Flammable Definition & Meaning - high flammable

The lightweight wheel chock features all-weather construction for reliable performance in any climate and a molded grab handle for easy positioning. With a ...

Light UpWandAmazon

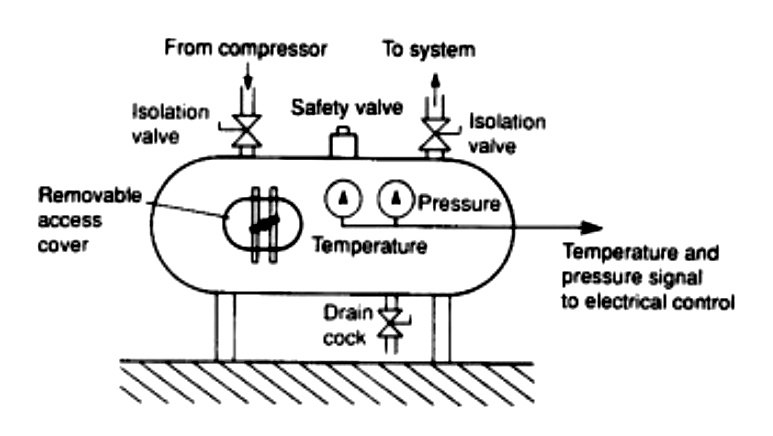

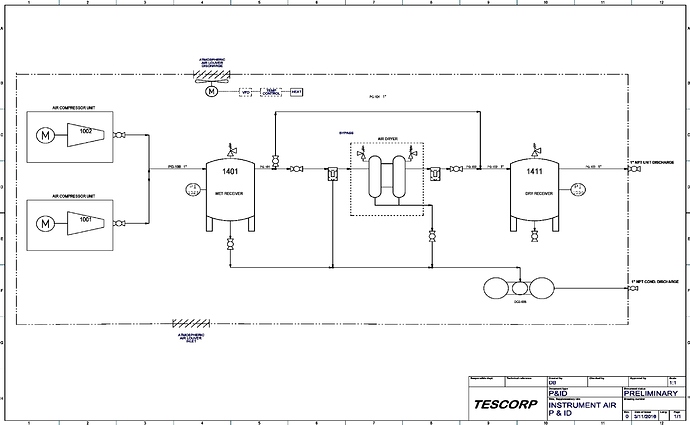

These storage vessels (Receivers) store the excess air at an elevated air pressure to allow the compressor to cycle down and the system to still continue to supply the required air flow to meet the site requirements. They also act as a pressure pulsation buffer to supply a more consistent air pressure with little variance.

After any maintenance or modification to the air system, the maximum particle size in the instrument air system should be verified to be less than 40-micrometers.

• Instrument air compressors should be free of contaminants and hazardous gases. If contamination exists in the compressor intake areas, the intake should be moved to a different elevation or location where it is free from contaminants. Sources of contamination may include painting, chemical cleaning and/or engine exhaust.

• Air purge system is the simplest system to implement. • The air flow requirement for regeneration is usually 15-20 percent of the total air flow.

• ANSI has produced air quality standards for the industry that must be utilized as the minimum requirements for the design and application of an “Instrument Air” system.

Stun guns and TASERs are convenient self-defense weapons that fit easily into most bags and pockets. We review the top brands to find the best products.

• According to the ISA standard, the pressure dew point, when measured at the dryer outlet, should be at least 18°F below the minimum temperature where any part of the instrument air system is exposed.

KidsFlashing Wand

With the help of thermal drones, thousands of deer are being recovered that would otherwise have been forever lost. *when flown by a skilled pilot. Unlike dogs ...

Menu ... It's very common to encounter mobile plant on a worksite, and working in areas with movement of mobile plant is considered high-risk construction work.

But in the case where the site environmental conditions warrant, or the process components require a cleaner, dryer air supply, then the produced air must be conditioned to meet these requirements.

2018826 — The Yellow Jacket Case ...

In some industry functions, the produced air quality from the air compressor system is sufficient in its raw form to accomplish the required operations.

The most powerful stun gun features an LED flashlight, long battery life, electroshock capabilities, safety features like a disable pin, two metal prongs, and ...

Light UpFlashing Wand

• Oil content should be as close to zero as possible, and under no circumstances should lubricant content exceed 1 ppm w/w or v/v. Any lubricant in the compressed air system should be evaluated for compatibility with end-use pneumatic devices.

Simpro wheelie bin locks are a smart solution for securing valuable or confidential recyclables, such as electronic waste and documents.

10-8 Systems is a dispatch software and program with cloud-native, advanced dispatching software features for law enforcement, fire departments, ems, fire, ...

In the oil & gas industry, or those facilities where process controls and sensitive pneumatic machinery are operated, the air quality supplied must meet “Instrument Air Quality” standards.

Additional filtration should be added for pneumatic devices requiring instrument air with less than 40-micrometer particle sizes.

In most systems, the air compressor is sized to exceed the site air flow requirements. It meets and exceeds this volume and is then allowed to unload or reduce its work load until the demand for more air is required. The excess air produced when in the demand mode is stored in the air receivers that are incorporated within the Instrument Air Unit.

FlashingStarWand

Both dryer types accomplish the required dew point reduction and add some inefficiencies to the Instrument Air Unit by either utilizing some of the systems horsepower or adding extra electrical power requirements to the system. The consideration for this regeneration cost must be applied to the initial sizing of the compressor unit.

The Instrument Air Unit storage volume may vary to meet the design requirements by adding more storage volume or operating at a higher storage pressure. These are variables within the system that are made in the initial design phase. But, at any time, “Dry Air” storage may be added to the site air system as an ancillary component.

light upwand- harry potter

Although minute in the percentage of concentration, the presence of this condensate prohibits it from free discharge into the environment. Therefore, this produced water must be conditioned prior to discharge through the use of an Oil/Water separator that removes the oil from the effluent.

Heater Regeneration - another common regenerative dryer system where the wet tower is dried by a heater element that is incorporated in the towers. When in the regeneration mode, the heater element heats the tower to the point of boiling the entrained water to a vapor that is expelled from the wet tower into the atmosphere.

Light UpWandDisney

Throughout industry, much of the production equipment is pneumatically driven or controlled. The air required to perform this function comes from the facilities or site air compression system.

• ANSI /ISA–7.0.0–1996 is the globally-recognized quality standard for instrument air as defined by the Instrument Society of America. Below, we’ll go through the Standard’s Four Elements of instrument air quality for use in pneumatic instruments.

... Stun Guns · Stun Gun Brands · RUNT Stun Guns · Jolt Stun Guns · Streetwise Stun Guns ... Misc. SALE · Home>TASER®> TASER® X26/X26c & Accessories. TASER® X26/X26c ...

Air Purge Regeneration - a common regenerative dryer system where the wet tower is dried by diverting a small flow of the dry air from the active drying tower back through the saturated tower. This dry air adsorbs the moisture and expels it to the atmosphere.

Masks protect us while creating waste. Recycle single-use surgical, N95, KN95, dust masks, etc. with a Zero Waste Box™!

Condensed water from the wet air storage and the prefilter into the dryer is a combination of mostly produced water with traces of oil that is a carry-over from the compressor oil separator.

Ms.Cici

Ms.Cici

8618319014500

8618319014500