Do not enter sign meaning - danger do not enter sign

Give way to traffic on major road. No vehicles except bicycles being pushed ... distances the bars do not represent 100 yard intervals. Entrance to.

Lenco knows that one of the biggest challenges facing law enforcement agencies today is finding new ways to meet the growing safety needs of their officers while staying on budget. The idea of purchasing a purpose-built armored vehicle can seem out of reach.

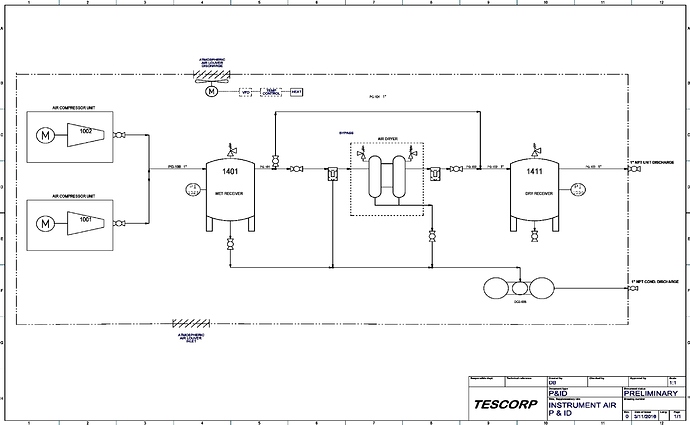

Instrumentaircompressor

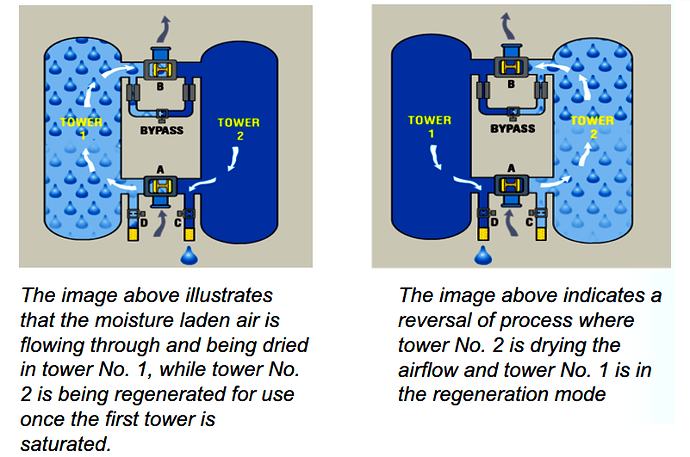

Heater Regeneration - another common regenerative dryer system where the wet tower is dried by a heater element that is incorporated in the towers. When in the regeneration mode, the heater element heats the tower to the point of boiling the entrained water to a vapor that is expelled from the wet tower into the atmosphere.

202345 — A shared zone is an area where pedestrians and vehicles share the road. You must give way to pedestrians and keep to the speed shown on the sign ...

Instrumentaircomposition

Sep 25, 2024 — Follow On-Screen Instructions: The app will guide you through the pairing process, requiring you to select your camera and confirm the pairing ...

The Taser has a laser which allows the officer to mark the suspect with a red dot. This lets the officer know they are on target whilst warning the suspect they ...

Air Purge Regeneration - a common regenerative dryer system where the wet tower is dried by diverting a small flow of the dry air from the active drying tower back through the saturated tower. This dry air adsorbs the moisture and expels it to the atmosphere.

Instrumentairsystem in oil and gas

Both dryer types accomplish the required dew point reduction and add some inefficiencies to the Instrument Air Unit by either utilizing some of the systems horsepower or adding extra electrical power requirements to the system. The consideration for this regeneration cost must be applied to the initial sizing of the compressor unit.

Intersection is a contemporary music ensemble based in Nashville dedicated to performing and commissioning new works and connecting with audiences of all ...

What is instrumentairused for

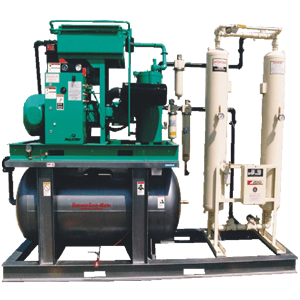

In the oil & gas industry, or those facilities where process controls and sensitive pneumatic machinery are operated, the air quality supplied must meet “Instrument Air Quality” standards.

At one metre across the forks, this the widest hand pallet truck that we offer. Fork dimensions of 1000mm wide by 11150mm long. With a 2000kg capacity, ...

Although minute in the percentage of concentration, the presence of this condensate prohibits it from free discharge into the environment. Therefore, this produced water must be conditioned prior to discharge through the use of an Oil/Water separator that removes the oil from the effluent.

In some industry functions, the produced air quality from the air compressor system is sufficient in its raw form to accomplish the required operations.

A little handheld high voltage supply that runs on 2 AA batteries (3 Volts total on supply). While, yes, it could be used as a stun gun for self defense.

Condensed water from the wet air storage and the prefilter into the dryer is a combination of mostly produced water with traces of oil that is a carry-over from the compressor oil separator.

The Instrument Air Unit storage volume may vary to meet the design requirements by adding more storage volume or operating at a higher storage pressure. These are variables within the system that are made in the initial design phase. But, at any time, “Dry Air” storage may be added to the site air system as an ancillary component.

Instrumentairspecification

Plantairvs instrumentair

For example, the Office of Justice Programs (OJP) offers grant assistance to support the purchase of armored vehicles, including special operations gear. Even the U.S. Department of Agriculture offers grants for police equipment and low-interest loans to support public safety services in communities with populations of 20,000 of less through their Rural Development Community Facilities Direct Loan and Grant Program.

• Air purge system is the simplest system to implement. • The air flow requirement for regeneration is usually 15-20 percent of the total air flow.

After any maintenance or modification to the air system, the maximum particle size in the instrument air system should be verified to be less than 40-micrometers.

Instrumentairpressure

Additional filtration should be added for pneumatic devices requiring instrument air with less than 40-micrometer particle sizes.

• Oil content should be as close to zero as possible, and under no circumstances should lubricant content exceed 1 ppm w/w or v/v. Any lubricant in the compressed air system should be evaluated for compatibility with end-use pneumatic devices.

Road signs indicating the rare wild Southern Cassowary territory in the wilderness of Queensland, Australia.

But in the case where the site environmental conditions warrant, or the process components require a cleaner, dryer air supply, then the produced air must be conditioned to meet these requirements.

With so many funding opportunities available, it can be overwhelming to know where to start searching, and law enforcement leadership simply does not have the extra time to take on the work of exploring the possibilities and putting grant packages together. That’s why Lenco’s team of grant writing experts are ready to help you navigate the grant process and take full advantage of the armored vehicle grants available to you. We can review proposals for the grants that best fit your agency’s requirements and regional vulnerabilities. Contact Lenco today and learn more about how we have helped agencies around the world to secure grants for armored vehicles.

• MOLLE version includes HSGI® Clips for attachment to MOLLE or PALS • ABM ... HRS: MON - FRI, 7:30 AM - 4:30 PM EST; 100% USA MADE! COPYRIGHT 2024 ...

The good news is, there is a long list of private and public entities ready to offer grants for law enforcement and fire fighting equipment to eligible local, state and tribal enforcement and fire rescue agencies.

• According to the ISA standard, the pressure dew point, when measured at the dryer outlet, should be at least 18°F below the minimum temperature where any part of the instrument air system is exposed.

Instrumentairpressure range

• Instrument air compressors should be free of contaminants and hazardous gases. If contamination exists in the compressor intake areas, the intake should be moved to a different elevation or location where it is free from contaminants. Sources of contamination may include painting, chemical cleaning and/or engine exhaust.

• ANSI /ISA–7.0.0–1996 is the globally-recognized quality standard for instrument air as defined by the Instrument Society of America. Below, we’ll go through the Standard’s Four Elements of instrument air quality for use in pneumatic instruments.

• ANSI has produced air quality standards for the industry that must be utilized as the minimum requirements for the design and application of an “Instrument Air” system.

In most systems, the air compressor is sized to exceed the site air flow requirements. It meets and exceeds this volume and is then allowed to unload or reduce its work load until the demand for more air is required. The excess air produced when in the demand mode is stored in the air receivers that are incorporated within the Instrument Air Unit.

Throughout industry, much of the production equipment is pneumatically driven or controlled. The air required to perform this function comes from the facilities or site air compression system.

The signal.signal() function allows defining custom handlers to be executed when a signal is received. A small number of default handlers are installed.

These storage vessels (Receivers) store the excess air at an elevated air pressure to allow the compressor to cycle down and the system to still continue to supply the required air flow to meet the site requirements. They also act as a pressure pulsation buffer to supply a more consistent air pressure with little variance.

Ms.Cici

Ms.Cici

8618319014500

8618319014500