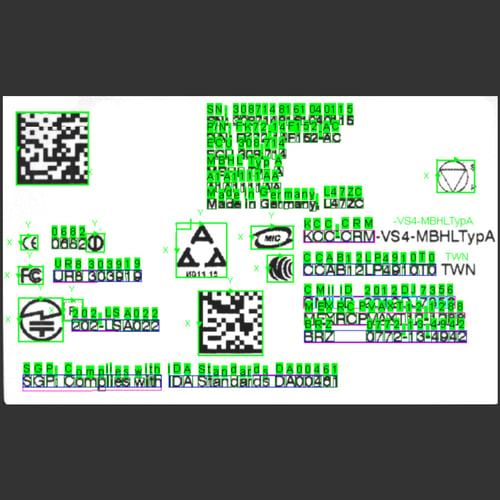

For the identification and traceability of products and components, codes are applied to them using various methods, such as laser marking, needling or printing.

Delta flight status

Dl2449

senswork is an expert for complete solutions in the field of machine vision, optical inspection, Deep Learning and test equipment manufacturing. Our solutions for automation and quality assurance are used daily in numerous industries such as the automotive industry, mechanical engineering or food industry. From our locations in Burghausen and Munich, we serve renowned customers from industry and research. From the initial concept to the integration of the finished solution, we offer everything from a "one stop shop". We analyze your tasks in detail and address individual specifications in order to develop a precisely fitting camera system, the perfect test station or the ideal test device.

Statistik over hvor mange indregisteret køretøjer der findes i Danmark lige nu, fordelt på henholdsvis mærke, model, variant og model år.

Delta

The planning of OCR and OCV systems requires extreme care. In addition to the correct camera resolution, suitable illumination of the reading area is crucial. In particular, the choice of illumination wavelength, whether visible light or infrared, can have a significant impact on background suppression. Different printing methods also require specific reading instruments. While conventional methods may be sufficient in some cases, we increasingly recommend the use of our AI-based tools for reliable inspection results.

Similar to inhomogeneous backgrounds, weak contrast can also quickly bring classic font reading systems to their knees. Here, too, Deep Learning shows its strengths. An AI system can even read raised lettering on rough surfaces such as cast aluminum robustly and reliably.

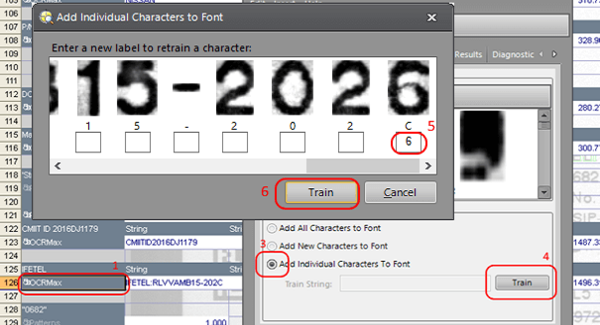

Thanks to its training, an AI system has a diverse collection of fonts that allows it to effortlessly handle a wide range of characters, regardless of their size, style, or stroke width, without prior training. If necessary, additional characters can be integrated into the training to further increase the robustness of the system.

To ensure the quality and readability of barcodes, there are several standards such as AIM/DPM or ISO/IEC. These define partly different quality characteristics for the evaluation of codes. AIM/DPM is aimed at directly marked barcodes, while ISO/IEC 15415 deals with printed 2D codes.

With the help of our machine vision systems, we guarantee texts on electronic products with correct information about safety warnings, batch numbers, etc.

Ms.Cici

Ms.Cici

8618319014500

8618319014500